Académique Documents

Professionnel Documents

Culture Documents

3312 8009 56 ENG Brochure Conjet Equipment For Hydrodemolition A3 LR

Transféré par

seljak_veseljakTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

3312 8009 56 ENG Brochure Conjet Equipment For Hydrodemolition A3 LR

Transféré par

seljak_veseljakDroits d'auteur :

Formats disponibles

Distributor/Agent

The Complete Conjet Hydrodemolition Solution

Products

CONJET AB

P.O. BOX 507 SE-136 25 HANINGE SWEDEN PHONE: +46 (0)8 55 65 22 40 FAX: +46 (0)8 55 65 22 60 E-MAIL: conjet@conjet.com WEBSITE: www.conjet.com

3312 8009 56 0911

Conjet AB was established in 1990 through a Management Buy Out from the Atlas Copco group where the development of hydrodemolition star ted in 1983. Hydrodemolition is used for removing damaged and sound concrete from sensitive structures such as bridges, tunnels and quays in conjunction with repair and refurbishments.

Significantly faster than alternative methods. Safer for the operator as well as for bypassers.

Equipment

A complete hydrodemolition system consists of high pressure water pump feeding water through a high pressure hose to a lance or rotor fitted on a Robot or Jetframe. In addition to these products Conjet offers a complete range of accessories, consumables and spare parts. Conjet has five different hydrodemolition machines to cater for different applications. In addition Conjet has extensive experiences from designing and manufacturing customised solutions.

Equipment for Hydrodemolition

Hydrodemolition method

Hydrodemolition uses a high-speed water jet to remove concrete. The porous material concrete has a high compressive strength but its tensile strength is roughly ten times lower. The water penetrates the porous concrete and creates an internal pressure, which when exceeding the tensile strength of the material removes it. Percussive methods (e.g. jack hammers and hydraulic breakers) on the other hand, have to overcome the compressive strength and thereby risk to damage the remaining structure. The main benefits of using Conjet hydrodemolition can be summarized as follows:

Training

Conjet has a well developed training program including an operations and maintenance training that is included with the products. Products are delivered with detailed operations and maintenances manuals as well as Spare Parts Lists. Conjet is an ISO 9001 certified company and all its products fulfil all known safety and environmental regulations including the CE marking.

A rough uneven surface without micro

cracks is left behind.

This provides a superior bonding interface

for the new concrete.

Concrete can be removed from underneath

the reinforcment. The reinforecement is cleaned.

Support

Technical support and service is delivered through Conjets global network of representatives with extensive support from Conjet.

Selective removal will remove the damaged

concrete and leave the good behind.

References

Bridges: Tunnels: Viaducts: Water P ower Plants: Power Canals: Dr y docks: Dry Parking Decks: Turbines: Golden Gate, Ca, USA Channel Tunnel, France/UK Rio Verde, Italy Guri Dam, Venezuela Panama Canal, Panama Dubai Dry Docks, UAE Heathrow Airport, UK Drava River, Slovenia

Pictures are illustrative only and do not necessarily show the configuration of the products on the market at the given point in time. These products must be used in conformity with safe practice and applicable statues, regulations, codes and ordinances. Subject to change without prior notice. Copyright Conjet AB, Sweden 2009 All unauthorized copying or sampling strictly prohibited

APPLIED WATERJET TECHNOLOGY

Robot 324

Robot 365

Robot 432 D

Jetframe 114

CCU 208

Powerpack

The most compact, light weight flexible and cost effective Hydrodemolition Robot on the market.

The compact Robot 324 is designed for: - Confined spaces and easy operation - Horizontal concrete removal - Vertical concrete removal - Under up concrete removal - Below track level concrete removal - Circular tunnels - Steel and concrete tubes - Pillars with and without tower* - Steep sloops with the winch kit* - Surface preparation with hydraulic rotor*

The most versatile Hydrodemolition Robot with superior reach and stability on the market.

The most powerful Hydrodemoltion Robot in the market for large scale horizontal surfaces.

