Académique Documents

Professionnel Documents

Culture Documents

SWIMMING POOL HYDRAULIC ANALYSIS

Transféré par

dcoveTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

SWIMMING POOL HYDRAULIC ANALYSIS

Transféré par

dcoveDroits d'auteur :

Formats disponibles

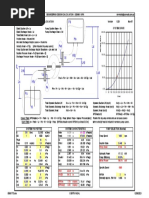

SWIMMING POOL HYDRAULIC ANALYSIS WORKSHEET

POOL NAME_______________________________________________

DATE ____________

POOL ADDRESS___________________________________________________________________

Shape_____________ Perimeter ft._______________ Width__________

Length____________ Min. Depth _______________ Break_________

Max. __________

Depth

Depth

Slope = 1 ft. in_____ft. Area = _________ Sq. ft. Volume = _________ gallons

Gunite _________ Poured _________ Other___________ Pipe Matl_______________

Outdoor or Indoor

______________________________________________________________________________

Design Flow Rate = Pool Volume

Turnover time *1

(

(

)

)

Gal. =

Min.

gpm

Check minimum skimmer flow rate. If turnover rate is inadequate for minimum skimmer operation (as per

manufacturer or 25 gpm) then design flow rate must be increased to provide minimum skimmer flow rate.

I. Number of Skimmers Required:

Quantity = no. of skimmers required from Swimming Pool Rules.

Surface Area of Pool _________ sq. ft.

No. of skimmers provided ____________.

No. of skimmers required_____________

II. Skimmer Flow Rate:

A.) If wall returns are utilized:

Skimmer flow rate = Design flow rate x 0.8

= _________gpm. x 0.8 = ___________gpm

B.) If floor returns are utilized:

Skimmer flow rate = Design flow rate = _______________gpm

Flow through each Skimmer:

Skimmer flow

for each skimmer

III.

skimmer flow rate (above) = (

no. of skimmers provided (

Number of Inlets Required:

gpm) = ______ gpm

)

*2

(15' max. spacing)

No. of inlets = perimeter = (___________) = __________ (Use next

15'

(

15'

)

whole number)

*1 For pool use minimum 6 hr. turnover (360 min.)

For other pools, use table in Rule .07

*2 Must be at least 25 gpm.

IV.

Pipe Size Selection

A. Skimmer Line Size:

Select pipe size which give max. 4 6 fps velocity at skimmer flow rate.

No. Skimmers Branch 1

Served by Pipe ________

Branch 2

_______ __

Branch 3

_______ __

Branch 4

_________

Pipe Size

________

_______ __

_______ __

_________

Flow in Pipe

________

_______ __

_________

_________

Velocity (fps)

________

________ __

_______ __

__________

(Indicate which chart used for velocity numbers) ____________________

B. Return Line Size:

Select pipe size and branches, which give max. 5 - 10 fps velocity at

design flow rate.

No. inlets

Branch 1

served by pipe _______

Branch 2

________

Branch 3

________

Branch 4

________

Pipe Size

________

________

________

________

_______

________

________

________

Flow in pipe

Velocity (fps) _______

________

________

________

(Indicate which chart used for velocity numbers) ______________

C. Main Drain Size:

Select pipe size which gives max. 6 fps velocity at design flow

rate.

Pipe size _______Design flow rate_________Velocity (fps) _____

V. Main Drain Grate Selection

Main drain outlet: (4 to 1 open area ratio each drain)

(2 required)

( 1 fps max. velocity through grate-each

drain) *1

Pipe

Size

Grate

Size (each)

Flow

Area (each)

Velocity

(fps.)

(Total Flow,)

(Both Drains)

Frame & Grate Cat. No. ___________ Quan.___________

*1 If therapy flow is through these grates, this flow must also be figured into all calculations.

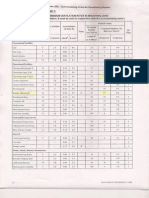

MAIN DRAIN LINE LOSS: *

If wall returns are utilized: Head loss calculation must be based on:

Main drain flow rate = 0.2 x design flow rate

= 0.2 x ___________gpm

= ________________gpm

Straight Pipe Length (Size_______)

= _________

________ elbows x equiv. length ______= _________

________ tees

x equiv. length ______= _________

________ valves x equiv. length ______= _________

Total equiv. length =

= _________

Friction loss per 100' ________ x total equiv. length ___________ 100 = _________

*1

* (enter on page 6)

If floor returns are utilized: Head loss calculations are based on 100% flow thru

skimmers.

