Académique Documents

Professionnel Documents

Culture Documents

Flame Arrester

Transféré par

iran1362Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Flame Arrester

Transféré par

iran1362Droits d'auteur :

Formats disponibles

Installation, Operation and Maintenance Manual for Flame Arrester

Models 7618, 7628

IOM-7618 Rev. B 11577 Ref. ID: 96056

2009 Groth Corporation

Page 2 of 16 Table of Contents I. INTRODUCTION II. INSPECTION AND INSTALLATION 1. TABLE 1 FLAME ARRESTER MAWP 2. TABLE 2 HOUSING AND FLANGE BOLT TORQUE III. MAINTENANCE 1. FIGURE 1 TYPICAL MODEL 7618 FLAME ARRESTER 2. TABLE 3 ELEMENT HOUSING WEIGHT 3. TABLE 4 FLAME ARRESTER ASSEMBLY WEIGHT IV. SPARE PARTS 1. TABLE 5 FLAME BANK ASSEMBLY KIT 2. TABLE 6 GASKET KIT V. MODEL IDENTIFICATION APPENDIX A MODEL 7618 FLAME ARRESTER (2-12) APPENDIX B MODEL 7618 END OF LINE FLAME ARRESTER (2-12) APPENDIX C MODEL 7618 FLAME ARRESTER (14-36) APPENDIX D MODEL 7628 FLAME ARRESTER (2-12) APPENDIX E MODEL 7628 FLAME ARRESTER (14-36) 3 4 4 4 6 6 7 7 9 10 10 11 12 13 14 15 16

Page 3 of 16 I. INTRODUCTION Groth Corporations flame arresters are designed to inhibit flame propagation in gas piping systems and to protect low pressure tanks containing flammable liquids. They protect low flash point liquids from externally caused sources of heat and ignition, providing increased fire protection and safety. The flame arresters consist of two main components, the arrester bases and the flame element housing. The bases serve as the connecting interface to the piping system. The housing accommodates the flame element and is instrumental in stopping the flame passage. The depth of the flame element absorbed the heat from the vapor flow, cooling the vapor to prevent auto-ignition on the protected side. The flame element is comprised of small parallel triangular passageways aligned so that an approaching flame front is slowed down and then quenched before it can propagate to the protected side of the device. All Groth Corporation flame elements utilize spiral wound, crimped ribbon constructed of corrosion resistant materials, to insure the best flame quenching performance with minimum pressure drop. Depending on the design of the system in which it is used, the arrester bases can include optional ports for temperature or pressure monitoring devices. These devices can activate warning or shutdown systems if abnormal conditions are detected. A flame arrester should be treated as a safety device and maintained by a knowledgeable repair technician. Carefully read and understand this Manual before installing or servicing this product.

For information not contained in this manual, please contact: Groth Corporation 13650 N. Promenade Blvd. Stafford, TX, 77477 USA Phone: 281-295-6800 Fax: 281-295-6999 www.grothcorp.com

Page 4 of 16 II. INSPECTION AND INSTALLATION All Groth Corporation's flame arresters are bi-directional and the installation on a tank or piping system depends to a great extent on the design of the system. The Model 7618 is recommended for vertical installation in closed piping systems or venting to atmosphere. If a Model 7618 is installed in a horizontal line, it should be equipped with drain ports for removal of condensation from the housing. WARNING: Do not pipe both drainage connections to a common line as this can provide a passage for flame to by-pass the flame arrester element. The Model 7628 is designed for either vertical or horizontal installation. These series of flame arresters have 150# ANSI flange drilling compatibility, [30 & 36 model 7618 & 7628 have API 650 drilling], and are pneumatically tested to 15 PSIG at the factory. Follow the guidelines listed in Table 2 for flange make-up torque. The arresters are NOT rated for full flange pressure and do not require high bolting torque. Recommended torque values are based on pressures [MAWP] in Table 1. Consult factory for higher pressure applications. TABLE 1: FLAME ARRESTER MAWP [PSIG (kPa)] Size 2 3 4 6 8 10 12 Model 7618 Alum Model 7618 CS/SS Model 7628 Alum Model 7628 CS/SS

50 (345) 100 (690) 150 (1034) 275 (1965) 50 (345) 100 (690) 140 (965) 275 (1965) 50 (345) 100 (690) 140 (965) 275 (1965) 50 (345) 100 (690) 140 (965) 275 (1965) 50 (345) 100 (690) 90 (620) 200 (1379) 50 (345) 100 (690) 75 (482) 150 (1034) 50 (345) 100 (690) 75 (482) 150 (1034) Sizes > 12 (7618 & 7628): MAWP = 15 PSIG TABLE 2: BOLT TORQUE [ft-lbs (Nm)] Flange* Housing Raised Flat Model Model Face Face 7618 7628 60 (82) 60 (82) 60 (82) 40 (54) 60 (82) 60 (82) 60 (82) 40 (54) 60 (82) 60 (82) 60 (82) 40 (54) 105 (143) 105 (143) 105 (143) 105 (143) 105 (143) 105 (143) 105 (143) 105 (143) 140 (190) 170 (231) 170 (231) 220 (300) 140 (190) 170 (231) 170 (231) 220 (300) 240 (326) N/A 40 (54) 40 (54) 240 (326) N/A 40 (54) 40 (54) 340 (462) N/A 40 (54) 40 (54) 340 (462) N/A 40 (54) 40 (54) 460 (626) N/A 40 (54) 40 (54) 105 (143) N/A 40 (54) 40 (54) 105 (143) N/A 60 (82) 60 (82)

Size 2" 3 4 6 8 10 12 14" 16" 18" 20" 24" 30" 36"

*Torque values are for reference only and based on a nitrile binder synthetic gasket, 1/16" thick and unlubricated threads.

