Académique Documents

Professionnel Documents

Culture Documents

Small Bore Piping Failures

Transféré par

Kalaivani ArunachalamCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Small Bore Piping Failures

Transféré par

Kalaivani ArunachalamDroits d'auteur :

Formats disponibles

A drain line (see arrow) on a discharged bottle failed twice due to high vibration, causing safety hazards and

requiring repairs at a refinery.

Beta Machinery says pulsation studies often overlook branch connections

Small-bore piping (SBP) can be the Achilles heel of a compressor package. Beta Machinery Analysis (Beta) said vibration-related SBP failures appear to be increasing due to the growing complexity and instrumentation of compressor packages. SBP, also known as branch connections, are generally 2 in. (50 mm) or smaller in diameter. Betas President, Russ Barss, said SBP vibration is often overlooked because a typical pulsation study does not include the small-bore piping. API 618 guides the design of reciprocating compressor packages to avoid pulsation- and vibration-related issues, but is silent on small-bore piping (see June 2008, COMPRESSORTechTwo). Gufran Noor, general manager of Betas field engineering group, said, During the past few years, our company has experienced a significant increase in field audits for small-bore piping installed at refineries, compressor stations, petrochemical facilities and offshore platforms. Small bore represents the most common type of failure and the most significant risk to a facility. SBP can include a variety of attachments to vessels and the main process piping. SBP includes temperature/ pressure sensors (gauges, taps and thermowells), instrumentation lines or tubing, site glasses, pressure safety valves, blowdown lines, inspection

SMALL-BORE PIpING FAILUREs ON THE RIsE

flanges on scrubbers, and drain or vent lines. Beta said SBP problems occur because the main process piping vibrates due to the normal operation of the machine. Any rigid SBP attached to such a pipe will also vibrate. Although the vibration level of the main pipe or vessel may be acceptable, the vibration may be magnified for the SBP, depending on the geometry of the cantilevered attachment. Beta noted that if the SBP is resonant, the vibration can be amplified as much as 30 times higher than the process piping. At these high amplitudes, the risk of SBP failure is high. There are numerous resistance temperature detectors (RTDs), relief pipes, gauges and site glasses on a compressor or pump package; and one or more of the SBP components may be resonant sometime during the units operation. The likelihood of high SBP vibration also occurs when compressors or pumps on a package are operating at different speeds, or when variable speed drives are used. And if the operating conditions of the package or the gas composition change from the initial design point, it can create a different vibration scenario. Barss said variations in SBP fabrication can also result in vibration problems. Because branch connections are small, the installation is often left to shop employees or field installers. This means that minor differences can occur in the fabrication, which is why some units might be acceptable while other, so-called, identical units can experience problems, he added. When SBPs fail, volatile gases and

At a compressor station, this small-bore piping (SBP) (see arrow) failed at the connection to the main piping, causing a gas release and fire.

MARCH 2012 COMPRESSORTechTwo BetaMachinery.com

A field engineer performs a vibration audit, including small-bore piping (SBP), at a facility in Abu Dhabi.

fluids can escape and machinery can be damaged. At a minimum, the equipment will immediately shut down, causing an expensive production outage while the SBP is repaired, Noor said. For example, last year U.S. officials ordered an oil pipeline to temporarily shut down following two vibration-related SBP failures. In the same month, a 1 in. (25 mm) pipe cracked at one pump station and a 0.5 in. (13 mm) nipple failed on a pressure transmitter manifold at another station. Both incidents resulted in spills. There are many other examples of SBP failures that occur at gas compressor stations. Beta said a two-step approach should be taken to proactively address SBP vibration. Before the compressor package is built, a vibration consultant should evaluate the SBP design. After the unit is commissioned, a vibration check should be conducted to evaluate the SBP as well as the main piping and vessels. Noor said detecting SBP vibration requires a specialized testing procedure, which is more detailed than the usual API 618 pulsation study. Jordan Grose, manager of pump services, said, Of course, small-bore failures are nothing new to the industry. But were seeing more machines running at higher speeds, which means there are more chances that small-bore piping will be resonant. Another factor is that equipment operators are taking advantage of advances in technology and instrumentation in order to more closely moni-

tor whats happening in their systems. They want more data about pressures, temperatures, flow levels and all sorts of things. These control systems require more sensors and ports and more small-bore piping. Grose said, Unfortunately, industry and industrial standards are not sufficiently equipped to handle the growing SBP vibration problem. The issue certainly deserves to be given much more attention at the design phase.

