Académique Documents

Professionnel Documents

Culture Documents

Development of A Catalyst For Solution of Polyvinyl Alcohol in Non-Aqueous Medium

Transféré par

ramitkatyal21881Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Development of A Catalyst For Solution of Polyvinyl Alcohol in Non-Aqueous Medium

Transféré par

ramitkatyal21881Droits d'auteur :

Formats disponibles

Chinese Journal of Polymer Science Vol. 26, No.

4, (2008), 399404

Chinese Journal of Polymer Science 2008 World Scientific

DEVELOPMENT OF A CATALYST FOR SOLUTION OF POLY(VINYL ALCOHOL) IN NON-AQUEOUS MEDIUM

Prafulla Chetri, Narendra Nath Dass and Neelotpal Sen Sarma*

Material Science Division, IASST, Paschim Boragaon, Guwahati-781 035, Assam, India

Abstract Chloro ethane dimethyl sulfoxide, C2H5ClDMSO (EClDMSO) was prepared by interaction of acrylic acid with conc. Hydrochloric acid in dimethyl sulfoxide (DMSO) and subsequent decarboxylation with H2O2 solution. The formation of the compound was confirmed by spectral and analytical methods; the molecular weight was determined by cryoscopic method. The solubility of poly(vinyl alcohol) (PVA) in different solvents or mixed solvents at 40C, 50C and 60C temperature in the presence of 0.01% of EClDMSO was determined. It turned out that EClDMSO helps dissolution of PVA, and is very effective catalyst in the preparation of esters and acetals of PVA. Keywords: Chloro ethane dimethyl sulfoxide; Poly(vinyl alcohol); Catalyst; Solubility.

INTRODUCTION Practically water is the only solvent in which poly(vinyl alcohol) (PVA) can be dissolved[1]. PVA is not soluble in non-aqueous medium due to strong intermolecular and intramolecular hydrogen bonding. The solubility of PVA in water depends on the degree of hydrolysis and molecular weight[2]. Fully hydrolyzed PVA are soluble only in hot to boiling water whereas partially hydrolyzed grades (88 mol%) are soluble at room temperature[3]. Due to the solubility problem some important derivatives of PVA like esters, ethers, acetals are difficult to prepare from PVA. Acetals are prepared from PVA in water by heterogeneous reaction process[47] and so the maximum extent of acetalization achieved is 86 mol%, although some patents claim 100 mol% acetalization[8]. Similarly, polyvinyl esters are prepared either by the polymerization of the vinyl esters or by the transvinylation method[911]. Due to the solubility problem of PVA in organic solvent the derivatives of PVA are synthesized in aqueous medium[12]. It is not possible to synthesize an ester by homogeneous esterification of PVA with the corresponding acid in aqueous medium. To solve this problem a catalyst C2H5ClDMSO (EClDMSO) is synthesized, which can help PVA to go into solution in an organic solvents or in a mixed solvents. EXPERIMENTAL Materials and Methods Acrylic acid (Bayers Germany) was purified according to the procedure adopted by ONeil [13] . Commercial-grade dimethyl sulfoxide (BDH) was purified by successive drying over a Linde molecular sieve and barium oxide, and finally by distillation under reduced pressure [14] . Hydrochloride acid (BDH) and hydrogen peroxide (E. Merck) 30 vol% were analytical grade and were used without further purification. PVA (BDH) having viscosity average molecular weight of 14000 was used (contained 0.1% acetate group) without further purification. The infrared spectrum of the catalyst was recorded in the 2004000 cm1 region with a Perkin-Elmer 883

*

Corresponding author: Neelotpal Sen Sarma, E-mail: neelot@sify.com Received May 28, 2007; Revised July 18, 2007; Accepted August 16, 2007