Page 5 of 16 The following guidelines should be observed at installation: WARNING: Groth Corporation's flame arresters have been tested by Factory Mutual Research. To maintain the approval classification, all arresters must be installed within 10 pipe diameters of the open end of the vent pipe or the potential ignition source. 1. Remove any flange protectors and discard all packing material. Inspect flange faces and flame element for damage or contamination. 2. Inspect the gasket seating surface of the tank nozzle or piping. It must be clean, flat, free of scratches, corrosion and tool marks. 3. Aluminum flame arresters are furnished with flat face flanges; they should only be installed on a mating flat face flange with a full face gasket. WARNING: Installation of an aluminum arrester in piping with raised face flanges can cause permanent distortion of the base flanges. This may result in vapor leakage at the flange connection. Adjacent piping must have appropriate structural support to prevent excessive loads on the flame arrester flanges. 4. Inspect the gasket; make sure that the material is suitable for the application. Center the gasket within the bolt circle. 5. Set the arrester between its mating flanges or on the nozzle. Position the lifting handles and jacking nuts to facilitate future removal of the flame arrester housing (See Maintenance Instructions section). Install the studs and tighten nuts hand tight. WARNING: The handles on the arrester housing are to be used for handling the element only during inspection and maintenance. DO NOT use the handles to lift the entire flame arrester assembly. Notes: When installing Model 7628 in the horizontal position, the eccentric portion of the housing must be positioned upward (See Page 14). In this position condensation will tend to move in the direction of flow and not collect in the element. Leave space behind mating pipe flange for insertion of studs, as there may not be sufficient space to insert studs from the flame arrester side.

6. Torque all fasteners to half the value listed in Table 2 in a staggered, alternating pattern to provide an evenly compressed gasket joint. 7. Make up the final torque and check that no further nut rotation occurs at the specified torque value.

Page 6 of 16 WARNING: After installation, all connections must be inspected for vapor leakage. This may be accomplished by static pressure test, gas detector, or "bubble" test using a liquid leak detector. III. MAINTENANCE For maximum operating efficiency the element of a flame arrester must be inspected for clogging at regular intervals. Frequency of inspection and maintenance should be based on the experience gained in each application. For ease of service, the flame element housing can be easily removed for inspection and maintenance without removing the arrester from the line. It is recommended that the arrester be removed for inspection of the element at least once per year or any time that one of the following conditions occurs: Excessive pressure drop is encountered at a known flow rate. A flame front is detected. Note: Flame arresters equipped with a steam jacket can not be serviced in-line. The arrester must be removed from the pipeline or tank nozzle for inspection and maintenance. 1. Purge the line or tank with an inert gas before attempting to remove the arrester for maintenance. CAUTION: The connecting pipeline must be free of all hazardous or flammable vapors before inspection procedures begin. Before disassembling consult Material Safety Data Sheets (MSDS) for all products that were exposed to in service. The components should be cleaned according to MSDS procedures. Take appropriate safety precautions regarding eye protection, skin contact & respiration. 2. Refer to Fig. 1 which illustrates a typical flame arrester with the element removed.