Robot 432 Diesel with its heavy duty protective hood can handle the largest pumps and achieve the highest production in the market and it is designed for: - Horizontal concrete removal - Surface preparation with hydraulic rotor* - Scarifying with double lance* High removal capacity - rated for pump power up to 1100 kW (1500 hp) The PLC based control system monitors the process and is easy to learn and use Two level cut, i.e. concrete is removed to two different depths in one pass Wheels that provide stability and good manouverability Diesel engine powered Reactivation button for safety reasons Remote control with cable or radio* Emergency stop circuit securing Robot and Powerpack Cable or Bluetooth* interface with Conjet Powerpacks

Heavy duty Jetframe to be mounted on carrier for extended reach or bolted to surfaces in confined spaces.

Jetframe 114 has been designed for: Areas out of reach for robots Can be fitted to a tool carrier e.g. skylift access platform, fork lift or crane Easy to bolt to concrete surfaces Support legs Controllable from Conjet CCU or Conjet Robot A hydraulic driven rotor*, a single or double lance* can be attached Under water use*

*option

CCU 208 controls the movements and functions of Jetframes and additional accessories.

CCU 208 is a hydraulic unit with following features: PLC based, Closed Loop Control Monitoring System 4 fixed preloaded programs with possibility to save 16 user defined programs Two level cut, i.e. concrete is removed to two different depths in one pass Reactivation button for safety reasons Remote control with cable or radio* Emergency stop circuit securing Robot and Powerpack Cable or Bluetooth* interface with Conjet Powerpacks

*option

Probably the most reliable high pressure water pump installation designed and built for contractors.

Conjet Powerpacks are designed for: Operating 24 hours/day, 7 days/week - Reliable High Pressure Pump - Reliable engine from Caterpillar - Dimensions as a 20 ft ISO container - Rigid design - Certified for sea freight Safety - Designed to improve operator and third parties safety - Remotely controlled from Robot or CCU - Integrated emergency stop circuits - Pump/engine separated from control room - Separate room for storage of parts, hoses, etc - Theft and vandalism proof design. Environmental - Exhaust emission meets U.S. EPA and EU regulations - Silenced to meet noise emission regulations - Insulated to meet different climate conditions - Over spill tray with grating floor to collect, oil, cooling water, or fuel

Robot 365 MPA with its versatile Multi Purpose Arm is designed for: - Horizontal concrete removal - Vertical concrete removal (up to 6.4 m) - Under up concrete removal (up to 6.0 m) - Below wheel base (down to 3.3 m) - Circular tunnels with special feed beam* - Surface preparation with hydraulic rotor* - Scarifying with double lance* Stability through large extendable wheel base up to 2.8 m (9 ft) Adjustable height of steering wheels in - Scarifying with double lance* order to improve positioning of the feed beam Low weight makes it ideal for operating on Powered by electricity platforms and scaffoldings Powered by electricity - no exhaust gases - no exhaust gases - no health threat for operator PLC based, Closed Loop Control - no health threat for operator Monitoring System Easy to operate and manoeuvre 4 fixed preloaded programs with possibility PLC based control system monitors the process and is easy to learn and use to save 16 user defined programs Reactivation button for safety reasons Two level cut, i.e. concrete is removed to Remote control with cable or radio* two different depths in one pass Emergency stop circuit securing Robot and Reactivation button for safety reasons Powerpack Remote control with cable or radio* Cable or Bluetooth* interface with Conjet Emergency stop circuit securing Robot Powerpacks and Powerpack Cable or Bluetooth* interface with Conjet Powerpacks *option *option

Technical Data

Length standard 4000 mm (20 ft) Width standard 2000 mm (10 ft) Cutting length standard 3500 mm (18 ft) Width feed beam 2000 mm (6 ft 7 in) Cutting width 2150 mm (7 ft 1 in) Height 500 mm (1 ft 8 in)) Weight 300 kg (660 lb) Per mitted reaction force ermitted 2000 N Other dimensions available on request

Technical Data

Length standard Width standard Height Weight Power supply 7.5 kW 1750 mm (5 ft 9 in) 770 mm (2 ft 6 in) 1300 mm (4 ft 3 in) 300 kg (660 lb) 380-480 V, 16 A

Jetframe 101 NAL TA NALT

*option

The smallest mechanised hydrodemolition unit on the market, replaces hand lances.