400

P. Chetri et al.

grating IR spectrophotometer. The proton NMR spectrum was recorded with a WH 60 NMR spectrometer. The spectrum was obtained on solution containing 100 g/L EClDMSO in CHCl3 (d) with tetramethyl silane as an internal reference. X-ray powder diffraction pattern of the catalyst was obtained using CuK radiation. The measuring conditions were 30 kV, 10 mA with a scattering angle of 260 and a step angle of 0.05. The molecular weight of the catalyst was determined by depression of' freezing point method. For this experiment the solvent used was benzene. Molecular weights of the polymers were determined by GPC method with a Waters GPC-150C instrument using tetrahydrofuran (THF) as the solvent at 25oC. Intrinsic viscosity [] was determined at 30oC by Ubbelohde viscometer using dimethyl formamide (DMF) as the solvent. Differential scanning calorimetric (DSC) thermogram of the polymers were traced by Perkin-Elmer DSC-7 kinetic software in air at a scanning rate of 10 K/min. Preparation of EClDMSO Acrylic acid (0.10 moL) and concentrated HCl (0.12 moL) were mixed with DMSO (5.0 mol). The mixture was then heated at 50oC for 0.5 h. The solution was then treated with 30 vol% H2O2 for decarboxylation when brisk evolution of gases occurred. The gas evolved was identified to be CO2 by analytical and IR method. On freezing the solution, a white needle type crystal appeared. The product was filtered and washed with petroleum ether. The product was then recrystallized several times from acetone and stored over anhydrous calcium chloride. The yield of the product was 90%. RESULTS AND DISCUSSION The following reaction may take place between acrylic acid and conc. HCl for the production of EClDMSO [15] .

The first step of the reaction was electrophilic addition. Decarboxylation takes place in the second step, and this step can be accelerated by an electron-withdrawing chloro group at carbon[16, 17]. H2O2 probably acts as decarboxylating catalyst. Microanalysis, IR and 1H-NMR spectral data supported the presence of one DMSO molecule as solvent of crystallization. The molecular weight of the compound, measured, by depression of the freezing point method with benzene as the solvent, was found to be 142.5. These findings support the proposed molecular structure. Interestingly no solid came out if DMF, N , N -dimethyl acetamide (DMA), dioxane etc. were used in place of DMSO, indicating that DMSO acts as molecule of crystallization. By microanalysis the elements present in EClDMSO were found as: Calculated: C = 33.68%, H = 7.72%, Cl = 24.91%, S = 22.45%; Found: C = 33.61%, H = 7.71%, Cl = 24.89%, S = 22.44%. The melting point of the compound was found to be 160oC. The IR spectrum of EClDMSO is shown in Fig. 1. The characteristic band for EClDMSO appeared at 1310 and 760 cm1 due to CCl group [18]. The band at 950 cm1 seemed to relate S O stretching vibration which indicated the presence of DMSO molecule. The bands at 1430, 1410, 1340 and 1130 cm1 appeared due to the DMSO molecule[19].

Development of a Catalyst for Solution of Poly(vinyl alcohol) in Non-aqueous Medium

401

Fig. 1 IR spectrum of C2H5ClDMSO (in KBr)

A typical 1H-NMR spectrum for EClDMSO is shown in Fig. 2. The signals observed at = 2.02.7 and 3.34.2 were due to CH3 and CH2Cl protons, respectively. A signal at = 2.9 was due to the DMSO molecule. These signals confirmed the formation of the compound.

Fig. 2 1H-NMR spectrum of C2H5ClDMSO (in CDCl3)

The powdered diffraction pattern of the catalyst showed three intense peaks corresponding to 2 values 16.35, 20.35 and 24.25. Based on the XRD results an orthorhombic structure D2h can be predicted for the compound. The crystal may be a nearly orthorhombic structures with two interpenetrating faces having sides 5.424, 4.366 and 3.672 and the molecular formula EClDMSO. Solubility of PVA PVA is soluble in DMF, DMSO, glycol and glycerol at hot condition when the degree of hydrolysis of PVA is

402

P. Chetri et al.

less than 88 mol%[20, 21]. PVA used in this experiment is 98 mol% and only a trace amount of this is soluble in DMF, DMSO, glycol and glycerol at hot condition. The solubility of PVA in different solvent or mixed solvent was determined by flask method [22] . To measure the amount of solubility in different solvents a weighted amount of PVA was gradually added to 100 mL non-aqueous organic solvents or mixed solvents in presence of 0.01g EClDMSO at three different temperature namely 40 C, 50 C and 60 C just before a faint turbidity appeared. For solvent mixture like DMF/benzene, a measured volume of benzene was added drop wise to the solution of PVA in DMF just before a faint turbidity appeared. The experiment also carried out using non-aqueous organic solvents or mixed solvents without using any EClDMSO at the same three temperatures (Table 1) using the same procedure. The experiment was repeated thrice to get the accurate result.

