Académique Documents

Professionnel Documents

Culture Documents

Veneered End Table: Project 17901EZ

Transféré par

BSulli0 évaluation0% ont trouvé ce document utile (0 vote)

72 vues4 pagesThe document provides plans and instructions for building a veneered end table. The table features a curly birch veneer top with an inlaid border frame made of mitered birch. It includes a materials list and step-by-step instructions for cutting and assembling the various parts made of birch solid stock. Detailed guidance is given for applying veneers, cutting joints and grooves, and fastening the parts together to complete the project.

Description originale:

Titre original

EZVeneeredEndTable

Copyright

© Attribution Non-Commercial (BY-NC)

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentThe document provides plans and instructions for building a veneered end table. The table features a curly birch veneer top with an inlaid border frame made of mitered birch. It includes a materials list and step-by-step instructions for cutting and assembling the various parts made of birch solid stock. Detailed guidance is given for applying veneers, cutting joints and grooves, and fastening the parts together to complete the project.

Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

72 vues4 pagesVeneered End Table: Project 17901EZ

Transféré par

BSulliThe document provides plans and instructions for building a veneered end table. The table features a curly birch veneer top with an inlaid border frame made of mitered birch. It includes a materials list and step-by-step instructions for cutting and assembling the various parts made of birch solid stock. Detailed guidance is given for applying veneers, cutting joints and grooves, and fastening the parts together to complete the project.

Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 4

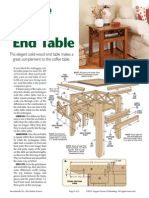

Project 17901EZ:

Veneered End Table

A curly birch veneer adds an especially distinctive look to this trestle style end

table. Adding further to its visual appeal is a border of veneer inlay and a mitered

birch frame. All other parts are made of birch solid stock, although as usual, just

about any kind of hardwood is also suitable.

Veneered End Table Materials List

Part Description Size No. Req’d

A Leg 3/4" x 9-3/8" x 19" 2

B Foot 1-5/8" x 1-5/8" x 11" 2

C Support 1-3/8" x 1-3/8" x 9-3/4" 2

D Cleat 3/4" x 3/4" x 8" 2

E Stretcher 1/2" x 2 x 19-3/4" 1

F Peg 3/4" x 3/4" x 2-1/2" 2

G Top 1/2" x 10-5/8" x 19-5/9" 1

H Veneer As required.

I Inlay As required

J Short Top Frame 3/4" x 2-1/2" x 15" 2

K Long Top Frame 3/4" x 2-1/2" x 24" 2

Veneered End Table Complete

Schematic

Veneered End Table Step-by-Step

Instructions

1. Cut the top (G) from 1/2" fir plywood to overall length and width.

2. Make sure the corners are square.

3. Choose a finer veneer for the top of part G.

4. Choose an inexpensive type of veneer such a poplar for the bottom of part

G. NOTE: Both the top and bottom of the plywood will require veneer in

order to equalize stresses.

5. Apply the veneer to both sides of the top so that it runs at right angles to the

grain direction of the face veneer on the plywood. NOTE: The grain of fir

plywood will eventually telegraph through.

6. Use a dado head cutter and, working carefully to avoid splintering the ve-

neer, cut the 5/ 16" x 5/16" rabbet around the perimeter of the top.

7. Cut the frame parts (J and K) to size.

8. Use a shaper to cut the groove for the veneer inlay.

9. Glue the inlay in place and allow to dry.

10. Cut the miter.

11. Make repeated passes over the table saw blade to cut the 1/4" wide x 3/8"

deep groove.

12. Drill holes at the miters to take 3/8" diameter by 1-1/2" long dowel pins.

13. Glue and clamp parts J and K to the top and allow to dry overnight.

14. Cut the remaining parts to the dimensions shown.

15. Sand, stain, and finish each individual piece prior to assembly and allow to

dry.

