Académique Documents

Professionnel Documents

Culture Documents

ch-14 Ac Plant Ea

Transféré par

neeraj kumar singhDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

ch-14 Ac Plant Ea

Transféré par

neeraj kumar singhDroits d'auteur :

Formats disponibles

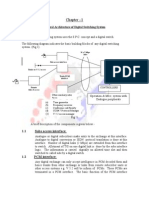

CHAPTER FOURTEEN

AC PLANT & ENGINE ALTERNATORS- OPERATION & MAINTENANCE

Introduction

An air-conditioning system which enables the conditions inside to be maintained can

be explained as a series of cycles:-

1. The Refrigeration Cycle.

2. The Air cycle.

3. The cooling water cycle.

The Refrigeration Cycle

For all compression type mechanical refrigeration systems, the refrigeration cycle

consists of four processes i.e.

1. Heat gain by the refrigerant in the evaporator

2. Pressure rise in the compressor

3. Heat loss in the condenser

4. Pressure loss in the expansion valve.

Compression process, that is the pressure rise is accomplished at the expense of

energy added to the compressor in the form of shaft work. The expansion, i.e. pressure loss is

allowed to occur adiabatically (with no loss or gain, of heat) in the expansion valve where the

energy released by the expanding refrigerant is not utilised for doing any external work but

causes evaporation of a portion of liquid. Basically in a refrigeration cycle the heat transfer

process does not involve any work and the pressure change processes do not involve any heat

transfer.

The four processes of refrigeration cycle can be explained in the four steps

-Thermodynamic processes.

1. Evaporation

Liquid refrigerant at low pressure absorbs heat from the space or room to be cooled

and evaporates in the evaporator or cooling coil.

RTTC NAGPUR Page 101 of 161

RTTC NAGPUR Page 102 of 161

2. Compression

The refrigerant vapor drawn from the evaporator is compressed in a compressor

consisting of a piston and cylinder. The saturated refrigerant vapor is super heated and its

boiling point is raised due to increased pressure.

3. Condensation

The super heated high-pressure vapor rejects its super heat in the condensing medium

(water) and condenses into liquid.

4. Expansion

The high pressure liquid refrigerant from the condenser in passing through the

expansion valve is reduced to low pressure and temperature. The expansion valve is a

combined pressure reducing and monitoring device.

Air Cycle (Ref. Fig. 2)

The air handling unit comprises of a chamber for mixing the fresh outside air drawn

through electronic air Filters with the return air from conditioned room. This chamber is also

referred to as weather-maker room. The mixture of fresh air and return air is then passed

through the mechanical air filters for eliminating the large size dust particles if present in the

return air. The pre-heaters also called as strip heaters are generally switched on it winter

season. Spray humidifiers are provided for humidifying the air as per the instructions from

sensing device and by pass damper actuated by the damper motor as per the instructions from

sensing device Thermostat.

The air further is passed over the cooling coil (evaporator which is cooling-cum-

dehumidifying equipment) where transfer of heat takes place. Spray eliminators are provided

to arrest the water drops. The re-heaters a set of electrical or warm water heaters are provided

for monsoon heating. Air stat is located near the reheated and senses the temperature of

reheated and helps in avoiding the fire risks.

The air circulating fan (Blower) is located in blower room driven by the fan motor.

The blower draws the air over the evaporator or cooling coils and pushes it to the Air

conditioned switch room through supply ducts.

The air further comes back to weather maker room and air cycle is repeated.

Humidistat and thermostat are located in the weather maker room.

RTTC NAGPUR Page 103 of 161

Water Cycle

Water is used as cooling medium in the condenser in preference to air, because at a

given temperature, the heat capacity of water is about 3,500 times more than air. Only in very

small systems, air cooling is resorted to in condensers.

Water can be cooled in many ways:-

a) by bringing air and water together indirectly as is done in automobile radiator;

b) by evaporative cooling, as in a cooling pond, spray pond or cooling tower.

In evaporative cooling, the water can be cooled below the atmospheric dry bulb

temperature, whereas in radiator cooling, the water cannot be cooled below the dry bulb

temperature. Since the cooling effect is more with evaporative cooling, a smaller amount of

circulating water is sufficient. Of all cooling arrangements, the cooling tower is the one

mostly used in air-conditioning & refrigeration plants.

In a typical cooling tower system, the water from the sump flows to the centrifugal

pump by gravity. The pump forces the water through the condenser, where it picks up heat

from the condensing refrigerant. Warm water from the condenser goes to the spray nozzles in

the tower. As the sprays fall down, the water comes in contact with the air flowing across.

Part of the water evaporates and causes cooling. As there is continuous evaporation of water,

the loss is made good by means of a make-up connection controlled by a float valve, from the

city water supply or an overhead tank. A quick fill connection is also given, so that it can be

used for filling the cooling tower tank quickly whenever required. An overflow (bleeder)

connection is provided so that a small quantity of water is continuously drained out to keep

the water fresh and clean and to reduce formation of scales in the water piping. Drain

connections is given for draining the water for the purpose of cleaning or shutting down the

system for a long time. A strainer is provided at the entrance of the suction pipe in the cooling

tower, so that extraneous matter will not get into the pipe and interfere with its working.

Under certain conditions, it becomes necessary that a small portion of the cooled water is not

allowed to flow through the condenser but goes directly back to the cooling tower. For this

purpose, a valve is provided between the inlet and outlet connections of the condenser to

enable a portion of the cooled water to bypass the condenser.

It is seen that water is circulated in the condenser, so that the refrigerant may be

condensed to a liquid at high pressure. Where an enormous quantity of cold water is readily

available, there is no need to recover the water and reuse it. But in towns and cities, water is

too valuable to be used in such an extravagant manner. The warm water leaving the

condenser will have to be cooled and re-used.

RTTC NAGPUR Page 104 of 161

Chilled water (indirect) system

In this plant chilled water cycle is additional to that of the three cycles provided in

direct A/C plants.

In this system, the heat inside the air conditioned space is picked up by cold supply air, which

gets heated up and this warm return air gives up its heat to the chilled water in the

dehumidifier (cooling coil) after passing over the preheater and mechanical filter. In chilled

water system, heat picked up by the chilled water is given up to the refrigerant at the chiller.

Refrigerant vapor gets compressed in the compressor and gives up the heat at the condenser

to the water, which is taken to the cooling tower and given up in the atmosphere. Thus by a

series of heat transfer process, both the heat entering the conditioned space and the heat

produced inside it are given back to the outside atmosphere. In chilled water plant, the boiling

refrigerant is not used to extract heat directly from the air. It is used for chilling water to a

low temperature and this chilled water is circulated through the cooling coil, where it picks

up heat from the air passing over its surface and comes back to the chiller to be chilled again.

A separate pump set is used for circulating this chilled water. This is known as the chilled

water system or indirect system because heat is first removed by chilled water. Where as in

direct system the heat is directly picked up from return air and given up at cooling tower.

RTTC NAGPUR Page 105 of 161

AIR CONDITIONING

1. Introduction: -

With the advancement of science and technology, specially the

electronics equipments, the Air Conditioning has become a day-to-day need.

Besides the industrial need, the Air conditioning is used for human comforts.

Even in the household it serves the people in the form a refrigerator, deep

fridger, so, its need is felt from household to the office, work place, industries,

shops etc.

Presently every individual has to have some knowledge of Air Conditioning to

meet his day-to-day need.

This booklet includes giving the reader the most basic knowledge of Air

conditioning and refrigeration.

2. Objective:

The objective of this booklet is to give the knowledge which will make a

person capable to attend the minor defects arising out of day to day working and to

carry out the preventive maintenance of the Air-cooled Air Conditioning system or

units.

3. Terminologies:

Air conditioning engineering required some technical terms to be

frequently used. These terms are described below.

1.1. Air Conditioning

This word is more or less known to everybody. To general

masses it appears to be a system of activities, which keep the temperature of a

desired place within certain limits. However its utility varies from place to

place. For example, whatever is suitable for human comforts may not be

suitable for cold storage.

For telephone exchange building the meaning of Air Conditioning

is different from others. The Air conditioning is provided for the exchange to

cater the following needs.

