Académique Documents

Professionnel Documents

Culture Documents

Optimal Generation Scheduling of Hydropower Plant With Pumped Storage Unit

Transféré par

Alexander DeckerCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Optimal Generation Scheduling of Hydropower Plant With Pumped Storage Unit

Transféré par

Alexander DeckerDroits d'auteur :

Formats disponibles

Journal of Energy Technologies and Policy www.iiste.org ISSN 2224-3232 (Paper) ISSN 2225-0573 (Online) Vol.3, No.

11, 2013 Special Issue for International Conference on Energy, Environment and Sustainable Economy (EESE 2013)

Optimal Generation Scheduling of Hydropower Plant with Pumped Storage Unit

Krittaphong Chitphairot Somboon Nuchprayoon* Department of Electrical Engineering, Faculty of Engineering, Chiang Mai University Chiang Mai 50200, THAILAND *Email address of corresponding author: sn@eng.cmu.ac.th Abstract The generation scheduling problem of hydropower plant in the presence of pumped storage unit is complex. This work has proposed a solution strategy to determine the optimum generation based on the analysis of hourly and annual generation costs. The hourly and annual costs are linear functions of power output and energy generation, respectively. The power output was formulated as a linear function of hydraulic head and discharge rate, without computing the conversion efficiency from a hill diagram. The mathematical relationships between power, hydraulic head, and discharge rate can be determined from loading & efficiency test data and validated by using a field test. The optimum generation was stated as capacity factor and varied with water drawdown of the plant. The optimum time interval and duration of the pumped storage unit can be determined by analyzing the hourly marginal operating costs, simplified by using a composite cost function. The proposed strategy has been simulated with the generation data of the Bhumibol hydropower plant. Keywords: generation scheduling, hydropower plant, pumped storage 1. Introduction Hydropower in Thailand is roughly 10% of generation capacity, accounting for 5% of annual generation (Electricity Generating Authority of Thailand, 2012). The hydropower generation in Thailand serves as a peak shaving given that water resource is limited. The Electricity Generating Authority of Thailand (EGAT) has installed 171-MW pumped storage unit at the Bhumibol hydropower plant, 2x180-MW pumped storage units at Sri Nagarind hydropower plant, and 4x250MW pumped storage units at the Lam Takong hydropower plant. A pumped storage unit requires two reservoirs. During periods of high demand (daytime), water is released from the upper reservoir to generate electricity. Conversely, water is pumped from the lower reservoir during periods of low demand (nighttime). In so doing, the marginal operating costs during the low-demand periods must be economically lower than the marginal operating costs during the high-demand periods, given that there are energy losses in the transformation process as shown in Figure 1. Thus, the hourly marginal operating costs are the key determinants of whether pumped storage operation would be economical. Pumped storage unit can be either reversible hydro turbine or separated generating and pumping equipment. Pumping energy can be supplied by either external grid or another unit of the plant. The planning and scheduling problems of pumped storage unit are extensive and complex in response to the increasing penetration of intermittent operation of renewable resources. Those problems investigated reservoir size, cycle efficiency, plant characteristics [Galloway & Ringlee, 1966; McDaniel & Gabrielle, 1966; Cohen and Wan, 1985) load characteristics (Hoffer, 1995), inflow rates (Zhao & Davison, 2009), short-term operation (Ferreira, 1992; Borghetti, DAmbrosio, Lodi, & Martello, 2008), dispatch coordination of hydro and thermal plants (Crampes & Moreaux, 2010). The existing problems did not take into account the generation costs of hydroelectric units although their costs are significant. By neglecting generation costs, conventional procedure attempted to keep run time of all units equally so that maintenance costs and cycles could be balanced. This is definitely inconsistent with economic operation. Thus, the objective of this work is to optimize the operation of a hydropower plant with pumped storage unit. Time horizon is both day and week. The generation scheduling problem is to determine the power output of each unit in each time period to minimize the hydro generation costs.