Table 1. Solubilities of PVA in gram per liter at different organic solvents and mixed solvents in the presence and absence of 0.01% EClDMSO at different temperature Solubility (g/L) Sample Solvent PVA with EClDMSO PVA without EClDMSO no. 40C 50C 60C 40C 50C 60C 1 DMF 30.0 33.3 36.5 Sw 1.17 2.02 2 DMSO 31.0 34.1 37.2 Sw 1.37 2.32 3 N,N-Dimethyl acetamide 27.7 29.8 33.1 4 CH3COOH 9.2 12.1 15.0 5 C2H5OH 2.1 3.1 5.8 6 Glycol 8.1 10.2 12.3 Sw 1.70 Sw 1.82 7 Glycerol 10.2 13.0 15.2 14.9 17.0 19.0 8 DMF + C2H5OH (5:4 V/V) 9 DMSO + C2H5OH (5:3 V/V) 20.4 22.3 24.0 10 CH3COOH + C2H5OH (5:2 V/V) 3.8 5.6 7.3 11 DMF + Toluene (5:2 V/V) 10.9 22.3 27.0 12 DMSO + Toluene (5:1 V/V) 24.7 27.8 30.9 13 DMF + Benzene (5:3 V/V) 18.8 20.1 22.8 14 DMSO + Benzene (5:2 V/V) 25.3 27.8 30.0 15 CH3COOH + THF (2:1 V/V) 2.1 2.9 5.5 16 C2 H5OH + THF (5:1 V/V) 1.9 2.3 4.5 17 DMF + Dioxane (5:4 V/V) 20.9 24.1 26.0 18 DMSO + Dioxane (5:3 V/V) 24.2 26.0 28.5 19 DMA+Toluene(5:3 V/V) 8.7 11.9 13.6 20 DMA + Benzene (5:l V/V) 8.9 10.9 12.0 21 Glycol + Benzene (2:1 V/V) 0.32 0.74 0.98 22 Glycerol + Benzene (2:1 V/V) 0.73 1.02 1.19 Sw: Swelling; : Insoluble

Mechanism for dissolution of PVA in the presence of EClDMSO can be described in the following way. PVA cannot be soluble in non-aqueous medium due to its strong hydrogen bonding. When PVA dissolves in water, PVA go into solution due to the minimization of this hydrogen boding as follows:

PVA in water

Development of a Catalyst for Solution of Poly(vinyl alcohol) in Non-aqueous Medium

403

The same type of hydrogen bonding is also formed when EClDMSO is added either to DMSO or to DMF because chlorine in EClDMSO pulls electron towards itself.

PVA in DMSO

PVA in DMF

So, this way EClDMSO helps PVA to go into solution in DMF and DMSO. From the Table 1 it is seen that EClDMSO is the most efficient catalyst for dissolving PVA in DMSO at 60C. In the case of mixed solvent the ratio of the solvent also plays a role and mixture of DMSO and Toluene (5:1 V/V) is found to be optimum. Again it is also observed that the solubility of PVA in DMF at 40C is near about the same as that in DMSO/benzene (5:2 V/V) mixture. Preparation of Esters and Acetals of PVA PVA, 4.4 g, (0.10 mol, based on CH2CHOH as the repeat unit) was dissolved in 150 mL of a solvent mixture of DMF and benzene (4:1, V/V) in presence of EClDMSO at 60C in a round-bottom flask. The molar ratio of PVA to EClDMSO was maintained at 1:(1.4 103). Corresponding organic acid or aldehyde (0.11 mol) in 100 mL DMF was then added slowly to the PVA solution. Homogeneous esterification or acetalization of PVA was carried out by heating the reaction mixture, at (90 1)oC. The water produced during the reaction was removed from the reaction medium as it was formed using the Dean and Stark principle. After completion of the reaction the solvent was removed by distilling under vacuum. The ester or the acetal as the case might be was precipitated by pouring the reaction mixture into a mixed solvent of acetone and petroleum ether (1:2 V/V) four times in volume of the ester or the acetal solution with constant stirring. Reprecipitation was done twice to ensure the complete removal of unreacted PVA and organic acid or aldehyde. To remove PTSA, EClDMSO and the last traces of other impurities the product was washed with benzene, dried at 40C and stored over anhydrous calcium chloride. The percentage of unconverted hydroxyl groups in the ester or acetal was estimated by acetylation process. The acetylation was done with a mixture richer in acetic anhydride (1 vol. of acetic anhydride, 3 vol. of pyridine) for ten hours at 60C. As a result, the unreacted acetic anhydride was hydrolyzed to acetic acid and was titrated with standard sodium hydroxide. Thus the percentage of unconverted hydroxyl groups can be estimated. The esters and acetals synthesized are noted in Table 2 along with their physical properties. The esters and acetals were soluble in a number of organic solvents like DMF, DMSO, dioxane, THF, chloroform, acetone, ethanol, cyclohexanol, methanol, acetic acid, methylene dichloride, etc.[23].

