Académique Documents

Professionnel Documents

Culture Documents

RC2095 3 1

Transféré par

montyviaderoTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

RC2095 3 1

Transféré par

montyviaderoDroits d'auteur :

Formats disponibles

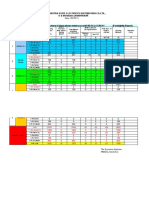

WF46-0010

Project

RCM&E PLANS SERVICE

A .46cu. in. two-stroke glow engine. DESIGNED BY Alex Whittaker

PLAN No: RC2095 No. of Sheets:

First published in

RCM&E March. 2012

General Notes

This drawing is to be used in

conjunction with the RCM&E

column write up for machining

methods, dimensional fits and

assembly.

Typical Dimensional Tolerance

0 DecimoI PIoces 0.bmm

I DecimoI PIoces 0.Zmm

Z DecimoI PIoces 0.Imm

3 DecimoI PIoces 0.0bmm

AnguIor 0.Z"

Section on A-A

PISTON (Scale 2:1) Material - Cast Iron

Underside

A

A

Completed Piston

21.00*

1

8

.5

1

7

19.00

6

5

.0

0

1

8

.5

8

.3

5

12

1

6

.5

*Note

Make Liner prior to making Piston. Outside

Diameter to be lapped to size to match liner

19.5

R

6

1mm Dia Hole for

future Gudgeon

Pin removal

Section on A-A

WF46-0011 GUDGEON PIN (Scale 2:1)

Material - Silver Steel

A

A

Completed Gudgeon Pin

5.000

18.5

End Elevation

2

.5

3

Chamfer 0.25mm

Notes-

1. The Gudgeon pin diameter should be made to

a minimal clearance to match the piston.

Side View

Section on A-A

WF46-0012 LITTLE END PLUG (Scale 4:1)

Material - Bronze

A

A

Completed Plug

End Elevation

Notes-

1. Test fit the plug in the gudgeon pin & piston

to ensure a sliding fit within the liner.

1.1 3

2

.5

1

5

.0

R0.25

R10.5

View of Completed Liner

WF46-0013 CYLINDER LINER

Section on A-A Front Elevation

Plan View

Material - Carbon Steel EN8M (212M36)

A

3

5

.2

5

28.1

0

.7

5

11.0

T

S

F

R

11.0

T

S

F

R

A

21.000

4b"

Sectional Elevation on B-B

4b"

Outside of Liner Port Development

78.54 (25mm Dia)

Circumference

3

4

.5

Underside of Liner Lip

11.39 15.285

Bottom edge of Liner

11.39 13.94 13.94

6.298 6.298

Section on A-A

Front Elevation

A

Material - Mild Steel or Brass

Completed Barrel

10.0

1 - Hole Drill & Tap M3

A

WF46-0015 CARBURETTOR BARREL (Scale 2:1)

I - HoIe 3mm

1

2

.69

.4

5.7

Section on A-A Front Elevation

A

Material - Aluminium alloy HE30 (6082) 3/4" (19mm) Hex Bar

Completed Carburettor

Body

Plan View

2 - Holes Drill & Tap M3

WF46-0014 CARBURETTOR BODY (Scale 2:1)

10

3

0

.7

5

5

.5

1

6

8

1

.2

5

5

1

3

.5

1

7

.2

5

8

8

4

5

.8

5

View on Arrow C

1

2

.8

10.0

5.7

1 - Holes Drill & Tap M6

B B

Section on B-B

6.8

C

A

1- Hole Drill & Tap

M2.5 x 6 Deep

o0"

1.5

Venturi angle cut using a

Countersink Drill

R2

I3

1

8

.7

5

I0.00

Section on A-A

Front Elevation

A

Material - Aluminium Alloy HE30 (6082)

Completed Carb Spacer

A

WF46-0016 CARB BARREL SPACER (Scale 2:1)

I - HoIe 3mm

1

0

.5

1

.2

II.Z

8.Zb

Plan View

Front Elevation

Material - Brass Hex Stock

Completed Nipple

WF46-0017 NIPPLE (Scale 2:1)

I - HoIe Imm fhrough

1

9

4

.2

5

9

.5

A

/

F

M6 Thread

9

.5

5

2

.7

5

3.5

2.35

4.25

2

.2

5

Remove Sharp Corners

10.97

ref

9"