16. Place the top face down on a pad to prevent scratching.

17. Locate one cleat on the top.

18. Drill pilot holes for the cleat screws, being sure to use a depth stop so you

do not drill through the top.

19. Attach the cleats with screws as shown.

20. Place one end of the stretcher in the leg slot.

21. Locate the other end of the stretcher so that the ends are square with the top.

22. Fasten the stretcher with screws as indicated.

23. Turn the table upright.

24. Insert the pegs into slots with thumb pressure or a light tap to complete the

project.

These plans were originally published in Volume 6, Issue 5 of The Woodworker’s

Journal (Sept./Oct. 1982, pages 30-31).

Vous aimerez peut-être aussi

- Pine Cabinet: Project 11142EZDocument5 pagesPine Cabinet: Project 11142EZBSulliPas encore d'évaluation

- The Pochade and Wet Panel Carrier Do It Yourself PlanD'EverandThe Pochade and Wet Panel Carrier Do It Yourself PlanÉvaluation : 4 sur 5 étoiles4/5 (1)

- Router Bit Box: Project 20261EZDocument6 pagesRouter Bit Box: Project 20261EZBSulliPas encore d'évaluation

- How to Make Picture Frames (Best of AW): 12 Simple to Stylish Projects from the Experts at American Woodworker (American Woodworker)D'EverandHow to Make Picture Frames (Best of AW): 12 Simple to Stylish Projects from the Experts at American Woodworker (American Woodworker)Évaluation : 5 sur 5 étoiles5/5 (1)

- Record and Tape Cabinet: Project 11185EZDocument8 pagesRecord and Tape Cabinet: Project 11185EZBSulliPas encore d'évaluation

- A Collection of Woodwork Patterns for the Making of Children's ToysD'EverandA Collection of Woodwork Patterns for the Making of Children's ToysPas encore d'évaluation

- Chest of Drawers: Project 11819EZDocument7 pagesChest of Drawers: Project 11819EZBSulli100% (1)

- DIY Writing DeskDocument7 pagesDIY Writing DeskStephen MoorePas encore d'évaluation

- Pianos: Their Construction, Tuning, And Repair - With Numerous Engravings And DiagramsD'EverandPianos: Their Construction, Tuning, And Repair - With Numerous Engravings And DiagramsÉvaluation : 5 sur 5 étoiles5/5 (2)

- Wall-Hung Telephone Cabinet: Project 11257EZDocument6 pagesWall-Hung Telephone Cabinet: Project 11257EZBSulli100% (1)

- Wintertime Shimmer Quilt & Table Runner: 2 Sophisticated Projects to Piece & AppliquéD'EverandWintertime Shimmer Quilt & Table Runner: 2 Sophisticated Projects to Piece & AppliquéPas encore d'évaluation

- Writing Desk: Project 13586EZDocument7 pagesWriting Desk: Project 13586EZBSulliPas encore d'évaluation

- Family Handyman Ultimate 1 Day ProjectsD'EverandFamily Handyman Ultimate 1 Day ProjectsÉvaluation : 5 sur 5 étoiles5/5 (1)

- Box of Shapes Toy: Project 18618EZDocument5 pagesBox of Shapes Toy: Project 18618EZBSulliPas encore d'évaluation

- Router Bit Box 2 PartesDocument11 pagesRouter Bit Box 2 Partesapi-3830394100% (1)

- Wall Hung Magazine and Book Rack: Project 14211EZDocument3 pagesWall Hung Magazine and Book Rack: Project 14211EZBSulliPas encore d'évaluation

- Early American Step Table: Project 18321EZDocument4 pagesEarly American Step Table: Project 18321EZBSulliPas encore d'évaluation

- Ultimate WorkbenchDocument8 pagesUltimate WorkbenchEric Gruff0% (1)

- Country Curio Clock: Project 12231EZDocument7 pagesCountry Curio Clock: Project 12231EZBSulliPas encore d'évaluation

