Académique Documents

Professionnel Documents

Culture Documents

Milling: VFT RPM Din

Transféré par

Shoaib MughalTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Milling: VFT RPM Din

Transféré par

Shoaib MughalDroits d'auteur :

Formats disponibles

LAB #4 MACHINING EXPERIMENT II MILLING Purpose: To study the operation of milling.

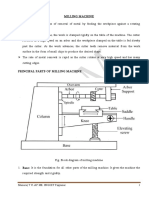

Machine: Milling machines Tools: sine bar, gage blocks, 6 inch dial caliper, steel ruler, fly-cutter (3 diameter high-speed end mill (!"#$ , edge-finder (%.# .

Material: &luminum block (appro'imately #$'3$ perations: &. (ecure the )orkpiece in the table of the milling machine using the *ice. !. #. 3. +lean milling machine *ise thoroughly. ,lace parallels under the )orkpiece to raise the surface to be milled abo*e the le*el of the *ise -a)s. &fter the )orkpiece is in place, tighten the *ise securely, then tap the )orkpiece lightly )ith a dead blo) hammer to seat it. .o not tighten the *ise again because this )ould alter the position of the )orkpiece and tightness of the parallels.

/. Machine (etup !. #. +heck the diameter of the cutter )ith a *ernier calipers. +alculate 0,M for cutting speed 1 !2% ft"min. V ( ft " min !# RPM = D(in 3hen using the 3hite +he*alier Mills. (et the speed of mill by ad-usting the 0,M knob and reading the speed on the analog meter. 456 and 476 scales represent high and lo) gear ranges. Note: do not cut at a speed lo)er than 8%% rpm )hile in the high gear range. (+heck )ith the lab instructor to *erify your setup before you continue . +alculate feed (in inch"min for a feed per tooth 1 %.%%3$. 9eed1 feed per tooth ' no. of cutter teeth ' 0,M Note: Power feed: speed is displayed on the digital readout. Adjust with the dial while moving away from your part. :f po)er feed is not a*ailable, use handles for manual feed. Note: The direction of feed is optional on a vertical milling machine.

3.

2.

+. Milling the top surface using fly (facemilling cutting !. #. 3. 2. 8. 6. <. =. >. !%. /efore starting the machine, be sure the cutting tool is clear of the )orkpiece. :f not, lo)er the )orkpiece by lo)ering the knee. Mo*e the table )ith the ' and y a'is handles to position the )orkpiece under the cutter. 7o)er the cutting tool or raise the table using the crank until it touches the top surface of the )orkpiece gently. (et the micrometer dial on the knee to ;ero. 7o)er the table by %.%#%$, by turning the knee hand)heel counter clock)ise. Mo*e the table longitudinally so that the cutter is clear of the )orkpiece at either end. Turn the machine on. 0aise the table (or lo)er the cutter %.%3%$ (! graduation is %.%%!$ from ;ero so that the final thickness of the )orkpiece is %.><%$?%.%%#$. @se multiple cuts and monitor the thickness of the )orkpiece. Angage the po)er feed )ith the le*er. Bote: Table tra*els in the direction of the feed engagement le*er. &fter )orkpiece has been milled on the top surface, disengage po)er feed and turn spindle off.

.. Andmilling of slots !. #. 3. 2. 8. 0eplace the face mill cutter )ith an edge finder (run the edge finder abo*e !C rpm Touch the corners of the )orkpiece to set the origin of the )orkpiece (the lab instructor )ill demonstrate the procedure . +onsider the diameter of the edge finder and offset the ;ero point accordingly. 0eplace the edge finder )ith a !"#$ end mill. Make a slot ! (through slot as sho)n in 9igure using the same procedure in +.#-+.!%. The cutting speed should be 8% ft"min and depth of the slot should be %.!%$. Dou )ill need multiple cuts. Make the slot # as sho)n in 9igure using the same procedure in +.#-+.!%. The depth of slot should be %.%8%$.

A. (lope machining !. #. @se a sine bar to set up the )orkpiece to be tilted at !%%. @se the !"#$ endmill or a fly cutter to generate the slope using multiple path cuts.

Ite!s to "e inclu#e# in the report !. #. Measured dimensions of the finished part (all the dimensions sho)n on the dra)ing +utting conditions used for each feature

3.