FIGURE 1 - TYPICAL MODEL 7618 FLAME ARRESTER

Page 7 of 16 3. Loosen the housing nuts and remove only those studs necessary to withdraw the housing. Do not remove studs with spreader nuts. WARNING: The handles on the arrester housing are to be used for handling the element only during inspection and maintenance. DO NOT use the handles to lift the entire flame arrester assembly. 4. If the flame arrester is in a horizontal line, attach whatever lifting equipment is required to remove the element [see weight table 3]. TABLE 3 - ELEMENT HOUSING WEIGHT [Lb. (kg)] Models 7618 / 7628 Size Aluminum Alum/SS Steel 2" 5 (2) 10 (5) 15 (7) 3" 10 (5) 10 (5) 20 (9) 4" 15 (7) 20 (9) 35 (16) 6" 30 (14) 45 (20) 75 (34) 8" 45 (20) 70 (32) 115 (52) 10" 70 (32) 110 (50) 175 (80) 12" 95 (43) 160 (73) 250 (114) 14 575 (261) 16 745 (339) 18 890 (405) Consult 20 1135 (516) Factory 24 1805 (820) 30 3095(1407) 36 4315(1961) TABLE 4 - FLAME ARRESTER ASSEMBLY WEIGHT [Lb. (kg)] Models 7618 Models 7628 Size 2" 3" 4" 6" 8" 10" 12" 14 16 18 20 24 30 36 Aluminum 15 (7) 25 (11) 40 (18) 80 (36) 130 (59) 200 (91) 285 (130) Alum/SS 20 (9) 30 (14) 45 (20) 100 (45) 155 (70) 245 (111) 345 (157) Steel 45 (70) 75 (34) 105 (48) 225 (102) 360 (164) 555 (252) 795 (361) 1110 (505) 1535 (698) 1765 (802) 2240(1018) 3360(1527) 5730(2605) 9240(4200) Size 2" 3" 4" 6" 8" 10" 12" 14 16 18 20 24 30 36 Aluminum 25 (11) 35 (16) 50 (23) 85 (39) 150 (68) 235 (107) 320 (125) Alum/SS 30 (14) 40 (18) 60 (27) 100 (45) 175 (80) 280 (127) 385 (175) Steel 70 (32) 95 (43) 105 (48) 225 (102) 360 (164) 555 (252) 795 (361) 1110 (505) 1535 (698) 1765 (802) 2240(1018) 3360(1527) 5730(2605) 9240(4200)

Consult Factory

Consult Factory

WARNING: If not supported, the element housing will drop onto the remaining studs when the bases are separated. Be careful to avoid contact with the housing while separating the bases.

Page 8 of 16 5. On the remaining studs, loosen the housing nuts incrementally while advancing the spreader nuts to separate the bases. When the bases are separated sufficiently to remove the housing, tighten the housing nuts so the bases form a rigid assembly when the housing is removed. 6. If a vertically mounted flame arrester is used to support a relief valve or similar equipment, tightening the housing nuts after separating the bases will provide sufficient support for the relief valve. 7. Remove the housing assembly for inspection. Visually inspect the flame element and supporting grids for damage or corrosion build-up from both sides. If the flame element appears to be damaged, it should be replaced immediately. WARNING: Failure to replace a damaged flame element can render the flame arrester ineffective 8. Verify that the element openings are not clogged by viewing a light source through the element passages. If the flame element is dirty or clogged it can be cleaned by one of the following methods: Compressed air High pressure steam or water purge Solvent wash followed by compressed air WARNING: Never try to clean the element by inserting a sharp tool or probe into the orifices. Any damage to the integrity of these passages can render the flame arrester ineffective. CAUTION: If compressed air, steam, or high pressure water jet is used to clean clogged element passageways, restrict access to the area to prevent injury from blown debris exiting the element. Use appropriate personal safety equipment for the cleaning method used. TIP: The best method of cleaning and frequency should be based on the experience gained in each application. 9. Inspect the sealing gasket for damage and replace if necessary. (See Table 6 for replacement gasket part numbers. 10. Install a gasket in the counter bore of each base. Position the element housing to align with the counterbores. Insert the studs and torque all fasteners to half the value listed in Table 2 in a staggered, alternation pattern to provide an evenly compressed gasket joint. If the arrester is in high temperature service or stainless steel external studs and nuts are used, apply an anti-seize compound such as moly-disulfide to all threaded components. 11. Make up the final torque and check that no further nut rotation occurs at the specified torque value. The torque values are based on original gaskets supplied by Groth Corporation.

Page 9 of 16 IV. SPARE PARTS Flame Bank Kits are available upon request. Kits include the flame arrester element and two nonasbestos gaskets. Kits are based on Model Number, Size, and Material. The kits only apply to valves manufactured since 1992; consult factory for sizes greater than 12. To procure appropriate kit, please contact Groth Corporation with the Serial Number, Model Number, Size, and Material.

Size 2 3 4 6 8 10 12 2 3 4 6 8 10 12 2 3 4 6

Housing Material Aluminum Aluminum Aluminum Aluminum Aluminum Aluminum Aluminum Aluminum Aluminum Aluminum Aluminum Aluminum Aluminum Aluminum Carbon Steel Carbon Steel Carbon Steel Carbon Steel

TABLE 5 FLAME BANK ASSEMBLY KITS Element Housing Material Kit P/N Size Material Aluminum KFB76180211 8 Carbon Steel Aluminum KFB76180311 10 Carbon Steel Aluminum KFB76180411 12 Carbon Steel Aluminum KFB76180611 2 Carbon Steel Aluminum KFB76180811 3 Carbon Steel Aluminum KFB76181011 4 Carbon Steel Aluminum KFB76181211 6 Carbon Steel 316 SS KFB76180215 8 Carbon Steel 316 SS KFB76180315 10 Carbon Steel 316 SS KFB76180415 12 Carbon Steel 316 SS KFB76180615 2 316 SS 316 SS KFB76180815 3 316 SS 316 SS KFB76181015 4 316 SS 316 SS KFB76181215 6 316 SS Aluminum KFB76180231 8 316 SS Aluminum KFB76180331 10 316 SS Aluminum KFB76180431 12 316 SS Aluminum KFB76180631

