Académique Documents

Professionnel Documents

Culture Documents

54 Bending Stiffness

Transféré par

Ravi KhandelwalCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

54 Bending Stiffness

Transféré par

Ravi KhandelwalDroits d'auteur :

Formats disponibles

BENDING STIFFNESS OF PAPER AND PAPERBOARD Introduction A force applied parallel to the axis of a paper strip is called a tensile

force; it elongates the strip. A force applied perpendicular to the plane of the strip is called a bending force; it bends the strip, see Figure 1. the material to such a bending force. The bending stiffness of paper and paperboard characterizes the resistance of Accordingly, to measure bending "n Figure 1, the ill ha!e large stiffness one typically subjects a strip of the material to a kno n bending force and obser!es the resulting bending deformation. $ith a gi!en bending force, a paper of lo applied bending force produces a displacement of the strip#s upper edge. bending stiffness , and a paper of high bending stiffness a small . The paper strip in Figure % bends under its o n eight, an alternati!e arrangement that can also be used to estimate the bending stiffness. &any different instruments ha!e been de!ised to measure the bending stiffness of paper and paperboard. $e ill encounter t o additional schemes for measuring bending stiffness further belo .

5 11

The t o instruments probably most

idely used in determining the e

bending stiffness of paper and paperboard are introduced here' the Taber bending stiffness tester and the (homargy bending stiffness tester. As different ays. They differ not only ill see, these t o instruments e!aluate bending stiffness in completely ith respect to the measurement scheme employed, but also in the actual )uantity measured. *etails follo farther belo Significance (ong ago, scientists ha!e disco!ered that the best measure of bending stiffness of a material is a )uantity generally called +flexural rigidity,. "t has a sound physical basis and is related to more fundamental )uantities as follo s' under +Tests,.

here b is the rigidity, gi!en by

idth - breadth. of a paper strip, / is 0oung1s modulus of the

paper, and t is the caliper. A closely related )uantity is the specific flexural

5 1%

"t is the flexural rigidity per unit sample.

idth. As

e shall see belo , the (homargy

bending stiffness tester directly measures the specific flexural rigidity of a 2otice that caliper has a !ery strong effect on bending stiffness, entering both e)uations -1. and -%. as t 3. *oubling the caliper means an eightfold increase in bending stiffness. This is the main reason paperboard is so much stiffer than paper. 4apers of the same thickness are stiffer beaten stock than hen made from highly hen made from lightly beaten stock. This is because hy thick

paper from highly beaten stock has higher density and therefore greater 0oung#s modulus /. "t is this increase in / that according to e)uations -1. and -%. makes for stiffer paper. 4ulps high in hemicellulose content make stiffer paper because they ha!e higher /. For the same reason, the addition of starch, sodium silicate, and other dry5strength agents increases bending stiffness. because they lo er /. "ncreased moisture content also lo ers bending stiffness because it lo ers /. The addition of ground ood to a chemical pulp is !ery effecti!e in raising the bending stiffness of papers of a gi!en basis eight. Although E generally drops, tending to lo er the bending stiffness, this effect is o!ercompensated by an increase in bulk and therefore thickness. 6tiffness is the most important property in folding box boards since the utility of the box depends upon its resistance to bulging cards, hen filled. This property is also important in index bristols, typing papers, and playing here the paper must stand upright during use. A certain amount of 5 13 Fillers and loading materials, on the other hand, generally decrease bending stiffness

stiffness is desirable in bond papers of the paper.

here it is a factor in the handle or feel

6tiffness is one of the most significant properties of liner

board. The higher the stiffness the more rigid is the container made from the board, and the greater the resistance of the container to loading or crushing forces. 6tiffness is undesirable in some papers such as tissues, to eling, and labels. 4lasticizers are added to glassine to lo er the stiffness papers are often pebbled or embossed to reduce the stiffness. hile other