End Elevation

WF46-0018 NEEDLE VALVE BODY (Scale 2:1) Material - Brass

A

A Completed Body

18.0

1

1

.5

2

9

27

7.4 4.5

11 4

6

.8

5

.7

5

8.8

18

23

4

.6

8

1

1

.5

3.2*

1.2

4

.5

Thread M4 x 0.5p

Z HoIes Zmm

^Z-HoIes 3.Zmm fo

be a light press fit for

copper feed pipes

Notes- Suitable for O.S Needle No.24081970

Copper feed pipes to

be a light press fit

1

.2

Section on A-A

WF46-0019 MIXTURE CONTROL DISC (Scale 2:1)

Material - Aluminium Alloy HE30 (6082)

A

Completed Disc

8.5

1.3

1

1

.6

Z4

6

.8

II.o

1 Hole drill to

suit for clevis

Z-HoIes driII I.Zmm fhrough

on on 8.Zmm PCD

R

1

0

A

Section on A-A

8

.2

Section on A-A

WF46-0020 PROP DRIVER (Scale 2:1)

Front Elevation

A

A

Completed Driver

7.54

9

.1

5

2

2

.7

5

3

.3

7

5

5.04 Key depth

1

7

.8

Key

2.94

3b"

Serrated front

face 40 off

0.3mm deep

Rear Elevation

9.15

1

1

.5

R10

6

8

0.5

Material - Aluminium Alloy HE30 (6082)

3 of 3

Vous aimerez peut-être aussi

- Despiece Motor y Conjunto PDFDocument23 pagesDespiece Motor y Conjunto PDFBorralla CinzaPas encore d'évaluation

- Side Elevation End View: Title Projection Sheet A4 First Published in RCM&E Magazine February / March 2012. 1:1Document1 pageSide Elevation End View: Title Projection Sheet A4 First Published in RCM&E Magazine February / March 2012. 1:1montyviaderoPas encore d'évaluation

- 200: Shell Cassettes Corner Node - Type 230-60Document8 pages200: Shell Cassettes Corner Node - Type 230-60sasikumarPas encore d'évaluation

- WF46-0005 Barrel Details: General ToleranceDocument1 pageWF46-0005 Barrel Details: General TolerancemontyviaderoPas encore d'évaluation

- CR 13045 PIER R00 Calculation ReportDocument11 pagesCR 13045 PIER R00 Calculation Reportmusiomi2005Pas encore d'évaluation

- Steel Penstocks - 11 ManufactureDocument10 pagesSteel Penstocks - 11 ManufactureRicardo MartinezPas encore d'évaluation

- IPSS SPECIFICATIONDocument5 pagesIPSS SPECIFICATIONesskaydhakarPas encore d'évaluation

- Body Flange Design-Appx-2Document4 pagesBody Flange Design-Appx-2Matthieu100% (1)

- Wind Turbine Nacelle Datasheet Pack ENGDocument16 pagesWind Turbine Nacelle Datasheet Pack ENGMamelucoPas encore d'évaluation

- Cold Form Design in Scia PDFDocument127 pagesCold Form Design in Scia PDFchhouch100% (2)

- DIY Bench Top Tubing BenderDocument17 pagesDIY Bench Top Tubing BenderMalcolm DiamondPas encore d'évaluation

- 06 639Document15 pages06 639Fernando Sabino100% (1)

- Construction Drawings Rev4Document12 pagesConstruction Drawings Rev4api-301270531Pas encore d'évaluation

- Din 1480 2005Document6 pagesDin 1480 2005PacoPas encore d'évaluation

- Engine Base & BlockDocument47 pagesEngine Base & Blockkr_abhijeet7235658750% (2)

- Threading Tools (SST Series)Document8 pagesThreading Tools (SST Series)Gilberto ManhattanPas encore d'évaluation

- Bureau OF Indian Standards: ( Roup 3Document10 pagesBureau OF Indian Standards: ( Roup 3leua_690001837Pas encore d'évaluation

- F7212HDocument9 pagesF7212HSopon SrirattanapiboonPas encore d'évaluation

- JIS F 7208 duplex oil strainersDocument15 pagesJIS F 7208 duplex oil strainersSopon SrirattanapiboonPas encore d'évaluation

- Assembly Parts List and DrawingDocument1 pageAssembly Parts List and DrawingGusti Ryandi AriefPas encore d'évaluation

- Fresa Men ToDocument292 pagesFresa Men ToSandra CrisostomoPas encore d'évaluation

- Is 5513 VicatDocument9 pagesIs 5513 VicatMohamed RafiqPas encore d'évaluation

- Front and Rear SphereDocument4 pagesFront and Rear SphereRamalingam PrabhakaranPas encore d'évaluation