- ParquetDocument4 pagesParquetFernando FrayrePas encore d'évaluation

- Pine Desk Organizer: Project 13782EZDocument6 pagesPine Desk Organizer: Project 13782EZBSulli100% (1)

- Country Bench: Project 10307EZDocument8 pagesCountry Bench: Project 10307EZBSulliPas encore d'évaluation

- Shop Workstation: Project 20569EZDocument3 pagesShop Workstation: Project 20569EZBSulliPas encore d'évaluation

- Contemporary Coffee Table: Project 17631EZDocument5 pagesContemporary Coffee Table: Project 17631EZBSulliPas encore d'évaluation

- Recipe Box: Project 15193EZDocument5 pagesRecipe Box: Project 15193EZBSulli100% (1)

- Trestle Table and Benches: Project 18444EZDocument5 pagesTrestle Table and Benches: Project 18444EZAndre GaioPas encore d'évaluation

- Computer WorkstationDocument8 pagesComputer Workstation- yAy3e -100% (1)

- Cranberry Rake Box: Project 10571EZDocument3 pagesCranberry Rake Box: Project 10571EZBSulliPas encore d'évaluation

- Wood Working Plans - Toys - Rocking Horse PDFDocument6 pagesWood Working Plans - Toys - Rocking Horse PDFBen GerezPas encore d'évaluation

- U-Bild: Hope ChestDocument6 pagesU-Bild: Hope ChestEmilian BalutaPas encore d'évaluation

- Leg Tapering Jig: Project 14585EZDocument5 pagesLeg Tapering Jig: Project 14585EZBSulliPas encore d'évaluation

- Mesa China CarpinteriaDocument7 pagesMesa China CarpinteriaMCarrillo_1971Pas encore d'évaluation

- Barbecue Tray: Project 19830EZDocument4 pagesBarbecue Tray: Project 19830EZneilradcliffe3618Pas encore d'évaluation

- Woodworking Plans - Hope ChestDocument6 pagesWoodworking Plans - Hope ChestAhmet Aydogan100% (1)

- Desk Caddy: Woodworks: Advanced ProjectDocument8 pagesDesk Caddy: Woodworks: Advanced ProjectEucap MdzPas encore d'évaluation

- U-Bild: Three-Piece Bedroom SetDocument8 pagesU-Bild: Three-Piece Bedroom SetEmilian BalutaPas encore d'évaluation

- (Woodworking) Workbench - Woodworking Plans - Workbench - Popular Mechanics - Hard Maple PDFDocument7 pages(Woodworking) Workbench - Woodworking Plans - Workbench - Popular Mechanics - Hard Maple PDFAntonio CompanyPas encore d'évaluation

- 4 X 4 Off RoaderDocument6 pages4 X 4 Off Roaderhulusi67Pas encore d'évaluation

- Old World Weather Forecaster: Project 14438EZDocument10 pagesOld World Weather Forecaster: Project 14438EZBSulli100% (1)

- DP 00011Document14 pagesDP 00011Jason Weber100% (1)

- Book Case (Mission Style)Document8 pagesBook Case (Mission Style)khunchaiyai100% (3)

- Small Colonial Bench: Project 10297EZDocument5 pagesSmall Colonial Bench: Project 10297EZmhein68Pas encore d'évaluation

- Curvy Coffee Table: Woodworks: Advanced ProjectDocument8 pagesCurvy Coffee Table: Woodworks: Advanced ProjectmarciliomeiraPas encore d'évaluation

- Build A Toy BoxDocument10 pagesBuild A Toy BoxkhunchaiyaiPas encore d'évaluation

- Otting Bench: Special Tools and TechniquesDocument11 pagesOtting Bench: Special Tools and TechniquesFe TusPas encore d'évaluation

- Kucica Za PticeDocument9 pagesKucica Za PticeNikola0302Pas encore d'évaluation

- Parsons TableDocument3 pagesParsons Table- yAy3e -100% (1)