RTTC NAGPUR Page 106 of 161

a) To maintain the temperature

As per the latest instruction of the B.S.N.L the temperature in the

switch room of an electronics exchange is to be kept 230 ± 30C. It means that the

switch room temperature should be maintained between 200C to 260C within the

range of temperature the telecom equipment would maintain its own properties

without any adverse effect. So if the temperature range in the switch room is

maintained within the above-specified limits there will be no adverse effect on the

functioning. So if the thermostat of the A.C unit is set at following range the specified

status of temperature can satisfactorily be maintained.

Setting of the thermostat:

I. Cutout temperature: 230C

II. Cut in temperature: 250C

The temperature difference of cut in and cut out settings is called

differential. It is adjusted by a screw provided in the thermostat itself.

b) To maintain humidity:

As per the latest practice in the department the relative humidity in the

switch room to be maintain at 45% ± 15 %. Means the switch room relative humidity

range is to be 30% to 60%.

The relative humidity in the switch room is controlled by apparatus dew point

temperature. It is well known fact that cooling coil or the evaporator does two

functions. One is removal of heat by absorbing heat from the air conditioned area

and other function is to remove moisture by condensing it into water droplets. The

former one is sensible cooling and the later one is latent cooling. The total cooling of

the evaporator remains same. Only the division between these two functions can be

adjusted by regulating the apparatus dew point temperature.

RTTC NAGPUR Page 107 of 161

Example – 1

Switch room temperature is maintained – 740F

Relative humidity to be maintained – 450%

The apparatus dew point is to be set at – 510F

c) Dust Level:

The A.C units supply cold air to the specified space required for cooling.

This air is available to the evaporator as return air from that space, some times fresh

air and leakage in the package room. The mixed air contains a lot of dust particles,

which are harmful for the telecom equipments. So it is desired that the air supplied

after cooling is free from dust particles. Absolute cleaning of air is not possible.

However cleaning is done to reduce the quantum of dust particles in the supply air.

Two types of filters are used for cleaning the air to be supplied to the air conditioned

area.

The coarse filter is provided in the return air path to filter out the dust particles of

larger size. So its efficiency is referred as 90% down to 20 microns. It means the

filter will block 90% of the dust particles having the diameter of 20 microns.

The fine filters, filters out the dust particles of 5 microns having the efficiency of

99.9%.

d) Fresh Air:

Many times the air conditioned space is also utilized for human

occupancy. The human being requires oxygen for his breathing. So fresh air is

supplied to the air conditioned space to provide sufficient oxygen for human

occupancy. The fresh air is taken from outside, from a place which has high oxygen

content. The fresh air contains higher quantum of heat, moisture and dust particles.

So the fresh air is provided with coarse and fine filters. As per the latest circular of

the department the quantum of fresh air to be supplied is half air change per hour.

However the capacity of the fresh air fan should be one air change per hour.

Example:

The volume of the room, say – 18000cu.ft.(510 cu.mtr.)

Per hour half of this volume is to be replaced by fresh air fan i.e. 9000 cu.Ft. (205

cu. Mtr).

RTTC NAGPUR Page 108 of 161

9000

So, per minute it is to remove = = 150cu. ft.

60

and capacity of the fan should be = 150 x 2 = 300 cfm. (8.5 cu.mtr per minute).

e) To provide Air movement :

The air conditioners for telephone exchange are different from other

buildings. Here heat is continuously generated in the telecom racks (suite). The

quick dissipation of heat from the components is the basic need of air conditioning of

exchange building. So sufficient air velocity must be available to the racks for quick

transfer of heat from the heat generating components. So A.C system provided in the

exchange must be capable of supplying enough air with sufficient velocity to each

rack.

f) To remove bad odour :

Positive pressure is maintained in the air conditioned area

especially in the switch room the air conditioned area is kept closed to avoid

leakage of cold air in case of positive pressure or infiltration of hot air in case of

negative pressure in the air conditioned space. Abnormally positive pressure is

maintained as continuous leakage exists. Since the air conditioned area remains

normally closed bad odour in the air may occur. The continuous leakage and

supply of fresh air helps to reduce the bad odour of stagnated air of the air

conditioned space.

RTTC NAGPUR Page 109 of 161

TYPE OF THE A.C. UNITS USED IN THE

BHARAT SANCHAR NIGAM LIMITED

INTRODUCTION :-

There are various types of Air Conditioning systems and units are being used

through out the work. Keeping in view the present needs and situations a few types

of these units have been adopted by the Bharat Sanchar Nigam Limited for their use

in the Telephone Buildings.

OBJECTIVE :-

In this lesson the discussion will be done regarding the types of the A.C

units being used in the telephone exchange buildings, so that the trainees will be

able to select them as per requirement of the buildings.

Now a days the Department is installing electronic exchanges which

require constant air conditioning to maintain the desired temperature. These

exchanges are generally housed in small buildings. So, following types of Air

Conditioning units are found to be more suitable. These units are air cooled

condenser type.

1) Window Unit.

2) Split Unit

3) Package Unit.

1) WINDOW UNIT : -

It is compact unit having air cooled condenser. The design of this unit has

been done such a way that it can easily be installed or fitted in a window or a

small hole made in the wall where sufficient atmospheric air is available for

cooling of the condenser. That is why this unit is called Window unit. It is

comprising of the following major parts

a) Compressor

b) Condenser

c) Capillary

d) Evaporator

RTTC NAGPUR Page 110 of 161

e) Blower motor

f) Electrical controls

All these components are fitted on a single bed plate. This unit has a

constant flow liquid. This unit is made from 0.5 TR to 2 TR capacities. Mostly 1.5 TR

windows A.C. are used in Telecom Department. It is compact unit, easy to maintain

and install. This unit is factory charged and sealed.

It has some disadvantages also. It is operated on single phase A.C.

supply. As such it can not sustain voltage fluctuations due its poor power factor. It

does have humidity control. Since it required big opening in the wall, causes leakage

and infiltration of outside dust particles.

This unit is used where small air conditioning load is prevailing, such

as small exchanges administrative offices etc. it can reduce the humidity by

sweating moisture, but can not increase the relative humidity.

2. SPLIT UNIT

It is also just like window unit. It is operated on single phase A.C. supply

and having the similar components of window unit. The major difference of this unit

from that of window unit is that compressor and condenser is put together on a bed

place and installed outside of the building. The evaporator unit is made compact and

can be installed at any place of the building. The compressor condenser unit is

connected with the evaporator unit through two number of refrigerant pipes and

control cables. It means we have splitted the window A.C unit in two portions.

It has the advantage of the window A.C. unit that it does not require any

window for the installation, merely a small hole is required to draw the refrigerant

pipes and cables. It decreases the infiltrations of outside air into the room. Other

characteristics of this unit are more or less same to those of window unit.

It has some disadvantages over the window unit.

a. Length of refrigerant pipe is more increasing the cost and decreasing the

efficiency and effecting the performance of the unit.

b. It requires separate platform for installation of the

condenser compressor unit.

c. More maintenance cost than that of Window unit.

The evaporator of split unit is very handy and compact and can be

installed in horizontal and vertical positions. It is generally available in 3 TR.

RTTC NAGPUR Page 111 of 161

3. PACKAGE UNIT

The design of this unit is slightly different from that of window unit or split unit. It comprises

of the following components :-

i) Compressor

ii) Condenser

iii) Expansion valve

iv) Evaporator

v) Controls

From the name it appears that all the items are packed in a single

cabinet, but actually it is not like that, it is a split unit system. All these items are

divided into two sections comprising compressor and evaporator I/c controls, is

installed indoor. Like split A.C. unit both these sections are connected by the

refrigerant pipes and cables.

The package A.C system can be provided with additional control

system, such as :- Humidity control, fine filters, fire dampers etc. the package unit

has thermostatic expansion valve with external equalizer which is capable of

controlling the flow of liquid as per the load requirement with the help of the feller

bulb clamped at the end of the evaporator. The package A.C unit is available in the

market in various capacities. However, in B.S.N.L, we are using 5 TR, 7 TR and 10

TR. The 5 TR units are generally used in small exchanges ,7 TR and 10 TR units are

used in bigger exchanges with plenum, fine filters and ducting system.