Element Material Aluminum Aluminum Aluminum 316 SS 316 SS 316 SS 316 SS 316 SS 316 SS 316 SS 316 SS 316 SS 316 SS 316 SS 316 SS 316 SS 316 SS

Kit P/N KFB76180831 KFB76181031 KFB76181231 KFB76180235 KFB76180335 KFB76180435 KFB76180635 KFB76180835 KFB76181035 KFB76181235 KFB76180255 KFB76180355 KFB76180455 KFB76180655 KFB76180855 KFB76181055 KFB76181255

TABLE 6 - GASKET KIT PART NUMBERS Size Part No. Size Part No. 2 KS761802 14 KS761814 3 KS761803 16 KS761816 4 KS761804 18 KS761818 6 KS761806 20 KS761820 8 KS761808 24 KS761824 10 KS761810 30 KS761830 12 KS761812 36 KS761836 Synthetic Non-Asbestos Fiber sheet material with a nitrile binder. For special applications or chemical compatibility please contact factory.

Page 10 of 16 V. MODEL NUMBER IDENTIFICATION The nameplate on the Flame Arrester contains the Model Number, Serial Number, set pressures and flow capacity at a specified over-pressure. The Model Number contains additional information about materials of construction, soft goods and options. The following chart will assist in relating the Model Number to the characteristics of your valve: ----------------------

7618 7628

02 03 04 06 08 10 12 14 16 18 20 24 30 36

Element 1=Aluminum Body 5=316 SS 1=Aluminum Z=Special 3=CS 5=316 SS Z=Special

O = No Specials Z = Special Option O = No Jacket J = Steam Jacket

F = Flanged Outlet W = Weatherhood

EXAMPLE: Model 7618-04-11-FOO indicates a 4 Model 7618 with an Aluminum body an Aluminum flame element, flanged inlet/outlet connections, and no special options.

Page 11 of 16

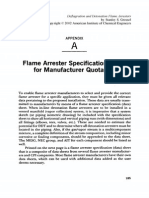

APPENDIX A: Model 7618 Flame Arrester (2-12)

ITEM 1 2 3 4 5 6 7 8 9 10 11 12 13

* *

STANDARD MATERIALS OF CONSTRUCTION ALUMINUM CARBON STL 316 SS BASE AL (356 T6) CS (WCB) 316 SS (CF-8M) HANDLE ALUM CS SS SPREADER HEX NUT SS SS SS HEX NUT SS SS SS STUD SS SS SS ELEMENT PLUG SS SS 303 SS ELEMENT ROD SS SS 316 SS ELEMENT GRID ALUM 316 SS 316 SS ELEMENT HOUSING ALUM CS 316 SS PIPE PLUG (OPTIONAL) ALUM CS 316 SS COUPLING (OPTIONAL) ALUM CS 316 SS GASKET NON-ASB NON-ASB NON-ASB FLAME ELEMENT ALUM (1) 316 SS 316 SS (1) Available in 316 SS * Recommended Spare Parts

DESCRIPTION

Page 12 of 16

APPENDIX B: Model 7618 End-of-Line Flame Arrester (2-12)

ITEM 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

* *

STANDARD MATERIALS OF CONSTRUCTION ALUMINUM CARBON STL 316 SS BASE AL (356 T6) CS (WCB) 316 SS (CF-8M) HANDLE ALUM CS SS HEX NUT SS SS SS STUD SS SS SS ELEMENT PLUG SS SS 303 SS ELEMENT ROD SS SS 316 SS ELEMENT GRID ALUM 316 SS 316 SS ELEMENT HOUSING ALUM CS 316 SS COUPLING (OPTIONAL) ALUM CS 316 SS PIPE PLUG (OPTIONAL) ALUM CS 316 SS GASKET NON-ASB NON-ASB NON-ASB FLAME ELEMENT ALUM (1) 316 SS 316 SS EYE NUT CS CS 316 SS HEX NUT SS SS SS WEATHERHOOD ALUM CS 316 SS BIRD SCREEN SS SS SS ADAPTER PLATE CS CS 316 SS (1) Available in 316 SS * Recommended Spare Parts

DESCRIPTION

Page 13 of 16

APPENDIX C: Model 7618 Flame Arrester (14-36)

ITEM 1 2 3 4 5 6 7 8 9 10 11 12 13

* *

STANDARD MATERIALS OF CONSTRUCTION ALUMINUM CARBON STL 316 SS BASE AL (356 T6) CS (WCB) 316 SS (CF-8M) SPACER ALUM CS 316 SS FLAME ELEMENT ALUM (1) 316 SS 316 SS ELEMENT HOUSING ALUM CS 316 SS STUD SS SS SS HEX NUT SS SS SS ELEMENT GRID ALUM 316 SS 316 SS ELEMENT SHAFT SS SS 316 SS GASKET NON-ASB NON-ASB NON-ASB LIFTING LUG ALUM CS 316 SS PIPE PLUG (OPTIONAL) ALUM CS 316 SS COUPLING (OPTIONAL) ALUM CS 316 SS SPREADER HEX NUT SS SS SS (1) Available in 316 SS * Recommended Spare Parts

