Académique Documents

Professionnel Documents

Culture Documents

Kingston Sinkhole Second Opinion

Transféré par

Daily FreemanCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Kingston Sinkhole Second Opinion

Transféré par

Daily FreemanDroits d'auteur :

Formats disponibles

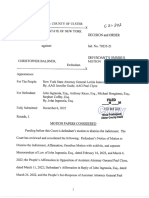

December 20, 2013 File No.

313604-000

Mr. Ralph Swenson, PE City Engineer, City of Kingston 420 Broadway Kingston, NY 12401 Dear Mr. Swenson: Brierley Associates Underground Engineers, PLLC (Brierley) has prepared this letter report which summarizes our Peer Review of the Washington Avenue Tunnel Stabilization Design. Our efforts focused on available historical and geotechnical information; review of the Mueser Rutledge Schematic Design Report, dated August 13, 2013; and, review of the GEA Engineering Report dated August 2013. This letter is intended to present the findings of our review and to provide the City of Kingston with comments, suggestions, and possible alternatives for the proposed design for remediation of the tunnel and shaft in the area of the Tannery Brook shaft. BACKGROUND The Washington Avenue Tunnel was constructed between 1909 and 1912 to convey combined storm water and sanitary sewage to an outfall at Roundout Creek. Subsequent to completion of the tunnel, the following events occurred in the vicinity of the Tannery Brook crossing at Washington Avenue: 1991-1992; Clough Harbour Associates undertook a program to investigate and design the installation of a drop shaft to connect the Tannery Brook flow channel to the existing CSO tunnel; a pilot borehole was advanced at the location of the drop shaft 1993; a 30-inch diameter steel drop shaft was installed to divert surface flow from Tannery Brook into the tunnel (It is our understanding that the objective of this project was to help alleviate flooding of Tannery Brook during storm events) 1998-2011; settlement/subsidence was observed and backfilled to south and west of the shaft on Washington Avenue May 2011; GroutTech, Inc. installed chemical grout around the 30-in. diameter drop shaft at top of rock (approx. 55 ft depth) and pumped cement-bentonite grout to ground surface May 2011; 6-inch water main near shaft broke and was repaired June 2011; Catch basin settled 24-inches and a 10-ft diameter sinkhole formed - Washington Ave was temporarily closed to traffic and detoured

City of Kingston December 20, 2013 Page 2 of 5

- 30 ft long steel sheeting was installed to protect 16-inch water main; and second row of sheeting adjacent to Tannery Brook to west of shaft was installed to cut-off subsurface seepage of water into shaft - SMT performed soil boring (B-1) to investigate ground/groundwater conditions - 6-inch water main was relocated to east side of sheeting July 2011; remote TV inspection of tunnel downstream of shaft; transition to rock tunnel approximately 160 ft downstream; minor leakage and sediment on invert was observed. - Began monitoring surface elevations and settlements April 2012; remote camera survey of shaft showed water leakage around the outside of the shaft penetration through the brick arch; sampled water draining into tunnel carrying gray fine sand and silt into tunnel - 3-ft by 7-ft deep sinkhole between sheeting and 16-in. water main; sheeting had dropped approx. 24-in. at this location; repair leak at bell joint in water main; backfill sinkhole - ConeTec performed 8 CPT probes near sinkhole area - Manned entry into tunnel via Tannery Brook shaft; no seepage observed around 30-in shaft; observed soil on invert 35 ft downstream with probable breach in crown June 2012; ConeTec performed 5 additional CPT probes along Washington Ave July 2012; An additional sinkhole located approximately 55 ft south of Tannery Brook Shaft was observed Feb 2013; ConeTec performed 11 additional CPT probes along/adjacent to Washington Ave March 2013; Hanson VanVleet conducted 3 soil borings and short rock cores; installed shallow and deep groundwater observation wells adjacent to Washington Ave near shaft. August-September 2013; installed and contact grouted approx. 170 feet of Link Pipe liner panels in the tunnel from the shaft to the south October 2013; Mueser Rutledge conducted 3 soil boring investigations (MR-1, MR-2, MR-3) along Washington Ave. from the shaft area to the south