The packages units are having 3 phase A.C motors which can sustain

more voltages fluctuations and better starting torque than single phase compressors

used in window A.C and split A.C unit. For heavy duty purpose the package units are

more suitable.

RTTC NAGPUR Page 112 of 161

FACTORS AFFECTING AIR CONDITIONING LOAD

Air Conditioning is provided to maintain the temperature, humidity,

and dust level, proper air circulation. Regular operations of the air conditioning

system is required to maintain the above parameters. Why regular operation is

required. Once it is cooled, it should remain cold. Since outside temperature is

higher and causes changes inside the room. Heat is gained in room through

various mediums. Following factors are responsible for quantum of heat gain.

1. Orientation and location of the building.

2. Type of the construction, materials, windows and doors.

3. size of the room.

4. occupancy.

5. light.

6. telecom equipment etc.

7. heat gain through delivery and return duct.

8. fresh air.

1. TYPE OF THE CONSTRUCTION, WINDOWS AND DOORS :

we know that the intensity of Sunrays is on peak between 14.00 to

16.00 hours in day time when the Sun remains in the western sky. We also know that

the latitude also influences the intensity of Sun rays. I.e.. heat gain. So, before

commencement of heat load calculation we will have to mark the orientation on the

working drawing of the space to be air conditioned.

2. TYPE OF THE CONSTRUCTION, WINDOWS AND DOORS :

Type of building also affects the heat gain. Different materials have

different co-efficient of heat gain.

3. SIZE OF THE ROOM :

If the room is big, there will be more heat gain and vice-versa.

RTTC NAGPUR Page 113 of 161

4. OCCUPANCY :

In every Air Conditioned space there must be some persons who carry

out the necessary work. Human body maintains a temperature 98.4 0 F which is much

higher than the temperature of the room. So, there will be transfer of heat from the

human body to the air of the room. Generally it is taken as 240 BTU/person/Hour,

this is sensible heat. In the similar way in breathing every person expels moisture. It

adds latent heat which is taken as 310 BTU/person/Hour.

5. LIGHT :

Light adds reasonable quantity of heat load. The total wattage

consumed by the light fitting/bulb is considered as heat load to the room. Now a

day’s fluorescent fitting is provided. Generally one number 4’ (feet) tube consumes

nearly 50 watts.

6. TELECOM EQUIPMENTS :

In B.S.N.L, in the switch room only Telecom Equipments are provided

with the computers etc. The heat load of the Telecom Equipments is to be taken from

D.O.T. circular No. 3-1/Director/EW/97 dated 17.7.97 (Guidelines for Optimization of

sub Station Capacities).

7. HEAT GAIN THROUGH DELIVERY & RETURN DUCT :

Whenever the cold air passes through the duct it absorbs heat from

outside air due to temperature difference. The heat gain through delivery duct is

taken as 12.5 %, whereas heat gain in the return duct is taken as 5% of the total

heat.

8. FRESH AIR :

In a switch room fresh air is required to replenish the oxygen

content for occupancy. So, fresh air is taken from out side. It contains moisture

as well as high temperature. Means fresh air adds Latent heat and Sensible heat

to the switch room.

RTTC NAGPUR Page 114 of 161

Installation of package A.C units (Air Cooled)

Purpose :- Now a days every Telephone Exchange requires Air Conditioning. The

modern Telephone Exchanges install the Electronics Equipments. So, the installation

of package A.C. units is one of the most important activities pertaining to the

electrical wing.

Objective :- After discussion of this the trainees will be able to install the package

A.C units in a proper &correct method, so that during their use there will be minimum

complaints.

4.1 Co-ordination :-

The installation of package A.C. system in any building required utmost

caution and coordination from the very beginning of the construction of the

building/Exchange. After obtaining the working drawing the JTO(E)has to study the

schedule of Accommodation thoroughly, specially the package room and the rooms

which are to be air conditioned. During construction of the building following

openings are to be made either in the walls or in the floors.

a) Opening for the delivery duct.

b) Opening for the return air duct/boxing.

c) Opening for fresh air fan in the package room wall.

d) Opening for refrigerant pipes and condenser cables.

e) Opening for main cable entry.

f) Opening for supply water pipe for humidification package unit and drainage pipe

for condensed water.

4.1.1 Opening for delivery duct :-

If the duct drawing is available with the junior engineer, the opening is

to be made as per that duct drawing. The openings are required in the package

room, switch room or in any other room where A.C. ducts are to be provided. If

approved duct drawing is not available with the JTO(E), the size of the opening is to

be decided on the basis of permissible air to be delivered by the duct is to be

known, and the number of package A.C. units i.e. their capacities are to be

calculated. As for example if two number of 7 TR capacity of package are kept as

RTTC NAGPUR Page 115 of 161

main and one number package A.C. is kept as standby, the approximate quantity of

air to be handled by the main duct will be = 2 x 7 x 500 (500 CFM has been

considered per TR) = 7000 cm. Now velocity of air to be delivered through the main

duct is to be decided as per the recommended chart for duct design. As per this

chart the maximum permissible velocity of air through main delivery duct is 500

meters per minute. Let us take 400 mtrs (1312 feet) per minute for this job. Now the

cross section of the main duct will be 7000/1312 = 5.34 Sq.feet. the opening of the

wall should be slightly more than the cross section of the duct, the opening may be

6 sq. feet (2 feet x 3 feet). In the same manner the opening for other branch duct etc.

can be calculated.

4.1.2 Opening of return air duct/boxing :

In the same method as specified above the opening for return air duct or

boxing can be calculated.

4.1.3 Opening for fresh air fan :-

Opening for the fresh air fan is kept in the package room. Generally the

size of the fresh air fan ducting is 600mmx600mm. So the opening can be made as

610mmx610mm allowing the frame work for fixing the duct. The location of the fresh

air fan should be such that the fresh air should not directly hit the delivery duct.

4.1.4 Opening for refrigerant pipes & condenser cables :-

This opening is also to be kept in the package room and the rooms

through which the pipes are to be laid. This opening varies on the basis of number of

package A.C. units. More the number, the opening should be more. For each

package A.C. two pipes and one cable for condenser are to be laid. However for 4

Nos. package A.C. units the opening of 150 mm x 600 mm will be enough to

accommodate 8 Nos. refrigerant pipes and 4 Nos. cables. The more the number of

package unit more will be size of the opening.

4.1.5. Opening for main cable entry :-

Generally 3 Nos. cables are drawn from the sub station to the package

room. The opening of size 150 mm x 300 mm will be sufficient. However, in place of

RTTC NAGPUR Page 116 of 161

that 3 Nos. holes of size 500 mm dia can be made in the floor or in the wall as per

site requirement. It should be near to the main control panel.

4.1.6 Opening for supply water pipe :

The opening for supply water pipe can be decided after consultation

with the civil engineering staff. The water supply can be taken from the nearest bath

room or from the overhead tank. However, an opening of size 25 mm will be

sufficient to provide 19 mm dia G.I. pipe for supplying of water for the humidification

package.

4.1.7 Opening for drain water pipe :-

This opening is required to provide G.I. pipe to drain out the sweating

water of the evaporator and over flow water from the humidification package unit.

Generally 40mm dia. G.I pipe is provided for this purpose a hole of size 50 mm will

be sufficient. The location should be to such a place so that water can be discharged

either to the nearest bath room or the outside drain.

4.2.1 Receipt of Material & Inspection :

After award of work, the materials and equipments will be received by

the Department specially, the package A.C. Units and condensers and the agency

will ask for payments. As soon as the equipment reaches at site these are to be

checked as per the technical specification mentioned in the agreement. Specially the

motors, compressors etc. & their make, model No. etc. If any deviation in

specification and the material/equipments supplied is found, the matter is to be

reported to the senior authority.

The equipment are also to be checked physically for the damages if

any damage caused during the transportation, loading and unloading. If any

damages are there, the details of the damages are to be intimated to the agency and

to the senior authority for further necessary action at their end.

Damages of the condenser and evaporator fins reduce the efficiency of

the unit. So the agency is to be asked to make the same good. If the damages are

found to be heavy, the agency should be asked to replace the item i.e. condenser or

evaporator.