Jetframe 101 Nalta is designed for: Improved operator safety and increased productivity Low weight - can be handled by single operator Small size - can be brought in through man holes Mounts on standard scaffolding tubes Handles curved surfaces down with radii down to 400 mm Rotor for surface preparation as option 2-3 times faster than manual lances

Technical Data

Type Pressure Reaction force Flow kW l/min (gpm) bar (P .S .I.) (N) (P.S .S.I.) 530-250kW 116 (31) 1150 (17000) 920 139 (37) 960 (14000) 1000 1350 (19600) 820 525-250kW 96 (25) 80 (21) 1650 (24000) 760 1150 (16700) 1290 345-360kW 163 (43) 1550 (22500) 1120 340-360kW 128 (34) 1000 (14500) 1890 350-480kW 256 (68) 1200 (16700) 1660 345-480kW 205 (54) 1550 (22500) 1400 340-480kW 160 (42) 545-750kW 342 (90) 1150 (16700) 2700 1450 (21100) 2340 540-750kW 268 (71) *Other specifications upon request.

Technical Data

Length Width over tracks 2350 mm (7 ft 9 in) 820 mm - 1220 mm (2 ft 8 in - 4 ft) Width feed beam 1520 mm (5 ft) Cutting width 1600 mm (5 ft 3 in) Cutting height under up/with ext. 1950 / 2450 mm (6 ft 5 in / 8 ft) Cutting hgt vert./with ext./shifted 2300/2750/3050 mm (6 ft 5 in / 8 ft / 10 ft) Cutting below track level 1000 mm (3ft 4 in) Height, carrier 1170 mm (3 ft 10 in) Weight 1100 kg (2425 lb) Power supply 7.5 kW 380-480 V, 16 A Per mitted reaction force/with ext. 1400 N / 950 N ermitted

Technical Data

Length Width over wheels Width, transport Width, feed beam Cutting width Cutting height under up Cutting height vertical Cutting below wheel level Height, mimimum Weight Power supply 11 kW Per mitted reaction force ermitted 3400 mm (11 ft 2 in) 1880 - 2580 mm (5 ft 10 in - 8 ft 2 in) 2300 mm ( 7 ft 7 in) 2000 mm (6 ft 7 in) 2100 mm (7 ft ) 6000 mm (20 ft) 6400 mm (21 ft) 3300 mm (10 ft 10 in) 1770 mm (5 ft 10 in) 2400 kg (5290 lb) 380-480 V, 32 A 2000 N, 3000N*

Technical Data

Length Width over wheels Width, transport Width with side covers Width, feed beam Cutting width Height Weight Per mitted reaction force ermitted 3500 mm (11 ft 6 in ) 1800 mm (5 ft 11 in) 2220 mm (7 ft 3 in) 2660 mm (8 ft 9 in) 2220 mm (7 ft 3 in) 2220 mm (7 ft 3 in ) 1500 mm (4 ft 11 in ) 2500 kg (5500 lb) 4000 N

Technical Data

Length, feed beam (2x1100 mm) Weight, feed beam (2x6 kg) Weight, cutting head Weight, step units (2x10 kg) Weight, hydraulic control unit 2200 mm ( 7 ft 2 in) 12 kg (26 lbs) 14 kg (29 lbs) 20kg (44 lbs) 90 kg ((200 lbs)

The Widest Range of Equipment for Hydrodemolition

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- 49 Complemento Dominar 400 UG en Ingles PDFDocument126 pages49 Complemento Dominar 400 UG en Ingles PDFJulian Uribe Herrera50% (4)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Wrong Answer SummaryDocument4 pagesWrong Answer SummaryЕвгений Тимоновский0% (2)

- Distribution Management: Get To Know Each OtherDocument43 pagesDistribution Management: Get To Know Each OtherBuyco, Nicole Kimberly M.Pas encore d'évaluation

- Conway Maritime Press - Anatomy of The Ship - Hms VictoryDocument121 pagesConway Maritime Press - Anatomy of The Ship - Hms VictoryWerner Welgens0% (1)