SUBSURFACE CONDITIONS Brierley undertook an independent assessment and interpretation of the subsurface conditions in the vicinity of the Tannery Brook Shaft and adjacent tunnel alignment along Washington Avenue. Locally, the bedrock geology comprises sedimentary limestone and shale, overlain by variable thickness (20 ft to 100+ ft) of unconsolidated sediments and soils of glacial and postglacial origin. The limestone bedrock in the Kingston area is known to be fractured and folded; and the fractures have been enlarged by dissolution of the carbonate rock due to groundwater flow within the Onondaga-Schoharie Limestone Aquifer. This karstic environment has created a pattern of partially open fractures in the limestone that provides a network of groundwater flow channels. Based on a number of exploration borings and Cone Penetration Test (CPT) probes previously carried out in the area of the Tannery Brook Shaft, the overlying surficial deposits in the relatively undisturbed areas of Washington Ave. comprise fill soils (approx. 5 feet thick) underlain by fine sand or silty sand (alluvium) varying in depth from 5 to 25 feet. The mostly

City of Kingston December 20, 2013 Page 3 of 5

medium dense to dense strata of fine sand and silt with interlayers of clay, which become more prevalent with depth, generally persist to a depth of approximately 50 feet. Below 50 feet, soils are predominantly softer layers of clay and silt of variable thickness, which in turn, are underlain by significantly stiffer clay/silt/granular tills. Where penetrated by a few local borings, the till ranged in thickness from approximately 1 to 3 feet. Weathered limestone bedrock was observed below the till where rock coring was performed in nearby adjacent groundwater observation well installations. Prior to installation of the Tannery Brook shaft, a pilot hole drilled to tunnel depth in 1992 (as documented in the letter report by Clough Harbour Associates, Attachment 1), places the top of bedrock at a depth of approximately 62 feet; an approximate 2-ft thick void in the bedrock was encountered at 71 to 73 ft depth, followed by approximate 2 ft thickness of soft silt and clay, overlying the top of the tunnel lining materials at approximate depth of 75 ft. The void over the crown of the tunnel is quite probably the result of overbreak in weak, weathered rock created during initial excavation of the tunnel; the vertical and lateral extent of the void has not been defined. To the north of the shaft, the bedrock surface rises rapidly to a shallower depth of approximately 20 ft below ground surface; and drops off to a depth of over 100 feet to the south of the shaft along Washington Ave. The attached Subsurface Investigation Plan (Attachment 2) and Geologic Profile (Attachment 3) illustrates our understanding of the subsurface conditions; the top of bedrock and tunnel elevations at the shaft location are interpreted from the pilot hole log as drilled by Clough Harbour in 1992. Borings and CPT probes advanced through the soils in the immediate vicinity of the two sinkhole areas observed along the tunnel alignment indicate that the more sensitive fine sand, silt and clay have been disturbed or locally mobilized due to settlements created by the sink hole activity. Relative densities of the in-place soils show a marked decrease from medium dense to very loose to loose granular materials, and from medium stiff and stiff to very soft clay as a result. Further inspections of the tunnel interior after the sinkhole events revealed a significant accumulation of fine sediments in the tunnel invert. As the 30-inch steel shaft casing was advanced through the bedrock, and through the support timbers and brick tunnel arch, it is perceived that subsidence around the shaft was caused by mobilization of the surrounding soils into the tunnel and into the void in the rock above the tunnel. This connection would have been difficult to seal properly at completion of the shaft installation. EXISTING DROP STRUCTURE We agree with GEAs assessment of problems associated with the existing vertical 75 ft deep, 30-inch diameter steel drop shaft; particularly, with respect to the current arrangement. There is no means to de-aerate the air that is introduced by the falling water, which in turn creates bubbles that lead to cavitation and progressive deterioration of the existing 100-year old tunnel brick lining during high flow events. Repeated surge events during heavy storm flows also contribute to the deterioration of the steel shaft penetration through the tunnel crown which promotes the migration, intrusion and infilling of the tunnel with surrounding soils and ground