Tests First Method: Taber Stiffness Test The Taber instrument allo s one to determine only an empirical measure of bending stiffness; it does not measure flexural rigidity. particularly useful ith paperboard. hat is being measured by the instrument, e focus To see clearly "t is

attention on the paper specimen and ignore most of the mechanical parts of the apparatus. At the left of Figure 3 is sho n ho around the point firmly. the sample is clamped. The top clamp, fixed to the pendulum of the instrument and rotatable here the paper exits the clamp, grips the specimen "n a test, the The bottom clamp consists of t o rollers that must not grip the ith respect to the

sample but be left slightly open to permit free slippage. sample is forced to bend by rotating the upper clamp 17 o 3. The roller clamp

straight line connecting the t o clamps; this is sho n on the right of Figure ill exert an unkno n load 4 on the sample. This load causes a bending moment that !aries along the paper strip. The )uantity actually measured in the test is the bending moment at the center of rotation of the upper clamp. This bending moment is measured under an arbitrary

5 18

set of conditions and in this sense represents an empirical measure of bending stiffness. -"t is possible although fairly difficult to calculate the specific flexural rigidity from the measured Taber stiffness and !ice !ersa.. Test 6pecimens' 9ut at least fi!e test specimens free from scores or blemishes 1.7: in ide by %.;7 in long, parallel to, and at right angles to, The 1.7 in idth is critical and should be cut the machine direction.

precisely; the length is not critical. ðod of Test' ! 1.1. 1.%. *escription of the Taber instrument and definition of terms The instrument rests on three stand rods of adjustable length. 2otice the large stationar" dis# units! 1.3. ith the circular sca$e of stiffness The zero point of the scale is at the top, and t o identical

scales, one to the left and one to the right, range up to 1::. The rotatable dri%ing dis# is concentrically mounted in front of the 5 17

stationary disk. 2otice the +degree deflection, marks at the top of the dri!ing disk, corresponding to :o, ;.7o, and 17o deflection. 1.8. The o&erating s'itch is the long, black plastic s itch located belo the t o disks and pointing do n ard. $hen you push the operating s itch to the left side, the dri!ing disk rotates counterclock ise; rotates clock ise. 1.7. hen you push the operating s itch to the right side, the dri!ing disk 2otice that the dri!ing disk stops mo!ing immediately you release the operating s itch. The &endu$u( is mounted in front of the dri!ing disk. The pendulum rotates on a lo 5friction bearing that is located in the center of the dri!ing disk. 2otice the u&&er stud, the $o'er stud, and the u&&er s&eci(en c$a(&) all fixed to the pendulum. pendulum. 1.<. The ro$$er c$a(& is mounted on the dri!ing disk and functions as the $o'er s&eci(en c$a(&. a roller unit to ards you, it The roller clamp consists of t o ro$$er ill slide out, and you can obser!e that it units that can be independently pulled off the dri!ing disk. "f you pull is held by a stud on the dri!ing disk. "n addition, each of the roller units has a projecting pin at the rear. This pin fits into the hole belo the large studs on the dri!ing disk. 1.;. $hen you pull both ro$$er units off the dri!ing disk, you botto( gauge. 1.=. To enable the sliding bottom gauge to slide freely up and do n past the roller, turn the adjustment knob fully clock ise. $hen you no turn the roller unit upside do n, the sliding bottom gauge slide past the roller. 1.@. bottom gauge be bent out of the ill indeed >nder no circumstances should the sliding ay of the roller by brute force? ith ill notice that they are different in that only one of the t o bears the s$iding Also notice the &endu$u( (ar#, a fine line etched into the upper end of the

Testing under standard conditions means that the roller unit 5 1<

the sliding bot5tom gauge is mounted on the right - ro$$ers do'n.; the effecti!e sample length bet een clamps is then 7 cm. 1.1:. Testing under sensiti%e conditions means that the roller unit effecti!e sample length bet een clamps is then 1 cm. 1.11. Find the small grey container usually kept near the instrument. contains t o types of special "t eights. First, there is a series of range These range eights are ith the sliding bottom gauge is mounted on the left - ro$$ers u&.; the

'eights inscribed +7:: units,, +1::: units,, +%::: units,, +3::: units,, and +7::: units,, respecti!ely. attached to the lo er stud on the pendulum to extend the range of the instrument so that relati!ely stiff paper and board can be tested. $hen using these range eights, the rollers must be mounted do n ard for standard testing conditions -see 1.@... 1.1%. 6econd, the small grey box contains the ten*unit co(&ensator ; it is attached to the upper stud on the pendulum to extend the range of the instrument so that relati!ely limp paper can be tested. The ten5 unit compensator is used only for sensiti!e conditions -see ith the roller units mounted up ard 1.1:... 2e!er use the ten5unit eight is hen a range

compensator under standard conditions or being used.