During the design phase, Beta engineers can work with the equipment owner, the engineering consultant and the compressor packager on techniques to avoid SBP vibration. The problem is that often this service is not specified by the owner or engineering consultant. Betas first tenet is that the use of SBP appendages should be avoided whenever possible. If they are necessary, then the unsupported cantilevered mass should be minimized by installing vent and drain valves as close as possible to main piping and bracing the cantilevered mass of the valves to the main pipe. SBP should be made of heavy-wall pipe with reinforced connections. Beta recommends the use of studding outlets if inspection openings are necessary. Beta field engineers are experienced in SBP vibration problem solving. This team has analyzed hundreds of compressor and pump sites using specialized test equipment and post-processing analysis techniques, said Noor. Evaluating the SBP on a typical gas compressor package takes about a half day in the field. The company uses an analysis and modeling technique that it has developed based on actual operational data. In one such study, Beta evaluated two acid gas (75% H2S) compressors at a remote location. It found that vibration levels for the compressor frame, cylinders, bottles, scrubbers and piping were acceptable. But a vibration assessment of smallbore appendages (including blind flanged sets, nozzles, tubing, indicators, etc.) found seven places on the

An oil pipeline is wired for a SBP analysis.

MARCH 2012 COMPRESSORTechTwo BetaMachinery.com

A Beta Machinery Analysis field engineer performing an SBP vibration study.

compressors where vibrations were 200 to 300% higher than the industry guidelines. If any of the SBP connections had failed, a lethal release of poisonous gas could have occurred. The companys operations and maintenance staff couldnt check this vibration because they lacked the right type of equipment, software, experience and measurement techniques, Noor said.

REPRINTED FROM MARCH 2012

Solutions to SBP problems are not always easy to solve. Many barriers exist including end-user equipment specifications that limit what types of equipment are useable and what is not. Unfortunately, some specs create inherently poor SBP vibration designs, Beta said. One example is to have redundant control system philosophies. In one case, a refinery had tertiary backups

Two

to its control system instrumentation, which ended up multiplying every SBP attachment vibration problem by three. The increased complexity, and increased amount of SBP connections, dramatically increased the risk of failure on every poorly designed connection. Beta estimated that it performs about half of the vibration design studies undertaken in the compression industry. It has worked with customers on these types of issues for 45 years. Beta doubled its workforce in the past five years and has moved to larger quarters in Calgary, Alberta, Canada. It also has staff in Houston, Texas, U.S.A.; Kuala Lumpur and China. Barss said, Our expertise includes acoustical and mechanical design, torsional analysis, foundation design, package piping layout, vibration troubleshooting and predictive maintenance for the gas compression, energy, and pulp and paper industries. The company said its Dynamic Structural Analysis services are also in high demand for offshore production facilities. Structural vibration can result when large compressors or pumps experience resonance and vibration problems on platforms or FPSOs. These issues are generally costly and complicated to resolve, Barss said. Most vibration issues, whether structural or small bore, are a lot more affordable, and safer, for our customers if taken care of at the design stage. A

Copyright Diesel & Gas Turbine Publications Printed in U.S.A.

COMPRESSORTech

BetaMachinery.com

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Serial Index CaterpillarDocument260 pagesSerial Index CaterpillarRamón Mangles90% (10)

- Accounting Principles Ifrs Version Global 1st Edition Weygandt Solutions ManualDocument26 pagesAccounting Principles Ifrs Version Global 1st Edition Weygandt Solutions ManualKimberlyMendezyptr98% (40)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- CATALOGO DE VALVULAS OsvatDocument218 pagesCATALOGO DE VALVULAS OsvatGabriel Piñon Conde67% (3)

- PC210-240-7K M Ueam001704 PC210 PC230 PC240-7K 0310 PDFDocument363 pagesPC210-240-7K M Ueam001704 PC210 PC230 PC240-7K 0310 PDFCarlos Israel Gomez100% (10)

- ANEP-25 (Environmental Factors For Surface Ships)Document81 pagesANEP-25 (Environmental Factors For Surface Ships)Bahadır HarmancıPas encore d'évaluation

- ID 2051814.1 Oracle Support Sample SetupDocument9 pagesID 2051814.1 Oracle Support Sample SetupFerasHamdanPas encore d'évaluation