City of Kingston December 20, 2013 Page 4 of 5

water. Similarly, repeated, turbulent storm flow events also contribute to successive downstream migration of the deterioration of the brick tunnel lining and subsequent development of additional sinkholes. Even though the tunnel is presently lined with PVC Link Pipe materials, turbulence and vibrations created during storm flow events may still adversely impact the integrity of the overlying 100 year old brick lining, timber supports and dry packing materials REMEDIAL DESIGN APPROACH We have reviewed GEA/Mueser Rutledge approach to remediation and stabilization of the Tannery Brook Drop Structure; the existing 30-inch diameter shaft; the tunnel; and the ground above and adjacent to the tunnel. Based on the current approach to improving the existing shaft, tunnel and ground conditions as proposed by Mueser Rutledge, we offer the following observations and recommendations: The remedial measures to prevent further ground loss into the tunnel should include contact grouting of potential void space between the initial tunnel timber support and the final lining. To avoid damaging the recently installed Link Pipe liner, the contact grouting can be accomplished by drilling down from the ground surface. It is our opinion that jet grouting encasement is all that is necessary versus the full jet grout arch to prevent future soil loss into the tunnel. The vibrating pile densification (dynamic compaction) might damage utilities. Shaft penetration grouting should be performed. The type of grout used will depend on the anticipated size of voids in, or behind the tunnel lining/shaft penetration. Concrete grouts are generally the most cost effective for large voids, and water activated polyurethane grouts are most effective for sealing hairline cracks. The area of the connection of the shaft to the tunnel will likely require use of both types of grout. Provide instrumentation to monitor for vibration and settlements at adjacent structures and utilities during construction

ALTERNATIVE REMEDIATION APPROACH We would also like to provide an alternative approach to the restoration and stabilization of the tunnel and adjacent ground conditions, including construction of a new drop shaft as follows: Abandon and completely seal off the inside/outside of the existing 30-inch steel drop shaft that penetrates the crown of the existing tunnel; Construct/install a new shaft offset approximately 5-feet from the existing tunnel alignment and excavate a lined connection adit into the side wall of the existing tunnel; provide a positive water-tight seal around this connection; Provide an inlet vortex structure as proposed by GEA at the new drop shaft location; or otherwise provide for de-aeration/venting of air entrainment to dissipate energy from the falling water flow; Conduct thorough contact grouting of the existing tunnel exterior that is exposed to overlying soils along the portion of the alignment extending south of the Tannery Brook

City of Kingston December 20, 2013 Page 5 of 5

shaft; and to overlap with the bedrock portion of the tunnel at the north and south extremities of this reach (approximately over length of 180 ft). To avoid penetrating the existing PVC liner installed within the tunnel, execute the contact grouting by drilling down from the ground surface. In lieu of vibrating pile densification and jet grouting of the surrounding soils, install rammed aggregate geopiers to densify the ground and support Washington Avenue. The geopiers would be approximately 30 inches diameter, extend to depth of approximately 20 ft, and spaced at 7 to 10 ft grid pattern beneath the roadway over a length of approximately 180 feet. The installation and compaction of the stone filled piers will provide densification of the surrounding soils and support the road; Construct a load transfer platform to distribute traffic loads from the pavement to the rammed aggregate piers. The load transfer platform would consist of structural fill, geogrids and sub-base material. Install instrumentation to monitor for settlements at adjacent structures and utilities during construction

We look forward to meeting with you in January to discuss our observations and recommendations in more detail.

Sincerely Yours, BRIERLEY ASSOCIATES UNDERGROUND ENGINEERS, PLLC

A. J. McGinn, PE, PhD President and CEO Attachments: Tannery Brook Shaft Pilot Hole Log Subsurface Investigation Plan Geologic Profile

Vous aimerez peut-être aussi

- Shaft Collar in Deep Overburden - Aur Resources - LouvicourtDocument8 pagesShaft Collar in Deep Overburden - Aur Resources - LouvicourtEEPPas encore d'évaluation

- Seismic Soil-Tunnel Interaction and Retrofit of Posey-Webster TunnelsDocument21 pagesSeismic Soil-Tunnel Interaction and Retrofit of Posey-Webster TunnelsYuamar BasarahPas encore d'évaluation

- A.V. Watkins Dam Modification Cement-Bentonite Slurry Cutoff WallDocument13 pagesA.V. Watkins Dam Modification Cement-Bentonite Slurry Cutoff WallMUHAMMAD ALIPas encore d'évaluation