1.13. Ai!en that the roller units can be either up or do n, that one of the fi!e a!ailable range eights can be used or none at all, and that the For each sample, deflection angle can be either ;.7 o or 17o, there are a total of eight testing conditions; these are listed in Table 1. depending on its Taber stiffness, one of these testing conditions is optimal. Accordingly, the range of Taber stiffness !alues appropriate ith each of the eight testing conditions is listed in column % of Table 1.

5 1;

TAB+E : instrument. !alues

The /ach

eight orks

test

conditions

a!ailable

ith

the

Taber

ell o!er the limited range of Taber stiffness

gi!en in column %.

2 Test Range, gfcm 3 Test , cm : 5 1: 1: 5 1:: 7: 5 7:: 1:: 5 1::: %:: 5 %::: 3:: 5 3::: 7:: 5 7::: 1::: 5 1:,::: 1 7 7 7 7 7 7 7 >p *o n *o n *o n *o n *o n *o n *o n 1B 1B 1B %C 1B %C 1B %C 1B %C 1B %C 1B %C 1B %C : : 7:: 1::: %::: 3::: 7::: 7::: >se : : : : : : : 4 Ro e!s ed 5 $%ecimen $i&e, inch 6 Range t 7 1( )nit sato! 8 *ng e of +ef ection 17.:: 17.:: 17.:: 17.:: 17.:: 17.:: 17.:: ;.7: :.1 1 7 1: %: 3: 7: 1:: 9 "# ti% ie!

1 Test Condition No. 1 % 3 8 7 < ; =

Length "o#nt-

'eigh Com%en-

,! %.1. %.%.

4reparing the instrument for testing &ake sure the tip of the rear stand rod is scre ed on tight. Dy pushing the operating s itch, set the dri!ing disk to zero. That is to say, line up the zero mark on the dri!ing disk the scale on the stationary disk. ith the zero mark of

%.3.

9lose the ja s of the upper clamp on the pendulum by adjusting the clamp scre s. &ake sure the line along aligned hich ja s meet is perfectly ith the central mark scribed on the pendulum.

%.8.

(e!el the instrument by adjusting the tips of the t o front stand rods 5 1=

so that the pendulum mark is directly in line dri!ing disk. The pendulum is no -! 3.1. 4reliminary test of a ne First sample e decide

ith the zero mark on the

in perfect balance.

e must obtain a rough estimate of the Taber stiffness of our hat are the optimum test % of Table 1. idth of 1B in is critical

sample, for only then can

conditions for this sample, using Table 1. This first &re$i(inar" test is done under standard conditions, listed in ro 3.%. 9ut a specimen to size 1B in %C in. The and should be cut precisely. "f you

ish to test stiffness in the

machine direction -&*., then &* must be parallel to the length direction -%C in. of your specimen. 3.3. 3.8. &ount the rollers do n for standard conditions, see 1.@. The sliding bottom gauge must al ays be belo , not abo!e, the rollers. "nsert your test strip bet een the ja s of the upper clamp and the rollers of the roller clamp, ith the specimen resting lightly on the ith the central sliding bottom gauge. As you center the specimen in the upper clamp by adjusting the clamp scre s, make sure it lines up mark on the pendulum. 3.7. 2ext, center the specimen bet een the rollers. &o!e the left hand ithout roller to ard the specimen until the roller contacts it contact

deflecting the pendulum. Then bring the right hand roller into light ith the specimen. En the head of each of the adjustment knobs is scribed a black line. Ebser!e the position of this line on the right hand adjustment knob and then back off F turn. This procedure ensures not only constant clearance in all tests but also enough clearance so the specimen can slide bet een the rollers. condition is not satisfied, your measurements are meaningless. 3.<. 4ush the operating s itch, see 1.8., to the left side. This sets the dri!ing disk in counterclock ise rotation, and the specimen is 5 1@ "f this

deflected. The end point is indicated 1.7., is aligned

hen the pendulum mark, see These t'o

ith the 17o mark on the dri!ing disk.