- Department of Mechanical Engineering: Mech412: Machine Design II Second Semester, 2020-2021Document3 pagesDepartment of Mechanical Engineering: Mech412: Machine Design II Second Semester, 2020-2021mhd slmnPas encore d'évaluation

- Alpema Standards Rev1 2000Document8 pagesAlpema Standards Rev1 2000anonimppPas encore d'évaluation

- Internal Snap Rings DIN 7993 Part B SizesDocument2 pagesInternal Snap Rings DIN 7993 Part B SizesRajaSekarsajja100% (1)

- Dexter's Plastic Can: 2.008 Design & Manufacturing IIDocument7 pagesDexter's Plastic Can: 2.008 Design & Manufacturing IIUygur ZerenPas encore d'évaluation

- AA01042A Fisura Horse CollarDocument5 pagesAA01042A Fisura Horse CollarSebastiánRodrigoPérezHenríquezPas encore d'évaluation

- Calculation 240 (Rev02)Document15 pagesCalculation 240 (Rev02)KM YapPas encore d'évaluation

- PEM Self Clinching Keyhole StandoffsDocument6 pagesPEM Self Clinching Keyhole StandoffsAce Industrial SuppliesPas encore d'évaluation

- Normal Grating Manual 531-09Document36 pagesNormal Grating Manual 531-09esaraviaPas encore d'évaluation

- IS 2486 Part-2 (1989)Document28 pagesIS 2486 Part-2 (1989)tanto_deep_15Pas encore d'évaluation

- Advanced Tool Design PDFDocument4 pagesAdvanced Tool Design PDFgsudhanta1604Pas encore d'évaluation

- ETABS 2015 Concrete Frame Design: ETABS 2015 15.0.0 License # 1TYYZ6WT9WKC6EXDocument8 pagesETABS 2015 Concrete Frame Design: ETABS 2015 15.0.0 License # 1TYYZ6WT9WKC6EXTeomnerCabreraPas encore d'évaluation

- C95 Eu PDFDocument36 pagesC95 Eu PDFMihaela PopPas encore d'évaluation

- Shipbuilding water filters JIS standardDocument8 pagesShipbuilding water filters JIS standardSopon SrirattanapiboonPas encore d'évaluation

- Technical Specs and Repair Guide for 10mm DrillsDocument14 pagesTechnical Specs and Repair Guide for 10mm DrillspopokatePas encore d'évaluation

- 4500 MT Pleasant St. NW N. Canton, OH 44720 - Web Site:: The Timken CompanyDocument4 pages4500 MT Pleasant St. NW N. Canton, OH 44720 - Web Site:: The Timken Companyila reehasPas encore d'évaluation

- Bill No 5 Metal WorksDocument8 pagesBill No 5 Metal WorksAmy FitzpatrickPas encore d'évaluation

- Tugas Welding Fixture 1Document1 pageTugas Welding Fixture 1Rahmat HidayatPas encore d'évaluation

- MBG - 531-09 Metal Bar Grating ManualDocument36 pagesMBG - 531-09 Metal Bar Grating ManualCarlo Monsalve100% (1)

- OVHD Compressor Maintenance JobDocument8 pagesOVHD Compressor Maintenance JobMuhammad Usman KaimkhaniPas encore d'évaluation

- 2 Speed TransmissionDocument57 pages2 Speed TransmissionNatalie WyattPas encore d'évaluation

- Injector InstalacionDocument6 pagesInjector Instalacionjose luis herreraPas encore d'évaluation

- Shell Assembly 1000Document2 pagesShell Assembly 1000Danny Milton Silva VasquezPas encore d'évaluation

- Matecconf Mtem2019 03010Document6 pagesMatecconf Mtem2019 03010metal squad metal squadPas encore d'évaluation

- Steel Floor Deck Guide SpecificationsDocument5 pagesSteel Floor Deck Guide SpecificationsRafaArdiSyahrezaPas encore d'évaluation

- 2520 z000 STD 1780 06 - B Anchor Bolt DetailDocument2 pages2520 z000 STD 1780 06 - B Anchor Bolt Detailabdul mujeebPas encore d'évaluation

- Ci 6563 1 DCDocument223 pagesCi 6563 1 DCyosriPas encore d'évaluation

- Boiler Steam Dump SilencerDocument7 pagesBoiler Steam Dump SilencerRaju Gopinathan Nair100% (1)