- Fontenelle Dam Incident: Lessons in Foundation TreatmentDocument18 pagesFontenelle Dam Incident: Lessons in Foundation TreatmentMarcelo ProtzPas encore d'évaluation

- 243 Design Construction - Cut-Off Walls Under The Arapuni DamDocument19 pages243 Design Construction - Cut-Off Walls Under The Arapuni DamSelah AbdulahiPas encore d'évaluation

- Cement Bentonite Slurry Wall StrengthDocument12 pagesCement Bentonite Slurry Wall StrengthvhgaitanPas encore d'évaluation

- Use of A Digger Shield For TBM Adverse Ground Conditions - Cobbles - BouldersDocument10 pagesUse of A Digger Shield For TBM Adverse Ground Conditions - Cobbles - Bouldersdafo407Pas encore d'évaluation

- Wilson1 RETC2011Document8 pagesWilson1 RETC2011markus morattiPas encore d'évaluation

- The Vienna Donau City Tower 2000mm Flat SlabsDocument16 pagesThe Vienna Donau City Tower 2000mm Flat SlabsSakisPas encore d'évaluation

- Micro PilesDocument13 pagesMicro PilesAndrew WinnerPas encore d'évaluation

- Earth Pressures on Ottawa Outfall Sewer TunnelDocument16 pagesEarth Pressures on Ottawa Outfall Sewer TunnelFelipe PereiraPas encore d'évaluation

- Northside Storage Tunnel, Sydney: Investigation, Design and ConstructionDocument9 pagesNorthside Storage Tunnel, Sydney: Investigation, Design and ConstructionHarold TaylorPas encore d'évaluation

- Ambersen Dam Stabilization PDFDocument12 pagesAmbersen Dam Stabilization PDFchutton681Pas encore d'évaluation

- Jon Williams Dam Sftey Article Townsville - PDF GHD Design Lenthalls Dam GatesDocument7 pagesJon Williams Dam Sftey Article Townsville - PDF GHD Design Lenthalls Dam GatesLenthallsdamgatefailPas encore d'évaluation

- Designing Cut-Off Walls Under Concrete DamDocument17 pagesDesigning Cut-Off Walls Under Concrete DamNazakat HussainPas encore d'évaluation

- WTC Construction & Destruction Geotechnical ChallengesDocument39 pagesWTC Construction & Destruction Geotechnical ChallengesnyghodsiPas encore d'évaluation

- Sutong Bridge FoundationsDocument16 pagesSutong Bridge FoundationsDimitris PantelakisPas encore d'évaluation

- Tunnel and Shaft Construction For The Pingston Hydro ProjectDocument11 pagesTunnel and Shaft Construction For The Pingston Hydro ProjectZeynep Ahmet GülerPas encore d'évaluation

- M5 East - The Design of Australia's Longest Driven Motorway TunnelDocument7 pagesM5 East - The Design of Australia's Longest Driven Motorway TunnelHarold TaylorPas encore d'évaluation

- Finn and Wu (2013) Dynamic Analysis of An Earthfill Dam On OC Silt With Cyclic Strain SofteningDocument15 pagesFinn and Wu (2013) Dynamic Analysis of An Earthfill Dam On OC Silt With Cyclic Strain SofteningszarnaniPas encore d'évaluation

- Universidad Católica San Pablo, Arequipa Estabilidad Estatica TaludesDocument57 pagesUniversidad Católica San Pablo, Arequipa Estabilidad Estatica TaludesJuan GomezPas encore d'évaluation

- Bouldin Dam Case HistoryDocument8 pagesBouldin Dam Case HistoryNat TikusPas encore d'évaluation

- Deep Shaft Design and ConstructionDocument14 pagesDeep Shaft Design and ConstructionFabio Nascimento100% (3)

- 1129 Cofferdam Ohio River Power PDFDocument16 pages1129 Cofferdam Ohio River Power PDFDiego Montaña P100% (1)

- Tunnels: BackgroundDocument6 pagesTunnels: BackgroundMarvin ZimmermanPas encore d'évaluation

- Research Paper Shashank 1augDocument7 pagesResearch Paper Shashank 1augGemini GoelPas encore d'évaluation