(ar#s) for(ing one $ine) &oint to "our reading on the sca$e . This is your left hand reading. 3.;. Gepeat this procedure on the right hand side, obtaining your right hand reading. Take the a!erage of your left hand and your right hand readings. This, the final result of your pre5liminary test, is the Taber stiffness of your sample in units of gfcm. .! 8.1. Final test 9onsult Table 1. "f the result of your preliminary test falls in the range : to 1: gfcm, do the final test under sensiti!e conditions, i.e. the of Table 1. This calls for the rollers to result obtained under

conditions gi!en in the first ro stud on the pendulum.

be up and for the ten unit compensator to be attached to the upper 2otice that your ne these sensiti!e conditions must be multiplied by :.1, the (u$ti&$ier gi!en in the eighth and last column of Table 1. 8.%. "f the result of your preliminary test falls in the range 1: to 1:: gfcm, then by lucky coincidence the standard conditions employed in your preliminary test are optimal, and you can accept this result as final. These conditions are gi!en in the second ro that the multiplier is 1 in this case. 8.3. "f the result of your preliminary test falls in the range 7: to 7:: g fcm, then according to ro multiplier is 7. 8.8. 6imilar remarks apply to other ranges, and the remainder of Table 1 is self5explanatory. Enly t o more aspects re)uire comment. The first is that the ranges in the second column of Table 1 o!erlap to some 5 %: 3 of Table 1 do the final test ith the 7:: unit eight attached to the lo er stud on the pendulum. "n this case the of Table 1. 2otice

extent. 6uppose, for example, that your preliminary test ga!e a Taber stiffness of <: gfcm; this falls and also ithin the range 1: to 1:: -second ro . of Table 1.. "n

ithin the range 7: to 7:: g fcm -third ro

such a case, use the more sensiti!e conditions, in this case the conditions associated )uestion is or checks ith the range 1: to 1:: g fcm. The second

hen to change from the standard deflection angle of 17 o ith relati!ely thick board that cracks of Table 1, hen deflected 17 o. As indicated in the last ro

to ;.7 o. This may be necessary

a deflection angle of ;.7 degrees re)uires a multiplier t ice as great as that at 17o. Geport' Geport the a!erage Taber bending stiffness !alues in g fcm

for your paper and paperboard samples in the machine direction and the cross direction. Also report @7H confidence inter!als. "n your +Gecord of Test *ata,, form 4T5%, be certain to indicate clearly the test conditions used. Geference TA44" T 8=@

Second Method: +ho(arg" Bending Stiffness Tester As has already been pointed out, this instrument measures the specific flexural rigidity. bending stiffness $e sa earlier that this is the only measure of ith a sound physical basis. ill

A strip of paper or paperboard is held !ertically in a clamp !ibrating at a fixed fre)uency. The free length of strip projecting abo!e the clamp undergo forced !ibration. This free length is adjusted for resonance, a

condition !isually recognizable as maximum !ibrational amplitude of the strip#s free end. The free length at resonance, called resonance length, is 5 %1

determined. The specific flexural rigidity is calculated from this resonance length and the kno n basis eight. $hereas the Taber instrument is limited in application to fairly stiff paper and paperboard, the (homargy stiffness tester can co!er a much ider range of stiffness !alues and is effecti!e e!en to basis eights of about %7 gIm %. ith tissue paper, do n

4atterns of Jibration' (et l be the free length of strip projecting abo!e the !ibrating clamp and ( the resonance length. As l is !aried in relation to (, a se)uence of !ibrational patterns ill be obser!ed, and a fe typical ith patterns are sho n in Figure 8. The !ibration l _ %.7 (. Figure 8 also indicates that, starting the amplitude of !ibration decreases sharply raised. ith l K ( is the fundamental ith the fundamental l K (, hen l is either lo ered or

!ibration that should be utilized; a!oid the irrele!ant o!ertone !ibration

5 %%

Test 6pecimens' depend on sample

9ut 7 test strips 17 mm

ide for both machine idth be uniform.

direction and cross5machine direction.