RTTC NAGPUR Page 117 of 161

4.3.1 Adherence to the specifications :

Before commencing the installation, the specification, package room

layout plan and duct layout plan are to be thoroughly studied and match them with

site condition. If there is any kind of difference, the matter is to be put to the higher

authority. Materials brought at site by the contractor are to be checked as per

specification of the agreement.

4.4 Location of the condenser :

Location of the condenser is to be decided as early as possible. While

deciding the location following points are to be considered.

(a) Condenser is to be placed as near as possible to the package A.C.

unit, so that the length of the refrigerant pipe is less.

(b) Sufficient fresh air should be available for cooling.

(c) There should not be any obstruction to flow of discharge air from the

condenser or there should not be any short cycling of discharged air.

(d) Orientation should be considered. Fine or tubes of the condenser

should not be exposed to direct sun rays.

4.5 Foundation :-

Foundation for the following items are to be made as per agreement.

a) Package unit

b) Control panel

c) Condenser

4.6 Placement of the Equipment :

Before placing the equipment of foundation, JTO should be satisfied

about the finishing of the foundation. Then ant vibration mountings are to be placed,

specially for package units.

4.7 Ducting :

Generally G.I. sheets are brought at site and fabrication is done at

site. So following checks are to be conducted specially besides the specifications.

RTTC NAGPUR Page 118 of 161

a) Thickness as per aspect ratio.

b) Tie rods are to be provided from the ceiling.

c) Measurement of ducts before hanging.

d) Cross breaking are to be provided on the sheet to increase the strength.

e) Neoprene insulation is to be provided while making joints of two section of the

duct.

4.8 Refrigerant piping :-

a) Refrigerant piping from the package unit to the condenser are to be laid on

angle iron frame work.

b) Fixing of clamp should be done after wrapping that portion of the pipe with

felt.

c) The route of the pipe should be decided in such a way so that the number of

bends are minimum.

4.9 Brazing :-

a) brazing should be done with good quality of material and flux. If possible 3%

silver rod may be used.

b) Acid should not be used at all as flux.

c) Before brazing surfaces of the pipes are to be cleaned.

4.10 Cabling :-

a) Cable should be laid on cable tray.

b) Two nos. loop earthing for each package unit.

c) Cable tray should be made in such a way that there should not be any sharp

bend of the cable.

d) Cable tray should be made in such a way that there should not be any sharp

bend of the cable.

4.11 Pressure Testing :-

RTTC NAGPUR Page 119 of 161

a) After brazing the system should be cleaned by flushing with dry Nitrogen or dry

air, so that the dust particles and carbon particles are removed from the system.

b) Now the leakage of the refrigerant piping system is to be checked. This is done

by pressuring the system with dry Nitrogen.

c) On the high side i.e. condenser side around 350 PSI is to be given, whereas

about 200 PSI pressure should be given to the evaporation side.

d) The pressure should be increased slowly. Now all the probable points of leakage

may be checked by soap bubbles. Pressure and temperature are to be noted.

e) Keeping the system under pressure for 24 hours check the pressure again at the

same temperature. If the pressure shows the same initial reading, it means that

there is no leakage in the system. If the pressure is slightly decreased, observe it

for another 24 hours.

f) If after 24 hours again there is further decrease of pressure, it means, there is

minor leakage. Now the leakage is to be detected and rectified and get the

system of vacuumisation.

4.12 Vacuumisation:

After getting the system completely leak proofed we can put the system

to the vacuumisation. For this purpose a good quality vacuum pump should be used

which is capable of evacuation the system upto 5 micron. A two stage rotary vacuum

pump is suitable for this purpose. The vacuum pump should evacuate at least

vacuum upto 100 micron. However the pump should be run for 4 hours at least, so

that the moisture content in the oil and in the system will get sufficient time to

evaporate. Now let the system be kept on vacuum for 24 hours. Slight fall in vacuum

may occur. This is due to the evaporation of moisture/water particles in side the

system. After that vacuum should stabilized. If further fall of vacuum occurs, if means

that there is some leakage in the system.

4.13 Purging :-

After leak test and vacuumisation we should do the purging. Purging

means to break the vacuum with same type of refrigerant gas and have a positive

pressure of 5 PSI. Again vacuum is to be done and purging is to be done again. After

two nos. of purging the system should be vacuumised for gas charging.

RTTC NAGPUR Page 120 of 161

4.14 Gas Charging :

Gas can be charged to the system from the high side as well as from

the low pressure side of the system. If we want to charge the refrigerant gas in the

liquid form, the gas cylinder is to be kept in inverted position and is to be connected

to the high pressure side i.e. between the discharge line and expansion valve.

However, during pouring gas, the compressor of the system can not be run. When

the standing pressure of the system (for R-22 gas) reaches nearly 100 PSI the

cylinder valve can be closed and the compressor can be run for a few minutes. Again

gas can be fed to the system by stopping the compressor. In this process charging

can be done till the operating pressure i.e. discharging and suction pressure match

with the designed parameters.

Gas charging can be done from the suction side. However we should

be careful enough so that liquid should not enter the compressor.

After doing the gas charging the compressor should run for a couple of hours to

stabilize the system. Now check it up whether the discharge pressure and suction

pressure are matching with the design conditions or not. Otherwise it will have to be

checked that all the tubes of the evaporator are equally cooled. If so, it means that

the unit is properly charged. If all the tubes of the evaporator are not equally, it

means the unit is under charged and the reason is to be searched out.

4.15 Testing During Gas Charging :

During gas charging it has been seen that the system sometime

charged with less quantity of gas. So far proper gas charging we should observe the

following precautions :-

1. WINDOW AC UNIT:

a) The quantity of refrigerant gas is to be measured before charging. The quantity is

specified in the technical booklet of the machine.

b) Suction pressure should match with the operating parameters of the machine or

of the compressor.

c) Ampere taken by the machine should match with the rated ampere specified on

the machine.

d) Charging should preferably done in the summer month.

RTTC NAGPUR Page 121 of 161

e) Superheat i.e. the temperature difference between the ends of the Evaporator

should be around 100F (5.60C).

f) We should also observed that most of the refrigerant ;tube of the evaporator

should have equal temperature except the last tube, which is responsible for

super heating.

2. PACKAGE A.C.

a) Suction and discharge pressure should match with the operating parameters.

Where these parameters are not mentioned they should be obtained from the

temperature.

b) Super heat i.e. the temperature difference between the ends of the Evaporator

should be around 100F (5.60C).

c) Ampere taken by the machine should match with the rated ampere specified on

the machine.

d) We should also observed that most of the refrigerant tubes of the evaporator

should have equal temperature except the last tube, which is responsible for

super heating.

RTTC NAGPUR Page 122 of 161

OPERATION AND MAINTENANCE

OPERATION :-

We have discussed various topics about planning design and

installation of the Air Conditioning units. To get the best out of the air conditioning

system we must keep the unit in healthy condition. Operation is the vital activity

responsible for better performance of the air conditioning unit. Normally we use

window A.C. split A.C and air cooled type package A.C. unit. Now we shall discuss

the points to be observed for better operation. Through the operation and

maintenance are interrelated we shall discuss these items separately.

A. WINDOW A.C. UNIT :

i) Proper connection of the electrical cable ;with the related switch gear is

required.

ii) Proper voltage should be available. If low voltage or fluctuation prevails

;in supply source, voltage stabilizer is to be installed.

iii) In case of abnormal noise from the unit it is to be switched off and

service man is to be called in.

iv) In case of malfunctioning of the unit the matter is to be put to the

knowledge of the maintenance authority.

v) Once the unit is off it should be switched on only after elapsing of at

least 3 minutes, so the pressure of both side of compressor is

equalized.

B. SPLIT A.C. UNIT :-

i) Since the design and working of split A.C. Unit is more or less similar to that of

window A.C. unit, same precautions are to be adopted. Only differences are that

the compressor and condenser unit is installed outside of the building. To observe

the abnormal noise and malfunctioning in the compressor – condenser unit the

user is supposed to inspect this item occasionally.