- Romanoff1962 PDFDocument24 pagesRomanoff1962 PDFabsharaslam3765Pas encore d'évaluation

- Microsoft Word - Chap 03 Foundation TreatmentDocument18 pagesMicrosoft Word - Chap 03 Foundation TreatmentCristhian PardoPas encore d'évaluation

- Cofferdams and CaissonsDocument7 pagesCofferdams and CaissonsradhakrishnangPas encore d'évaluation

- Stabilization of Rock Slope Over Tunnel PortalDocument1 pageStabilization of Rock Slope Over Tunnel PortalLeonardo CruzPas encore d'évaluation

- Fema 484 Part 8Document64 pagesFema 484 Part 8וויסאם חטארPas encore d'évaluation

- WATERRSSSDocument2 pagesWATERRSSSShady RainPas encore d'évaluation

- Scour ProjectDocument26 pagesScour ProjectANSHUL SHEOKANDPas encore d'évaluation

- Settlement of Embankment Dams - Don'T Forget About The BedrockDocument25 pagesSettlement of Embankment Dams - Don'T Forget About The BedrockSarmad BarwaryPas encore d'évaluation

- Geological Criteria For Dams: Deeptesh Karmalkar ES16BTECH11013Document4 pagesGeological Criteria For Dams: Deeptesh Karmalkar ES16BTECH11013Deeptesh KarmalkarPas encore d'évaluation

- 2008 - Tugun Bypass Tunnel - 13th ATC 2008Document10 pages2008 - Tugun Bypass Tunnel - 13th ATC 2008DaGoose81Pas encore d'évaluation

- BridgeDocument30 pagesBridgeNurul NadhirahPas encore d'évaluation

- Support of Deep Excavation in Soft Clay A Case History StudyDocument8 pagesSupport of Deep Excavation in Soft Clay A Case History StudyAlfredo A LopezPas encore d'évaluation

- Excavation of Swelling Rock by Measuring The Displacement Under RoadbedDocument10 pagesExcavation of Swelling Rock by Measuring The Displacement Under RoadbedMapeixPas encore d'évaluation

- Eng 01 00013 With CoverDocument24 pagesEng 01 00013 With CoverJose SantosPas encore d'évaluation

- A DSM Wall For Excavation SupportDocument14 pagesA DSM Wall For Excavation SupportmarmeiraisPas encore d'évaluation

- Shaft Sinking: Department of Mining Engineering Muet Jamshoro (11-04-2014)Document21 pagesShaft Sinking: Department of Mining Engineering Muet Jamshoro (11-04-2014)Carlos Arturo Casas HuamánPas encore d'évaluation

- 10 Boyce Irvington NATDocument12 pages10 Boyce Irvington NATCarlos PlazaolaPas encore d'évaluation

- Background On Teton Dam FailureDocument30 pagesBackground On Teton Dam Failureashish_agarwal_69Pas encore d'évaluation

- Local Scouring Around A Circular Pier in Open ChannelDocument5 pagesLocal Scouring Around A Circular Pier in Open Channelomed muhammadPas encore d'évaluation

- Sopport of Tunnel in Weak Rock-Jacobs AssociatesDocument22 pagesSopport of Tunnel in Weak Rock-Jacobs AssociateswjzabalaPas encore d'évaluation

- 20210921-EMI Soil Characterization Memo Rev 3Document71 pages20210921-EMI Soil Characterization Memo Rev 3Maroua HammamiPas encore d'évaluation

- Performance of Lime Cement-Stabilized Soils For The I-15 Reconstruction ProjectDocument9 pagesPerformance of Lime Cement-Stabilized Soils For The I-15 Reconstruction ProjectLeonardo TejedorPas encore d'évaluation

- Failure of Swift2 DamDocument68 pagesFailure of Swift2 DamHosein JavaheriPas encore d'évaluation

- Tunneling Problems For 1020 MW Tala Hydroelectric Project in Bhutan HimalayasDocument10 pagesTunneling Problems For 1020 MW Tala Hydroelectric Project in Bhutan HimalayasHarold TaylorPas encore d'évaluation

- Case Study Delayed Failure of A Deep Cutting in Lodgement TillDocument10 pagesCase Study Delayed Failure of A Deep Cutting in Lodgement TillthadikkaranPas encore d'évaluation