Actually, the test results do not

idth but it is essential that the

The strip length re)uired for a measurement depends on the specific flexural rigidity of the specimen and must, of course, exceed the resonance length. A length of %: cm should be ade)uate for most grades. ill ha!e a resonance length greater than %: cm. Enly extremely stiff board

$hereas the specimen length is not critical, it is important that the ends of the strip are cut cleanly and at a right angle to their length. ðod of Test' Figure 7 is a schematic representation of the hich the test strip is held by the

instrument and indicates the manner in Mold the strip !ibrating clamp

t o clamps, the upper !ibrating clamp and the lo er Lpulling clampL. ith one hand and open the spring5loaded ja s of the ith the other hand. "nsert the strip, making sure it is as

nearly !ertical as possible. Also, the strip

5 %3

Figure 7' 6chematic dra ing of the (homargy tester

ith sample.

should be as far back in the clamp as possible, making contact of the strip, and tighten the clamp.

ith the back

plate of the clamp. Epen the ja s of the pulling clamp, insert the lo er end $ith the knurled knob at the right side of the apparatus, lo er the strip until it is exactly le!el scale. Turn on the instrument unit. Epen the !ibrating clamp and raise the strip by means of the knurled knob. 9lose the !ibrating clamp. 6lo ly pull the strip do n ard, thereby continuously shortening the strip#s free end. Ebser!e the !ibrating strip edge5on from the front and notice the different !ibrational patterns discussed earlier. Ebtain an estimate of the resonance length at the point of maximum amplitude in the fundamental mode. To determine the >se the resonance length more precisely, proceed as follo s. &ake the free strip length slightly longer than the estimated resonance length. horizontally mounted lens to focus the stroboscopic light coming from the top of the instrument onto the top edge of the !ibrating paper strip and use the second lens for obser!ation. 0ou should see four lines' t o outer lines corresponding to the extreme points of !ibration, and t o inner bright lines due to the stroboscopic light. merge As you carefully shorten the length of the ill mo!e out ard and suddenly ay to pinpoint !ibrating strip, the t o bright inner lines ith the toggle s itch at the bottom of the ith the top surface of the !ibrating clamp. 9arefully adjust the zero of the !ernier scale to the zero of the stationary

ith the t o outer lines. This is the most precise

resonance. Gead the resonance length from the scale in mm. *etermine the resonance length of fi!e specimens and find the a!erage in mm. 9alculation of the 6pecific Flexural Gigidity' 9alculate the specific eight, $ m,

flexural rigidity from the resonance length, (, and the basis

according to the e)uation

"n e)uation -3., the con!ersion factor % 1:5 @ -units omitted. assures that the specific flexural rigidity is obtained in m2m pro!ided the resonance length, (, is inserted in mm and the basis eight, $ m, in gIm %. For example, suppose you found that (K8.37 cm and $K7: gIm %. Then, specific flexural rigidity K %1: 5 @ 83.78 7: m2m K :.37= m2m 2otice that ( Geport' as inserted not in cm as gi!en but in mm as re)uired. Geport the mean specific flexural rigidity in m2 m for the Also report @7H

machine direction and the cross5machine direction. confidence inter!als. Geference TA44" T 737

-2ote' "n TA44" 6tandard T 737, the area moment of inertia is incorrectly referred to as Langular impulseL..

Vous aimerez peut-être aussi

- Scope: Provisional Method - 1994 © 1984 TAPPIDocument3 pagesScope: Provisional Method - 1994 © 1984 TAPPIМаркус СилваPas encore d'évaluation

- SM 4 ExperimentsDocument19 pagesSM 4 ExperimentsSarath TejaPas encore d'évaluation

- 51 Bursting StrengthDocument8 pages51 Bursting StrengthJad Jd0% (1)

- Bursting StrengthDocument8 pagesBursting StrengthRobin Saha0% (1)

- Strength of MaterialsDocument24 pagesStrength of Materialsmech bhabhaPas encore d'évaluation

- Drag CoefficientDocument8 pagesDrag CoefficientEngr Mohammad FarhanPas encore d'évaluation

- Tearing Resistance of PaperDocument13 pagesTearing Resistance of PaperkakakhmmPas encore d'évaluation

- Direct Shear TestingDocument14 pagesDirect Shear TestingIlhamPas encore d'évaluation

- Practical No 10 Satyam YadavDocument3 pagesPractical No 10 Satyam YadavBrijesh UkeyPas encore d'évaluation

- Tensile TestingDocument13 pagesTensile TestingAric NgPas encore d'évaluation

- Direct: E) FfirciseDocument7 pagesDirect: E) FfirciseTantanPas encore d'évaluation

- Strength of Materia Lab Manual UET, LahoreDocument14 pagesStrength of Materia Lab Manual UET, LahoreRizwan Khurram100% (3)