- GD N Bad PracticesDocument11 pagesGD N Bad PracticesViknes RamanPas encore d'évaluation

- Genotyping STRVSSNP WebDocument1 pageGenotyping STRVSSNP Webseljak_veseljakPas encore d'évaluation

- FibreC PDFDocument38 pagesFibreC PDFseljak_veseljakPas encore d'évaluation

- Genotyping STRVSSNP WebDocument1 pageGenotyping STRVSSNP Webseljak_veseljakPas encore d'évaluation

- What Is The Difference Between Free Earth Support Method and Fixed Earth Support MethodDocument1 pageWhat Is The Difference Between Free Earth Support Method and Fixed Earth Support Methodseljak_veseljakPas encore d'évaluation

- Low Pressure MacinesDocument3 pagesLow Pressure Macinesseljak_veseljakPas encore d'évaluation

- Fibre CDocument38 pagesFibre Cseljak_veseljak100% (1)

- How To Change The Network Type - (Solved) - Windows 7 - Windows 7Document4 pagesHow To Change The Network Type - (Solved) - Windows 7 - Windows 7seljak_veseljakPas encore d'évaluation

- Baseline, Scheduled and Actual Fields: Project Project Standard and Professional General Questions and AnswersDocument2 pagesBaseline, Scheduled and Actual Fields: Project Project Standard and Professional General Questions and Answersseljak_veseljakPas encore d'évaluation

- Hyperdesmo PB 2K - 0Document4 pagesHyperdesmo PB 2K - 0seljak_veseljakPas encore d'évaluation

- Beams On Elastic FoundationDocument15 pagesBeams On Elastic FoundationOmar Eladel Mahmoud100% (2)

- Daclar Manual Jan06Document43 pagesDaclar Manual Jan06seljak_veseljakPas encore d'évaluation

- Why Windows 10 Sucks or Everything Wrong With Windows 10Document9 pagesWhy Windows 10 Sucks or Everything Wrong With Windows 10seljak_veseljakPas encore d'évaluation

- Load CasesDocument10 pagesLoad Casesseljak_veseljakPas encore d'évaluation

- Hyperdesmo - v2.2Document5 pagesHyperdesmo - v2.2seljak_veseljakPas encore d'évaluation

- Milgram Experiment - Wikipedia, The Free EncyclopediaDocument13 pagesMilgram Experiment - Wikipedia, The Free Encyclopediaseljak_veseljak100% (1)

- EABASSOC Concrete Foaming AgentDocument1 pageEABASSOC Concrete Foaming Agentseljak_veseljakPas encore d'évaluation

- Formule TrigonometriceDocument5 pagesFormule TrigonometriceandreiwlPas encore d'évaluation

- Column Calculation To EN1993Document3 pagesColumn Calculation To EN1993seljak_veseljakPas encore d'évaluation

- Formula RioDocument1 pageFormula RioGiuseppe ManginoPas encore d'évaluation

- ArianismDocument8 pagesArianismseljak_veseljakPas encore d'évaluation

- Structural Software in MalasiaDocument4 pagesStructural Software in Malasiaseljak_veseljakPas encore d'évaluation

- Milgram Experiment - Wikipedia, The Free EncyclopediaDocument13 pagesMilgram Experiment - Wikipedia, The Free Encyclopediaseljak_veseljak100% (1)

- Milgram Experiment - Wikipedia, The Free EncyclopediaDocument13 pagesMilgram Experiment - Wikipedia, The Free Encyclopediaseljak_veseljak100% (1)

- Rules of Thumb - Structural Engineering Other Technical Topics FAQ - Eng-TipsDocument9 pagesRules of Thumb - Structural Engineering Other Technical Topics FAQ - Eng-Tipsseljak_veseljakPas encore d'évaluation

- The Principles of Friesian PhilosophyDocument6 pagesThe Principles of Friesian Philosophyseljak_veseljakPas encore d'évaluation

- Structural Software in MalasiaDocument4 pagesStructural Software in Malasiaseljak_veseljakPas encore d'évaluation