- Case study of 2014 sinkholes in Kuala Lumpur due to construction and soil erosionDocument1 pageCase study of 2014 sinkholes in Kuala Lumpur due to construction and soil erosionamirah100% (1)

- Diaphragm WallDocument5 pagesDiaphragm WallChandra Prakash Khatri0% (1)

- Optimizing Project Schedule and Cost by Utilizing Available Steel SectionsDocument9 pagesOptimizing Project Schedule and Cost by Utilizing Available Steel SectionsBiswajit dasPas encore d'évaluation

- FINAL PAPER - CSM To Retain A Trench Excavated in Reclaimed Land-Case StudyDocument8 pagesFINAL PAPER - CSM To Retain A Trench Excavated in Reclaimed Land-Case StudyAnikaPas encore d'évaluation

- Hoover Dam (USA) : Problem Technology/ EquipmentDocument8 pagesHoover Dam (USA) : Problem Technology/ EquipmentEdence PuahPas encore d'évaluation

- Transactions of the American Society of Civil Engineers, Vol. LXVIII, Sept. 1910 The New York Tunnel Extension of the Pennsylvania Railroad. The North River Tunnels. Paper No. 1155D'EverandTransactions of the American Society of Civil Engineers, Vol. LXVIII, Sept. 1910 The New York Tunnel Extension of the Pennsylvania Railroad. The North River Tunnels. Paper No. 1155Pas encore d'évaluation

- Transactions of the American Society of Civil Engineers, vol. LXVIII, Sept. 1910 The New York Tunnel Extension of the Pennsylvania Railroad. The East River Tunnels. Paper No. 1159D'EverandTransactions of the American Society of Civil Engineers, vol. LXVIII, Sept. 1910 The New York Tunnel Extension of the Pennsylvania Railroad. The East River Tunnels. Paper No. 1159Pas encore d'évaluation

- Transactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Reinforced Concrete Pier ConstructionD'EverandTransactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Reinforced Concrete Pier ConstructionPas encore d'évaluation

- Scientific American Supplement, No. 497, July 11, 1885D'EverandScientific American Supplement, No. 497, July 11, 1885Pas encore d'évaluation

- Kingston Rent Control Appellate Court DecisionDocument9 pagesKingston Rent Control Appellate Court DecisionDaily FreemanPas encore d'évaluation

- Joseph Maloney's Affidavit in SupportDocument12 pagesJoseph Maloney's Affidavit in SupportDaily FreemanPas encore d'évaluation

- Lawsuit Filed by Charles Whittaker Against Donald Markle and Joseph MaloneyDocument9 pagesLawsuit Filed by Charles Whittaker Against Donald Markle and Joseph MaloneyDaily FreemanPas encore d'évaluation

- NY AG Report On Saugerties Police Officer Dion JohnsonDocument15 pagesNY AG Report On Saugerties Police Officer Dion JohnsonDaily FreemanPas encore d'évaluation

- Ulster County Sales Tax Revenues 2022Document2 pagesUlster County Sales Tax Revenues 2022Daily FreemanPas encore d'évaluation

- Fire Investigators Report On Oct. 10, 2023, Fire in KerhonksonDocument19 pagesFire Investigators Report On Oct. 10, 2023, Fire in KerhonksonDaily FreemanPas encore d'évaluation

- Lawsuit Filed by Frank and Pam Eighmey Against Town of WoodstockDocument46 pagesLawsuit Filed by Frank and Pam Eighmey Against Town of WoodstockDwayne Kroohs100% (1)

- Ulster County Executive Jen Metzger's Open LetterDocument2 pagesUlster County Executive Jen Metzger's Open LetterDaily FreemanPas encore d'évaluation

- Out of Reach 2023Document17 pagesOut of Reach 2023Daily Freeman100% (1)

- Ulster County Solar PILOTs Audit - Review of Billing and CollectionsDocument7 pagesUlster County Solar PILOTs Audit - Review of Billing and CollectionsDaily FreemanPas encore d'évaluation

- Vassar College Class Action ComplaintDocument25 pagesVassar College Class Action ComplaintDaily FreemanPas encore d'évaluation