- Two-Piece Mounts1Document8 pagesTwo-Piece Mounts1VitorMelloPas encore d'évaluation

- SAMSUNG SEM-3036E - Piping Design Manual (Rack Piping) PDFDocument48 pagesSAMSUNG SEM-3036E - Piping Design Manual (Rack Piping) PDFPrashant SinghPas encore d'évaluation

- Plastic Injection Mold Design for Toolmakers - Volume II: Plastic Injection Mold Design for Toolmakers, #2D'EverandPlastic Injection Mold Design for Toolmakers - Volume II: Plastic Injection Mold Design for Toolmakers, #2Pas encore d'évaluation

- Tightening Slows But Risk Premiums Remain LowDocument36 pagesTightening Slows But Risk Premiums Remain LowmontyviaderoPas encore d'évaluation

- Transocean LTDDocument86 pagesTransocean LTDmontyviaderoPas encore d'évaluation

- Prospectus Emission 500MDocument83 pagesProspectus Emission 500MmontyviaderoPas encore d'évaluation

- United States Securities and Exchange Commission Washington, D.C. 20549 FORM 10-QDocument32 pagesUnited States Securities and Exchange Commission Washington, D.C. 20549 FORM 10-QmontyviaderoPas encore d'évaluation

- Turquía 7.25% - 2038 - US900123BB58Document61 pagesTurquía 7.25% - 2038 - US900123BB58montyviaderoPas encore d'évaluation

- Plan 2016 028 Cash Restrictions enDocument6 pagesPlan 2016 028 Cash Restrictions enZerohedge100% (4)

- Rig Count Summary - 112316Document1 pageRig Count Summary - 112316Jahangir MalikPas encore d'évaluation

- Ally PraDocument148 pagesAlly PramontyviaderoPas encore d'évaluation

- United States: (12) Patent Application Publication (10) Pub. No.: US 2008/0135032 A1Document7 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2008/0135032 A1montyviaderoPas encore d'évaluation

- 3Q16 Earnings Release: São Paulo, November 14, 2016Document19 pages3Q16 Earnings Release: São Paulo, November 14, 2016montyviaderoPas encore d'évaluation

- InterimManagementReport September30 2016Document116 pagesInterimManagementReport September30 2016montyviaderoPas encore d'évaluation

- Valeant 5.5 - 2023 - USC94143AE14Document160 pagesValeant 5.5 - 2023 - USC94143AE14montyviaderoPas encore d'évaluation

- Gold Fields - in The NewsDocument2 pagesGold Fields - in The NewsmontyviaderoPas encore d'évaluation

- Ford Motor 7.7% - 2097 - US345370BS81Document16 pagesFord Motor 7.7% - 2097 - US345370BS81montyviaderoPas encore d'évaluation

- Teekay-Corporation 1Q 2016Document24 pagesTeekay-Corporation 1Q 2016montyviaderoPas encore d'évaluation

- Fre40975 ch10Document3 pagesFre40975 ch10montyviaderoPas encore d'évaluation

- Sovereign Default Risk ValuationDocument259 pagesSovereign Default Risk ValuationmontyviaderoPas encore d'évaluation

- Sec Bont 1104659 16 126128Document32 pagesSec Bont 1104659 16 126128montyviaderoPas encore d'évaluation

- Saxo Bank Latin America Bond InspirationDocument8 pagesSaxo Bank Latin America Bond InspirationmontyviaderoPas encore d'évaluation

- Saxo Bank Latin America Bond InspirationDocument8 pagesSaxo Bank Latin America Bond InspirationmontyviaderoPas encore d'évaluation

- Dell 5.4% - 2040Document84 pagesDell 5.4% - 2040montyviaderoPas encore d'évaluation

- Teekay-Corporation 1Q 2016Document24 pagesTeekay-Corporation 1Q 2016montyviaderoPas encore d'évaluation

- Analyzing Investing Activities: Intercorporate Investments: ReviewDocument34 pagesAnalyzing Investing Activities: Intercorporate Investments: ReviewAli MaksumPas encore d'évaluation

- Teekay-Corporation 1Q 2016Document24 pagesTeekay-Corporation 1Q 2016montyviaderoPas encore d'évaluation

- Barrick North America 7.5% 2038 US06849RAC60 (Finra) ABX - GGDocument166 pagesBarrick North America 7.5% 2038 US06849RAC60 (Finra) ABX - GGmontyviaderoPas encore d'évaluation