204 EESE-2013 is organised by International Society for Commerce, Industry & Engineering.

Journal of Energy Technologies and Policy www.iiste.org ISSN 2224-3232 (Paper) ISSN 2225-0573 (Online) Vol.3, No.11, 2013 Special Issue for International Conference on Energy, Environment and Sustainable Economy (EESE 2013)

Figure 1. Generation and pumping intervals of pumped storage unit 2. Hydro Scheduling Problem The power output of hydroelectric unit is a function of discharge rate, net hydraulic head, and conversion efficiencies of turbine and generator, which can be described by using the so-called hill diagram shown in Figure 2. The net head is equal to the gross head less the head losses of penstock. The head loss is proportional to the square of discharge rate. On daily or hourly basis, little changes in both forebay and tailrace elevation are observed so that the net head might be considered constant. As a result, the power output is dependent of the discharge rate in the short run. To avoid using the hill diagram, the power output (P) may be expressed as a linear function of net head (h) and discharge rate (q) as follows:

P(h, q) = a + bh + cq

(1)

where a, b, and c are the linear coefficients obtained from analyzing loading & efficiency test data of hydroelectric unit (Netsawang, 2007). Then, it should be validated by using a field test.

Figure 2. Simpliefied hill diagram The hydro scheduling problem is an optimization problem involving hydro-thermal coordination. The objective function is to minimize fuel costs. The set of constraints comprises power balance, water balance, generation 205 EESE-2013 is organised by International Society for Commerce, Industry & Engineering.

Journal of Energy Technologies and Policy www.iiste.org ISSN 2224-3232 (Paper) ISSN 2225-0573 (Online) Vol.3, No.11, 2013 Special Issue for International Conference on Energy, Environment and Sustainable Economy (EESE 2013)

limits, spinning reserve, storage limits, etc. (Wood & Wollenberg, 1996). The main constraint is water drawdown requirement, specified on daily or weekly basis. The decision variables are unit status (binary) and power output (real) of all units in all time periods. The problem is usually formulated as a Mixed Integer Programming (MIP) problem. In the presence of pumped storage unit, the problem is complicated because it is divided into generating and pumping intervals. The critical decision is to determine when and how much water should be pumped. Given the amount of water, the pumping energy is higher than the generating energy. Note that the cycle efficiency is defined as the ratio of generating energy to pumping energy. A typical value of the cycle efficiency is 2/3 (Wood & Wollenberg, 1996). Consequently, the marginal operating cost during pumping interval must be less than twothird of the marginal operating cost during generating interval. 3. Costs of Hydro Generation Although there is no fuel cost for hydroelectricity, but generation costs still exist and should not be ignored especially cost differences among various hydroelectric units. The hydro generation costs can be determined by using the Activity Based Costing (ABC) method (Phoothiwut, 2005). The ABC method identifies activities and their cost drivers. Then, each cost component was classified as fixed or variable cost. Examples of fixed cost are land rent, depreciation, interest, civil O&M cost. Examples of variable cost are fuel oil, chemicals, calcium hydroxide, operating expenses, and electrical O&M cost. The fixed costs are distributed equally to all hydroelectric units of the plant, while the variable costs are distributed to each unit in proportional to its energy generation and run time. The hydro generation costs may be stated as hourly cost and annual cost function. The hourly cost is a function of power output, while the annual cost is a function of energy generation or capacity (plant) factor. Meanwhile, the marginal operating cost varies with load from time to time. To compute the marginal operating cost directly, it requires economic dispatch solution which depends on a number of dispatching (thermal) units. Alternatively, an indirect method may employ the composite cost function (Wood &Wollenberg, 1996), considering the total operating costs as a quadratic function of cumulative generation. In so doing, the marginal operating cost can easily be computed. As shown in Eq. (2); CC is the composite cost, G is the cumulative generation, while d, e, and f are quadratic coefficients obtained from estimating economic dispatch solution over a pre-specified range of generation.

CC (G ) = d + eG + fG 2

4. Solution Strategy

(2)

It is proposed that the hydro generation costs should be taken into account when solving the hydro-thermal coordination problem. The power output of hydroelectric unit is a linear function of net head and discharge rate as shown in Eq. (1). The hourly and annual costs are linear functions of power output and energy generation, respectively. The cost function coefficients can be determined from fixed and variable costs of each hydroelectric unit. So, the objective function of the problem is to minimize the total costs of hydro generation over all time periods. When a pumped storage unit is in operation, the marginal operating cost can be determined by using the composite cost function as shown in Eq. (2). Upon solution, it can be foreseen that the high-cost unit, such as pumped storage unit, would have less run time than the low-cost unit. Minimum run time may be enforced as a constraint to satisfy maintenance cycle. To simplify the scheduling plan, the operating duration and water drawdown are given as parameters on a daily basis. When both parameters have high values, most units would be in operation. On contrary, only low-cost units would be in operation when both parameters have low values. In case of pumped storage operation, the generating and pumping intervals shall be determined from the cumulative generation, without computing the marginal operating cost. 5. Simulation Results The proposed strategy has been applied to solve the scheduling problem of the Bhumibol hydropower plant, the largest hydropower plant in Thailand. The plant composes of eight units with the total installed capacity of 779.2 MW. Units 1-4 are identical with generation capacity of 4x82.2 MW. Units 5-6 are identical with generation 206 EESE-2013 is organised by International Society for Commerce, Industry & Engineering.