DESCRIPTION

Page 14 of 16

APPENDIX D: Model 7628 Flame Arrester (2-12)

ITEM 1 2 3 4 5 6 7 8 9 10 11 12 13

* *

STANDARD MATERIALS OF CONSTRUCTION ALUMINUM CARBON STL 316 SS BASE AL (356 T6) CS (WCB) 316 SS (CF-8M) GASKET NON-ASB NON-ASB NON-ASB FLAME ELEMENT ALUM (1) 316 SS 316 SS ELEMENT PLUG SS SS 303 SS ELEMENT ROD SS SS 316 SS HANDLE ALUM CS SS SPREADER HEX NUT SS SS SS PIPE PLUG (OPTIONAL) ALUM CS 316 SS HEX NUT SS SS SS STUD SS SS SS COUPLING (OPTIONAL) ALUM CS 316 SS ELEMENT GRID ALUM 316 SS 316 SS ELEMENT HOUSING ALUM CS 316 SS (1) Available in 316 SS * Recommended Spare Parts

DESCRIPTION

Page 15 of 16

APPENDIX E: Model 7628 Flame Arrester (14-36)

ITEM 1 2 3 4 5 6 7 8 9 10 11 12 * *

STANDARD MATERIALS OF CONSTRUCTION ALUMINUM CARBON STL 316 SS ELEMENT HOUSING ALUM CS 316 SS BASE AL (356 T6) CS (WCB) 316 SS (CF-8M) FLAME ELEMENT ALUM (1) 316 SS 316 SS COUPLING (OPTIONAL) ALUM CS 316 SS RETAINER ELEMENT ALUM 316 SS 316 SS ELEMENT SHAFT SS 316 SS 316 SS STUD SS SS SS HEX NUT SS SS SS GASKET NON-ASB NON-ASB NON-ASB LIFTING LUG ALUM CS 316 SS PIPE PLUG (OPTIONAL) ALUM CS 316 SS GUIDE ROLLER ALUM CS 316 SS (1) Available in 316 SS * Recommended Spare Parts

DESCRIPTION

Page 16 of 16

Vous aimerez peut-être aussi

- Valve Philosophy Valve Application GeneralDocument3 pagesValve Philosophy Valve Application GeneralWade ColemanPas encore d'évaluation

- Peco Filter CaseDocument11 pagesPeco Filter CaseLuis MaureraPas encore d'évaluation

- E07 QDocument20 pagesE07 QSoledad Fernández SantosPas encore d'évaluation

- Dokumen - Tips Gas Filtration Products Absolute 2015-09-04 Gas Filtration ProductsDocument28 pagesDokumen - Tips Gas Filtration Products Absolute 2015-09-04 Gas Filtration ProductsCorne SalcedoPas encore d'évaluation

- Coalescer PallDocument16 pagesCoalescer PallJeEJyZaPas encore d'évaluation

- 3.0 Systems Division-FiltersDocument8 pages3.0 Systems Division-Filtersmatteo2009Pas encore d'évaluation

- Quick Open ClosureDocument12 pagesQuick Open ClosurecliffrajjoelPas encore d'évaluation

- 6-76-0002 Bolt Tension For FlangesDocument33 pages6-76-0002 Bolt Tension For Flangesrovergamma100% (1)

- BHMN Valve Sizing HandbookDocument30 pagesBHMN Valve Sizing Handbookdj22500Pas encore d'évaluation

- Floating and Trunnion Ball Valves PDFDocument15 pagesFloating and Trunnion Ball Valves PDFAlienshowPas encore d'évaluation

- FRP Flange DesignDocument29 pagesFRP Flange DesignSubhadip RoyPas encore d'évaluation

- Smart Trap PDFDocument2 pagesSmart Trap PDFdmitos100% (1)

- Flame Arrester - Technical DetailsDocument16 pagesFlame Arrester - Technical DetailsAnonymous 3DHogIPas encore d'évaluation

- SA 980 P 11432 CS Globe Valve Rev T02Document3 pagesSA 980 P 11432 CS Globe Valve Rev T02altipatlarPas encore d'évaluation

- Ansi Valve Leakage Standards Gemco ValveDocument1 pageAnsi Valve Leakage Standards Gemco ValvenithyaPas encore d'évaluation

- Polyacrylamide Plant: Mechanical Datasheet For Steam TrapsDocument2 pagesPolyacrylamide Plant: Mechanical Datasheet For Steam Trapsbecpavan100% (1)

- Integrity Testing of Water Filtration Membrane Systems: Standard Practice ForDocument14 pagesIntegrity Testing of Water Filtration Membrane Systems: Standard Practice ForOh No PotatoPas encore d'évaluation

- Minimum Submergence Required For Vortex Breaker - Industrial Professionals - Cheresources - Com CommunityDocument7 pagesMinimum Submergence Required For Vortex Breaker - Industrial Professionals - Cheresources - Com CommunitySHIPas encore d'évaluation

