Académique Documents

Professionnel Documents

Culture Documents

Battery Saver

Transféré par

sof009Description originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Battery Saver

Transféré par

sof009Droits d'auteur :

Formats disponibles

Cordless Power Tool Batteries and other batteries that contain Nickel Cadmium (N iCd) Cells can be Re-Conditioned

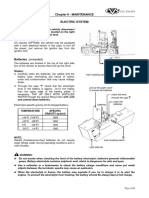

to perform as well as new or even better than new. Proper maint enance after the procedure will insure years of usable life. The First and most common procedure for Re-Conditioning a NiCd cell is by using a Technique called "VOLTAGE SURGING". Over time the crystals within a NiCd cell begin to co mbine and get larger. This causes them to loose capacitance and also break through the inner seals of the cell. Surging the NiCd cell using a higher voltage causes the crystals within the NiCd cell to shatter and become smaller. These smaller crystals have a greater surface area and therefor e contain a greater capacitance for energy. Crystals primarily grow larger during "OVER CHARGING". Over Charging is the enemy of a NiCd Cells so Remember to leave your batteries on the charger for only the minimum charging time OR LESS! This is usually an hour or less for Rapid Charge rs or 2 to 4 hrs for standard chargers. It is also best to only charge your batteries immediatel y before you use them. Storing your batteries with a full charge encourages crystal growth. Storing y our batteries on a low charge , but not dead, is best. To keep crystal growth under control, you must also perform the surge process below once every 3 months to keep you NiCd battery at its peak. F ollow these maintenance techniques to insure years of dependable use. The "VOLTAGE SURGING" Technique below may be repeated until the battery holds a dependable charge but wait at least 15 minutes between "SURGING" to allow for the vapors wi thin the cell to cool. Surging the battery without waiting will result in the cell EXPLODING! Mo st batteries will only require one or two "VOLTAGE SURGES" but extremely damaged cells may take up to 2 0 surges. For batteries up to 9.6 volts you will want to run two wires from a good 12 volt battery, such as a car battery or two 6 volt lantern batteries run in series. use like size cells and n ot a combination. Clamp the ground wire from the car battery to the negative side of the tool battery. Small alligator clamps work good for this application. The positive terminal on the tool battery is us ually golden in color and the negative is usually silver in color. Use a voltage meter to be sure. O ne end of the positive wire should be rigidly attached to the car battery and the other end of the posi tive wire should be stripped at the end. Then simply tap the stripped end of the positive wire agai nst the positive terminal on the tool battery for about 10 seconds tapping rapidly at a rate of 2 to 3 times per second. See charts below for exact recommended "SURGE TIME" for your battery pack size and your specific power source voltage. Check the voltage of the tool battery with a volt

age tester and if it does not give a voltage equal to or slightly higher than the tool batteries rate d voltage, then repeat these steps for a few more seconds until it does (waiting 15 minutes between sur ges). See Fig. A. For batteries of 9.7 volts to 19.9 volts you will need at least 24 volts. Four 6 volt lantern batteries run in series also works. It is also possible to use other tool batteries wired together in series as a power source, but if you are using two 18 volt tool batteries in series you will generate 36 volts and 10 seconds will be to long. Shorten re-conditioning process to 6 or 7 seconds. You can also use 2-18 volt tool batteries in series for re-conditioning 24 volt tool batteries. Using other DC power sources such as welders and battery chargers can also be used for the "VOLTAGE S URGING" but small transformers won't work because they don't deliver enough amps. Use lamp cord thickness wire or larger and always use safety goggles! STEP BY STEP INSTRUCTIONS 1.) Using a voltage tester, determine the polarity of your battery (pos. & neg.) 2.) Use Tables E, F & G to determine the "Surge Time" for your particular battery size and power source. 3.) 'TapZap' your battery for the suggested time and allow to cool for 15 minutes. Then place on charger for 15 minutes. It may work again. 4.) After a short charging let the battery sit. After sitting 1hour check the voltage to see if it is slowly draining. A slow drain will indicate a short. 5.) If battery fails to charge, or hold a charge then repeat steps 3 & 4. This process can be repeated up to 25 times. The previous Re-Conditioning method will work 90% of the time but occasionally a battery will still not retain its rated voltage. For those of you who are mechanically inclined, there is another option. Remove the battery cell cluster as shown in Fig. C. Test each individual cell f or voltage with a voltage tester. If an individual cell fails to register at least one volt, that particu lar cell will need to be Re-Conditioned. There may be a fibrous insulator on top and/or bottom of the cells that will need to be drilled to reach the individual cells, but do not drill into the battery c ells themselves! NOTE: Each cell will have to be tested for Polarity (+ or -), the cells are rot ated so the positive end of the cell on some will be facing up and others will be facing down. Once you locate the bad cell(s) use a 12 volt car battery to Re-Condition the individual cell by holding