- Arianism - Christian HeresyDocument1 pageArianism - Christian Heresyseljak_veseljakPas encore d'évaluation

- ArianismDocument8 pagesArianismseljak_veseljakPas encore d'évaluation

- 8 Expert Tips For Facilitating Better MeetingsDocument2 pages8 Expert Tips For Facilitating Better Meetingsseljak_veseljakPas encore d'évaluation

- If Correlation Doesn't Imply Causation, Then What DoesDocument49 pagesIf Correlation Doesn't Imply Causation, Then What Doesseljak_veseljakPas encore d'évaluation

- Tiguan VWDocument6 pagesTiguan VWMeor Amri100% (2)

- Carspotting: The Real Adventures of Irvine Welsh by Sandy MacnairDocument40 pagesCarspotting: The Real Adventures of Irvine Welsh by Sandy MacnairBlack & White Publishing100% (1)

- Tivyside Classified 031115Document5 pagesTivyside Classified 031115Digital MediaPas encore d'évaluation

- History of Skid RowDocument17 pagesHistory of Skid RowkatherinetreesPas encore d'évaluation

- SAP Trg. Log Sheet - All ModulesDocument51 pagesSAP Trg. Log Sheet - All Modulespawandubey9Pas encore d'évaluation

- The Economic Impact of The World Cup On BrazilDocument7 pagesThe Economic Impact of The World Cup On Brazileadona15Pas encore d'évaluation

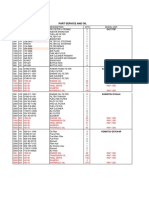

- Part Service and Oil: CAT 775FDocument5 pagesPart Service and Oil: CAT 775FWildan Zainun NasiqinPas encore d'évaluation

- PESO Online Explosives-Returns SystemDocument1 pagePESO Online Explosives-Returns Systemgirinandini0% (1)

- Assignment 3Document1 pageAssignment 3Roshan Shanmughan50% (2)

- Crewing Model PDFDocument8 pagesCrewing Model PDFDedy KristiawanPas encore d'évaluation

- Manual Do Fis Jit VWDocument23 pagesManual Do Fis Jit VWJose Augusto Santos NetoPas encore d'évaluation

- PROWAG - Accessibility GuidelinesDocument114 pagesPROWAG - Accessibility GuidelinesSlim ShadyPas encore d'évaluation

- SIRE 2.0 Question Library - Question Programming Attributes - Version 1.0 (January 2022)Document86 pagesSIRE 2.0 Question Library - Question Programming Attributes - Version 1.0 (January 2022)Caner DoguPas encore d'évaluation

- Transportation Engineering II (Lec - 3)Document9 pagesTransportation Engineering II (Lec - 3)ali hasanPas encore d'évaluation

- 9700 w04 ErDocument17 pages9700 w04 ErwegdanPas encore d'évaluation

- 2022 Utility and Street Rehabilitation ProjectDocument26 pages2022 Utility and Street Rehabilitation ProjectinforumdocsPas encore d'évaluation

- In The Small Design Office: ToolsDocument10 pagesIn The Small Design Office: ToolslapuPas encore d'évaluation

- Airbus ChecklistDocument2 pagesAirbus Checklistantonio cardona garciaPas encore d'évaluation

- Oct 18 To Planning CommissionersDocument12 pagesOct 18 To Planning CommissionerssamtlevinPas encore d'évaluation

- ModelSp KS-En191P D6010526abDocument13 pagesModelSp KS-En191P D6010526abPranab MishraPas encore d'évaluation

- WTC PlansDocument175 pagesWTC PlansAngelo De DominicisPas encore d'évaluation

- CUMMINS SegmentationDocument5 pagesCUMMINS SegmentationSushantiMishraPas encore d'évaluation

- Uic Code: Standard Wagons - Wagons For Combined Transport - CharacteristicsDocument94 pagesUic Code: Standard Wagons - Wagons For Combined Transport - CharacteristicsSuat SayimPas encore d'évaluation

- Private & Confidential Page 1 of 34Document34 pagesPrivate & Confidential Page 1 of 34Er. Rajesh ChatterjeePas encore d'évaluation