Académique Documents

Professionnel Documents

Culture Documents

9 Tool Maker Microscope

Transféré par

somu_amuCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

9 Tool Maker Microscope

Transféré par

somu_amuDroits d'auteur :

Formats disponibles

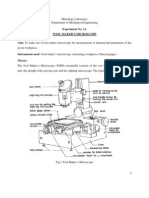

TOOL MAKER MICROSCOPE

The tool makers microscope is an essential part of engineering inspection, measurement and calibration in metrology labs. But what makes a tool maker microscope fully functional are its glass grading and optics system. Since what are being viewed under these microscopes are metals and precision instruments. It is important that the objective and the eye piece lenses are made of fine uality glasses only. These essential parts are what makes the device very durable and gives it the ability to withstand the wear and tear associated with the everyday stress of factory usage. !nd much because of this, it is also important that the body, structure, and mechanisms of a tool maker microscope are created with highly durable materials, most preferably good uality metals. Because the conditions inside an industrial laboratory are not as good as a home or office laboratory setup, the microscopes body should be capable of low heat production. It should also be able to resist corrosion, oscillation, and pollution " because all of these elements are present inside an industrial laboratories and production plants. There are tool maker microscopes that are e uipped with a cross hair reticle on the eye piece, coupled with a protractor on the tube. These are good instruments used to accurately measure the distance or the diameter of the tool under observation. The microscopes stage is also built with a millimeter measuring system that also allows for the measurement of the specimen. The stage when moved, produce the distance traveled with which the microscope effectively measures. #ight now, uality tool maker microscopes are using semiconductor laser devices as directors. Instead of the cross hairs, a red point is virtually marked on the microscopes working surface in order to locate the parts that have to be measured by the microscope. The $$% imaging system can also be used as a measurement system as well. This is another advanced feature of the newer versions of a tool maker microscope models. ! $$% camera that has the ability to measure diameters and distances is a lot more convenient to use, especially to beginners.

But aside from all of these, a tool maker microscope should also have a good illumination system. It is the light that allows for the superior viewing of tools and specimens. The higher the luminance value of the light provided by the microscope, the better its performance is. If necessary, an incandescent lamp should not be used for these applications. The light that is ideal is the one that produces a nice level of brightness with less heat. &s have life spans too. !nd because most of a tool maker microscope uses a built'in lighting system, the light to be used should last for an e(tended period of time, if and when possible.

Fig. Tool Makers Microscope

Working principle T)) is based on the principle of optics. The Tool )akers )icroscope *T))+ essentially consists of the cast base, the main lighting unit, the upright with carrying arm and the sighting microscope. The rigid cast base is resting on Tool )akers )icroscope three foot screws by means of which the e uipment can be leveled with reference to the built'in spirit level. The base carries the co'ordinate measuring table, consists of two measuring slides, one each for directions - and ., and a rotary circular table provided with the glass plate. The slides run on precision balls in hardened guide ways warranting reliable travel. Two microme er screws eac! o" !em !a#ing meas$ring range o" % o &' mm permi !e meas$ring a(le o (e )isplace) in !e )irec ions * an) +. T!e range o" mo#emen s o" !e carriage can (e wi)ene) $p o ,' mm in !e * )irec ion an) $p o '% mm in !e + )irec ion wi ! !e $se o" ga$ge (locks. T!e ro ar- a(le !as (een pro#i)e) wi ! ./% gra)$a ion an) wi ! a /% min$ e #ernier. The rotary motion is initiated by activation of knurled knob. Slots in the rotary table serve for fastening different accessories and completing elements. The sighting microscope has been fastened to column with a carrier arm. The carrier arm can be adjusted in height by means of a rack. The main lighting unit has been arranged in the rear of the cast base and e uipped with projection lamp where rays are directed via stationary mounted mirror through table glass plate into the sighting microscope. Meas$ring principle Tool )akers )icroscope is a precision /ptical )icroscope that consists of single or multiple objective lenses, which magnifies the object under observation and by the help of eyepiece lens the object is focused and viewed. ! high precision micrometric -'. stage and the 0 a(is travel are used to measure the three dimensions 1&ength *-+, 2idth *.+ and %epth *0+3. The angle is measured with the help of a rotating stage and eyepiece graduation.

Applica ions 4(amination of form tools, plate and template gauges, punches and dies, annular grooved and threaded hobs etc. )easurement of glass graticules and other surface marked parts. Shallow bores and recesses. The determination of relative position of various points on work. )easurement of angle by using a protractor eyepiece. $omparison of thread forms with master profiles engraved in the eyepiece, measurement of pitch and effective diameter. $omparison of enlarged, projected image with a tracing fi(ed to the projecting screen.