Skimmer flow rate

= design flow rate

Main drain flow rate

=0

Main drain head loss

= 0 (enter 0 on page 6)

*1 = based on above main drain flow rate

CALCULATE RETURN LINE LOSS:*

AT

STATE WHICH CHART, GRAPH, NOMIGRAPH, ETC. USED___________________ADD

BOTTOM OF COLUMN

1.

Straight pipe size______________________________ = _______@_______gpm

# ____Elbows x Equiv. Length_________________________ = _______

# ____Tees

x Equiv. Length ________________________ = _______

#____ Valves x Equiv. Length ________________________ = _______

Friction loss per 100' ___________________x total equiv. length _______ 100 = _____ ft.

(for above pipe size)

2.

Straight pipe size_______________________________ = _______ @ _________gpm

# ____Elbows x Equiv. Length _________________________ = _______

# ____Tees

x Equiv Length _________________________ = _______

#____ Valves x Equiv. Length _________________________ = _______

Friction loss per 100' ___________________x total equiv. length _______ 100 = ______ ft.

(for above pipe size)

3.

Straight pipe size________________________________= _______@_______gpm

# ____Elbows x Equiv. Length _________________________ = _______

# ____Tees

x Equiv. Length ________________________ = _______

#____ Valves x Equiv. Length _________________________ = _______

Friction loss per 100' ___________________x total equiv. length _______ 100 = _______ ft.

(for above pipe size)

4.

Straight pipe size________________________________= _______@_______gpm

# ____Elbows x Equiv. Length _________________________ = _______

# ____Tees

x Equiv. Length _________________________ = _______

#____ Valves x Equiv. Length _________________________ = _______

Friction loss per 100' ___________________x total equiv. length _______ 100 = _______ ft.

(for above pipe size)

5.

Straight pipe size________________________________= _______@_______gpm

# ____Elbows x Equiv. Length _________________________ = _______

# ____Tees

x Equiv. Length _________________________ = _______

#____ Valves x Equiv. Length _________________________ = _______

Friction loss per 100' ___________________x total equiv. length _______ 100 = ________ ft.

(for above pipe size)

6.

Straight pipe size________________________________= _______@_______gpm

# ____Elbows x Equiv. Length _________________________ = _______

# ____Tees

x Equiv. Length _________________________ = _______

#____ Valves x Equiv. Length _________________________ = _______

Friction loss per 100' ___________________x total equiv. length _______ 100 =

________ ft.

(for above pipe size)

Friction loss due to inlet resistance at ____________ gpm =

(from manufacturer)

Total Return Line friction loss =

(add all

totals)

ft.

ft.

*(Enter on page 6)

CALCULATE SKIMMER LINE LOSS: *

AT

STATE WHICH CHART, GRAPH, NOMIGRAPH, ETC. USED __________________ADD

BOTTOM OF COLUMN

1.

Straight pipe size ________________________________ = _________ @_______gpm

#______ Elbows x Equiv. Length ___________________________= _________

#______Tees

x Equiv. Length___________________________ = _________

#______ Valves x Equiv. Length ___________________________ = _________

ft.

Friction loss per 100' _____________________ x total equiv. length _________ 100 =

2.

Straight pipe size _________________________________ = _________@ _______ gpm

# ______ Elbows x Equiv. Length __________________________ = _________

# ______ Tees

x Equiv. Length __________________________ = _________

#_______ Valves x Equiv. Length __________________________ = _________

ft.

Friction loss per 100' ______________________x total equiv. length _________ 100 =

(for above pipe size)

3.

Straight pipe size __________________________________ = _________ @ _______gpm

#______Elbows x Equiv. Length ____________________________ = _________

#______Tees

x Equiv. Length ____________________________ = _________

#______Valves x Equiv. Length ____________________________ = _________

ft.

Friction loss per 100' ______________________ x total equiv. length _________ 100 =

(for above pipe size)

4.

Straight pipe size __________________________________ = __________ @ ________gpm

#______Elbows x Equiv. Length _____________________________ = __________

#______Tees x Equiv. Length _____________________________ = __________

#______Valves x Equiv. Length _____________________________ = __________

ft.