the Negative wire to the Negative side of the cell and then hold the Positive wire to the Positive side o f the cell for 2 to 3 seconds, but no longer. Repeat this process for each cell that doesn't register at least on volt. This process will work on 18v and 24v batteries as well as lower voltages becaus e the individual cells are the same. Another Method for Re-conditioning NiCd cells that is still in development is th e Freeze Technique. We are finding that some batteries that do not respond to the surging technique respond to the Freeze Technique. This is a simple procedure. All you have to do is freeze your batte ry pack in the freezer for 1 hour and then rapidly tap the bottom of the battery pack with something like t he but end of a screwdriver for about a minute. The freezing of the internal crystals makes the m more fragile and the vibration physically breaks them apart. This is hard on the cells and should on ly be performed after the surge process has failed. After you have tapped on the battery pack immedia tely place the battery back in your tool and turn it on. It won't work much because the pack is still frozen but putting a load on the battery in this condition will encourage the internal crystal structure t o break apart, which is good! Single cell batteries like A,AA,B,C and D batteries have been shown to re spond well to this technique using a hammer and giving the butt end of the battery a good solid hit , but not too hard as to break the battery housing. If you attempt to surge your batteries 20 times and then freeze your battery 5 t imes and you are still not getting your battery to charge then you are either performing the process improp erly or your batteries are just too far gone. One of the most common reasons for failure is improper p olarity surging. If you surge the battery backwards this process will not work.

Vous aimerez peut-être aussi

- Marine Electrics Made Simple or How to Keep the Batteries ChargedD'EverandMarine Electrics Made Simple or How to Keep the Batteries ChargedPas encore d'évaluation

- YSUUSYs NiCd Battery RepairDocument6 pagesYSUUSYs NiCd Battery Repairrwesseldyk50% (2)

- Battery Ezy FixDocument6 pagesBattery Ezy FixArnaud LafichePas encore d'évaluation

- Se Batteries UpDocument5 pagesSe Batteries Upbasheer almetwakelPas encore d'évaluation

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaD'EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaPas encore d'évaluation

- Battery LifeDocument7 pagesBattery LifecvbnPas encore d'évaluation

- HTTPS: - Static - Secure.website - Wscfus - 1295322 - 9402876 - Se-Batteries-Up PDFDocument5 pagesHTTPS: - Static - Secure.website - Wscfus - 1295322 - 9402876 - Se-Batteries-Up PDFبشير المتوكلPas encore d'évaluation

- SIS-Preventive Maintenance For BatteriesDocument2 pagesSIS-Preventive Maintenance For BatteriesmkPas encore d'évaluation

- Murray Electrical From MA-S-1612 2004 Quick ReferenceDocument35 pagesMurray Electrical From MA-S-1612 2004 Quick ReferenceleowccheungPas encore d'évaluation

- General Installation Commissioning Guidelines For VRLA Batteries - 0Document3 pagesGeneral Installation Commissioning Guidelines For VRLA Batteries - 0PrashantKumar100% (1)

- Battery Desulfator 12vDocument11 pagesBattery Desulfator 12vAnonymous hndaj8zCA100% (1)

- How To Repair A Dead Laptop BatteryDocument6 pagesHow To Repair A Dead Laptop BatteryLouR2011Pas encore d'évaluation

- GmdssDocument5 pagesGmdssВалера СтариковPas encore d'évaluation

- 12VAC, 500ma Circuit For 12V SLA Battery ChargerDocument5 pages12VAC, 500ma Circuit For 12V SLA Battery ChargerrdbassesPas encore d'évaluation

- Automatic Battery Charger CircuitDocument10 pagesAutomatic Battery Charger CircuitNisar AhmedPas encore d'évaluation

- New Battery InstructionsDocument2 pagesNew Battery InstructionsRichy MatherPas encore d'évaluation

- Jump Start A Dead Laptop Battery 3 MethodsDocument3 pagesJump Start A Dead Laptop Battery 3 MethodsHugh Ell - auPas encore d'évaluation

- tsb02 13 03 PDFDocument8 pagestsb02 13 03 PDFTOSHAPas encore d'évaluation

- Battery Charging Guide - 6 VoltDocument5 pagesBattery Charging Guide - 6 VoltKidus DawitPas encore d'évaluation

- Battery Cross RefDocument130 pagesBattery Cross ReftorjanicePas encore d'évaluation

- Model: BT-250 Digital Battery Tester: Owners Manual For 12 Volt BatteriesDocument7 pagesModel: BT-250 Digital Battery Tester: Owners Manual For 12 Volt BatteriesmaungPas encore d'évaluation

- Installation, Operation and Maintenance of BatteriesDocument48 pagesInstallation, Operation and Maintenance of Batteriessiva74481630% (1)