Vous aimerez peut-être aussi

- Engineering Metrology and Measurements NotesDocument131 pagesEngineering Metrology and Measurements NotesBALAMUGUNDAN91% (32)

- Optics and Optical Instruments: An IntroductionD'EverandOptics and Optical Instruments: An IntroductionÉvaluation : 4 sur 5 étoiles4/5 (5)

- An Introduction To Murano Glass ChandeliersDocument12 pagesAn Introduction To Murano Glass ChandeliersAlbriciPas encore d'évaluation

- Rooftop Solar Installation Project Proposal TemplateDocument6 pagesRooftop Solar Installation Project Proposal TemplateJames CubittPas encore d'évaluation

- Traditional Profiles Description Size Vertex Code Vertex IllustrationDocument56 pagesTraditional Profiles Description Size Vertex Code Vertex IllustrationAllen EspeletaPas encore d'évaluation

- Profile ProjectorDocument17 pagesProfile ProjectorMariam ZakirPas encore d'évaluation

- Micrometers - Slide Gauges and Calipers - Principles, Construction, Operation and Use of Appliances for Fine Mechanical MeasurementsD'EverandMicrometers - Slide Gauges and Calipers - Principles, Construction, Operation and Use of Appliances for Fine Mechanical MeasurementsPas encore d'évaluation

- Module IV: Computer-Aided and Laser Metrology TechniquesDocument9 pagesModule IV: Computer-Aided and Laser Metrology TechniquesShiba SahuPas encore d'évaluation

- ME250 Straightness Measurement using AutocollimatorDocument10 pagesME250 Straightness Measurement using AutocollimatorpradabkPas encore d'évaluation

- Chavi Novel - Washintonil ThiurmanamDocument172 pagesChavi Novel - Washintonil ThiurmanamSakthivel83% (12)

- Tool Makers MicroscopeDocument13 pagesTool Makers MicroscopeLokesh LokiPas encore d'évaluation

- Calibration MicroscopeDocument6 pagesCalibration MicroscopeJeAyuSPutriPas encore d'évaluation

- Tool Maker MicroscopeDocument4 pagesTool Maker MicroscopeShyam SenthilPas encore d'évaluation

- The ToolmakeeerDocument31 pagesThe ToolmakeeerVarunPas encore d'évaluation

- The Tool MakerDocument4 pagesThe Tool MakerRitesh YadavPas encore d'évaluation

- Toolmakers Microscope MeasurementsDocument7 pagesToolmakers Microscope MeasurementsskumarPas encore d'évaluation

- MI Tool Makers MicroscopeDocument9 pagesMI Tool Makers MicroscopeGurpreet KaurPas encore d'évaluation

- Metrology Measuring ToolsDocument28 pagesMetrology Measuring ToolsRadha KrishnaPas encore d'évaluation

- M.E., Cad/Cam Unit I For Non-Destructive TestingDocument17 pagesM.E., Cad/Cam Unit I For Non-Destructive TestingBarathkannan Lakshmi PalanichamyPas encore d'évaluation

- Tool Makers MicroscopeDocument2 pagesTool Makers Microscopesukriti dhauni100% (1)

- How To Use Micrometer On Microscopes: Biology 1Document7 pagesHow To Use Micrometer On Microscopes: Biology 1Rakeesh VeeraPas encore d'évaluation

- Toolmakersmicroscope 140722144506 Phpapp02Document32 pagesToolmakersmicroscope 140722144506 Phpapp02Arjun ReghuPas encore d'évaluation

- Chapter ThreeDocument14 pagesChapter ThreeBogdan Constantin CristeaPas encore d'évaluation

- Engineering Materials AssignementDocument11 pagesEngineering Materials AssignementHassaan YousafPas encore d'évaluation

- Measuring Device for Precision Work: The Toolmaker's MicroscopeDocument11 pagesMeasuring Device for Precision Work: The Toolmaker's MicroscopeSanas AmolPas encore d'évaluation

- Optical InferometryDocument2 pagesOptical Inferometryajay ranaPas encore d'évaluation

- Tool Makers MicroscopeDocument11 pagesTool Makers Microscopeirfanajai100% (1)

- Autocollimator ProjectDocument11 pagesAutocollimator ProjectAryan VigneshPas encore d'évaluation

- Mechanical Measurement and Control Assignment No.-06Document9 pagesMechanical Measurement and Control Assignment No.-06Ayush TiwariPas encore d'évaluation

- Experiment No. 1A Tool Maker'S MicroscopeDocument4 pagesExperiment No. 1A Tool Maker'S MicroscopePraveen KumaarPas encore d'évaluation