Table 2. Physical properties of esters and acetals of PVA Yield mp (C) Sample no. Tga (C) [] (dL/g) Mn 105 Mw 105 DPnb 102 Esters/Acetals 1 N (%) 1 Poly(vinyl propionate) 85 185 46 0.42 0.14 0.30 3.00 2 Poly(vinylbenzoate) 84 215 49 1.54 0.87 1.41 5.90 3 Poly(vinyl borate) 80 245 56 0.78 0.32 0.60 5.26 4 Poly(vinyl cinnamate) 82 207 50 1.38 0.77 1.28 7.35 5 Poly(vinyl butyral) 90 258 38 0.72 0.15 0.55 3.87 6 Poly(vinyl crotonal) 88 205 40 0.64 0.13 0.50 3.57 7 Poly(vinyl acetal) 85 225 54 1.12 0.42 0.72 6.32 a Obtained from DSC analysis; b Calculated from GPC trace

404

P. Chetri et al.

It was observed that the degrees of polymerization were different for different products. This might be due to the variation caused by the fraction of hydroxyl groups of' PVA converted into derivatives with different acids and aldehydes. Again, the degree of polymerization might change due to the oxidative or catalytic degradation[24] of the esters or acetals by EClDMSO. The degradation might result in the cleavage of the main molecular chain of the polymer resulting in a decrease in molecular mass of the polymer constitution.

ACKNOWLEDGEMENT Authors are thankful to DST, GoI for financial help.

REFERENCES

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 Billmeyer, F.W.Jr., Text Book of Polymer Science, Wiley Interscience, New York, 1984, p.393 Urbanski, J., Czerwinski, W., Janicka, K., Majewska, F. and Zowall, H., Hand Book of Analysis of Synthetic Polymers and Plastics, John Wiley and Sons. Inc, Aberdeen, 1977, p.392 Lindemann, M.K, Encycl. Polym. Sci. Technol., ed. by Bikales, N.M., John Wiley and sons, Inc., New York, 1971, Vol.14, p.169 Shibatani, K. and Fujii, K., J. Polym. Sci. A-1, 1970, 8: 1647 Minamino, H., 1994, Jpn. Pat., 06,239,929 Asahima, K. and Sakashita, K., 1989, Jpn. Pat., 01,318,009 Flory, P.J., J. Am. Chem. Soc., 1950, 72: 5052 Harrison, S.A. and Wheeler, D.N., J. Am. Chem. Soc., 1951, 73: 839 Rosen, I., McCain, G.H., Endrey, A.L. and Sturm, C.I., J. Polym. Sci., A-1, 1963, 1: 951 Gamichon, C. and Herery, P., J. Polym. Sci. Polym. Chem. Ed., 1982, 20: 3261 Terada, K., Myazaki, H. and Maruyama, H., 1992, Jpn. Pat., 264,387,02 McNally, J.G. and van Dyke, R.H., 1942, U.S. Pat., 2,269,216 O'Neil, T., J. Polym. Sci., A-l, 1972, 10: 569 Drago, R.S., Hart, D.M. and Carlson, R.L., J. Am. Chem. Soc., 1965, 87: 1900 Chetri, P., Islam, N. and Dass, N.N., J. Polym. Sci. A, 1996, 34: 1613 Gould, E.S., Mechanism and Structure in Organic Chemistry, Holt, Rinehart, and Winston, New York, 1959, p.346 Fraenkel, G., Belford, R.L. and Yonkwich, P.E., J. Am. Chem. Soc., 1954, 76: 15 Bellamy, L.J., Advances in Infrared Group Frequencies, Methven, London, 1968, p.233 Silverstein, R.M., Bassler, G.C. and Morrill, T.C., Spectrometric Identi Fication of Organic Compounds, Wiley, New York, 1981, p.164 Saunders, K., J. Organic Polymer Chemistry, 2nd ed., Chapman and Hall, New York, 1988, p.121 Brandrup, J., Immergut, E.H. and Grulke, E.A., Polymer Handbook, John Wiley & Sons, New York, 1999, p.504 Maiti, S., J. Macromol. Sci. Chem., 1982, A18: 955 Chiklis, C.K. and Grasshoff, J.M., J. Polym. Sci. A-2, 1970, 8: 1617 Sobbolev, D., A First Course in Polymer Chemistry, Mir Publishers, Moscow, 1971, p.304