- Plans Dovetail Jig StandDocument6 pagesPlans Dovetail Jig Standhmam_88100% (1)

- Chess Table: Project 18732EZDocument4 pagesChess Table: Project 18732EZfuel4hatredPas encore d'évaluation

- Chess Table: Project 18732EZDocument4 pagesChess Table: Project 18732EZwoodsmithcaPas encore d'évaluation

- Project 18732EZDocument4 pagesProject 18732EZBSulliPas encore d'évaluation

- Woodworking Plans - Chesstable PDFDocument4 pagesWoodworking Plans - Chesstable PDFInform7105Pas encore d'évaluation

- End Table: MahoganyDocument3 pagesEnd Table: Mahoganyrherdez100% (1)

- Woodworking Plans - Box-Joint JigDocument8 pagesWoodworking Plans - Box-Joint Jig_Godfather100% (3)

- 2 - Woodworking Plans - OakplateDocument6 pages2 - Woodworking Plans - OakplatemacpatorPas encore d'évaluation

- Pot Plant StandDocument5 pagesPot Plant Standhjholden100% (1)

- Paper Towel HolderDocument5 pagesPaper Towel HoldermchiovettaPas encore d'évaluation

- Barbecue Tray: Project 19830EZDocument4 pagesBarbecue Tray: Project 19830EZBSulliPas encore d'évaluation

- Leg Tapering Jig: Project 14585EZDocument5 pagesLeg Tapering Jig: Project 14585EZBSulliPas encore d'évaluation

- Project 18732EZDocument4 pagesProject 18732EZBSulliPas encore d'évaluation

- Ez Shaker WashstandDocument7 pagesEz Shaker WashstandBrian-Patty SullivanPas encore d'évaluation

- Rope Whipping SheetDocument6 pagesRope Whipping SheetBSulliPas encore d'évaluation

- Workshop Tote Box: Project 20466EZDocument3 pagesWorkshop Tote Box: Project 20466EZBSulli100% (1)

- Writing Desk: Project 13586EZDocument7 pagesWriting Desk: Project 13586EZBSulliPas encore d'évaluation

- EZTowelbar W Glass ShelfDocument2 pagesEZTowelbar W Glass ShelfBSulliPas encore d'évaluation

- Shaker Single Drop Leaf TableDocument6 pagesShaker Single Drop Leaf TableLory Dena HeathPas encore d'évaluation

- Workbench Helper: Project 20518EZDocument3 pagesWorkbench Helper: Project 20518EZBSulliPas encore d'évaluation

- Wooden Combs: Project 16483EZDocument3 pagesWooden Combs: Project 16483EZBSulliPas encore d'évaluation

- Weather Station: Project 14445EZDocument4 pagesWeather Station: Project 14445EZBSulliPas encore d'évaluation

- Wooden Coat Hanger: Project 16474EZDocument3 pagesWooden Coat Hanger: Project 16474EZBSulliPas encore d'évaluation

- Carved Walking Stick: Project 16695EZDocument3 pagesCarved Walking Stick: Project 16695EZBSulli100% (2)

- Wall-Hung Telephone Cabinet: Project 11257EZDocument6 pagesWall-Hung Telephone Cabinet: Project 11257EZBSulli100% (1)

- Valentine Box: Project 10766EZDocument5 pagesValentine Box: Project 10766EZBSulliPas encore d'évaluation

- EZVeneer BraceletDocument3 pagesEZVeneer BraceletBSulliPas encore d'évaluation

- EZStoolDocument4 pagesEZStoolBSulliPas encore d'évaluation

- Box of Shapes Toy: Project 18618EZDocument5 pagesBox of Shapes Toy: Project 18618EZBSulliPas encore d'évaluation

- EZTenon JigDocument3 pagesEZTenon JigBSulliPas encore d'évaluation

- EZRouted BookendsDocument3 pagesEZRouted BookendsBSulliPas encore d'évaluation

- Porch Swing: Project 16258EZDocument5 pagesPorch Swing: Project 16258EZBSulli100% (1)