- Makita BatteryDocument80 pagesMakita BatteryΒΑΣΙΛΕΙΟΣ ΒΑΣΙΛΑΚΗΣPas encore d'évaluation

- Battery-Guide Glo EngDocument21 pagesBattery-Guide Glo EngMd Rodi BidinPas encore d'évaluation

- Automotive Electrical and Electronics EngineeringDocument5 pagesAutomotive Electrical and Electronics EngineeringKarthik SwaminathanPas encore d'évaluation

- Battery Protector Cut Out Switch With ATtiny85 ForDocument13 pagesBattery Protector Cut Out Switch With ATtiny85 Forapo katsaroPas encore d'évaluation

- Batteries: Tests and Checks Mariners Must KnowDocument11 pagesBatteries: Tests and Checks Mariners Must KnowKalaivani PeriyasamyPas encore d'évaluation

- GMDSS Batteries Tests and Checks Mariners Must KnowDocument9 pagesGMDSS Batteries Tests and Checks Mariners Must KnowKunal Singh100% (2)

- Report On Repairing of Batteries'Document7 pagesReport On Repairing of Batteries'LETVANGLEN CHONGLOIPas encore d'évaluation

- UnionBattery 2000mahDocument6 pagesUnionBattery 2000mahOprita Cristescu AlinaPas encore d'évaluation

- 3 Dollar Battery ChargerDocument6 pages3 Dollar Battery ChargerbelmopanPas encore d'évaluation

- Sun Xtender Battery Owners ManualDocument2 pagesSun Xtender Battery Owners ManualRhetWyliePas encore d'évaluation

- KH 967 Universal Battery Charger: Operating ManualDocument10 pagesKH 967 Universal Battery Charger: Operating ManualchaparipPas encore d'évaluation

- Battery Replacement GuideDocument4 pagesBattery Replacement Guidest_vasuPas encore d'évaluation

- Electric HD1500-5Document24 pagesElectric HD1500-5Munkhmanlai ChuluunbaatarPas encore d'évaluation

- Battery Test: The PCM Memory Must Be Reset After Reconnecting The BatteryDocument3 pagesBattery Test: The PCM Memory Must Be Reset After Reconnecting The BatteryLazarus GutaPas encore d'évaluation

- Mecc Alte Portable Ts GuideDocument9 pagesMecc Alte Portable Ts GuidesfePas encore d'évaluation

- Ferrari - Cap6.3 Manutenzione F121618 EDocument23 pagesFerrari - Cap6.3 Manutenzione F121618 EJoseph VasquezPas encore d'évaluation

- Automatic Battery Charger CircuitsDocument25 pagesAutomatic Battery Charger Circuitsrowell ramosPas encore d'évaluation

- Daily On Load / Off Load TestDocument8 pagesDaily On Load / Off Load TestFlexiPas encore d'évaluation

- Owner'S Manual For Minn Kota Onboard DC Alternator Battery Chargers Models: MK-1-DC, MK-2-DC, MK-3-DCDocument9 pagesOwner'S Manual For Minn Kota Onboard DC Alternator Battery Chargers Models: MK-1-DC, MK-2-DC, MK-3-DCЯрослав БогдановPas encore d'évaluation

- Charging Method and EquipmentDocument16 pagesCharging Method and EquipmentlrpatraPas encore d'évaluation

- Lead Acid BatteriesDocument5 pagesLead Acid BatteriesRanjan KumarPas encore d'évaluation

- How Can You Recondition Your Battery?: PrecautionsDocument32 pagesHow Can You Recondition Your Battery?: PrecautionsSKPas encore d'évaluation

- GMDSS Battery Test NotesDocument14 pagesGMDSS Battery Test NotesRavinder SinghPas encore d'évaluation

- GMDSS Batteries: Tests and Checks Mariners Must Know: Written by On January 31, 2016Document22 pagesGMDSS Batteries: Tests and Checks Mariners Must Know: Written by On January 31, 2016larina20049273Pas encore d'évaluation

- Vision User's Manual OpzvDocument10 pagesVision User's Manual Opzvloi130391Pas encore d'évaluation

- Kuster Electronic Gauges: Service ManualDocument12 pagesKuster Electronic Gauges: Service Manualfauzi mahmoodPas encore d'évaluation

- Lithium Valley User ManualDocument10 pagesLithium Valley User ManualChristine May CagaraPas encore d'évaluation

- Harging EAD CID: Learn How To Optimize Charging Conditions To Extend Service LifeDocument4 pagesHarging EAD CID: Learn How To Optimize Charging Conditions To Extend Service LifebigsloPas encore d'évaluation

- Ba Battery Tester MBT 101 enDocument8 pagesBa Battery Tester MBT 101 enDamian FediukPas encore d'évaluation