- KGe Profiler ManualDocument5 pagesKGe Profiler ManualReinaldo PulidoPas encore d'évaluation

- Lab Report TorsionDocument4 pagesLab Report TorsionhhazimabPas encore d'évaluation

- Direct Shear TestDocument11 pagesDirect Shear Testshahrolhazrien91% (34)

- T 815Document25 pagesT 815윤병택Pas encore d'évaluation

- Triaxial TestDocument14 pagesTriaxial TestSi Rerumpai LautPas encore d'évaluation

- Mate 453 Tensile TestDocument23 pagesMate 453 Tensile TestElijah ObengPas encore d'évaluation

- Guidance Test SpecimensDocument10 pagesGuidance Test SpecimensferrarifanaticPas encore d'évaluation

- Tensile Strength, Breaking Length, Tensile Index, Stretch, Tensile Energy Absorption, and Tensile StiffnessDocument22 pagesTensile Strength, Breaking Length, Tensile Index, Stretch, Tensile Energy Absorption, and Tensile StiffnessSujanto WidjajaPas encore d'évaluation

- Tensile Strength, Breaking Length, Tensile Index, Stretch, Tensile Energy Absorption, and Tensile StiffnessDocument24 pagesTensile Strength, Breaking Length, Tensile Index, Stretch, Tensile Energy Absorption, and Tensile StiffnessWudassie AyelePas encore d'évaluation

- Lab 6 Direct ShearDocument4 pagesLab 6 Direct ShearAlison GilbertPas encore d'évaluation

- K Ge Reeds Profiling Machine ManualDocument6 pagesK Ge Reeds Profiling Machine ManualNeuromante3223Pas encore d'évaluation

- SM Lab ManualsDocument27 pagesSM Lab ManualspraveenampilliPas encore d'évaluation

- Experiment No-8: To Study The Anisotropy Ratio of Aluminium Sheet by 20% Cold RolledDocument2 pagesExperiment No-8: To Study The Anisotropy Ratio of Aluminium Sheet by 20% Cold RolledDharmendra KumarPas encore d'évaluation

- Laboratory Manual: THIRD SEMESTER B.Tech MechanicalDocument45 pagesLaboratory Manual: THIRD SEMESTER B.Tech MechanicalhanPas encore d'évaluation

- Test of Packaging MaterialDocument16 pagesTest of Packaging MaterialPrashanta Pokhrel100% (1)

- KD - KC 2022 - G6 Criteria B and C Lab Report TemplateDocument9 pagesKD - KC 2022 - G6 Criteria B and C Lab Report Templateyouyoonseo04880Pas encore d'évaluation

- Impressor BarcolDocument8 pagesImpressor BarcolMarco CortésPas encore d'évaluation

- Astm d412 1968 PDFDocument13 pagesAstm d412 1968 PDFHassan Mehmood100% (1)

- Section I of ExperimentDocument3 pagesSection I of ExperimentGrace TongPas encore d'évaluation

- Film Properties-Tests and DetailsDocument40 pagesFilm Properties-Tests and DetailsShubham Kumar100% (2)

- Tensile Test On Brittle Material 2 DoneDocument12 pagesTensile Test On Brittle Material 2 Done202302090036Pas encore d'évaluation

- One Material Property That Is Widely Used and Recognized Is The Strength of A MaterialDocument3 pagesOne Material Property That Is Widely Used and Recognized Is The Strength of A MaterialWaleed JaddiPas encore d'évaluation

- Lab Session 5 Mom 2Document5 pagesLab Session 5 Mom 2m.sheraz malikPas encore d'évaluation

- VatDocument7 pagesVatFaisal HossainPas encore d'évaluation

- Recipiente Sub PresiuneDocument10 pagesRecipiente Sub Presiunec_e_z_a_rPas encore d'évaluation

- Norma Tension Superficial D1331Document4 pagesNorma Tension Superficial D1331cristiangggPas encore d'évaluation

- Relationship Between Shear Stress and Shear StrainDocument4 pagesRelationship Between Shear Stress and Shear Strainwindgust820% (1)

- 2002 Int Ansys Conf 147Document13 pages2002 Int Ansys Conf 147Ashutosh SrivastavaPas encore d'évaluation

- Bending Moment of BeamDocument11 pagesBending Moment of BeamAin Sherin100% (1)