Journal of Energy Technologies and Policy www.iiste.org ISSN 2224-3232 (Paper) ISSN 2225-0573 (Online) Vol.3, No.11, 2013 Special Issue for International Conference on Energy, Environment and Sustainable Economy (EESE 2013)

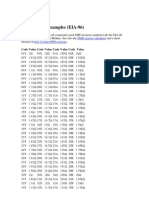

capacity of 2x82.2 MW. Unit 7 has generation capacity of 115 MW. Unit 8 is a pumped storage unit with generation capacity of 171 MW and pumping capacity of 161 MW. The cycle efficiency is 75%. The reservoir has annual inflow of 5,000-6,000 MCM. The plant has annual generation of 1,000-1,500 GWh. Tables 1 and 2 shows the power output functions and generation cost functions of all eight units, respectively. Figure 3 illustrates the comparisons of annual costs and average costs by varying capacity factor. It was found that units 1-4 have the lowest cost and unit 7 has the highest cost. Units 1-6 have the average cost lower than the average cost of the plant, while units 7-8 have the average cost higher than the average cost of the plant. Figure 4 shows the optimum capacity factor, operating duration, and generation proportion of each unit when capacity factor of the plant was varied between 10-50%. Given the operating cost data in the year 2008, the composite cost function can be computed as follows:

CC (G ) = 1, 051, 040.37 + 972.78G + 0.0201G 2 [Baht/h] 370 G 27,300 [MW] Table 1. Power output functions of the Bhumibol hydropower plant Unit 1 2 3 4 5 6 7 8 Power output (MW) (3)

P(h, q) = 58.04 + 0.84h + 0.60q P(h, q) = 56.83 + 0.88h + 0.54q P(h, q) = 57.43 + 0.83h + 0.61q P(h, q) = 57.87 + 0.84h + 0.60q P(h, q) = 61.24 + 0.85h + 0.63q P(h, q) = 61.16 + 0.85h + 0.62q P(h, q) = 87.66 + 1.41h + 0.48q P(h, q) = 124.27 + 1.91h + 0.49q

h net head (m) q discharge rate (CMS)

Table 2. Generation cost functions of the Bhumibol hydropower plant Hourly cost (Baht/h) Bhumibol plant Units 1-4 Units 5-6 Unit 7 Unit 8 Bhumibol plant Units 1-4 Units 5-6 Unit 7 Unit 8

Ch ( P) = 286,760 + 192P Ch ( P) = 25,880 + 168P Ch ( P) = 28,330 + 194P Ch ( P) = 60, 440 + 250P Ch ( P) = 89,310 + 222P

Annual cost (million Baht/y)

Ca ( E ) = 628 + 0.19 E Ca ( E ) = 68 + 0.17 E Ca ( E ) = 67 + 0.19 E Ca ( E ) = 90 + 0.25E Ca ( E ) = 133 + 0.22E

P power output (MW) E generation (GWh/y)

207 EESE-2013 is organised by International Society for Commerce, Industry & Engineering.

Journal of Energy Technologies and Policy www.iiste.org ISSN 2224-3232 (Paper) ISSN 2225-0573 (Online) Vol.3, No.11, 2013 Special Issue for International Conference on Energy, Environment and Sustainable Economy (EESE 2013)

Figure 3. Comparisons of annual costs and average costs of the Bhumibol hydropower plant

Figure 4. Determinations of capacity factor, operating duration, and generation proportion of the Bhumobol hydropower plant

208 EESE-2013 is organised by International Society for Commerce, Industry & Engineering.

Journal of Energy Technologies and Policy www.iiste.org ISSN 2224-3232 (Paper) ISSN 2225-0573 (Online) Vol.3, No.11, 2013 Special Issue for International Conference on Energy, Environment and Sustainable Economy (EESE 2013)