RTTC NAGPUR Page 123 of 161

C. PACKAGE A.C. UNIT :-

The design and function of the package unit are slightly different from

that of window A.C. unit ;for proper operation we should observe the following points

:-

i) Proper voltage should be available (3 phase)

ii) It should be 415 ± 6%.

iii) Volume control damper should be open.

iv) After switching; on the unit we should observe the suction pressure is less,

there will be less cooling, sometimes may be formation of ice just after the

expansion valve. Under these conditions the plant is not to be operated.

v) In case of abnormal noise in the blower section/compressor the plant not be

operated and the matter is to be reported to the maintenance staff.

MAINTENANCE :

Maintenance in Air Conditioning system is the main activity responsible

for better performance of the system. Now we will discuss the method of servicing,

repair i/c attending the defects.

1. WINDOW A.C. UNIT :-

In the Bharat Sanchar Nigam Limited normally we use 1.5 TR window

A.C. unit, both in technical and administrative buildings. There are various

manufacturers in the market. The basic principle of this unit is same. However, there

may be minor design differences in electrical wiring and physical shape. The

tentative wiring diagram is given below (Annexure –‘A’).

First we will have to operate the selector switch to switch on the

blower motor. The blower motor may have two speeds or three speeds. On operating

the selector switch further the connection is extended to the thermostat and then to

the compressor through the over load. From the outgoing of the overload direct

supply goes to the running winding and to the running capacitor. The other terminal

of the running capacitor is connected to the starting winding. The overload has inbuilt

coil as shown in the diagram, through which starting capacitor gets supply through a

normally braking contact. The starting relay is provided to disconnect the starting

capacitor after the compressor get started. The connection of the relay coil as well as

breaking circuit has been shown in the diagram above.

RTTC NAGPUR Page 124 of 161

After operating the selector switch it is observed that the blower motor

functions well. As soon as it picks up speed the compressor should be switched on

by further actuating the selector switch. Now the compressor should pick up the

speed. If the compressor does not pick up the speed and gives humming abnormal

sound it means that it has some starting problems and the matter is to be put into the

knowledge of the maintenance staff.

If the compressor does give any kind of sound at all there may be the

discontinuity in the connection ;of the compressor such as – in the thermostat,

overload, and selector switch. In that case also the maintenance staff is to be

intimated.

For purpose of maintenance of window A.C. Unit following points are mentioned.

1. Cleaning of Filters :-

Most of the complaints are occurred due to dirty filters. The filters may

be of various types., viz – Coir filters, synthetic filters or metallic filters. These filters

require regular cleaning. Normally cleaning once in a week may be sufficient.

However in the dusty area the frequency of cleaning may be increased.

Accumulation of dust particles on the filters chokes it and reduces the

air flow drastically. It may cause ice formation on the evaporator coil. This occurs due

to insufficient air flow through the coil and liquid refrigerant does not get enough heat

to vaporize. It may cause liquid flood back to the compressor and damage the

compressor. The choking of the filter causes overloading of the blower motor. So,

dirty filter is the major factor causing damage of the window A.C. unit.

RTTC NAGPUR Page 125 of 161

TROUBLE SHOOTING CHART

Sr.No. Item Causes Remedies

1. Failure of i. Supply failure i. Check the main supply

compressor ii. Selector switch faulty ii. Check the selector switch

iii. Failure of thermostat iii. Check the thermostat for its

iv. Disconnection in over continuity.

load iv. Check the overload for its

continuity

2. Compressor fails i. Starting winding broken i. Check the continuity of

to start produces ii. Running capacitor faulty starting winding, resistance

hum sound, trips iii. Starting relay is not should be 3.8 ohms.

on over load being energized ii. Check the Run Capacitor

iv. Starting capacitor iii. Check the starting relay for

faulty its energisation .

v. Heating coil of the iv. Check the starting

overload may be capacitor.

broken v. Check the continuity of

heating coil of the overload

3 Starting relay I . High Voltage i. Voltage correction is

ii. Compressor short cycle required

burnt out

iii. Incorrect running ii. Check as per

capacitor. recommendation of the

manufacturer

4 Starting Capacitor i. Compressor short cycle i. As discussed above

ii. Relay contact sticking

burnt out ii. Check the relay contact

point for their proper

functioning .

5 Running i. High voltage. i. Voltage correction is

Capacitor burnt required .

out

6 Head pressure i. Poor condensation i. (a)Condenser is to be

too high ii Unit overcharged cleaned .

iii. High ambient (b) Air flow is to be checked

temperature . ii. Suction and discharge

iv. Choking in strainer / pressure is to be checked .

capillary tube . iii. Water splashing

arrangement is to be made

iv. Replace capillary tube /

strainer .

NORMS OF ENGINE ALTERNATORS FOR DIFFERENT TYPES OF TELECOM

INSTALLATION:

RTTC NAGPUR Page 126 of 161

In view of the present difficult power supply position, it has become necessary

to provide suitable standby power plant equipment so that as far as possible the

telephone exchanges work uninterrupted without having to shutdown either partially

or totally. This necessitates provision of Engine Alternator in all the installations.

The following guidelines have been approved for provisioning of standby

engine alternators.

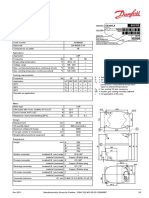

Capacity required for SMPS , Battery, Air-conditioning , DG set and MSEB Supply

0.5 K RSU 2K RSU 2K MBM 5K MBM

Qty Cap. Qty Cap . Qty Cap . Qty Cap.

Bty. 2 200 AH 2 400 AH 2 1000 AH 2 2000 AH

PP(SMPS) 1(3+1) 25 A 1(3+1) 100 A 1(5+1) 100 A 1(9+2) 100 A

Inverter Nil Nil 1 1KVA (2+1) 1 KVA (3+1) 1 KVA

A/C (1+1) 1.5 TR (2+1) 1.5 TR (2+1) 7.5 TR (3+1) 7.5 TR

(1+1)** 1.5 TR (1+1)** 1.5 TR

DG Set 1 10 KVA 1 30 KVA 1 75 KVA 1 100 KVA

MSEB

5 KW (1- Phase ) 25 KVA ( 3 Phase ) 60 KVA ( 3 Phase) 80 KVA (3 Phase )

Connection

AVR

1* 10 KVA Nil Nil Nil Nil Nil Nil

(Servo type)

Note :- * wherever supply fluctuation demands for stabilizer

** For A/C of PP room

At 2 K / 5 K MBM , Provision for 1 WLL , BTS has been met .

These standards will broadly cover the requirements of most of the

exchanges. However discretion will have to be exercised by the local officers

regarding the capacity of the Engine alternators. In all cases, the Engine Alternator

set must feed the total busy hour load of the local exchange/exchanges, the trunk

exchange, the transmission equipment etc located in the same building and should

also meet the load of blowers of A/C Plants and minimum lights and fans required for

operation.

Provisioning of Engine Alternator may be treated as protective works and

estimates sanctioned accordingly.

RTTC NAGPUR Page 127 of 161

GUIDELINES FOR OPTIMISATION OF ENGINE ALTERNATOR CAPACITIES.

1. For the purpose of the calculating Eng Alternator capacity, following load and

their peak demand may be considered.

Sl.No Type of load Load Peak Load

I. E.I. & Fan

a. Equipment Area 30 watt/sqmt. 40%

b. Administrative & General 15watt/sqmt 80%

II. Power Plugs

a. Administrative 20 watt/sqmt 25%

b. Technical 15watt/sqmt 10%

III. Lifts As per actual 100%

IV. Pumps As per actual 50%

V Compound Light As per actual Nil

VI. Fire Fighting As per actual Nil

VII Air Conditioning Load 2.25 KVA/Ton 100% for main units

(A/C Load – Essential and nil for s/by. (*)

only)

(*) This will include load on account of Window A/C also.

a) Exchange Power Load

(i) C-DOT :-

(As per information received from ADG(XT))

2K 2.5K 3K 3.5K 4K 5K 6K

7.5KW 8.5KW 9.25KW 11KW 11KW 12.75KW 15.65KW

** Add 0.75 KW for next 1 K each upto a total capacity of 10K

(ii) E-10B:-

As per information received from ADG(ES-II)

RTTC NAGPUR Page 128 of 161

10K 15K 20K

20.93KW 26.76KW 32.56KW

iii) Other new technology Exchanges :-

As per ADG(ES-II) U.0. NO. 40-18/94-ESL-II Dt. 15.4.97

Para- FETEX OCB EWSD AXE • AT&T

meter

10K 20.93KW O.8w/line 1SKW 20.4KW 26.188KW

20K 26.76KW O.8w/line 28KW 36.0KW 58.333KW

30K 32.56KW O.8w/line 32KW 50.0KW

40K 38.38KW O.8w/line 38KW 64.0KW 85.978KW

50K 44.19KW O.8w/line 44KW 80.0KW

b) Rectifier efficiency 75%, Power factor = 0.7, Peak Load-100%

1. Provision for unforeseen load may not be taken.

2. For calculation of Eng Alternator load, telecom bldgs may be classified into

three categories.

a. G+1 bldg. at Tehsil For substation purpose, load may be taken for

Taluka (H/Q) full A/C and ultimate capacity of switch room.

b. G+2 bldgs. at For the purpose of Eng Alternator capacity for

District (H/Q) ∗ G/F - as per usage

∗ 1st Floor - Complete load including A/C for two switches of ultimate

capacity.