- Piping Class - AS20Document2 pagesPiping Class - AS20Дмитрий РыбаковPas encore d'évaluation

- Mechanical RegulatorDocument12 pagesMechanical Regulatorshashi chaugulePas encore d'évaluation

- B A S Ket Strainer Pressure Drop-LiquidsDocument4 pagesB A S Ket Strainer Pressure Drop-LiquidsguillemaraPas encore d'évaluation

- Monolithic Insulated Joint BrochureDocument8 pagesMonolithic Insulated Joint Brochuremarita_msPas encore d'évaluation

- Flame ArresterDocument2 pagesFlame ArresterAariz KhanPas encore d'évaluation

- Dp&T-Sup Centrifugal Pumps Specification: 0 Original IssueDocument19 pagesDp&T-Sup Centrifugal Pumps Specification: 0 Original IssueAllyson LisboaPas encore d'évaluation

- L&T Ball ValveDocument12 pagesL&T Ball ValvecdsenthilPas encore d'évaluation

- Pipe Material For OxygenDocument3 pagesPipe Material For Oxygenc_pythonPas encore d'évaluation

- Seprasol Plus: Liquid/Gas CoalescersDocument4 pagesSeprasol Plus: Liquid/Gas CoalescersSiavash YarahmadiPas encore d'évaluation

- Thermal Degassing Fundamentals R4i1 enDocument6 pagesThermal Degassing Fundamentals R4i1 enAnonymous v5uipHPas encore d'évaluation

- Butterfly ValvesDocument6 pagesButterfly ValvestezgidenPas encore d'évaluation

- Vane Separator (Brochure PEERLESSMFG)Document6 pagesVane Separator (Brochure PEERLESSMFG)Julio OrtegaPas encore d'évaluation

- Orifice Plate Showing VenaDocument6 pagesOrifice Plate Showing VenahugepotatoPas encore d'évaluation

- Special Closures Literature2Document2 pagesSpecial Closures Literature2ruben'sPas encore d'évaluation

- Safety Valve Technical DetailsDocument5 pagesSafety Valve Technical DetailsvineethvskkdPas encore d'évaluation

- Sparta Engineering Cold Temp Verification CalculatorDocument8 pagesSparta Engineering Cold Temp Verification CalculatorAksheyPas encore d'évaluation

- Flame ArrestorDocument10 pagesFlame ArrestorAdnan Khan100% (1)

- 02 Samss 006Document17 pages02 Samss 006inatt101Pas encore d'évaluation

- Instrument Alarms, Trips and Set Points List: 0 1980 RPM 1980 RPM VAIDocument1 pageInstrument Alarms, Trips and Set Points List: 0 1980 RPM 1980 RPM VAInastyn-1Pas encore d'évaluation

- FAUDI Aviation Diesel - Products-ENDocument25 pagesFAUDI Aviation Diesel - Products-ENAttila HontváriPas encore d'évaluation

- Equivalent PressureDocument1 pageEquivalent PressureSarfaraz KhanPas encore d'évaluation

- Ksi PietroDocument4 pagesKsi PietroJohn F Diaz HPas encore d'évaluation

- Datasheet For Side Entry MixerDocument4 pagesDatasheet For Side Entry Mixervinoj chandranPas encore d'évaluation

- Datasheet For Vent ScrubberDocument5 pagesDatasheet For Vent ScrubbercliffrajjoelPas encore d'évaluation

- Bleed or Drip RingDocument2 pagesBleed or Drip RingAnonymous 6ZWS6IG2J9Pas encore d'évaluation

- Flame Arrester GuideDocument6 pagesFlame Arrester GuideNigin ParambathPas encore d'évaluation

- E 106Document1 pageE 106Bith SMGPas encore d'évaluation

- Selamat Datang: Venting of Atmospheric and Low-Pressure Storage Tanks - ISO 28300Document67 pagesSelamat Datang: Venting of Atmospheric and Low-Pressure Storage Tanks - ISO 28300Krishna N HPas encore d'évaluation

- Pig Receiver Data Sheet 91303 - 8 InchDocument4 pagesPig Receiver Data Sheet 91303 - 8 InchSinaPas encore d'évaluation

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument5 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodPas encore d'évaluation

- ETL Pressure Relief Valves Datasheet PDFDocument6 pagesETL Pressure Relief Valves Datasheet PDFNanasaheb PatilPas encore d'évaluation

- Crosby SizingDocument89 pagesCrosby SizingNattapong Pongboot100% (1)

- Cone Design ToolDocument1 pageCone Design ToolPramod KumarPas encore d'évaluation

- EHB en 7.5 Sizing According To ISO 4126 1Document10 pagesEHB en 7.5 Sizing According To ISO 4126 1XpizmonPas encore d'évaluation

- ABO Ball ValveDocument6 pagesABO Ball ValveSunil BajpaiPas encore d'évaluation

- CPA 50E Type A RF Dimensional Specifications - May 2013Document1 pageCPA 50E Type A RF Dimensional Specifications - May 2013Karthick RamasubramanianPas encore d'évaluation