- Shaker Sewing TableDocument21 pagesShaker Sewing TableFeng Shu jiPas encore d'évaluation

- Stacking Desk Tray: Project 19874EZDocument4 pagesStacking Desk Tray: Project 19874EZBSulliPas encore d'évaluation

- Shop Workstation: Project 20569EZDocument3 pagesShop Workstation: Project 20569EZBSulliPas encore d'évaluation

- Recipe Box: Project 15193EZDocument5 pagesRecipe Box: Project 15193EZBSulli100% (1)

- Rolling Toy: Project 19376EZDocument3 pagesRolling Toy: Project 19376EZBSulliPas encore d'évaluation

- EZSalad TongsDocument3 pagesEZSalad TongsBSulliPas encore d'évaluation

- Coffin Texts Vol 8Document0 pageCoffin Texts Vol 8shasvinaPas encore d'évaluation

- Fill in The GapsDocument4 pagesFill in The GapsRajeev NiraulaPas encore d'évaluation

- The Philosophy of Immanuel Kant: Alfred WeberDocument18 pagesThe Philosophy of Immanuel Kant: Alfred WeberGerald Jem BernandinoPas encore d'évaluation

- Water Pump ReportDocument15 pagesWater Pump ReportMohammed BashierPas encore d'évaluation

- 17 FalileyevDocument6 pages17 FalileyevMuzeul Naţional de Istorie a MoldoveiPas encore d'évaluation

- North African Music 2Document24 pagesNorth African Music 2NessaladyPas encore d'évaluation

- Mindset Reset 2019 PDFDocument10 pagesMindset Reset 2019 PDFAdina100% (1)

- Parsons Aas Graphic Design 08Document18 pagesParsons Aas Graphic Design 08mushonzPas encore d'évaluation

- Empathy at Work: - Ability To Share Someone Else's Feelings orDocument5 pagesEmpathy at Work: - Ability To Share Someone Else's Feelings orVital Jorge Do CantoPas encore d'évaluation

- TleDocument15 pagesTleChristine Joy Dela CruzPas encore d'évaluation

- B03 04 2010 Novac PDFDocument4 pagesB03 04 2010 Novac PDFDejan MilenkovicPas encore d'évaluation

- Mrs Dalloway AnalysisDocument8 pagesMrs Dalloway AnalysisStéphaniePas encore d'évaluation

- Oxford Present Perfect - Simple, Continuous, Passive - Making The Right NoisesDocument2 pagesOxford Present Perfect - Simple, Continuous, Passive - Making The Right NoisesLucas ArtolaPas encore d'évaluation

- SocksanditsmanufacturingDocument9 pagesSocksanditsmanufacturingMian ShoaibPas encore d'évaluation

- Wattle and Daub: Craft, Conservation and Wiltshire Case StudyDocument112 pagesWattle and Daub: Craft, Conservation and Wiltshire Case StudyPriyanka SutePas encore d'évaluation

- Guidelines & Specifications - Civil & Tower Works PDFDocument32 pagesGuidelines & Specifications - Civil & Tower Works PDFHeaven's Prince0% (1)

- Mantras Om or Aum and The Gayatri MantraDocument131 pagesMantras Om or Aum and The Gayatri MantraFrancis Lobo67% (3)

- Primitive Folk MootsDocument164 pagesPrimitive Folk MootsMilena ChornaPas encore d'évaluation

- The Division of Old TestamentDocument29 pagesThe Division of Old TestamentJin AmatorioPas encore d'évaluation

- Digital Propeller Clock Using ArduinoDocument12 pagesDigital Propeller Clock Using ArduinoUday YadavPas encore d'évaluation

- Different Types of Printing Method Block PrintingDocument2 pagesDifferent Types of Printing Method Block PrintingPrabhu RichardPas encore d'évaluation