- Flow Past A Circular Cylinder: William J. DevenportDocument16 pagesFlow Past A Circular Cylinder: William J. DevenportNivesh Agarwal100% (1)

- LevelerDocument8 pagesLevelertheravikantPas encore d'évaluation

- 1.Strength-of-Materials V+Document36 pages1.Strength-of-Materials V+sriramPas encore d'évaluation

- Elastic Properties of Solids - ManualDocument9 pagesElastic Properties of Solids - ManualMuzamil ShahPas encore d'évaluation

- Torsion of ShaftDocument8 pagesTorsion of ShaftHan Keong ChiewPas encore d'évaluation

- Lab 08 - Rubber Stopper and Centripetal Force 5 1Document1 pageLab 08 - Rubber Stopper and Centripetal Force 5 1Arsath malik ArsathPas encore d'évaluation

- Aim Equipment Theory: Mechanical & Systems Engineering Laboratory Assignment 1: Tensile Test On Mild SteelDocument18 pagesAim Equipment Theory: Mechanical & Systems Engineering Laboratory Assignment 1: Tensile Test On Mild Steelbodkhe harshPas encore d'évaluation

- Ring Frame End Breakage Distribution: D e X 0.75 TDocument9 pagesRing Frame End Breakage Distribution: D e X 0.75 TArj RajshahiPas encore d'évaluation

- 分切机操作工序(中亚制)Document4 pages分切机操作工序(中亚制)fanghe LiuPas encore d'évaluation

- Exercrse: Triaxia1 Shear ofDocument7 pagesExercrse: Triaxia1 Shear ofTantanPas encore d'évaluation

- Report Full Direct Shear Test Edit (Repaired)Document15 pagesReport Full Direct Shear Test Edit (Repaired)Asyraf Malik100% (15)

- The Numerical Analysis of Roll Deflection During Plate RollingDocument4 pagesThe Numerical Analysis of Roll Deflection During Plate RollingVikram TambePas encore d'évaluation

- Direct Shear TestDocument16 pagesDirect Shear TestNishanth Nanthakumar25% (4)

- A Model Boat Builder's Guide to Sail Making - A Collection of Historical Articles on the Planning and Construction of Model SailsD'EverandA Model Boat Builder's Guide to Sail Making - A Collection of Historical Articles on the Planning and Construction of Model SailsPas encore d'évaluation

- 71+10 New Science Activities: An interactive approach to learning scienceD'Everand71+10 New Science Activities: An interactive approach to learning sciencePas encore d'évaluation

- The Mechanical Properties of Wood: Including a Discussion of the Factors Affecting the Mechanical Properties, and Methods of Timber TestingD'EverandThe Mechanical Properties of Wood: Including a Discussion of the Factors Affecting the Mechanical Properties, and Methods of Timber TestingPas encore d'évaluation

- The Book of Basic Machines: The U.S. Navy Training ManualD'EverandThe Book of Basic Machines: The U.S. Navy Training ManualÉvaluation : 4 sur 5 étoiles4/5 (4)

- Engg Book ListDocument29 pagesEngg Book ListRavi KhandelwalPas encore d'évaluation

- A Torque Cancelling System For Quick-Motion Robots: Daigoro IsobeDocument21 pagesA Torque Cancelling System For Quick-Motion Robots: Daigoro IsobeRavi KhandelwalPas encore d'évaluation

- Linear Vs Non-Linear Contact Analysis 082207Document9 pagesLinear Vs Non-Linear Contact Analysis 082207Senthil KumarPas encore d'évaluation

- Documento 22Document18 pagesDocumento 22Ravi KhandelwalPas encore d'évaluation

- Mechanics of Materials and StructuresDocument32 pagesMechanics of Materials and StructuresRavi KhandelwalPas encore d'évaluation

- Mobile Numbering System 813Document72 pagesMobile Numbering System 813Ravi KhandelwalPas encore d'évaluation

- 3.8. Parametric Functions2Document3 pages3.8. Parametric Functions2Ravi KhandelwalPas encore d'évaluation

- ContentDocument1 pageContentRavi KhandelwalPas encore d'évaluation

- Soil NailingDocument24 pagesSoil NailingVivekPas encore d'évaluation

- Class 18 March 2020 PDFDocument13 pagesClass 18 March 2020 PDFMuskan NehraPas encore d'évaluation