- Groth 7618 7628Document16 pagesGroth 7618 7628Julian GaleanoPas encore d'évaluation

- Omega Elastomeric Couplings - Installation ManualDocument2 pagesOmega Elastomeric Couplings - Installation ManualmmkattaPas encore d'évaluation

- ATS73 Maint ManDocument12 pagesATS73 Maint Manpr_oilPas encore d'évaluation

- Automation PVT LTD.: Fugitive Emission: Installation, Operation, Maintenance & Safety ManualDocument11 pagesAutomation PVT LTD.: Fugitive Emission: Installation, Operation, Maintenance & Safety ManualDanielle JohnsonPas encore d'évaluation

- 390 InstructionsDocument48 pages390 InstructionsemaanazeemPas encore d'évaluation

- s05nmdl2sm PDFDocument22 pagess05nmdl2sm PDFmn_aminPas encore d'évaluation

- PolyesterDocument2 pagesPolyesteriran1362Pas encore d'évaluation

- ºF ºC ºF ºC Lower Limit Upper Limit Color Code MaterialDocument1 pageºF ºC ºF ºC Lower Limit Upper Limit Color Code Materialiran1362Pas encore d'évaluation

- 319 ElcometerDocument5 pages319 Elcometeriran1362Pas encore d'évaluation

- HSE. Chloride Stress Corrosion Cracking in Austenitic Stainless SteelDocument62 pagesHSE. Chloride Stress Corrosion Cracking in Austenitic Stainless Steelfallalovaldes100% (1)

- Limits of Detection: Handheld XRF AnalyzersDocument2 pagesLimits of Detection: Handheld XRF AnalyzersDede RismunandarPas encore d'évaluation

- ºF ºC ºF ºC Lower Limit Upper Limit Color Code MaterialDocument1 pageºF ºC ºF ºC Lower Limit Upper Limit Color Code Materialiran1362Pas encore d'évaluation

- HB MehlDocument5 pagesHB Mehliran1362Pas encore d'évaluation

- A FastenerTorqueChartsDocument2 pagesA FastenerTorqueChartsMuhammad JawadPas encore d'évaluation

- Vulcoferran 2190Document2 pagesVulcoferran 2190iran13620% (1)

- Piping Engineer BookDocument107 pagesPiping Engineer BookMiguel Angel GrimaldoPas encore d'évaluation

- Installation Manual SPS Heat Exchanger - UKDocument8 pagesInstallation Manual SPS Heat Exchanger - UKiran1362Pas encore d'évaluation

- Aramid FibersDocument6 pagesAramid Fibersiran1362Pas encore d'évaluation

- Epoxy ChalkingDocument2 pagesEpoxy Chalkingiran1362100% (1)

- Industrial DrawingDocument3 pagesIndustrial Drawingiran1362Pas encore d'évaluation

- Stress Corrosion CrackingDocument16 pagesStress Corrosion CrackingzaxaderPas encore d'évaluation

- Atlas Grade Datasheet 2205 Rev May 2008Document2 pagesAtlas Grade Datasheet 2205 Rev May 2008timparker01Pas encore d'évaluation

- Shell and Tube Heat Exchangers StandardsDocument50 pagesShell and Tube Heat Exchangers Standardsiran1362Pas encore d'évaluation

- Boedeker Plastics - PTFE, FEP, and PFA DatasheetDocument3 pagesBoedeker Plastics - PTFE, FEP, and PFA Datasheetiran1362Pas encore d'évaluation

- HSE. Chloride Stress Corrosion Cracking in Austenitic Stainless SteelDocument62 pagesHSE. Chloride Stress Corrosion Cracking in Austenitic Stainless Steelfallalovaldes100% (1)

- Shell & Tube Installation, Operation & Maintenance ManualDocument14 pagesShell & Tube Installation, Operation & Maintenance Manualnidhul07Pas encore d'évaluation

- Tube PlugDocument14 pagesTube PluggshdavidPas encore d'évaluation

- Product Information: Chemonit 31 (NR)Document4 pagesProduct Information: Chemonit 31 (NR)iran1362Pas encore d'évaluation

- Steam Trap Part 6Document3 pagesSteam Trap Part 6iran1362Pas encore d'évaluation

- Catalog Steam TrapDocument6 pagesCatalog Steam Trapiran1362Pas encore d'évaluation

- Steam Trap Part 8Document1 pageSteam Trap Part 8iran1362Pas encore d'évaluation

- Steam Trap Part 7Document2 pagesSteam Trap Part 7iran1362Pas encore d'évaluation

- Steam Trap Part 2Document2 pagesSteam Trap Part 2iran1362Pas encore d'évaluation

- Steam Trap Part 3Document2 pagesSteam Trap Part 3iran1362Pas encore d'évaluation

- Steam Trap Part 5Document2 pagesSteam Trap Part 5iran1362Pas encore d'évaluation

- Steam Trap Part 1Document4 pagesSteam Trap Part 1iran1362Pas encore d'évaluation