- MS Subbalakshmi Songs ListDocument11 pagesMS Subbalakshmi Songs ListSindhu RamisettyPas encore d'évaluation

- EAPP2Document6 pagesEAPP2Kimberly PinuelaPas encore d'évaluation

- Burger - Theory of The Avant Garde Chap 4Document15 pagesBurger - Theory of The Avant Garde Chap 4monkeys8823Pas encore d'évaluation

- Thea 481 - Play Paper On HarvestDocument1 pageThea 481 - Play Paper On Harvestapi-279886285100% (2)

- Daily Technique (By Edson Lopes) - LigadoDocument2 pagesDaily Technique (By Edson Lopes) - LigadoellulzinhoPas encore d'évaluation

- Madame Du Barry - Noel Williams 1909Document421 pagesMadame Du Barry - Noel Williams 1909Kassandra M Journalist100% (1)

- 1000 Most Common English WordsDocument4 pages1000 Most Common English WordsRebecca CameronPas encore d'évaluation

- MetaphysicsDocument12 pagesMetaphysicsDummy AccountPas encore d'évaluation

- Asinaria PDFDocument176 pagesAsinaria PDFCésar Arroyo LPas encore d'évaluation

- House Rules: How to Decorate for Every Home, Style, and BudgetD'EverandHouse Rules: How to Decorate for Every Home, Style, and BudgetPas encore d'évaluation

- Crochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsD'EverandCrochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsÉvaluation : 4.5 sur 5 étoiles4.5/5 (10)

- The Martha Manual: How to Do (Almost) EverythingD'EverandThe Martha Manual: How to Do (Almost) EverythingÉvaluation : 4 sur 5 étoiles4/5 (11)

- 100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiD'Everand100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiÉvaluation : 5 sur 5 étoiles5/5 (2)

- Edward's Menagerie New Edition: Over 50 easy-to-make soft toy animal crochet patternsD'EverandEdward's Menagerie New Edition: Over 50 easy-to-make soft toy animal crochet patternsPas encore d'évaluation

- Swatch This, 3000+ Color Palettes for Success: Perfect for Artists, Designers, MakersD'EverandSwatch This, 3000+ Color Palettes for Success: Perfect for Artists, Designers, MakersÉvaluation : 3.5 sur 5 étoiles3.5/5 (3)

- Crochet Impkins: Over a million possible combinations! Yes, really!D'EverandCrochet Impkins: Over a million possible combinations! Yes, really!Évaluation : 4.5 sur 5 étoiles4.5/5 (10)

- Little Happy Circus: 12 Amigurumi Crochet Toy Patterns for Your Favourite Circus PerformersD'EverandLittle Happy Circus: 12 Amigurumi Crochet Toy Patterns for Your Favourite Circus PerformersÉvaluation : 5 sur 5 étoiles5/5 (3)

- Crochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiD'EverandCrochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiÉvaluation : 4 sur 5 étoiles4/5 (3)

- Edward's Menagerie: Dogs: 50 canine crochet patternsD'EverandEdward's Menagerie: Dogs: 50 canine crochet patternsÉvaluation : 3 sur 5 étoiles3/5 (5)

- Amigurumi Cats: Crochet Sweet Kitties the Japanese Way (24 Projects of Cats to Crochet)D'EverandAmigurumi Cats: Crochet Sweet Kitties the Japanese Way (24 Projects of Cats to Crochet)Pas encore d'évaluation

- Modern Crochet Style: 15 Colourful Crochet Patterns For You and Your HomeD'EverandModern Crochet Style: 15 Colourful Crochet Patterns For You and Your HomeÉvaluation : 5 sur 5 étoiles5/5 (1)

- Treasure Bookmaking: Crafting Handmade Sustainable JournalsD'EverandTreasure Bookmaking: Crafting Handmade Sustainable JournalsPas encore d'évaluation