Vous aimerez peut-être aussi

- Jackfruit Sap As GlueDocument36 pagesJackfruit Sap As GlueCaraDele72% (54)

- Poly Lactic Acid Plant CostDocument2 pagesPoly Lactic Acid Plant CostIntratec SolutionsPas encore d'évaluation

- Emulsion Polymerization of Vinyl Acetate, Ethylene, and N-Methylol AcrylamideDocument6 pagesEmulsion Polymerization of Vinyl Acetate, Ethylene, and N-Methylol Acrylamideramitkatyal21881Pas encore d'évaluation

- Biodegradable Plastic From Cassava - 119701Document3 pagesBiodegradable Plastic From Cassava - 119701Gean GenizaPas encore d'évaluation

- Types of PVA Glue and How To Use ItDocument2 pagesTypes of PVA Glue and How To Use ItSaleem FarhanPas encore d'évaluation

- Economics of Azodicarbonamide Production ProcessesDocument4 pagesEconomics of Azodicarbonamide Production ProcessesfdfPas encore d'évaluation

- 2017 - Avani Product CatalogDocument11 pages2017 - Avani Product CatalogCorneliaPas encore d'évaluation

- Modern Bamboo Brochure Reference 2019Document43 pagesModern Bamboo Brochure Reference 2019Diandra MuassabPas encore d'évaluation

- Protease Revisting The Types and Potential PDFDocument8 pagesProtease Revisting The Types and Potential PDFValeriu MunteanuPas encore d'évaluation

- Economics of ABS Production ProcessesDocument4 pagesEconomics of ABS Production ProcessesfdfPas encore d'évaluation

- Estimationofmarketsizeandpotentialoffibrecementboardsformumbaimarket 140324113249 Phpapp01Document49 pagesEstimationofmarketsizeandpotentialoffibrecementboardsformumbaimarket 140324113249 Phpapp01amittopnoPas encore d'évaluation

- Di-Calcium Phosphate by Direct Acidulation of Phosphate RockDocument111 pagesDi-Calcium Phosphate by Direct Acidulation of Phosphate RockAshutosh GuptaPas encore d'évaluation

- CIR Dicalcium Phospate PDFDocument75 pagesCIR Dicalcium Phospate PDFNurulPas encore d'évaluation

- 3164 PDFDocument133 pages3164 PDFnoelPas encore d'évaluation

- Linear Alkyl Benzene SurveyDocument357 pagesLinear Alkyl Benzene SurveyBrahma Teja LbPas encore d'évaluation

- AzodicarbonamideDocument1 pageAzodicarbonamideToniHospitalerPas encore d'évaluation

- The Manufacture of Soda Ash in The Arabian GulfDocument10 pagesThe Manufacture of Soda Ash in The Arabian GulfManohkaran VelooPas encore d'évaluation

- Extraction of Oil From Seed PDFDocument6 pagesExtraction of Oil From Seed PDFNahid Akhter KathaPas encore d'évaluation

- Determination of 17 Organotin Compounds by GCQQQDocument24 pagesDetermination of 17 Organotin Compounds by GCQQQiwonnascribdnomorePas encore d'évaluation