- Ulster County First Quarter 2023 Financial ReportDocument7 pagesUlster County First Quarter 2023 Financial ReportDaily FreemanPas encore d'évaluation

- Ulster County Multi-Jurisdictional Hazard Mitigation Plan ResponseDocument3 pagesUlster County Multi-Jurisdictional Hazard Mitigation Plan ResponseDaily FreemanPas encore d'évaluation

- HydroQuest UCRRA Landfill Siting Report 1-05-22 With MapsDocument29 pagesHydroQuest UCRRA Landfill Siting Report 1-05-22 With MapsDaily FreemanPas encore d'évaluation

- Tyrone Wilson StatementDocument2 pagesTyrone Wilson StatementDaily FreemanPas encore d'évaluation

- New York State Senate Committee Report On Utility Pricing PracticesDocument119 pagesNew York State Senate Committee Report On Utility Pricing PracticesDaily FreemanPas encore d'évaluation

- Real Property Tax Audit With Management Comment and ExhibitsDocument29 pagesReal Property Tax Audit With Management Comment and ExhibitsDaily FreemanPas encore d'évaluation

- Ulster County Executive Jen Metzger, Municipal Leaders Letter Over Rail SafetyDocument3 pagesUlster County Executive Jen Metzger, Municipal Leaders Letter Over Rail SafetyDaily FreemanPas encore d'évaluation

- Central Hudson Class Action LawsuitDocument30 pagesCentral Hudson Class Action LawsuitDaily FreemanPas encore d'évaluation

- Schumer RRs Safety LetterDocument2 pagesSchumer RRs Safety LetterDaily Freeman100% (1)

- Letter To Ulster County Executive Regarding Request For Updated Emergency PlanDocument1 pageLetter To Ulster County Executive Regarding Request For Updated Emergency PlanDaily FreemanPas encore d'évaluation

- Ulster County Executive Jen Metzger Open Letter On County FinancesDocument2 pagesUlster County Executive Jen Metzger Open Letter On County FinancesDaily FreemanPas encore d'évaluation

- Terramor Application Withdrawa February 2023Document1 pageTerramor Application Withdrawa February 2023Daily FreemanPas encore d'évaluation

- Central Hudson Response To Public Service Commission ReportDocument92 pagesCentral Hudson Response To Public Service Commission ReportDaily FreemanPas encore d'évaluation

- Ulster County Judge Ruling Dismisses Murder Charge Against State TrooperDocument23 pagesUlster County Judge Ruling Dismisses Murder Charge Against State TrooperDaily FreemanPas encore d'évaluation

- Public Service Investigation Report On Central HudsonDocument62 pagesPublic Service Investigation Report On Central HudsonDaily FreemanPas encore d'évaluation

- Ulster County Executive Jen Metzger Order Regarding Implementation of The New York State Climate Leadership and Community Protection ActDocument4 pagesUlster County Executive Jen Metzger Order Regarding Implementation of The New York State Climate Leadership and Community Protection ActDaily FreemanPas encore d'évaluation

- Democrats' Lawsuit Seeking New Ulster County Legislative MapsDocument21 pagesDemocrats' Lawsuit Seeking New Ulster County Legislative MapsDaily FreemanPas encore d'évaluation

- 2022 Third Quarter Financial ReportDocument7 pages2022 Third Quarter Financial ReportDaily FreemanPas encore d'évaluation

- Jane Doe v. Bard CollegeDocument55 pagesJane Doe v. Bard CollegeDaily FreemanPas encore d'évaluation

- Settlement Behaviour of Deep Engineered FillDocument10 pagesSettlement Behaviour of Deep Engineered FillDanny LamPas encore d'évaluation

- Bentonite Grade Details..Document6 pagesBentonite Grade Details..moto rola100% (1)

- E-Auction Raw Lignite Ballclay Silica Sand PDFDocument3 pagesE-Auction Raw Lignite Ballclay Silica Sand PDFshiva1720Pas encore d'évaluation

- The Lithospere 2 - Soil ScienceDocument78 pagesThe Lithospere 2 - Soil ScienceAcep AbdullahPas encore d'évaluation

- Production of Pavement Blocks from Plastic WasteDocument9 pagesProduction of Pavement Blocks from Plastic WasteJyoti GaurPas encore d'évaluation