Friction loss per 100' _______________________x total equiv. length __________ 100 =

(for above pipe size)

5.

Straight pipe size _________________________________ = ___________ @______gpm

#______Elbows x Equiv. Length ____________________________ = ___________

#______Tees x Equiv. Length _____________________________ = ___________

#______Valves x Equiv. Length _____________________________ = ___________

ft.

Friction loss per 100' _______________________x total equiv. length ___________ 100 =

(for above pipe size)

6.

Straight pipe size __________________________________ = ___________ @ _______gpm

#______Elbows x Equiv. Length _____________________________ = ____________

#______Tees x Equiv. Length _____________________________ = ____________

#______Valves x Equiv. Length _____________________________ = ____________

ft.

Friction loss per 100' ________________________x total equiv. length ____________ 100 =

(for above pipe size)

Friction loss over the weir at _____________________ gpm =

(from manufacturer)

Total Skimmer Line friction loss =

(add all

totals)

ft.

ft.

*(Enter on page 6)

Total Dynamic Head Required:

Main Drain Line Loss

(from page 3)

ft.

Return Line Loss

(from page 4)

ft.

Filter Loss When Dirty

*(see below)

ft.

Skimmer Line Loss

(from page 5)

ft.

Heater Loss

(from manufacturer)

ft.

Other (Multiport valves, etc.)

(from manufacturer)

ft.

ft.

Total Loss

Pump Selection: (Submit Curve)

Make _______________________

Model ____________________, __________gpm @ _________ TDH

Backwash rate _________________gpm @ ____________ TDH**

Filter Selection:

Filter area required = ( Design flow rate ) = (

( Flow Rate per sq. ft. )

(

) = ____________________________

)

Flow rate per sq. ft. = (Diatomite = 1 gpm per sq. ft.) (Hi rate = 15 gpm per sq. ft.)

(Sand

= 5 gpm per sq. ft.) (Cartridge = .3 gpm per sq. ft.)

Cat. No. ______________________

Model ___________________________________________________

Filter Area ____________________sq. ft. No. Tanks ____________________ Size _____________________

Pump Specifications ____________ HP ____________ Cycle ____________ Phase________ Volt_______RPM

Certified Contractor ________________________________________Certification Number _________________

Representing _________________________________________________________________________________

Approved & Checked By _______________________________________________

(Health Dept.)

* Cartridge Filter

Sand Filter

Pressure D.E.

Vacuum D.E.

= 23.1 ft.

= 34.7 ft.

= 57.8 ft.

= 4.3 ft.

** Backwash TDH = TDH - Return Piping and Fixtures + Backwash Line Loss

Date _________________

Vous aimerez peut-être aussi

- Design Standards For Swimming Pools 1-5-10 PDFDocument41 pagesDesign Standards For Swimming Pools 1-5-10 PDFPratyusha Halder80% (5)

- Swimming Pool Design-A PDFDocument135 pagesSwimming Pool Design-A PDFFaizal Achmad100% (1)

- Swimming Pool Design PresentationDocument55 pagesSwimming Pool Design PresentationRichard LIpaPas encore d'évaluation

- Swimming Pool Design Rev-0Document2 pagesSwimming Pool Design Rev-0Haytham Samir75% (4)

- Swimming Pool DesignDocument22 pagesSwimming Pool DesignKiran Basu88% (16)

- Swimming Pool DesignDocument49 pagesSwimming Pool Designcashlover100% (1)

- Engineering Design Calculation - Dennis Kirk Single Stage Centrifugal Pump Calculation (Clean Water Use) System CurveDocument1 pageEngineering Design Calculation - Dennis Kirk Single Stage Centrifugal Pump Calculation (Clean Water Use) System Curvebuntimehta007Pas encore d'évaluation

- Background: 1 Slugging Caused by PiggingDocument33 pagesBackground: 1 Slugging Caused by PiggingGary Jones100% (1)

- Swimming PoolDocument5 pagesSwimming PoolkapishsharmaPas encore d'évaluation

- Pool Calculation GuideDocument30 pagesPool Calculation Guideolomizana100% (2)

- Swimming Pool Design ReferenceDocument12 pagesSwimming Pool Design ReferencePhang S. Sun100% (2)