It was found that the optimum operating duration of units 1-4 is 890-4,870 h/y, units 5-6 is 862-4,423 h/y, unit 7 is 791-3,494 h/y, and unit 8 is 921-3,993 h/y. The optimum generation proportion of units 1-4 is 43-47%, units 56 is 21%, unit 7 is 12%, and unit 8 is 20-23%. Then, the plant was divided into 4 groups of scheduling, sorted by generation costs. It was mentioned that the larger the installed capacity, the higher the generation costs. Given the operating duration, daily discharge, and water rate; the scheduling plan can be set according to those four groups. As shown in Figure 5, group A would be in operation when both operating duration and daily discharge are low. That means low-cost units would be operated when water is limited. On the other hand, high-cost units would be operated when operating duration is low, but daily discharge is high. In such a case, water must be released in a limited time so that there is an opportunity for the high-cost unit to operate. In particular case, there would be infeasible to operate the plant. For instance, when the water rate is 4 CM/kWh, it is impossible to release more than 20 MCM within 8 hours so that the operation is infeasible. The pumped storage unit should be in generating mode when the cumulative generation is more than 20,500 MW and in pumping mode when the cumulative generation is less than 11,000 MW. As a result, the pumping duration is 57 h/y, which is approximated to one hour a week. It is observed that the pumping interval of the pumped storage unit is very sensitive to the marginal operating cost. Given that there is a narrow range of cost differences over the year, there is a limited time for the pumped storage unit to operate economically. But, there would be more chance to operate in pumping mode if the cycle efficiency is better.

Figure 5. Generation scheduling of the Bhumibol hydropower plant

6. Conclusion

This work presents the solution strategy for generation scheduling of a hydropower plant with pumped storage unit. By considering the generation costs of hydroelectric units, the generation scheduling plan is more economical than the conventional scheduling. Nonetheless, minimum run time may still be observed to avoid large variation of maintenance cycles. The pumped storage unit could operate in both generating and pumping modes. The generating interval depends on its generation costs, which are relatively higher than those of conventional unit. The pumping interval depends on the marginal operating cost and its cycle efficiency.

209 EESE-2013 is organised by International Society for Commerce, Industry & Engineering.

Journal of Energy Technologies and Policy www.iiste.org ISSN 2224-3232 (Paper) ISSN 2225-0573 (Online) Vol.3, No.11, 2013 Special Issue for International Conference on Energy, Environment and Sustainable Economy (EESE 2013)

Acknowledgements

The authors gratefully acknowledge the financial support from the Thai Research Fund, the Electricity Generating Authority of Thailand, and the Bhumibol hydro power plant under the grant MRG-WI525E066. The authors express their appreciation for the data support, kindly provided by Boonin Chuenchavalit, Worapoj Worapong, Subin Netsawang, and Chaisri Phoothiwut.

References

Borghetti, A., DAmbrosio, C., Lodi, A., & Martello, S. (2008). An MILP approach for short-term hydro scheduling and unit commitment with head-dependent reservoir. IEEE Transactions on Power Systems, 23, 1115-1124. Cohen, A. I., & Wan, S. H. (1985). An algorithm for scheduling a large pumped storage plant. IEEE Transactions on Power Apparatus and Systems, PAS-104, 2099-2104. Crampes, C., & Moreaux, M. (2010). Pumped storage and cost saving. Energy Economics, 32, 325-333. Electricity Generating Authority of Thailand. (2012). Annual Report 2012. Retrieved from http://www.egat.co.th Ferreira, L. A. F. M. (1992). Short-term scheduling of a pumped storage plant. IEE-Proceedings-C, 39, 52-528. Galloway, C. D., & Ringlee, R. J. (1966). An investigation of pumped storage scheduling. IEEE Transactions on Power Apparatus and Systems, PAS-85, 459-465. Hoffer, J. (1995). Probabilistic production costing simulation of a thermal system with a pumped-storage power plant. Electrical Power & Energy Systems, 17, 251-256. McDaniel, G. H., & Gabrielle, G. F. (1966). Dispatching pumped storage hydro. IEEE Transactions on Power Apparatus and Systems, PAS-85, 465-471. Netsawang, S. (2007). Optimal electricity generation scheduling for Bhumibol hydropower plant. Master thesis (Electrical Engineering), Chiang Mai University. Phoothiwut, C. (2005). Cost per unit of electric energy for Bhumibol hydro plant-Electricity Generating Authority of Thailand. Mater thesis (Accounting), Chiang Mai University. Wood, A. J., & Wollenberg, B. F. (1996). Power generation operation and control, second ed., John Wiley & Sons, New York. Zhao, G. & Davison, M. (2009). Optimal control of hydroelectric facility incorporating pumped storage. Renewable Energy, 34, 1064-1077.