- Copper Supply and Demand DynamicsDocument5 pagesCopper Supply and Demand DynamicsIsaiahogedaPas encore d'évaluation

- Overview of Chapters DemanaDocument3 pagesOverview of Chapters Demanamontyviadero0% (1)

- Sensor Performance Characteristics DefinitionsDocument12 pagesSensor Performance Characteristics DefinitionsKhairul FahzanPas encore d'évaluation

- Section 3.3.4 Neutral Earthing Resistors R1Document7 pagesSection 3.3.4 Neutral Earthing Resistors R1waelabouelelaPas encore d'évaluation

- Ladybug5 DatasheetDocument2 pagesLadybug5 DatasheetEloy Ricardo Franco FigueiraPas encore d'évaluation

- MSP430 Assembly Lab Manual for Number RepresentationDocument6 pagesMSP430 Assembly Lab Manual for Number Representation2017 Koh Guan TsinPas encore d'évaluation

- Syabas Water ApplicationDocument7 pagesSyabas Water ApplicationKen Chia0% (1)

- NETWORKING Top 100 interview questionsDocument22 pagesNETWORKING Top 100 interview questionsyrikki0% (1)

- Fiat 4061 PDFDocument6 pagesFiat 4061 PDFSamir YehyaPas encore d'évaluation

- Procedure For Management ReviewDocument3 pagesProcedure For Management ReviewMAYMODERN STEELPas encore d'évaluation

- Spec - LA 11,22,33 KV LA R1 Sep10Document14 pagesSpec - LA 11,22,33 KV LA R1 Sep10Amarjit KulkarniPas encore d'évaluation

- Manual de Teatro en Casa Nuevo PanasonicDocument56 pagesManual de Teatro en Casa Nuevo PanasonicMiguel Angel Aguilar BarahonaPas encore d'évaluation

- Social Skills LessonDocument5 pagesSocial Skills LessonAshley DavidsonPas encore d'évaluation

- Ficha Tecnica Viking PDFDocument11 pagesFicha Tecnica Viking PDFRichie ChicolPas encore d'évaluation

- MS 1472-2017Document65 pagesMS 1472-2017Thinagaran100% (2)

- Datasheet Modevapac v2.1 PDFDocument4 pagesDatasheet Modevapac v2.1 PDFParvezPas encore d'évaluation

- TablesDocument10 pagesTablesScott SiedschlagPas encore d'évaluation

- AeDocument12 pagesAeRoberto SanchezPas encore d'évaluation

- Palm Tower 3 Coverage ReportDocument61 pagesPalm Tower 3 Coverage ReportHassan DaudPas encore d'évaluation

- 4 Thermodynoamics ExercisesDocument25 pages4 Thermodynoamics ExercisesGoran MaliPas encore d'évaluation

- Rigging View Modular Overland ConveyorDocument84 pagesRigging View Modular Overland Conveyorrtyuibnm100% (2)

- CV Template ReceptionistDocument2 pagesCV Template ReceptionistMuhammad Waqas LatifPas encore d'évaluation

- Company Profile - QuosphereDocument5 pagesCompany Profile - QuosphereDivya Rao100% (2)

- Chap4 Student VersionDocument39 pagesChap4 Student VersionAzrif MoskamPas encore d'évaluation

- Finaldc 2Document10 pagesFinaldc 2Noel BactonPas encore d'évaluation

- Ajjarapu1998 PDFDocument11 pagesAjjarapu1998 PDFDanielXaveriusSagalaPas encore d'évaluation

- Regulatory Affairs Transformation SupportDocument4 pagesRegulatory Affairs Transformation SupportDhiraj LokhandePas encore d'évaluation

- Maharashtra State Electricity Distribution Co - LTD., O & M Division, NANDURBARDocument3 pagesMaharashtra State Electricity Distribution Co - LTD., O & M Division, NANDURBARPuru BornarePas encore d'évaluation

- Super Capacitors ConstructionDocument7 pagesSuper Capacitors ConstructionVivek BavdhanePas encore d'évaluation

- ACAS II Operations in The European RVSM EnvironmentDocument45 pagesACAS II Operations in The European RVSM Environmentali4957270Pas encore d'évaluation

- Motori Industriali Serie ASC Da 160 A 315mmDocument52 pagesMotori Industriali Serie ASC Da 160 A 315mmdungga1Pas encore d'évaluation

- Sap Abap Programming SyllabusDocument5 pagesSap Abap Programming SyllabusSURAJ KUMAR SAHUPas encore d'évaluation