- Inground Swimming Pool Construction PhotosDocument21 pagesInground Swimming Pool Construction PhotosdodidorrPas encore d'évaluation

- Design Calculation Sheet: Pool DimensionsDocument2 pagesDesign Calculation Sheet: Pool DimensionsBashir SherifPas encore d'évaluation

- Renolit Alkorplan 2000/3000/Touch/Ceramics: Reinforced Pool Liner To Enhance Your Swimming PoolDocument39 pagesRenolit Alkorplan 2000/3000/Touch/Ceramics: Reinforced Pool Liner To Enhance Your Swimming PoolGustavo SilvaPas encore d'évaluation

- Fire Risk Assessment for Office and Warehouse FacilityDocument21 pagesFire Risk Assessment for Office and Warehouse FacilitydcovePas encore d'évaluation

- Design and Construction of Swimming Pools Ib P Bc2017 014Document11 pagesDesign and Construction of Swimming Pools Ib P Bc2017 014Lakmal JayashanthaPas encore d'évaluation

- Swimming Pool DesignDocument111 pagesSwimming Pool Designdokundot75% (4)

- Schwimmbadbau enDocument34 pagesSchwimmbadbau enBojan Besedić100% (1)

- Swimming Pool CalculationsDocument62 pagesSwimming Pool Calculationssuri422010Pas encore d'évaluation

- Swimming Pool Design StandardsDocument30 pagesSwimming Pool Design StandardsAmeer Abbas71% (7)

- Swimming Pool Design Guide 200906Document36 pagesSwimming Pool Design Guide 200906Stanley Y, H, CHIUPas encore d'évaluation

- Swimming Pool GuideDocument126 pagesSwimming Pool Guideİsmet Sezer100% (4)

- Swimming Pool StandardDocument10 pagesSwimming Pool StandardsabasdgtPas encore d'évaluation

- Residential Swimming Pools StandardsDocument4 pagesResidential Swimming Pools StandardsSri Vinay ChowdariPas encore d'évaluation

- Cinema Design Guide1Document73 pagesCinema Design Guide1dcovePas encore d'évaluation

- Swimming Pool Construction GuideDocument48 pagesSwimming Pool Construction GuideKeri Mason100% (3)

- SWIMMING POOL DESIGN & CONSTRUCTION GUIDEDocument14 pagesSWIMMING POOL DESIGN & CONSTRUCTION GUIDEAiom AlPas encore d'évaluation

- Swimming Pool HydraulicsDocument6 pagesSwimming Pool Hydraulicstonyonly100% (1)

- Swimming Pool DesignDocument28 pagesSwimming Pool DesignLobsang MatosPas encore d'évaluation

- 109 Swimming Pool DesignDocument4 pages109 Swimming Pool Designredsun870% (1)

- Diversion Head Works TypesDocument81 pagesDiversion Head Works Typeszelalemniguse100% (6)

- Swimming Pool Gutter Designs ComparedDocument1 pageSwimming Pool Gutter Designs ComparedkkkhattabbbPas encore d'évaluation

- Surge Control PDFDocument14 pagesSurge Control PDFMohamed Guezguez100% (1)

- Pool Hydraulic Analysis FormDocument6 pagesPool Hydraulic Analysis FormtonyonlyPas encore d'évaluation

- Swimming Pools Design 2011 Rev3Document97 pagesSwimming Pools Design 2011 Rev3Chuksbozment0% (1)

- Pumps - Power CalculatorDocument9 pagesPumps - Power CalculatorPandiselvan JeganathanPas encore d'évaluation

- Guidance Notes - Swimming Pools BSDocument10 pagesGuidance Notes - Swimming Pools BSKCFUNG100% (6)

- Vent Sizing Applications For Reactive SystemsDocument10 pagesVent Sizing Applications For Reactive SystemsAritraDalalPas encore d'évaluation

- ASFP BlueBook European VersionDocument52 pagesASFP BlueBook European VersiondcovePas encore d'évaluation

- Swimming Pool Calculation: To Calculate Pipe SizingDocument21 pagesSwimming Pool Calculation: To Calculate Pipe SizingElia Mekdad100% (2)

- Calculation ETPDocument9 pagesCalculation ETPashok815350% (4)