- Automatic Aa Nicad ChargerDocument8 pagesAutomatic Aa Nicad ChargerGuillermo MaldonadoPas encore d'évaluation

- Battery Charge - Discharge BattconDocument5 pagesBattery Charge - Discharge BattconmatarakiPas encore d'évaluation

- Optimate 4 InstructionsDocument8 pagesOptimate 4 InstructionsTatayoyoPas encore d'évaluation

- Chapter 14Document10 pagesChapter 14ovidiu_blnPas encore d'évaluation

- 2.1.1 The Basic of Pneumatic SystemDocument4 pages2.1.1 The Basic of Pneumatic SystemmorolosusPas encore d'évaluation

- Using Sockets in PHPDocument7 pagesUsing Sockets in PHPJaNoLeRRoPas encore d'évaluation

- Voyager DVD ManualDocument80 pagesVoyager DVD ManualGianniPas encore d'évaluation

- Automatic Transfer Switch Changeover Type - SocomecDocument40 pagesAutomatic Transfer Switch Changeover Type - Socomecallanbatiancila100% (1)

- Cushion Tee: Butt Weld Ends DetailsDocument1 pageCushion Tee: Butt Weld Ends DetailsEHT pipePas encore d'évaluation

- End User Maksiprint Video Nadzor 21.03.2016Document27 pagesEnd User Maksiprint Video Nadzor 21.03.2016Emil MitevPas encore d'évaluation

- CH 19Document32 pagesCH 19Abebe Tesfaye0% (1)

- Testing Life Ccyle For ETL TestingDocument3 pagesTesting Life Ccyle For ETL TestingVamsi KarthikPas encore d'évaluation

- JCHT35K9 EngDocument5 pagesJCHT35K9 EngRodica PuscauPas encore d'évaluation

- Observation Close OutDocument360 pagesObservation Close OutJulio CruzPas encore d'évaluation

- 873003.Vw - How To Read Wiring Diagrams. (USA)Document83 pages873003.Vw - How To Read Wiring Diagrams. (USA)Fernando García100% (3)

- Why Rack Flue Spaces Are Important: Tech TalkDocument3 pagesWhy Rack Flue Spaces Are Important: Tech TalkhanlovePas encore d'évaluation

- T Rec I.431 199303 I!!pdf eDocument43 pagesT Rec I.431 199303 I!!pdf eAhbeberPas encore d'évaluation

- Chapter 15 Database Design Using The REA Data ModelDocument138 pagesChapter 15 Database Design Using The REA Data Modelislamelshahat100% (1)

- Maintenance Planner Position DescriptionDocument13 pagesMaintenance Planner Position Descriptiontohema100% (2)

- BTS Installation Guideline For INWI Project-V1 8Document74 pagesBTS Installation Guideline For INWI Project-V1 8pbcorei3Pas encore d'évaluation

- Bloque de DistribuciónDocument10 pagesBloque de DistribuciónRoberto ArpPas encore d'évaluation

- Chap 9Document64 pagesChap 9joPas encore d'évaluation

- 4 - ISO - 19650 - Guidance - Part - A - The - Information - Management - Function - and - Resources - Edition 3Document16 pages4 - ISO - 19650 - Guidance - Part - A - The - Information - Management - Function - and - Resources - Edition 3Rahul Tidke - ExcelizePas encore d'évaluation

- PDH/SDH Transmission SystemDocument24 pagesPDH/SDH Transmission Systemangelo_lopez1993Pas encore d'évaluation

- 2.7 Safety Features in VehiclesDocument24 pages2.7 Safety Features in VehiclesSue Suraya NazaPas encore d'évaluation

- cd4081 PDFDocument7 pagescd4081 PDFamd12Pas encore d'évaluation

- Host Manual 902 V1 3Document70 pagesHost Manual 902 V1 3jeevanowherePas encore d'évaluation

- UNIT I 2 MarksDocument5 pagesUNIT I 2 MarkscourageouscsePas encore d'évaluation

- As 5011-2001 Hygienic Production of Natural Casings For Human ConsumptionDocument10 pagesAs 5011-2001 Hygienic Production of Natural Casings For Human ConsumptionSAI Global - APACPas encore d'évaluation

- SRDF MetroDocument33 pagesSRDF Metrogabbu_Pas encore d'évaluation

- BondMaster1000eplus enDocument2 pagesBondMaster1000eplus enKuKu FunPas encore d'évaluation

- Msi ms-7326 Rev 200 SCHDocument39 pagesMsi ms-7326 Rev 200 SCHssanti2006Pas encore d'évaluation

- Manual Epson c79 c90 c91 c92Document7 pagesManual Epson c79 c90 c91 c92Muhammad Syafi'i MahjuriPas encore d'évaluation