210 EESE-2013 is organised by International Society for Commerce, Industry & Engineering.

This academic article was published by The International Institute for Science, Technology and Education (IISTE). The IISTE is a pioneer in the Open Access Publishing service based in the U.S. and Europe. The aim of the institute is Accelerating Global Knowledge Sharing. More information about the publisher can be found in the IISTEs homepage: http://www.iiste.org CALL FOR JOURNAL PAPERS The IISTE is currently hosting more than 30 peer-reviewed academic journals and collaborating with academic institutions around the world. Theres no deadline for submission. Prospective authors of IISTE journals can find the submission instruction on the following page: http://www.iiste.org/journals/ The IISTE editorial team promises to the review and publish all the qualified submissions in a fast manner. All the journals articles are available online to the readers all over the world without financial, legal, or technical barriers other than those inseparable from gaining access to the internet itself. Printed version of the journals is also available upon request of readers and authors. MORE RESOURCES Book publication information: http://www.iiste.org/book/ Recent conferences: http://www.iiste.org/conference/ IISTE Knowledge Sharing Partners EBSCO, Index Copernicus, Ulrich's Periodicals Directory, JournalTOCS, PKP Open Archives Harvester, Bielefeld Academic Search Engine, Elektronische Zeitschriftenbibliothek EZB, Open J-Gate, OCLC WorldCat, Universe Digtial Library , NewJour, Google Scholar

Vous aimerez peut-être aussi

- Innovation for Energy Efficiency: Proceedings of the European Conference, Newcastle upon Tyne, UK, 15–17 September 1987D'EverandInnovation for Energy Efficiency: Proceedings of the European Conference, Newcastle upon Tyne, UK, 15–17 September 1987D A ReayPas encore d'évaluation

- 4 - Energy Analysis Tools PDFDocument14 pages4 - Energy Analysis Tools PDFNelson MartinsPas encore d'évaluation

- LEEDpresentationDocument16 pagesLEEDpresentationAnirudh JaswalPas encore d'évaluation

- CEM Outline PDFDocument5 pagesCEM Outline PDFFakhri GhrairiPas encore d'évaluation

- 2013 World Energy Engineering WEEC NewspaperDocument20 pages2013 World Energy Engineering WEEC NewspaperAee AtlantaPas encore d'évaluation

- Energy Savings From Building Energy Management SystemsDocument14 pagesEnergy Savings From Building Energy Management Systemshb_scribPas encore d'évaluation

- Rich Operation Experiences and New Technologies On Adjustable Speed Pumped Storage Systems in JapanDocument8 pagesRich Operation Experiences and New Technologies On Adjustable Speed Pumped Storage Systems in JapanR0B0T2013100% (1)

- Energy Modeling For LEED ProjectsDocument3 pagesEnergy Modeling For LEED Projectsmartinmecanique666Pas encore d'évaluation

- BEMS ManualDocument111 pagesBEMS Manual이아름Pas encore d'évaluation

- 2022 LEED v4 Commissioning Masterclass Baumann ConsultingDocument50 pages2022 LEED v4 Commissioning Masterclass Baumann ConsultingEdwin SanchezPas encore d'évaluation

- Solar Air HeatingDocument17 pagesSolar Air Heatingapi-240887715Pas encore d'évaluation

- Forest Stewardship CouncilDocument25 pagesForest Stewardship CouncilCaleb KreegerPas encore d'évaluation

- CEM - Question Bank (Answers)Document25 pagesCEM - Question Bank (Answers)Ar Venu NatarajPas encore d'évaluation

- Energy Conversion PlantsDocument148 pagesEnergy Conversion Plantsdeepumohandas93Pas encore d'évaluation

- Ocean Thermal Energy Conversion Tide Current and Tide RangeDocument56 pagesOcean Thermal Energy Conversion Tide Current and Tide RangeSiddharth PatelPas encore d'évaluation

- Leed FlascardDocument42 pagesLeed FlascardVisha RojaPas encore d'évaluation

- Evolutionary Algorithms ClassificationDocument5 pagesEvolutionary Algorithms ClassificationBT KrishnaPas encore d'évaluation