- Approved List of Manufacturers: CategoryDocument3 pagesApproved List of Manufacturers: Categorytomj9104Pas encore d'évaluation

- Plano 236D PDFDocument27 pagesPlano 236D PDFArle SalasPas encore d'évaluation

- Process Equipment in Petroleum RefiningDocument2 pagesProcess Equipment in Petroleum RefiningKaify ScorpionPas encore d'évaluation

- Land Rover LR3 (2006) Owners ManualDocument358 pagesLand Rover LR3 (2006) Owners Manualt9mek100% (2)

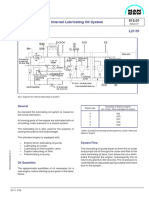

- Internal Lubricating Oil System: GeneralDocument3 pagesInternal Lubricating Oil System: GeneralAtanasio PerezPas encore d'évaluation

- hw10 Solution PDFDocument6 pageshw10 Solution PDFJason HuaPas encore d'évaluation

- Vel C6 ABAQUS Users Conference PDFDocument14 pagesVel C6 ABAQUS Users Conference PDFomidPas encore d'évaluation

- ENGEL Victory enDocument17 pagesENGEL Victory enValentinIvascuPas encore d'évaluation

- Asme B16.5Document11 pagesAsme B16.5jacquesmayol100% (1)

- TICA модульный чиллер TCADocument16 pagesTICA модульный чиллер TCAКирилл ЛевкевичPas encore d'évaluation

- Service Manual: F2 SeriesDocument36 pagesService Manual: F2 SeriesPramono DamarPas encore d'évaluation

- 11 111i 11III11l11111m1: Iiii LllllliDocument46 pages11 111i 11III11l11111m1: Iiii LllllliNashrul AfiqPas encore d'évaluation

- GB E4313 - AWS A5.1 E6013 Welding Rods - Carbon Steel ElectrodeDocument2 pagesGB E4313 - AWS A5.1 E6013 Welding Rods - Carbon Steel ElectrodeArfanAli100% (1)

- Product Guide B 200Document44 pagesProduct Guide B 200Sina ShirdelPas encore d'évaluation

- Flowserve PompeDocument76 pagesFlowserve Pompemariasofiarossi50% (2)

- Ee6601 SSD PDFDocument21 pagesEe6601 SSD PDFRohithPas encore d'évaluation

- Caterpillar Parts Manual - C15 Generator SetsDocument1 281 pagesCaterpillar Parts Manual - C15 Generator SetsZafeer100% (1)

- Bolt Capacities: Grade 4.6 Bolts in S355Document3 pagesBolt Capacities: Grade 4.6 Bolts in S355Ah ChiaPas encore d'évaluation

- Analysis of Balsa Wood Bridge ModelsDocument28 pagesAnalysis of Balsa Wood Bridge ModelsHazem EmamPas encore d'évaluation

- Vapor Pressure of A Pure LiquidDocument9 pagesVapor Pressure of A Pure LiquidLuluaPas encore d'évaluation

- Exercises On Stress StateDocument4 pagesExercises On Stress StatecusanhPas encore d'évaluation

- 216-Article Text-404-1-10-20200827Document3 pages216-Article Text-404-1-10-20200827BADINEHALSANDEEPPas encore d'évaluation

- Experimentalmechanics (1) UnlockedDocument127 pagesExperimentalmechanics (1) UnlockeddivyaPas encore d'évaluation

- Troubleshooting: 4-1. Error ModesDocument8 pagesTroubleshooting: 4-1. Error ModesluisPas encore d'évaluation

- Homelite String Trimmer Parts Manual HBC30 String Trimmer UT 15085Document12 pagesHomelite String Trimmer Parts Manual HBC30 String Trimmer UT 15085marcosPas encore d'évaluation

- 1.daily Report Manufacture Steel Structure. TGL 09.07 2Document133 pages1.daily Report Manufacture Steel Structure. TGL 09.07 2Rusman LumbantoruanPas encore d'évaluation

- Expansion Vessel Calculation SheetDocument2 pagesExpansion Vessel Calculation SheetsmcsamindaPas encore d'évaluation

- Testing, Adjusting & Balancing - ASHRAEDocument7 pagesTesting, Adjusting & Balancing - ASHRAEZainul Abedin Sayed100% (1)