- Copper On ABS PDFDocument3 pagesCopper On ABS PDFLukePas encore d'évaluation

- Vikas Eco PDFDocument60 pagesVikas Eco PDFAbhi PatPas encore d'évaluation

- Water Consumption in A Pharma Maufacturing Plant PDFDocument22 pagesWater Consumption in A Pharma Maufacturing Plant PDFSivakumar SelvarajPas encore d'évaluation

- Sgs Safeguards 13509 Organotin Compounds in Textile Articles en 09Document2 pagesSgs Safeguards 13509 Organotin Compounds in Textile Articles en 09taha000Pas encore d'évaluation

- Lecture 25 BromineDocument8 pagesLecture 25 Bromineishita.brahmbhattPas encore d'évaluation

- AzodicarbonamideDocument1 pageAzodicarbonamideBos KayuPas encore d'évaluation

- Som Piseth ProposalDocument57 pagesSom Piseth ProposalSom PisethPas encore d'évaluation

- Manufacturing Process With Chemical Reactions and Mass Balance For 6 Pharmaceutical DrugsDocument11 pagesManufacturing Process With Chemical Reactions and Mass Balance For 6 Pharmaceutical DrugsAdvanced Research PublicationsPas encore d'évaluation

- Petrochemical Engineering - II Unit - V: Aromatics-BTX DerivativesDocument25 pagesPetrochemical Engineering - II Unit - V: Aromatics-BTX DerivativesAnilKumarPas encore d'évaluation

- Vikas Eco RR - BoBDocument4 pagesVikas Eco RR - BoBlkamalPas encore d'évaluation

- Granules India PDFDocument29 pagesGranules India PDFP VinayakamPas encore d'évaluation

- Method For Preparing Anhydrous Iron ChloridesDocument4 pagesMethod For Preparing Anhydrous Iron ChloridesVioleta GrigorasPas encore d'évaluation

- Sodium Bicarbonate - Wikipedia, The Free EncyclopediaDocument12 pagesSodium Bicarbonate - Wikipedia, The Free EncyclopediaJoekkkPas encore d'évaluation

- Khair InformationDocument18 pagesKhair InformationtinkulalPas encore d'évaluation

- Os at KCLDocument62 pagesOs at KCLFinoj RodriguezPas encore d'évaluation

- Venous Blood CollectionDocument4 pagesVenous Blood CollectionSheila Mae BuenavistaPas encore d'évaluation

- APIC2012 Angel Fernandez & Zhao NaDocument34 pagesAPIC2012 Angel Fernandez & Zhao NaKomkomMarkoMarkoMarkovicPas encore d'évaluation

- India Glycol LTD Arpit Singh Final ReportDocument96 pagesIndia Glycol LTD Arpit Singh Final ReportARPIT SINGH100% (2)

- BASF Phthalic Anhydride Broschuere ScreenDocument11 pagesBASF Phthalic Anhydride Broschuere ScreenYasemin KaradağPas encore d'évaluation

- 1 s2.0 S1359836817335825 MainDocument15 pages1 s2.0 S1359836817335825 MainYineth PinzonPas encore d'évaluation

- Appendix I 4 IsegenBAR Specialist Studies Risk AssessmentDocument298 pagesAppendix I 4 IsegenBAR Specialist Studies Risk AssessmentMarvvvPas encore d'évaluation

- Nikita Project 01-06-2016Document38 pagesNikita Project 01-06-2016Shobhit GoswamiPas encore d'évaluation

- Apic2015 Zhao NaDocument24 pagesApic2015 Zhao NaSandip LadvaPas encore d'évaluation

- (Specialty Chemicals Division) Specializes in Manufacturing CHIRAL Products - Up To 99.9% Chiral PurityDocument6 pages(Specialty Chemicals Division) Specializes in Manufacturing CHIRAL Products - Up To 99.9% Chiral Purityagexpharma chemicalPas encore d'évaluation

- Polylactic Acid (PLA) - A Global Market Watch, 2011 - 2016 - BroucherDocument4 pagesPolylactic Acid (PLA) - A Global Market Watch, 2011 - 2016 - BroucherAxis ResearchMindPas encore d'évaluation

- Design and Simulation of Hydrogen Peroxide Plant: April 2018Document5 pagesDesign and Simulation of Hydrogen Peroxide Plant: April 2018Fahad AhmedPas encore d'évaluation