- Sustainable Design Requirements - LEEDDocument8 pagesSustainable Design Requirements - LEEDasgharPas encore d'évaluation

- 《小林陪你过LEED (Green Associate篇) 》 PDFDocument213 pages《小林陪你过LEED (Green Associate篇) 》 PDFyu zhangPas encore d'évaluation

- Leed Practice Test 100 Questions Part 6 Flashcards - QuizletDocument10 pagesLeed Practice Test 100 Questions Part 6 Flashcards - QuizletDavidLouisMugabePas encore d'évaluation

- Ocean Thermal Energy ConversionDocument13 pagesOcean Thermal Energy ConversionRandroxRPas encore d'évaluation

- Eks Energy PresentationDocument17 pagesEks Energy PresentationFrancisco Javier Marín SuárezPas encore d'évaluation

- Campus Benchmarking ToolkitDocument28 pagesCampus Benchmarking ToolkitRishabh RajPas encore d'évaluation

- Concept SummaryDocument15 pagesConcept SummaryRushabh ShahPas encore d'évaluation

- Aee Cem 2022Document8 pagesAee Cem 2022AmeetPas encore d'évaluation

- Saving EnergyDocument168 pagesSaving EnergythanhtanPas encore d'évaluation

- More Papers and Presentations Available On Above Site: Document byDocument10 pagesMore Papers and Presentations Available On Above Site: Document byBharadwaj SanthoshPas encore d'évaluation

- Organic Waste Converter: Presentation OnDocument8 pagesOrganic Waste Converter: Presentation OnLeo VictorPas encore d'évaluation

- Green Building/LEED AP Building Design & Construction Exam PreparationDocument5 pagesGreen Building/LEED AP Building Design & Construction Exam PreparationSalman KaziPas encore d'évaluation

- BCA-IDA Green Mark For New Data Centres Version NDC/1.0Document16 pagesBCA-IDA Green Mark For New Data Centres Version NDC/1.0Avk SanjeevanPas encore d'évaluation

- Green Building - LEEDDocument46 pagesGreen Building - LEEDHadee SaberPas encore d'évaluation

- Advantages and Disadvantages of Energy SourcesDocument9 pagesAdvantages and Disadvantages of Energy SourcesJulio CortezPas encore d'évaluation

- Test Questions2Document7 pagesTest Questions2vico1982100% (1)

- Design and Sizing of A Stand-Alone Solar Power Systems For A House in IraqDocument7 pagesDesign and Sizing of A Stand-Alone Solar Power Systems For A House in IraqLuis Perez Marquez100% (1)

- Test SpecsDocument7 pagesTest SpecsTiago NardelliPas encore d'évaluation

- CemDocument6 pagesCemSamaresh ChhotrayPas encore d'évaluation

- A Practical Guide To Energy EfficiencyDocument58 pagesA Practical Guide To Energy EfficiencyMangalika de SilvaPas encore d'évaluation

- Geothermal Power PlantDocument5 pagesGeothermal Power PlantJiana NasirPas encore d'évaluation

- AWDM 10 CH04 Water ConsumptionDocument49 pagesAWDM 10 CH04 Water ConsumptionJalijashPas encore d'évaluation

- 90.1-2016 HVAC FinalDocument175 pages90.1-2016 HVAC FinalHiei ArshavinPas encore d'évaluation

- Building It Uk (Ve6)Document2 pagesBuilding It Uk (Ve6)nihatmuratPas encore d'évaluation

- Dipl - Eng.M.Sc Architect LEED AP BD+C, PQPDocument9 pagesDipl - Eng.M.Sc Architect LEED AP BD+C, PQPhymerchmidtPas encore d'évaluation

- Energy Efficiency A Bridge To Low Carbon EconomyDocument356 pagesEnergy Efficiency A Bridge To Low Carbon Economydimitaring100% (1)

- LEED Certification WorkflowDocument1 pageLEED Certification WorkflowCarissa WatanabePas encore d'évaluation

- 15 Automotive Manufacturing Energy Saving FactsheetDocument2 pages15 Automotive Manufacturing Energy Saving FactsheetWaqar DarPas encore d'évaluation

- Voltage StabilityDocument5 pagesVoltage StabilityAadyaPas encore d'évaluation

- LEED® Canada Professional Accreditation Exam HandbookDocument22 pagesLEED® Canada Professional Accreditation Exam Handbookpat-con100% (1)