Vous aimerez peut-être aussi

- Milling Report SampleDocument3 pagesMilling Report SampleAmanda LamPas encore d'évaluation

- Exercise No. 1 Cutting Force Measurement Manufacturing Technology Lab I III Semester A & B AimDocument14 pagesExercise No. 1 Cutting Force Measurement Manufacturing Technology Lab I III Semester A & B AimThulasi RamPas encore d'évaluation

- TOOL MAKING-Bench Work-Practical. Reference Notes For Engineers.Document84 pagesTOOL MAKING-Bench Work-Practical. Reference Notes For Engineers.Kamatar PbkamatarPas encore d'évaluation

- Machine LabDocument16 pagesMachine Labtejashraj93Pas encore d'évaluation

- A Milling MachineDocument8 pagesA Milling MachinepedjaPas encore d'évaluation

- MCTD LabDocument38 pagesMCTD LabnidhidarklordPas encore d'évaluation

- Bonelle GrinderDocument11 pagesBonelle Grinderjohnjohn520% (1)

- Lap Report TemplateDocument7 pagesLap Report TemplateMd Sajib SheikhPas encore d'évaluation

- Cantilever Toolbox DesignDocument6 pagesCantilever Toolbox DesignKunal Rmth100% (2)

- Milling MachineDocument10 pagesMilling MachineNEF RIDERSPas encore d'évaluation

- Unit 5Document8 pagesUnit 5Narendra YadavPas encore d'évaluation

- Gear CuttingDocument3 pagesGear CuttingBarun DePas encore d'évaluation

- Milling OperationsDocument4 pagesMilling Operationsinboxsweets100% (1)

- 104 10Document42 pages104 10Ismail MullaPas encore d'évaluation

- Milling MachineDocument8 pagesMilling Machinegirma workuPas encore d'évaluation

- Machine Shop: C C C C C C C CDocument23 pagesMachine Shop: C C C C C C C CLakhvir SinghPas encore d'évaluation

- Hammer Full ReportDocument9 pagesHammer Full ReportVince Ong100% (3)

- 04 Lathe OperationsDocument31 pages04 Lathe OperationskatarenaveenPas encore d'évaluation

- Production TechnologyDocument12 pagesProduction TechnologySuhaib AshrafPas encore d'évaluation

- Lab MannualsDocument15 pagesLab MannualsJatin PahujaPas encore d'évaluation

- 4 - Sem Lab Manual: Spur Gear MillingDocument10 pages4 - Sem Lab Manual: Spur Gear MillingPRASSAN SHAHPas encore d'évaluation

- Alignment Tests On Milling MachineDocument4 pagesAlignment Tests On Milling Machinechandrarao chPas encore d'évaluation

- ME2258 Manufacturing Technology Lab IIDocument14 pagesME2258 Manufacturing Technology Lab IIதியாகராஜன் அரிதாஸ்Pas encore d'évaluation

- Adama Science and Technology University: Department of Thermal and Aerospace EngineeringDocument13 pagesAdama Science and Technology University: Department of Thermal and Aerospace Engineeringregassa rajiPas encore d'évaluation

- DrillingDocument3 pagesDrillingHilario PongaronPas encore d'évaluation

- Artcl Mortise and Tenon JointsDocument12 pagesArtcl Mortise and Tenon Jointsreader_jim100% (1)

- Key 4Document14 pagesKey 4Jury.rahulPas encore d'évaluation

- Rajshahi University of Engineering & TechnologyDocument7 pagesRajshahi University of Engineering & TechnologyMD Mahmudul Hasan MasudPas encore d'évaluation

- SOP Kinsland Ironworker #1003123456789112Document3 pagesSOP Kinsland Ironworker #1003123456789112saturnelPas encore d'évaluation

- Manufacturing A CheeseboardDocument14 pagesManufacturing A Cheeseboardapi-602237392Pas encore d'évaluation

- MACHINE TOOLS LabDocument40 pagesMACHINE TOOLS LabFarhan KhanPas encore d'évaluation

- SOP Kinsland Ironworker #10031234567891123Document3 pagesSOP Kinsland Ironworker #10031234567891123saturnelPas encore d'évaluation

- Unit I - Theory of Metal Cutting: Machine GrindingDocument24 pagesUnit I - Theory of Metal Cutting: Machine GrindingSasiKumarPas encore d'évaluation

- S. No Pg. No: I List of Figures IDocument15 pagesS. No Pg. No: I List of Figures Iyuvaraj shankarPas encore d'évaluation