- An Analytical Study On Impact of Credit Rating Agencies in India 'S DevelopmentDocument14 pagesAn Analytical Study On Impact of Credit Rating Agencies in India 'S DevelopmentRamneet kaur (Rizzy)Pas encore d'évaluation

- Stryker Endoscopy SDC Pro 2 DVDDocument2 pagesStryker Endoscopy SDC Pro 2 DVDWillemPas encore d'évaluation

- West Bengal Joint Entrance Examinations Board: Provisional Admission LetterDocument2 pagesWest Bengal Joint Entrance Examinations Board: Provisional Admission Lettertapas chakrabortyPas encore d'évaluation

- Chinaware - Zen PDFDocument111 pagesChinaware - Zen PDFMixo LogiPas encore d'évaluation

- IMO Special Areas Under MARPOLDocument2 pagesIMO Special Areas Under MARPOLRavi Viknesh100% (1)

- 13 - Conclusion and SuggestionsDocument4 pages13 - Conclusion and SuggestionsjothiPas encore d'évaluation

- Statement 1577731252322 PDFDocument11 pagesStatement 1577731252322 PDFPriyanka ParidaPas encore d'évaluation

- The Perceived Barriers and Entrepreneurial Intention of Young Technical ProfessionalsDocument6 pagesThe Perceived Barriers and Entrepreneurial Intention of Young Technical ProfessionalsAnatta OngPas encore d'évaluation

- A88438-23 Critical Procedure 11-01 - Pipeline Cut Outs - A5X9W9Document7 pagesA88438-23 Critical Procedure 11-01 - Pipeline Cut Outs - A5X9W9mahmoudPas encore d'évaluation

- Notes On Mass and Energy Balances For Membranes 2007 PDFDocument83 pagesNotes On Mass and Energy Balances For Membranes 2007 PDFM TPas encore d'évaluation

- Newton Gauss MethodDocument37 pagesNewton Gauss MethodLucas WeaverPas encore d'évaluation

- Risk, Return & Capital BudgetingDocument18 pagesRisk, Return & Capital BudgetingMuhammad Akmal HussainPas encore d'évaluation

- Price Action Trading Strategies - 6 Patterns That Work (Plus Free Video Tutorial)Document22 pagesPrice Action Trading Strategies - 6 Patterns That Work (Plus Free Video Tutorial)kalpesh kathar100% (1)

- Instructions For The Safe Use Of: Web LashingsDocument2 pagesInstructions For The Safe Use Of: Web LashingsVij Vaibhav VermaPas encore d'évaluation

- 25 - Marketing Channels - Value Networks.Document2 pages25 - Marketing Channels - Value Networks.zakavision100% (1)

- VKC Group of Companies Industry ProfileDocument5 pagesVKC Group of Companies Industry ProfilePavithraPramodPas encore d'évaluation

- Latifi LAMY Catalog 2013 PDFDocument76 pagesLatifi LAMY Catalog 2013 PDFWang LinusPas encore d'évaluation

- Basic Details: Government Eprocurement SystemDocument4 pagesBasic Details: Government Eprocurement SystemNhai VijayawadaPas encore d'évaluation

- (Rajagopal) Brand Management Strategy, Measuremen (BookFi) PDFDocument317 pages(Rajagopal) Brand Management Strategy, Measuremen (BookFi) PDFSneha SinghPas encore d'évaluation

- Tavera Vs Valdez 1 Phil 468Document2 pagesTavera Vs Valdez 1 Phil 468John AmbasPas encore d'évaluation

- Surface News - 20130704 - Low Res PDFDocument9 pagesSurface News - 20130704 - Low Res PDFYoko GoldingPas encore d'évaluation

- UNECE-Turkey-TCDO-Rail Freight Traffic in Euro-Asian LinksDocument20 pagesUNECE-Turkey-TCDO-Rail Freight Traffic in Euro-Asian LinksArsenePas encore d'évaluation

- Solar Power Plant in Iit HyderabadDocument9 pagesSolar Power Plant in Iit HyderabadHimanshu VermaPas encore d'évaluation

- Bid Evaluation Report Sample TemplateDocument2 pagesBid Evaluation Report Sample Templatemarie100% (8)

- Book Notes Covering: Andy Kirk's Book, Data Visualization - A Successful Design ProcessDocument10 pagesBook Notes Covering: Andy Kirk's Book, Data Visualization - A Successful Design ProcessDataVersed100% (1)

- Dolby Atmos Specifications PDFDocument24 pagesDolby Atmos Specifications PDFVanya ValdovinosPas encore d'évaluation

- Radix Sort - Wikipedia, The Free EncyclopediaDocument13 pagesRadix Sort - Wikipedia, The Free EncyclopediasbaikunjePas encore d'évaluation

- Grant Miller Resume-ColliersDocument3 pagesGrant Miller Resume-ColliersDeven GriffinPas encore d'évaluation

- Tourism: The Business of Hospitality and TravelDocument33 pagesTourism: The Business of Hospitality and TravelNajla Nabila AurelliaPas encore d'évaluation

- God Save The Queen Score PDFDocument3 pagesGod Save The Queen Score PDFDarion0% (2)