- Commercial Offer: EP Solutions Philippines IncDocument4 pagesCommercial Offer: EP Solutions Philippines IncJake ZozobradoPas encore d'évaluation

- LEED Design ReportDocument16 pagesLEED Design ReportIshan RanganathPas encore d'évaluation

- A3 Report: Title: Author (Date)Document2 pagesA3 Report: Title: Author (Date)gouri67Pas encore d'évaluation

- BIPV Europe 2008: Frost and SullivanDocument28 pagesBIPV Europe 2008: Frost and SullivanECD FanPas encore d'évaluation

- Net Zero Getting Started GuideDocument14 pagesNet Zero Getting Started GuideJenny KomatsuPas encore d'évaluation

- 2013 LEED BD-C Accredited Professional Exam Preparation SeminarDocument1 page2013 LEED BD-C Accredited Professional Exam Preparation SeminaramrezzatPas encore d'évaluation

- Castillo Reaction Paper PLC and SCADADocument2 pagesCastillo Reaction Paper PLC and SCADALaurence CastilloPas encore d'évaluation

- Detail Energy Audit Report-Draft-Pradeep Rice MillDocument56 pagesDetail Energy Audit Report-Draft-Pradeep Rice MillMohamed SihamPas encore d'évaluation

- Green Impact Audit Checklist UoLDocument6 pagesGreen Impact Audit Checklist UoLMarcos AquinoPas encore d'évaluation

- MBA Energy Management SystemDocument12 pagesMBA Energy Management SystemAnshul BhutaniPas encore d'évaluation

- Ce A Study Guide 2013Document10 pagesCe A Study Guide 2013kalyanm203515Pas encore d'évaluation

- 01 - LEED GA Study Guide PDFDocument262 pages01 - LEED GA Study Guide PDFFrancisco M. RamosPas encore d'évaluation

- Assessment of Knowledge, Attitude and Practices Concerning Food Safety Among Restaurant Workers in Putrajaya, MalaysiaDocument10 pagesAssessment of Knowledge, Attitude and Practices Concerning Food Safety Among Restaurant Workers in Putrajaya, MalaysiaAlexander DeckerPas encore d'évaluation

- Assessment For The Improvement of Teaching and Learning of Christian Religious Knowledge in Secondary Schools in Awgu Education Zone, Enugu State, NigeriaDocument11 pagesAssessment For The Improvement of Teaching and Learning of Christian Religious Knowledge in Secondary Schools in Awgu Education Zone, Enugu State, NigeriaAlexander DeckerPas encore d'évaluation

- Assessing The Effect of Liquidity On Profitability of Commercial Banks in KenyaDocument10 pagesAssessing The Effect of Liquidity On Profitability of Commercial Banks in KenyaAlexander DeckerPas encore d'évaluation

- Analysis of Teachers Motivation On The Overall Performance ofDocument16 pagesAnalysis of Teachers Motivation On The Overall Performance ofAlexander DeckerPas encore d'évaluation

- An Overview On Co-Operative Societies in BangladeshDocument11 pagesAn Overview On Co-Operative Societies in BangladeshAlexander DeckerPas encore d'évaluation

- Analysis of Blast Loading Effect On High Rise BuildingsDocument7 pagesAnalysis of Blast Loading Effect On High Rise BuildingsAlexander DeckerPas encore d'évaluation

- An Experiment To Determine The Prospect of Using Cocoa Pod Husk Ash As Stabilizer For Weak Lateritic SoilsDocument8 pagesAn Experiment To Determine The Prospect of Using Cocoa Pod Husk Ash As Stabilizer For Weak Lateritic SoilsAlexander DeckerPas encore d'évaluation

- Agronomic Evaluation of Eight Genotypes of Hot Pepper (Capsicum SPP L.) in A Coastal Savanna Zone of GhanaDocument15 pagesAgronomic Evaluation of Eight Genotypes of Hot Pepper (Capsicum SPP L.) in A Coastal Savanna Zone of GhanaAlexander DeckerPas encore d'évaluation

- 80010360Document2 pages80010360mdisicPas encore d'évaluation

- Textile AssignmentDocument8 pagesTextile AssignmentMahmudul Hasan Khan40% (5)

- Vem BrochureDocument8 pagesVem BrochureVamshi Krishnam Raju NadimpalliPas encore d'évaluation