- Coefficient of Compressibility Correlations of Soil and Rock Properties in Geotechnical EngineeringDocument1 pageCoefficient of Compressibility Correlations of Soil and Rock Properties in Geotechnical EngineeringTomasz CzPas encore d'évaluation

- Tecnical Note (Tarea 3)Document7 pagesTecnical Note (Tarea 3)Jannet FariasPas encore d'évaluation

- Understanding The Bach Dang Battlefield From Recent Research ResultsDocument13 pagesUnderstanding The Bach Dang Battlefield From Recent Research Resultsnvh92Pas encore d'évaluation

- Solution Manual For Principles of GeotecDocument14 pagesSolution Manual For Principles of GeotecHabib Musa MohamadPas encore d'évaluation

- Soil ClassificationDocument47 pagesSoil ClassificationEr VenkatPas encore d'évaluation

- Btec Higher National Diploma in Quantity Surveying Technology ADocument51 pagesBtec Higher National Diploma in Quantity Surveying Technology AlashPas encore d'évaluation

- Soil Properties Influence on Dam DesignDocument27 pagesSoil Properties Influence on Dam DesignJulfikar KhanPas encore d'évaluation

- Vibro ReplacementDocument31 pagesVibro ReplacementChris FindlayPas encore d'évaluation

- SCIENCE AND MATHS Exam Papers For BeginnersDocument25 pagesSCIENCE AND MATHS Exam Papers For BeginnersNival Kolambage60% (5)

- Colorful Clay Creations LessonDocument1 pageColorful Clay Creations Lessonapi-469735211Pas encore d'évaluation

- Identifying Dispersive Clays Using Pinhole Erosion TestsDocument28 pagesIdentifying Dispersive Clays Using Pinhole Erosion TestsAndyra Jaiz Baddu100% (1)

- Is.1498.1970 Soil ClassificationDocument28 pagesIs.1498.1970 Soil Classificationp09tp451Pas encore d'évaluation

- Agbo 2023 IOP Conf. Ser. Earth Environ. Sci. 1178 012019Document10 pagesAgbo 2023 IOP Conf. Ser. Earth Environ. Sci. 1178 012019Agbo sundayPas encore d'évaluation

- Essential Guide to Soil Types, Foundation Design and Damp ProofingDocument14 pagesEssential Guide to Soil Types, Foundation Design and Damp ProofingPriya ManePas encore d'évaluation

- Loam SoilDocument5 pagesLoam SoilTavonga Vere100% (1)

- Geological Evolution of The Holocene Yarra Delta and Its RelationshipDocument18 pagesGeological Evolution of The Holocene Yarra Delta and Its RelationshipDanny Lam100% (1)

- Cec 208 TheoryDocument87 pagesCec 208 TheoryAyomide AdelekePas encore d'évaluation

- Drilled Shaft 2Document126 pagesDrilled Shaft 2andradeinsuaPas encore d'évaluation

- Excavations at Wessex Court, Charles Street, Dorchester, Dorset, 1989Document170 pagesExcavations at Wessex Court, Charles Street, Dorchester, Dorset, 1989Wessex ArchaeologyPas encore d'évaluation

- The Effect of Hydrated Lime On The Petrography and Strength Characteristics of Illite ClayDocument10 pagesThe Effect of Hydrated Lime On The Petrography and Strength Characteristics of Illite ClayHamed SalehpourPas encore d'évaluation

- References Traffic TunnellingDocument92 pagesReferences Traffic TunnellingValderi FerreiraPas encore d'évaluation

- Behaylu HundeDocument69 pagesBehaylu HundeBiruk FisehaPas encore d'évaluation

- How Soil Series Are Classified and Their ImportanceDocument9 pagesHow Soil Series Are Classified and Their ImportanceBabatunde Idowu EbenezerPas encore d'évaluation

- What Is Fire Clay and Where To Get It in NatureDocument6 pagesWhat Is Fire Clay and Where To Get It in NatureRODRIGO TROCONISPas encore d'évaluation

- Bricks Civil EngineeringDocument39 pagesBricks Civil EngineeringNivashini VindhyaPas encore d'évaluation