- Long Bolt Flange Joint LeaksDocument5 pagesLong Bolt Flange Joint LeaksKalaivani ArunachalamPas encore d'évaluation

- DSM 1510002 SP 20 - V1.0Document28 pagesDSM 1510002 SP 20 - V1.0Kalaivani Arunachalam100% (2)

- CDR Vibration Test PlanDocument15 pagesCDR Vibration Test PlanKalaivani ArunachalamPas encore d'évaluation

- Lack of Mechanical Integrity Blamed For Leak at Exxon Mobil RefineryDocument4 pagesLack of Mechanical Integrity Blamed For Leak at Exxon Mobil RefineryKalaivani ArunachalamPas encore d'évaluation

- Retirement Planning GuideDocument26 pagesRetirement Planning GuideKalaivani ArunachalamPas encore d'évaluation

- Halo Lighting Product Catalog 1974Document68 pagesHalo Lighting Product Catalog 1974Alan Masters100% (1)

- sITE aVAIL 29-07-2021Document58 pagessITE aVAIL 29-07-2021ogbodoemaPas encore d'évaluation

- Dilg-Mbcrpp Isf Q2 2023Document2 pagesDilg-Mbcrpp Isf Q2 2023Mallari GabrielPas encore d'évaluation

- Role of Technology in AdvertisementtDocument29 pagesRole of Technology in AdvertisementtShalini ChatterjeePas encore d'évaluation

- (W. Wireline) Motor PGM365 DatasheetDocument7 pages(W. Wireline) Motor PGM365 Datasheetgonzalo andres HernandezPas encore d'évaluation

- Etap - Relay CoordinationDocument311 pagesEtap - Relay CoordinationManohar Potnuru100% (1)

- Hospital Management Information SystemDocument47 pagesHospital Management Information SystemNisarg100% (1)

- ResumeDocument3 pagesResumeabreddy2003Pas encore d'évaluation

- Resume For FaisalDocument3 pagesResume For FaisalFaisal Zeineddine100% (1)

- Alpha Testing Form LATESTDocument2 pagesAlpha Testing Form LATESTazizaharsad0% (1)

- 27U RackDocument6 pages27U Racknitin lagejuPas encore d'évaluation

- Community Building PDFDocument2 pagesCommunity Building PDFLauren100% (1)

- Ansi C29.2aDocument22 pagesAnsi C29.2afecasPas encore d'évaluation

- Tramlink Low-Floor Light Rail Vehicle: Rostocker Strassenbahn Ag, Rostock, GermanyDocument2 pagesTramlink Low-Floor Light Rail Vehicle: Rostocker Strassenbahn Ag, Rostock, GermanyLuca Marius CristianPas encore d'évaluation

- NFC Reader LibrarayDocument63 pagesNFC Reader Libraraysekhar479Pas encore d'évaluation

- REERTRDocument4 pagesREERTRvgteePas encore d'évaluation

- PS2 VerilogDocument11 pagesPS2 Veriloglizhi0007Pas encore d'évaluation

- M403 DatasheetDocument2 pagesM403 DatasheetmichelerenatiPas encore d'évaluation

- Sand Reclamation - Standard Devices: Shake Out MachinesDocument2 pagesSand Reclamation - Standard Devices: Shake Out MachinesKaarthicNatarajanPas encore d'évaluation

- Cummins ECM Reference NotesDocument11 pagesCummins ECM Reference NotesjuanPas encore d'évaluation

- The Relevance of YS/UTS RatioDocument21 pagesThe Relevance of YS/UTS RatiocarrespmPas encore d'évaluation

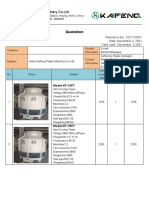

- KAIFENG Quotation For 150T Cooling TowerDocument13 pagesKAIFENG Quotation For 150T Cooling TowerEslam A. FahmyPas encore d'évaluation

- 2 Combined Dci Standards 6 13 13Document7 pages2 Combined Dci Standards 6 13 13api-32776059Pas encore d'évaluation

- Color Code - Canadian Standard - ABES - PROD.PW - MC.B017.E24806.ATTA003Document14 pagesColor Code - Canadian Standard - ABES - PROD.PW - MC.B017.E24806.ATTA003Adam Michael GreenPas encore d'évaluation