- Copper Sulphate Penta HydrateDocument2 pagesCopper Sulphate Penta HydrateBLi'H'Abiee100% (1)

- Acknowledgement : To Whom It May ConcernDocument8 pagesAcknowledgement : To Whom It May ConcernUsama MaoudPas encore d'évaluation

- Synthesis of Epichlorohydrin Kinetic PDFDocument6 pagesSynthesis of Epichlorohydrin Kinetic PDFTaylor PennaPas encore d'évaluation

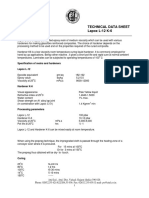

- Lapox Epoxy Resin l12 With Hardener K 6 1 1 KG PackingDocument2 pagesLapox Epoxy Resin l12 With Hardener K 6 1 1 KG PackingMadhu Bilugali MahadevaswamyPas encore d'évaluation

- PofsdkjnlkldsgDocument258 pagesPofsdkjnlkldsgzakizahirsyahPas encore d'évaluation

- Lecture 21 PhosphorousDocument53 pagesLecture 21 PhosphorousAnilKumar100% (2)

- Nickel and Ruthenium CatalystsDocument11 pagesNickel and Ruthenium CatalystsOscarOchoaPas encore d'évaluation

- New Terephthalic Acid ProcessDocument230 pagesNew Terephthalic Acid Processanon_139815068Pas encore d'évaluation

- Design and Optimization of A Catalytic Membrane Reactor For The DirectDocument8 pagesDesign and Optimization of A Catalytic Membrane Reactor For The DirectGerardOo Alexander SPas encore d'évaluation

- CM17214 Project Report PolystyreneDocument60 pagesCM17214 Project Report Polystyrenemridul bhawaPas encore d'évaluation

- Synopsis Project JocilDocument16 pagesSynopsis Project JocilbhatiaharryjassiPas encore d'évaluation

- Soluble SilicatesDocument311 pagesSoluble SilicatesSomboon BoonsomPas encore d'évaluation

- DeDocument3 pagesDesindromfall100% (1)

- Vishwaniketan Institute of Management, Entrepreneurship and Engineering Technology KHALAPUR-410202Document12 pagesVishwaniketan Institute of Management, Entrepreneurship and Engineering Technology KHALAPUR-410202piyush sapkalPas encore d'évaluation

- Global Benzaldehyde Market - PENTA S.R.O, Taj Pharmaceutical Limited, Jiangsu Jiamai Chemical Co. LTDDocument3 pagesGlobal Benzaldehyde Market - PENTA S.R.O, Taj Pharmaceutical Limited, Jiangsu Jiamai Chemical Co. LTDGeneric PharmaceuticalsPas encore d'évaluation

- Manu. Process Flow ChartDocument2 pagesManu. Process Flow ChartBaljeet Kumar PooniaPas encore d'évaluation

- Linear Alkyl BenzeneDocument9 pagesLinear Alkyl BenzeneFouad Achargui100% (1)

- CBB 4023 Plant Design IiDocument184 pagesCBB 4023 Plant Design IiKatherine AlvarezPas encore d'évaluation

- Index of Trade Names and Suppliers of Flame Retardants: Q 2006 by Taylor & Francis Group, LLCDocument2 pagesIndex of Trade Names and Suppliers of Flame Retardants: Q 2006 by Taylor & Francis Group, LLCramitkatyal21881Pas encore d'évaluation

- Pad Screen Vinyl Styrene - 2Document1 pagePad Screen Vinyl Styrene - 2ramitkatyal21881Pas encore d'évaluation

- Vinyl EsterDocument8 pagesVinyl Esterramitkatyal21881Pas encore d'évaluation

- Latent Curatives DescriptionsDocument3 pagesLatent Curatives Descriptionsramitkatyal21881Pas encore d'évaluation

- Wash PrimerDocument1 pageWash Primerramitkatyal21881Pas encore d'évaluation

- Surfactants For Use As CodispersantsDocument10 pagesSurfactants For Use As Codispersantsramitkatyal21881Pas encore d'évaluation

- Vinnapas Solid Resins Brochure 2016 - 7409 - ENDocument24 pagesVinnapas Solid Resins Brochure 2016 - 7409 - ENJohnPas encore d'évaluation