∗ 2nd Floor -Only E.I. and Fans Load. When

usage is not definite otherwise as per actual.

c. Multistoried bldgs (i.e. to be decided in consultation

more than G+2) Metro's with all the concerned Telecom units.

and mini metros.

Annexure - I

Department Of Telecommunications Engineering Instructions

Clause 3: Standard operating conditions:

The standard operating conditions are:-

a) Mean barometric pressure 736 mm of mercury, corresponding to altitude

of 300 meters above mean sea level.

b) Intake air temperature 35º C

RTTC NAGPUR Page 129 of 161

c) Humidity - Water vapor pressure of 27.4 mm of mercury, corresponding

to a relative humidity of 65 percent at 35º C.

d) Intake air depression and Equal to that obtaining with intake and

exhaust back pressure exhaust systems normally fitted to engine

recommended by the manufacturer.

e) Auxiliaries. The engine shall be driving all continuously running auxiliaries

which are, in service, mechanically connected to it, and which are

necessary for engine operation, such as coolant and lubricating oil pumps,

scavenging blowers and, in the case of air- cooled engine only, the

cooling fans.

Note:- For water cooled engines, in view of the wide choice of size and type of

radiators available to meet particular site requirements, the Indian Standard rating

specified in 4.1 shall be the power which the engine would develop if the radiator fan

was not driven by the engine.

The normal power requirements of an engine driven radiator fan and a starter

battery charging dynamo shall be stated for those engines which are commonly so

equipped.

Clause 4 Rated Power Output and Speed

The Indian standard rating of the engine shall be the net output in brake

horse-power of which it is capable of delivering continuously at rated crankshaft

speed in revolutions per minute when working under conditions specified in 3.1

provided that the engine is in good operating condition.

When an engine is required to work under conditions which depart from the

standard conditions specified in 3.1 the rated output of the engine at site conditions

shall be determined as follows:

a) For decrease in the atmospheric pressure, a deduction from the rated output of

the engine shall be made at the rate of 1.4 percent per 100 metres of altitude

about 300 metres. This de-rating is valid upto an altitude of 2500 metres above

mean sea level. For higher altitudes, the de-rating shall be agreed to between the

purchaser and the manufacturer.

RTTC NAGPUR Page 130 of 161

b) For any increase of the intake air temperature above 35% a further deduction

shall be made at the rate of 0.25% per degree centigrade where combination of

high atmospheric temperature and humidity occur, a further percentage deduction

from the rated output of the engine shall be made in accordance with Table I

which is based on a deduction at the rate of 1.75 percent/cm of mercury above

27.4 mm vapor pressure.

TABLE I

Percentage Departing For Atmospheric Humidity At Various Temperature:

Atmospheric

Temperature

Relative Humidity Percent

in O F 10 20 30 40 50 60 70 80 90 100

85 ..... ..... ..... ..... ..... 0.5 1.0 1.5 2.0 2.4

90 ..... ..... ..... ..... 0.4 1.0 1.6 2.2 2.7 3.3

95 ..... ..... ..... 0.2 0.9 1.6 2.2 2.9 3.6 4.2

100 ..... ..... ..... 0.7 1.5 2.2 3.0 3.8 4.6 5.3

105 ..... ..... 0.3 1.2 2.1 3.0 3.9 4.8 5.7 6.6

110 ..... ..... 0.7 1.8 2.8 3.8 4.9 5.9 6.9 8.0

115 ..... ..... 1.2 2.4 3.6 4.8 6.0 7.2 8.4 9.6

120 ..... 0.4 1.7 3.1 4.5 5.9 7.3 8.6 10.0 11.4

125 ..... 0.8 2.3 3.9 5.5 7.1 8.7 10.2 11.8 13.4

Note:- The reduction for humidity is related to the percentage (relative) humidity and

the corresponding temperature of the surrounding atmosphere.

Care should be taken to use the percentage humidity actually corresponding

to the maximum atmospheric temperature being considered. It is very rarely that high

percentage humidity is combined with very high temperature of values which justify

more than 6 percent de-rating for humidity in any part of the world, and this figure

may normally be taken as a maximum.

Inlet air at actual engine intake is, in many installation heated significantly

above the ambient atmospheric temperature, and this increase the reduction for

temperature. The reduction for humidity should not be wrongly enhanced by applying

a fitter for atmospheric percentage humidity to that locally elevated inlet air

temperature.

Where the site conditions are more favorable to the engine than the standard

conditions, an increased rating for the engine to suit the site conditions may be

agreed to between the manufacturer and the purchaser.

RTTC NAGPUR Page 131 of 161

Examples of de-rating for altitude, temperature, and relative humidity are given

below:

Example 1 –

A kirloskar engine of 200 BHP is installed at a place whose worst site condition are

given below . The engine is four stroke turbo charged without after cooling .

A) Altitude – 500 mtr

B) Maximum temp. in summer – 45 0 C

C) Humidity –30 %

Calculate the output of the engine under above mentioned conditions.

Solution :-

500 - 150

A) Duration due to altitude = x 2.5 = 1.75 %

500

113 - 86

B) Duration due to temperature = x 3 = 8.1%

10

C) Duration due to humidity = 1% (After interpolation of the reading at temp 110 0

F and 115 0 F)

Total duration = 10.85 %

200

So , the output of the engine will be at site = x (100 x 10.85)

100

= 178.3 BHP

Fuel Consumption

The engine manufacturer shall state the specific fuel consumption (SFC) at

no load and the specific fuel consumption (SFC) at rated output under the standard

reference conditions specified in section 1 of IS:- 10000(Part II) – 1980 for engines

of all ratings . All engines above 20 KW , SFC shall also be declared at 110 , 75 ,

50 and 25 % of the rated load . The consumption shall be stated in grams per brake

horse power in the case of liquid fuel engines and in terms of heat units per brake

horse power hour in the case of gas engines (based on the higher calorific value). A

typical generating set will consume above 0.3 ltrs . of fuel per KWH generated .

RTTC NAGPUR Page 132 of 161

Where site conditions are worse than standard reference conditions specified

in section 1 of IS:- 10000(Part II) – 1980 , the specific fuel consumption at site will

be higher than that under standard conditions and shall be increased at the rate of 3

percent for every 10 percent de-rating in the power output of the engine. A tolerance

of 5 % on fuel consumption at full load shall be allowed unless otherwise agreed to

between the manufacturer and purchaser.

WORKING OF ENGINE ALTERNATOR

Introduction

RTTC NAGPUR Page 133 of 161

Various forms of standby AC supply arrangements are available, out of which

the Engine Generator sets are most common. This consists of two separate

machines, an Engine and the other a Generator or Alternator.

An Engine is a machine which converts the natural forms of fuel energy into

mechanical energy. A Generator is an Electromagnetic machine which converts

mechanical energy into Electrical energy. A Diesel Engine in an internal combustion

engine (Engine which burns fuel inside the engine) which operates on liquid fuel. It

depends on heat developed by compressing air to ignite fuel, which is forced into the

combustion chamber at the instant of maximum compression and heat.

2. Construction of Internal Combustion Engines

The different parts of an internal combustion engine may be grouped as '

Stationary parts' and 'moving parts'. Stationary parts, are the parts are the Frame

work, Crank Case, cylinder block, cylinder head etc. and the moving parts are the

piston, connecting rod, crankshaft, camshaft, valve gear etc.