- Construction and Specification Considerations For Swimming Pool PDFDocument17 pagesConstruction and Specification Considerations For Swimming Pool PDFArshdeep KaurPas encore d'évaluation

- New Method for Calculating Evaporation from Occupied PoolsDocument4 pagesNew Method for Calculating Evaporation from Occupied PoolsSarosh MohiyuddinPas encore d'évaluation

- Flow MeasurementDocument45 pagesFlow MeasurementSomnath SwamyPas encore d'évaluation

- Indoor Pool Design Guide 2015Document28 pagesIndoor Pool Design Guide 2015al457@columbia.eduPas encore d'évaluation

- Swimming Pools Design (The Scottish Sports Counsil)Document23 pagesSwimming Pools Design (The Scottish Sports Counsil)Carlo Chan100% (2)

- PumpsDocument103 pagesPumpsKevin HuangPas encore d'évaluation

- Calculating Energy Savings of Indoor Swimming Pool MeasuresDocument4 pagesCalculating Energy Savings of Indoor Swimming Pool MeasuresAmeer AbbasPas encore d'évaluation

- Pool Overflow Stones Collection-2013Document96 pagesPool Overflow Stones Collection-2013Keri MasonPas encore d'évaluation

- Technical Proposal for Olympic Pool Filtration SystemDocument10 pagesTechnical Proposal for Olympic Pool Filtration SystemAlma DerajPas encore d'évaluation

- Draft BC Pool Design Guidelines September 2010Document60 pagesDraft BC Pool Design Guidelines September 2010Kim Wilkinson McGennPas encore d'évaluation

- Swimming PoolsDocument17 pagesSwimming PoolsspzemunPas encore d'évaluation

- Indoor Swimming PoolsDocument2 pagesIndoor Swimming PoolsjkgfgPas encore d'évaluation

- Swimming Pool Rules 2008Document63 pagesSwimming Pool Rules 2008ENG ENG100% (1)

- Swimming Pool Script 20100829Document8 pagesSwimming Pool Script 20100829Sameer Jagade100% (1)

- Swimming Pools, Resource Material For Students of Architecture.Document37 pagesSwimming Pools, Resource Material For Students of Architecture.shrikant100% (4)

- Guidelines for Swimming Pool ApprovalDocument5 pagesGuidelines for Swimming Pool ApprovaljbonvierPas encore d'évaluation

- Swimming Pool CalculationDocument3 pagesSwimming Pool CalculationVuong BuiPas encore d'évaluation

- Swimming-Pool Catalog (ABT)Document169 pagesSwimming-Pool Catalog (ABT)Ahrian Bena100% (1)

- Swimming Pool Calculations - Inyo Swimming Pool Products & Supplies - InYOPoolsDocument3 pagesSwimming Pool Calculations - Inyo Swimming Pool Products & Supplies - InYOPoolsMunirah AyubPas encore d'évaluation

- Swimming Pool: Decorative & Renovation SolutionsDocument6 pagesSwimming Pool: Decorative & Renovation SolutionsCam Nhật LinhPas encore d'évaluation

- Swimming Pool Design Guide: Types, Sizes, Planning BasicsDocument22 pagesSwimming Pool Design Guide: Types, Sizes, Planning BasicsSaurav ShresthaPas encore d'évaluation

- Swimming Pool Construction GuideDocument3 pagesSwimming Pool Construction Guidedarebusi1Pas encore d'évaluation

- Env Health Pool Hydraulic Analysis FormDocument5 pagesEnv Health Pool Hydraulic Analysis Formhabib shuaibPas encore d'évaluation

- Calculating Warp For The Rigid Heddle LoomDocument3 pagesCalculating Warp For The Rigid Heddle LoomedocelloPas encore d'évaluation

- Data SheetDocument1 pageData Sheetnirmal krisnaPas encore d'évaluation

- Phy107-General Practical Physics I HandoutDocument25 pagesPhy107-General Practical Physics I Handoutuchedubem83Pas encore d'évaluation

- Physics 2020 Paper 2Document5 pagesPhysics 2020 Paper 2Malack ChagwaPas encore d'évaluation

- Boiler inspection checklist guideDocument2 pagesBoiler inspection checklist guideSadiq KhattakPas encore d'évaluation

- Metric Measurement LabDocument2 pagesMetric Measurement LabCharls John ErcilloPas encore d'évaluation