- Pva Bonding Agent ADocument2 pagesPva Bonding Agent ANovaAriePas encore d'évaluation

- Join Telegram ChannelDocument19 pagesJoin Telegram ChannelaniketPas encore d'évaluation

- Production of Emulsion House Paint Using PolyvinylDocument5 pagesProduction of Emulsion House Paint Using PolyvinylOtegba GiftPas encore d'évaluation

- Pva 2019Document7 pagesPva 2019kashyap8291100% (1)

- Formulation 004Document2 pagesFormulation 004zlightyear100% (2)

- Global Polymer EmulsionsDocument33 pagesGlobal Polymer EmulsionsSérgio - ATC do Brasil100% (1)

- Polyvinyl Acetate Emulsions For Adhesives - Handbook of Adhesives (1990)Document20 pagesPolyvinyl Acetate Emulsions For Adhesives - Handbook of Adhesives (1990)JuanPas encore d'évaluation

- Sampling Methods and Sample Laboratory Preparation at The Department of Archaeological Sciences, University of Bradford (United Kingdom)Document7 pagesSampling Methods and Sample Laboratory Preparation at The Department of Archaeological Sciences, University of Bradford (United Kingdom)sri hartini hariaaPas encore d'évaluation

- Polyvinyl AlcoholDocument141 pagesPolyvinyl Alcoholnobica67% (3)

- Sizing AgentDocument25 pagesSizing AgentMd.Amir hossain khanPas encore d'évaluation

- Quilion DatasheetDocument20 pagesQuilion DatasheetDennisPas encore d'évaluation

- Cordial Adhesive PresenationDocument42 pagesCordial Adhesive Presenationomermeric bilginPas encore d'évaluation

- Orats Final Rar Vinylacetate enDocument276 pagesOrats Final Rar Vinylacetate enVarun pandeyPas encore d'évaluation

- Safety Data Sheet: 1. Identification of The Substance / Preparation and of The Company / UndertakingDocument4 pagesSafety Data Sheet: 1. Identification of The Substance / Preparation and of The Company / UndertakingYASHICA VAITTIANATHANPas encore d'évaluation

- Final Evaluation Final DraftDocument67 pagesFinal Evaluation Final DraftshubhPas encore d'évaluation

- Dr. Ahmed Taher El-Habab, R&D Chemist Consultant CVDocument10 pagesDr. Ahmed Taher El-Habab, R&D Chemist Consultant CVMoatz HamedPas encore d'évaluation

- NoPVA NumPartsBajo PDFDocument6 pagesNoPVA NumPartsBajo PDFAnyiSakuraPas encore d'évaluation

- Capstone Final Paper Stem 12c Group5Document126 pagesCapstone Final Paper Stem 12c Group5arboso.trishamaurice.cabralPas encore d'évaluation

- Polyvinylacetate & Derivatives: Jitendra SinghDocument25 pagesPolyvinylacetate & Derivatives: Jitendra SinghHILL RANGAMATIPas encore d'évaluation

- Ethylene Copolymer Water Based EmulsionDocument5 pagesEthylene Copolymer Water Based EmulsionRuberlei FerrerPas encore d'évaluation

- Vinyl Acetate Monomer VAM BrochureDocument2 pagesVinyl Acetate Monomer VAM BrochureMuslim Nasir100% (1)

- L2S1 Polym. Science Lecture PresentationDocument70 pagesL2S1 Polym. Science Lecture PresentationAruna KumarasiriPas encore d'évaluation

- Adhesives 1457983107255Document36 pagesAdhesives 1457983107255sakshi100% (1)

- Composite Films Based On Biorelated Agro-Industrial Waste and Poly (Vinyl Alcohol) - Preparation and Mechanical Properties CharacterizationDocument9 pagesComposite Films Based On Biorelated Agro-Industrial Waste and Poly (Vinyl Alcohol) - Preparation and Mechanical Properties CharacterizationalejandroPas encore d'évaluation

- Concept Check 1 - PhysicsDocument2 pagesConcept Check 1 - Physicskiana Jessica MonroePas encore d'évaluation

- Surface Interactions of Chemically Active Ceramic Tiles WithDocument7 pagesSurface Interactions of Chemically Active Ceramic Tiles WithreshmitapallaPas encore d'évaluation