Diesel cycle

All diesel engines are four stroke engines only. These four strokes are Suction

stroke, Compression stroke, Power stroke, and Exhaust stroke.

Suction stroke

Exhaust valve closes and inlet valve opens. The piston moves from top dead

centre (TDC) towards bottom dead centre (BDC). Partial vacuum is created in the

cylinder. The filtered air comes through inlet port.

Compression stroke

Inlet valve closes and exhaust valve remain closed. The piston moves from

BDC to TDC. The air is compressed and the temp of the air raises to about 1000° F

or 540° C.

Power stroke

Both the valves remain closed. Fuel is injected in the form of very fine spray through

injector. Fuel ignites due to temperature . Due to heavy expansion, the piston moves

towards the BDC and the energy is stored in the fly wheel.

Exhaust stroke

RTTC NAGPUR Page 134 of 161

The exhaust valve opens and the inlet valve remains closed. The piston

moves from BDC to TDC. The exhaust gases are expelled outside and the engine is

ready for next cycle of operation.

Air being Air Fuel is Combus Combu Remai

drawn being now tion stion ning

into being sends gases

DIFFERENT PARTS OF DIESEL ENGINE :

Various forms of standby power supply arrangements are available in our

Department. The Diesel Engine Alternator sets are most common among them.

Engine Alternator set consists of two separate machines, an Engine and the other an

alternator or Generator.

An Engine is a machine which converts natural form of energy into

mechanical energy.

An Alternator or Generator is an electro-magnetic machine which converts

mechanical energy to electrical energy.

A Diesel engine is an “Internal Combustion” engine (engine which burns fuel inside the

engine), which operates on liquid fuel. It depends on Heat developed by compressing

air to ignite the fuel, which is forced into the combustion chamber at the instant of

maximum compression and heat. Due to high compression the air charge reaches a

much higher temperature-high enough to cause the injected fuel to vaporizes and

ignite spontaneously. This is “Compression Ignition”, the essential feature of Diesel

engine.

Types of Diesel Engine Alternator

RTTC NAGPUR Page 135 of 161

Diesel Engine Alternators are available from 3.5 KVA to 250 KVA Capacity,

say, 3.5 KVA, 5.5 KVA, 7.5 KVA are available for single phase power supply and 10.5

KVA, 15 KVA, 33 KVA, 100 KVA, 150 KVA, 200 KVA, 250 KVA are available for three

phase power supply.

Stationary parts

. Bed Plate : Bottom most part made of cast iron.

. Crank case : It is fixed above the Bed plate and as a sump, the lubricating oil is

stored. The crank shaft is inside the crank case.

. Cylinder Block: It is fixed above the crank case either the cylinder or cylinder with

sleeve will be there inside.

. Cylinder head : It is the upper fitting of the cylinder block which closes it. The inlet

valve, the exhaust valve and the fuel injector are fitted on the cylinder head.

. Rocker box : It is above the cylinder head and it contains rocker arms which are

used for operating the valves.

. Inlet Manifold : Through which air is sucked into engine.

. Exhaust Manifold : Through which burnt out gases are thrown out.

. Air Filter : It sucks the natural air, filters it and then passes the clean air to the

combustion chamber. It may be dry or wet type.

. Silencer or Muffler: Sudden expansion of exhaust gases produce noise. Muffler

changes the velocity of the exhaust gases and reduces the pressure in steps.

. Asbestos rope : The exhaust pipe near the engine is covered by “Asbestos rope”

to prevent accidental burning.

RTTC NAGPUR Page 136 of 161

. Radiator : It cools the engine by water. It consists of upper tank, lower tank,

overflow pipe and water drain cock.

. Fuel Tank : It supplies the filtered fuel into fuel pump. It is having pre filter,

ceramic filter and fine filter. Big fuel tanks have fuel level indicator also. It has

drain cock. In smaller fuel tank “Dipstick” is used for fuel level. It has “min” &

“max” mark on it.

. Fuel pump: It accurately meters the fuel required and inject the fuel at the proper

timings through fuel injector.

. Fuel Injector : It supplies the fuel into combustion chamber at the correct time, in

the form of fine mist/spray at a high pressure (Say 150 kg/Sq.cm)

Moving parts

. Piston: It is sliding in a cylinder and performs all the strokes. Its functions are:

(i) To suck the air.

(ii) to compress the charged air.

(iii) To receive the pressure of the gases while they are expanding.

(iv) To expand the air. It has compression rings and oil rings.

. Connecting Rod: It connects the piston to the crank shaft. The function is to

transmit the force in either direction form the piston to the crank on the crank

shaft.

RTTC NAGPUR Page 137 of 161

.

. Crank Shaft: The engine power is tapped out from the Crank shaft only in multi-

cylinder engine. It will be a “zigzag shoed” shaft to which all the pistons are

attached through the connecting rods.

.

. Fly wheel: This is the heavy wheel attached to the one end of the crank shaft. It

stores up the surplus energy of the Power stroke and returns this stored energy

during other strokes.

. Cam Shaft: This is driven by the crank shaft. It controls and operates the fuel

injection pump. It also opens the inlet and exhaust valves at the appropriate time.

. Valve Gear : This is the gear wheel of crank shaft which drives the cam shaft via

spur gear.

. Spur Gear : This is the gear connected to the cam shaft. Spur gear’s and valve

gear’s teeth are so arranged that the cam shaft rotates only once for every two

rotations of the crank shaft.

.

RTTC NAGPUR Page 138 of 161

.

. Governor : It regulates the amount of Fuel supplied at each stroke and this

controls the engine speed and power. A “Spring guarded governor” is commonly

used in diesel engines.

.

. External Governor Lever: Small diesel engines are stopped by operating the

“external Governor Lever” by hand.

. Decompression Lever: It is used to leak the compression pressure of Air inside

the cylinder to some extent for making “ easy manual (starting) cranking” while

starting the small capacity engines.

RTTC NAGPUR Page 139 of 161

. Meters:

1. Speed Meter: It measures the speed of the engine. The speed should not

exceed 1500 RPM. Speed adjusting knob is there to adjust the low or high

speed.

2. Water temperature Meter : The temperature of the water in the cooling

system should not exceed 90º C. If it exceeds, an alarm will come; then

stop the engine for 15-20 minutes.

3. Oil temperature Meter: The oil temperature should not exceed 60º C.

4. Oil pressure Meter: The oil pressure should not go below 2.5 kg/cm

square. It should not go above 6 kg/cm square.

Fuel system of Diesel Engines

Fuel system comprises Fuel Pump, Fuel Injector and Injector nozzle. In P&T

Jerk pump system is employed. In this system for each injector there is a separate

pump and injector becomes a spring loaded, hydraulically operated automatic valve.

Requirements of fuel injection systems.

a) Accurate metering of small amounts of fuel.

b) Proper timing of fuel injection

c) Control of the rate of fuel injection.

d) Atomization of the fuel in accordance with the type of combustion chamber

used.

RTTC NAGPUR Page 140 of 161

Governing of IC Engines

The Variation of speed in a heat engine occurs due to the variation of load or

due to variation of the pressure of working fluids inside the cylinder. It is necessary to

control the variation of speed within certain desired limits for engines used as prime

movers for driving the alternators in order to maintain constant output voltage and

frequency.

Variation of speed due to variations of the pressure of working fluids inside the

cylinder is regulated by a flywheel.

Variation of speed due to change of load is adjusted automatically by a

"Governor" by varying the charge inside the cylinder. This is achieved by the

Centrifugal force of the flywheel against a spring.

Lubrication of IC Engines

Lubrication is the admittance of oil between two surfaces that are in contact

and in a relative motion, one to another may accomplish one or several of the

following purposes.

a) Reduce friction and wear.

b) Cool the surfaces by carrying away heat generated by friction.

c) Clean the surfaces by washing away carbon and metal particles caused by

wear.

d) Seal a space adjoining the surfaces, such as piston moving in a cylinder.

Cooling of I.C Engines

Part of the heat developed during combustion flows from the gases to the

walls of cylinder raising their temperature. Temperatures above 300° F may

evaporate the lubrication oil and injures the piston and head. The local temperature

may also cause cracks to the parts. Hence cooling system is necessary in an IC

engine.