- Reverberation Time Calculation SheetDocument2 pagesReverberation Time Calculation SheetdcovePas encore d'évaluation

- BR PDF Adm 2004 PDFDocument87 pagesBR PDF Adm 2004 PDFbigeazyePas encore d'évaluation

- Building Regs Part D Toxic Substances PDFDocument0 pageBuilding Regs Part D Toxic Substances PDFdcovePas encore d'évaluation

- Ahsrae 62.1 - 2004Document1 pageAhsrae 62.1 - 2004dcovePas encore d'évaluation

- Week2 Internal FlowDocument45 pagesWeek2 Internal FlowJose Carlos Obregón MartinezPas encore d'évaluation

- Chapter 4 WcuDocument29 pagesChapter 4 WcuKuba100% (3)

- 100 Coverflow SpillwaysDocument43 pages100 Coverflow Spillwaysmote34Pas encore d'évaluation

- Unit 4 Groundwater FlowDocument36 pagesUnit 4 Groundwater FlowdaanaahishmaelsPas encore d'évaluation

- Activity Fluid MachineryDocument1 pageActivity Fluid MachineryDryx LetranPas encore d'évaluation

- Chapter 3 ManometryDocument3 pagesChapter 3 ManometryJovilyn SantiagoPas encore d'évaluation

- 1.2 Fundamentals of Fluid Flow - Bernoulli's Energy TheoremDocument12 pages1.2 Fundamentals of Fluid Flow - Bernoulli's Energy TheoremTeodolfo Delos Trino Balanay100% (1)

- Constructing Potentiometric Surfaces Wells G & H Superfund Site, Woburn, MADocument27 pagesConstructing Potentiometric Surfaces Wells G & H Superfund Site, Woburn, MAedgar steven mancipe casasPas encore d'évaluation

- Traning Manual NREGA June 2009Document230 pagesTraning Manual NREGA June 2009Rama KrishnaPas encore d'évaluation

- Main Principles of Pumps Selection. Calculation of PumpsDocument22 pagesMain Principles of Pumps Selection. Calculation of PumpsJoko Nugroho100% (1)

- EXAMPLE 8-68: Prof. Dr. Ali PınarbaşıDocument29 pagesEXAMPLE 8-68: Prof. Dr. Ali PınarbaşıWallefer RodriguesPas encore d'évaluation

- Tunnelling and Underground Space Technology: A A B C A ADocument11 pagesTunnelling and Underground Space Technology: A A B C A AMoezselmi.12 SelmiPas encore d'évaluation

- Vw1004 Control KosoDocument27 pagesVw1004 Control KosolovelycatPas encore d'évaluation

- Watercad EraqDocument20 pagesWatercad EraqHaya MandoPas encore d'évaluation

- Proposed Water Tank Design A Solution To North Poblacion San Fernandos Inadequate Water SupplyDocument126 pagesProposed Water Tank Design A Solution To North Poblacion San Fernandos Inadequate Water SupplyZynne Chlyden ParinoPas encore d'évaluation

- Exit ExamDocument70 pagesExit ExamHaymanot MelakuPas encore d'évaluation

- Determination of Head Loss in Fixed & Fluidised BedDocument6 pagesDetermination of Head Loss in Fixed & Fluidised BedElaine PuiPas encore d'évaluation

- Media Filter From Dried Water Hyacinth (Eichhornia Crassipes)Document66 pagesMedia Filter From Dried Water Hyacinth (Eichhornia Crassipes)James Bryan Garcia SolimanPas encore d'évaluation

- Two Dimensional Flow of Water Through SoilDocument28 pagesTwo Dimensional Flow of Water Through SoilMinilik Tikur SewPas encore d'évaluation

- Adaptive Identification of A Pneumatic Pump: Diploma ThesisDocument86 pagesAdaptive Identification of A Pneumatic Pump: Diploma Thesisandreas vavatsikosPas encore d'évaluation

- Gravity-Powered Chemical Dose Controller For Sustainable, Municipal-Scale Drinking Water TreatmentDocument25 pagesGravity-Powered Chemical Dose Controller For Sustainable, Municipal-Scale Drinking Water TreatmentAshley HePas encore d'évaluation

- Em 77 PDFDocument12 pagesEm 77 PDFNeoXana01Pas encore d'évaluation