- Crochet in a Weekend: 29 Quick-to-Stitch Sweaters, Tops, Shawls & MoreD'EverandCrochet in a Weekend: 29 Quick-to-Stitch Sweaters, Tops, Shawls & MoreÉvaluation : 4 sur 5 étoiles4/5 (6)

- 100 Crochet Tiles: Charts and patterns for crochet motifs inspired by decorative tilesD'Everand100 Crochet Tiles: Charts and patterns for crochet motifs inspired by decorative tilesPas encore d'évaluation

- Modern Embroidery: A Book of Stitches to Unleash CreativityD'EverandModern Embroidery: A Book of Stitches to Unleash CreativityPas encore d'évaluation

- Crochet Iconic Women: Amigurumi Patterns for 15 Women Who Changed the WorldD'EverandCrochet Iconic Women: Amigurumi Patterns for 15 Women Who Changed the WorldÉvaluation : 4.5 sur 5 étoiles4.5/5 (30)

- Textiles Transformed: Thread and thrift with reclaimed textilesD'EverandTextiles Transformed: Thread and thrift with reclaimed textilesPas encore d'évaluation

- Funny Amigurumi: 16 Creatures & Their Accessories to CrochetD'EverandFunny Amigurumi: 16 Creatures & Their Accessories to CrochetÉvaluation : 5 sur 5 étoiles5/5 (1)

- Fairytale Blankets to Crochet: 10 Fantasy-Themed Children's Blankets for Storytime CuddlesD'EverandFairytale Blankets to Crochet: 10 Fantasy-Themed Children's Blankets for Storytime CuddlesÉvaluation : 5 sur 5 étoiles5/5 (3)

- Shetland Fine Lace Knitting: Recreating Patterns from the Past.D'EverandShetland Fine Lace Knitting: Recreating Patterns from the Past.Évaluation : 2 sur 5 étoiles2/5 (1)

- How to Embroider Almost Everything: A Sourcebook of 500+ Modern Motifs & Easy Stitch TutorialsD'EverandHow to Embroider Almost Everything: A Sourcebook of 500+ Modern Motifs & Easy Stitch TutorialsÉvaluation : 4.5 sur 5 étoiles4.5/5 (4)

- Modern Crochet Sweaters: 20 Chic Designs for Everyday WearD'EverandModern Crochet Sweaters: 20 Chic Designs for Everyday WearÉvaluation : 5 sur 5 étoiles5/5 (1)

- Crochet Cute Dolls with Mix-and-Match Outfits: 66 Adorable Amigurumi PatternsD'EverandCrochet Cute Dolls with Mix-and-Match Outfits: 66 Adorable Amigurumi PatternsÉvaluation : 4 sur 5 étoiles4/5 (5)

- Upcycling: 20 Creative Projects Made from Reclaimed MaterialsD'EverandUpcycling: 20 Creative Projects Made from Reclaimed MaterialsPas encore d'évaluation

- Edward's Crochet Doll Emporium: Flip the mix-and-match patterns to make and dress your favourite peopleD'EverandEdward's Crochet Doll Emporium: Flip the mix-and-match patterns to make and dress your favourite peopleÉvaluation : 5 sur 5 étoiles5/5 (1)

- Art Journals & Creative Healing: Restoring the Spirit through Self-ExpressionD'EverandArt Journals & Creative Healing: Restoring the Spirit through Self-ExpressionÉvaluation : 3 sur 5 étoiles3/5 (7)

- Supersize Crochet Animals: 20 Adorable Amigurumi Sized to SnuggleD'EverandSupersize Crochet Animals: 20 Adorable Amigurumi Sized to SnuggleÉvaluation : 5 sur 5 étoiles5/5 (2)

- The Fellowship of the Knits: Lord of the Rings: The Unofficial Knitting BookD'EverandThe Fellowship of the Knits: Lord of the Rings: The Unofficial Knitting BookÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)