Methods of cooling

a. Air cooling b. Liquid cooling.

RTTC NAGPUR Page 141 of 161

Air cooling

It is achieved by passing air over the cylinder and cylinder head. In order to

remove more heat, to maintain engine at suitable temperature, the radiating surface

should be increased by arranging cooling fins on hot areas.

Liquid cooling

Mostly water cooling is adopted. The cylinder block is essentially a box

incorporating the cylinder barrels. Surrounding the barrels is the cooling water which

also circulates round the cylinder head. From the head a tube communicates with

upper tank of the radiator and from the bottom of cylinder block, a pipe is connected

to the lower tank of the radiator.

Radiator consists of upper tank, lower tank and radiator tubes provided with

fins or mesh called grill. The water while flowing from upper tank to lower tank gets

cooled by the flow of atmospheric air with fan through grill.

In radiator soft water is to be filled. Hard water can be changed into soft water by

adding two ounces of sodium dichromate (Na 2Cr 2O7 ) mixed with four gallons of

water.

RTTC NAGPUR Page 142 of 161

PREPARATION FOR STARTING NEW ENGINES

NEW ENGINES WHEN DISPATCHED FROM THE WORK HAVE THEIR PORTS

AND OPENING SEALED WITH APPROPRIATE COVERS . ENSURE THAT ALL

COVERS ARE REMOVED BEFORE COMMISSIONING THE ENGINE .

LUBRICATION :

• Fill recommended grade of fresh oil in the sump to the high mark of the dip stick.

Add half litre more to compensate for the lub oil filter .

• Fill up the fuel pump governor with the same grade of lub oil from the plug

provider at the top of the governor housing . To check oil level in the governor .

Loosen the oil level control plug , painted red , provided on the inspection cover at

the rear of the governor housing .

• After starting the engine again check lub oil level in the oil sump and top up if

required .

FUEL :

• Check the fuel tank is cleaned fro inside .

• Fill the tank with cleaned HSD .

• Bleed the system as shown in the maintenance manual .

COOLENT:

• Fill the radiator with either fresh treated water or with coolant .

• Grease the water pump bearings with suitable grease .

• After starting the engine recheck water level in radiator and top up if required .

ELECTRICALS :

• Check battery for correct voltage and current capacity .

• Check battery cable are correctly connected and secure .

• Ensure correct polarity .

RTTC NAGPUR Page 143 of 161

STARTING AND STOPPING PROCEDURE – RB SERIES ENGINES

Before starting :-

• Check oil , water and fuel levels – top up if required .

• Check air cleaner choke indicator – on dry type of air cleaner .

• Clean engine with a dry cloth .

• Drain water from water separator provided in the fuel line .

• Crank the engine . As soon as engine fire , release the starter switch . keep

the ignition switch in ON position .

• Do not crank the engine for more than 10 sec at a time .

• If engine fails to start , wait for a minute and try again .

On Starting :-

• Check the oil pressure .

• Check battery charging .

• Check for leakages .

• Allow the engine to idle for 3 minute before loading the engine.

• While the machine is in operation , check engine oil pressure , water

temperature and battery charging rate at regular intervals .

Before Stopping :-

• Unloaded the engine and let it be idle for about 5 minute .

• Check the lube Oil pressure and water temperature.

• Stop the engine with the engine stopping lever .

After Stopping :-

• Check oil level after 30 minute and top up .

• Top up fuel tank .

• Check for leaks and rectify

RTTC NAGPUR Page 144 of 161

MAINTENANCE:

Recommended Schedule:

The following schedule of maintenance is based on normal operation of

engine. In case of severe operating conditions like extremely high atmospheric

temperatures, extremely dusty atmosphere, severe duty conditions etc., the

frequency of this schedule has to be increased.

1: Daily:

1.1: Check lub. oil level and top up if required.

1.2: At the end of day's work fill the fuel tank completely. Before starting drain the

moisture accumulated in the tank by loosening drain plug at the bottom of the

tank.

2: Every 50 hours:

2.1: Clean the air cleaner element by lightly tapping it on wooden block.

2.2: After initial run of 50 hours tighten all external nuts and bolts, especially the

cylinder head nuts.

3: Every 500 hours:

3.1: Drain the lub. oil from sump and refill with new lubricating oil. Clean lub. oil

strainer.

3.2: Clean, cooling air passage and the fins on cylinder liner and head.

3.3: Change the fuel filter element.

3.4: Change the lub. oil filter element.

3.5: Clean ceramic filter at the bottom of fuel tank. If necessary replace it.

3.6: If oil bath type air cleaner is used, change the oil and clean the element.

4: Every 800 hours:

Change the paper element of the air filter.

5: Every 1000 hours:

5.1: Knock out soot from exhaust silencer.

5.2: Check and if necessary decarbonise cylinder head, exhaust port etc. It is

advised that a mechanic from your dealer/distributor should check up your

engine.

6: Every 3000 hours:

It is recommended that the engine is overhauled at the end of 3000 hours.

RTTC NAGPUR Page 145 of 161

Maintenance Procedure:

1: Checking lub. oil

A dipstick is provided on the lub. oil filter casing. It carries minimum and

maximum oil level marks. If the level is below the minimum mark add lub

oil through the dipstick hole. The quantity of oil required to raise oil level

from minimum to maximum mark is 0.7 lit. (1.25 pints) for single cylinder

engine and

1.3 lits for twin cylinder engine approximately.

2: Cleaning lub. oil strainer

Remove lub. oil filter casing. The strainer is fixed to the lub. Oil pump body

by means of worm clip. Loosen this clip and pull the strainer towards

flywheel end. Clean it thoroughly from inside and outside by 'means of

kerosene. Refit it and fix the lub. oil filter casing.

3: Cleaning ceramic filter

First drain all the fuel from fuel tank and disconnect the tank to filter pipe.

Unscrew the holder at the bottom of fuel tank. This holder carries the

ceramic filter. The filter can be cleaned by washing it in clean oil and by

blowing air through it. If it is choked completely, replace it with a new filter.

Fuel oil invariably contains water in moisture form. This will corrode the

injection system. Hence, never run your engine without the ceramic filter,

which filters the water in the fuel.

4: Flushing the engine:

In order to prevent sludge formation, it is desirable to flush the engine with

the flushing oil at the time of changing oil. This is specially to be done

when the used oil is excessively dirty.

For flushing the engine use standard engine flushing oil available in the

market, preferably of the same SAE number as that of the engine oil. For

flushing the engine proceed as follows:-

4.1: Drain lub. oil from engine and fit the drain plug.

4.2: Fill the engine with flushing oil upto maximum level mark on the dip

stick.

4.3: Run the engine on light load for about 10 minutes and stop it.

4.4: Drain the flushing oil while the engine is still warm. Clean sump,

strainer and oil pockets.

The same flushing oil can be used for next time provided it is well

preserved in an air tight Container.

RTTC NAGPUR Page 146 of 161

STORING OF THE ENGINE

If the engine is going to remain idle for a considerable period (more than 2-3

months), it is necessary to preserve it in a particular way. This would prevent the

rusting of both external and internal parts. For this, follow the procedure given

below:-

1: Run the engine for a few minutes to warm it.

2: Drain the fuel from fuel tank, filter and all fuel pipes. Fill the system with suitable

preservative and turn the engine to remove any fuel remaining in the pressure pipe

and the injectors. The recommended preservative is SHELL FUSES OIL OR BOC

Calibrating Oil.

3: Drain and flush the lubricating oil system and fill the preservative oil. For this

SHELL ENGINE OIL of same SAE No.as that of lubricating oil can be used.

4: Clean the intake and exhaust system and spray the preservative into it.

5: Remove the injector and spray 1lit. of preservative oil for fuel system in the

cylinder bores. Replace the nozzles.

6: Clean the engine externally and apply rust-proof oil to all exposed machined parts

or unpainted parts. The recommended rust proof oils are Shell ensis fluid 260 or

BOC RCF 260 Caltex rust-proof compound.

7: Cover the engine to protect it from rain, sun and dust. When recommissioning

such an engine, first remove all preservative from the engine and then fill it with