- MC1413 D Integrated Circuit 7xdarlington Driver SO16 On SEMIDocument8 pagesMC1413 D Integrated Circuit 7xdarlington Driver SO16 On SEMIblueword66Pas encore d'évaluation

- On The Gaussian Error Function (1935) : Robert J. KolkerDocument4 pagesOn The Gaussian Error Function (1935) : Robert J. KolkerSanthosh KulandaiyanPas encore d'évaluation

- ASTM D287-92 (Metodo de Prueba Estandar para Gravedad API de Petroleo Crudo y Productos Del Petroleo Metodo Del Hidrómetro)Document3 pagesASTM D287-92 (Metodo de Prueba Estandar para Gravedad API de Petroleo Crudo y Productos Del Petroleo Metodo Del Hidrómetro)Juan MonjePas encore d'évaluation

- Control Unit ECUDocument2 pagesControl Unit ECUjag1961Pas encore d'évaluation

- Códigos de Falhas Hyundai R3607ADocument13 pagesCódigos de Falhas Hyundai R3607AGuemep GuemepPas encore d'évaluation

- 7695v2.1 (G52 76951X8) (A55 G45 - A55 G55)Document70 pages7695v2.1 (G52 76951X8) (A55 G45 - A55 G55)Dávid SzabóPas encore d'évaluation

- Acidizing TreatmentsDocument93 pagesAcidizing TreatmentsPeña Lucia100% (2)

- Procurement Guideline For ATL SchoolsDocument4 pagesProcurement Guideline For ATL SchoolsManKapPas encore d'évaluation

- Shaft Design Problem 10 - 12Document9 pagesShaft Design Problem 10 - 12BernalynMalinaoPas encore d'évaluation

- T.C. Electronic M3000 User ManualDocument78 pagesT.C. Electronic M3000 User ManualStanleyPas encore d'évaluation

- Tpa3110D2-Q1 15-W Filter-Free Stereo Class-D Audio Power Amplifier With Speakerguard™Document37 pagesTpa3110D2-Q1 15-W Filter-Free Stereo Class-D Audio Power Amplifier With Speakerguard™tran anh tuanPas encore d'évaluation

- Case Study 11 Centralia Underground Mine FireDocument11 pagesCase Study 11 Centralia Underground Mine Firemigire kennedyPas encore d'évaluation

- HHW 35 m6 GBDocument6 pagesHHW 35 m6 GBSuper WhippedPas encore d'évaluation

- SMD Resistor ExamplesDocument5 pagesSMD Resistor Examplesmarcbuss100% (1)

- Ncomputing VSpace Server Management Console User ManualDocument34 pagesNcomputing VSpace Server Management Console User ManualJeff IvanPas encore d'évaluation

- E-Line DLDocument21 pagesE-Line DLiulian17dPas encore d'évaluation

- 29L0054805FDocument49 pages29L0054805FszPas encore d'évaluation

- Pavement Evaluation and Overlay Des - DR MSA - LatestDocument103 pagesPavement Evaluation and Overlay Des - DR MSA - LatestSreedhar BhuduruPas encore d'évaluation

- DUNAN Fan Coil UnitDocument14 pagesDUNAN Fan Coil UnitDjordjePas encore d'évaluation

- Sand Control PDFDocument88 pagesSand Control PDFThọ Phương100% (1)

- The Family Handyman - October 2020 PDFDocument86 pagesThe Family Handyman - October 2020 PDFFabian MaunaPas encore d'évaluation

- 462116-01 AA - 1510 Excel ESI Command Codes Addendum - 10 Feb 2009Document103 pages462116-01 AA - 1510 Excel ESI Command Codes Addendum - 10 Feb 2009quyenducqdc100% (1)

- Water Technology 2015 2016 1Document86 pagesWater Technology 2015 2016 1Srinivas AkHilPas encore d'évaluation

- Seismic Force CANADA Code - CNBC2005-V421Document7 pagesSeismic Force CANADA Code - CNBC2005-V421Niko NištićPas encore d'évaluation

- Bends - Route SelectionDocument6 pagesBends - Route SelectionanishsrPas encore d'évaluation

- KYK CatalogueDocument94 pagesKYK Cataloguepriya kumariPas encore d'évaluation

- SYNC2000 - 4.00.022014 Protocol ConverterDocument2 pagesSYNC2000 - 4.00.022014 Protocol ConverterAnasSalemPas encore d'évaluation