- C7 - ShaperDocument11 pagesC7 - ShaperHans PinonPas encore d'évaluation

- Calibration of Precision Measuring InstrumentsDocument28 pagesCalibration of Precision Measuring InstrumentsSarath TejaPas encore d'évaluation

- End Mill GrindingDocument4 pagesEnd Mill GrindingtakudomePas encore d'évaluation

- DeWalt Rotary SurfacerDocument2 pagesDeWalt Rotary SurfacerDanPas encore d'évaluation

- Physics Lab Report.Document23 pagesPhysics Lab Report.Muhammad Sohag HussainPas encore d'évaluation

- Torsion Test1Document6 pagesTorsion Test1musher95100% (1)

- User Manual Pfaff Hobbylock 774Document21 pagesUser Manual Pfaff Hobbylock 774Martin CarrizalesPas encore d'évaluation

- Rap Drill and LatheDocument14 pagesRap Drill and LatheJoyce Saddhu MeettooPas encore d'évaluation

- Manufacturing Technology Lab IDocument43 pagesManufacturing Technology Lab IMECHANICAL SMCETPas encore d'évaluation

- 4th Sem Dme Machine Shop Records c20Document8 pages4th Sem Dme Machine Shop Records c20TRILOK KUMAR REDDYPas encore d'évaluation

- Before You Get Started: Safety Notice!Document5 pagesBefore You Get Started: Safety Notice!pc Express30Pas encore d'évaluation

- Exercise No. 1 Shear Angle Measurement AimDocument14 pagesExercise No. 1 Shear Angle Measurement AimKarthick JeyaramPas encore d'évaluation

- Up Workshop Manual 2020Document62 pagesUp Workshop Manual 2020Yash MittalPas encore d'évaluation

- Lab Sheet MillingDocument5 pagesLab Sheet MillingLalang Laut BestPas encore d'évaluation

- MT-2 Lab Manual Rajalaksmi PDFDocument11 pagesMT-2 Lab Manual Rajalaksmi PDFlenojerin3486Pas encore d'évaluation

- Milling MachineDocument6 pagesMilling MachineXQF PyariLalPas encore d'évaluation

- Machines Used in The Closing Room of A Large Manufacturing UnitDocument16 pagesMachines Used in The Closing Room of A Large Manufacturing UnitVishnu TejaPas encore d'évaluation

- Machine Shop Theory and Practi Ce: Mechanical EngineeringDocument14 pagesMachine Shop Theory and Practi Ce: Mechanical EngineeringJohn BorjaPas encore d'évaluation

- Wooden Train Track PlanDocument5 pagesWooden Train Track Planshootme2001Pas encore d'évaluation

- The Quick & Easy Triangle Block Tool: Make 100 Triangle, Diamond & Hexagon Blocks in 4 Sizes with Project Ideas; Packed with Hints, Tips & Tricks; Simple Cutting Charts, Helpful Reference TablesD'EverandThe Quick & Easy Triangle Block Tool: Make 100 Triangle, Diamond & Hexagon Blocks in 4 Sizes with Project Ideas; Packed with Hints, Tips & Tricks; Simple Cutting Charts, Helpful Reference TablesPas encore d'évaluation

- Singer Quantum Stylist 9960: Pocket Guide: Buttons, Dials, Settings, Stitches, and FeetD'EverandSinger Quantum Stylist 9960: Pocket Guide: Buttons, Dials, Settings, Stitches, and FeetPas encore d'évaluation

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsD'EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsÉvaluation : 5 sur 5 étoiles5/5 (1)

- Solution A 0.006 0.006 0.000036 M Q Ka /LDocument1 pageSolution A 0.006 0.006 0.000036 M Q Ka /Lhammada1001Pas encore d'évaluation

- Mass Transfer 5 Ed) : Left RightDocument1 pageMass Transfer 5 Ed) : Left Righthammada1001Pas encore d'évaluation

- Orifice DischargeDocument12 pagesOrifice Dischargehammada1001100% (3)

- Section A:Statics: Questions1: Q1, 2, 3&4Document2 pagesSection A:Statics: Questions1: Q1, 2, 3&4hammada1001Pas encore d'évaluation

- Verify Ohm's LawDocument3 pagesVerify Ohm's Lawhammada10010% (1)

- Conversion Us Uk Metric Si Units For Thermal EngineersDocument3 pagesConversion Us Uk Metric Si Units For Thermal Engineershammada1001Pas encore d'évaluation

- Pump Test Lab PDFDocument5 pagesPump Test Lab PDFhammada1001Pas encore d'évaluation