- Experiment No: 03 EXPERIMENT: Measurement of Different Parameters of A Machine Component Using The Optical ComparatorDocument7 pagesExperiment No: 03 EXPERIMENT: Measurement of Different Parameters of A Machine Component Using The Optical ComparatorAbienash Thangavel100% (1)

- Tool Makers Microscope PPT - Siddhant SinghDocument15 pagesTool Makers Microscope PPT - Siddhant SinghSiddhant Singh100% (1)

- Profile Projector ExperimentDocument3 pagesProfile Projector ExperimentTariq AslamPas encore d'évaluation

- Nikhil Lincoln Roll No - 47 S6 Me: Metrology and Machine Tools Assignment-2Document14 pagesNikhil Lincoln Roll No - 47 S6 Me: Metrology and Machine Tools Assignment-2Nikhil LincolnPas encore d'évaluation

- Microscope and Its TypeDocument25 pagesMicroscope and Its TypeapangirearnavPas encore d'évaluation

- 04-Use of Optic Aids Info SheetsDocument21 pages04-Use of Optic Aids Info SheetsRony Prayitno SimeonPas encore d'évaluation

- MicrometryDocument4 pagesMicrometryMofoluwaso Adedeji OyinloyePas encore d'évaluation

- Microscopically MeasurementDocument7 pagesMicroscopically MeasurementAnonymous TCbZigVq100% (2)

- Measure Micrometers AccuratelyDocument10 pagesMeasure Micrometers AccuratelyBhargav DindukurthiPas encore d'évaluation

- Manufacturing of Engineering: Name: Abdul-Aziz Asheq Fahad Alshammare ID Number: 427102865Document3 pagesManufacturing of Engineering: Name: Abdul-Aziz Asheq Fahad Alshammare ID Number: 427102865MaMLoOoOo7Pas encore d'évaluation

- Profile Projector 10052016Document24 pagesProfile Projector 10052016S MurthyPas encore d'évaluation

- High-Speed Measurement of Nozzle Swing Angle of Rocket Engine Based On Monocular VisionDocument10 pagesHigh-Speed Measurement of Nozzle Swing Angle of Rocket Engine Based On Monocular VisionSunil R HasabnisPas encore d'évaluation

- ProjectorDocument25 pagesProjectorMuhammad FarhanPas encore d'évaluation

- 1.tool Makers MicroscopeDocument7 pages1.tool Makers MicroscopeelavarasanPas encore d'évaluation

- Errors, Com para Tors, and Angular MeasurementsDocument20 pagesErrors, Com para Tors, and Angular MeasurementsbmdbmdbmdPas encore d'évaluation

- ME252 - Experiment 2Document3 pagesME252 - Experiment 2DanialPas encore d'évaluation

- Navarro Lab Exp 1Document7 pagesNavarro Lab Exp 1Lovely NavarroPas encore d'évaluation

- Profile ProjectorDocument25 pagesProfile Projectorrummanomar0% (2)

- The Stereo MicroscopeDocument8 pagesThe Stereo MicroscopeArielPas encore d'évaluation

- TMMDocument11 pagesTMMMANOJ MPas encore d'évaluation

- Research Paper On MicroscopesDocument8 pagesResearch Paper On Microscopeswlyxiqrhf100% (1)

- Profile Projector: Prepared and Presented byDocument25 pagesProfile Projector: Prepared and Presented byMuhammad FaridPas encore d'évaluation

- Department of Metallurgical and Materials EngineeringDocument9 pagesDepartment of Metallurgical and Materials EngineeringRaza AliPas encore d'évaluation

- Zeiss Ultra OptimeterDocument13 pagesZeiss Ultra OptimeterLokesh kumar MeenaPas encore d'évaluation

- Size Detection of Firebricks Based On Machine Vision TechnologyDocument4 pagesSize Detection of Firebricks Based On Machine Vision TechnologyMekaTronPas encore d'évaluation

- Compound Light MicroscopeDocument7 pagesCompound Light MicroscopeAila Janella ValdezPas encore d'évaluation

- Report Experiment ThreadDocument11 pagesReport Experiment Threadsparklingstars2705Pas encore d'évaluation

- Tool Makers MicroscopeDocument7 pagesTool Makers MicroscopeAnand Babu100% (2)

- Auto Collimator SDocument7 pagesAuto Collimator SRamanjooloo DeelanPas encore d'évaluation

- Measuring Microscopic ObjectsDocument7 pagesMeasuring Microscopic ObjectsPatriz CachoPas encore d'évaluation

- Title PageDocument11 pagesTitle PageRaja Muaz AliPas encore d'évaluation

- ToolmakerDocument19 pagesToolmakerchandrarao chPas encore d'évaluation

- Profile Projector Inspection GuideDocument25 pagesProfile Projector Inspection GuideMuhammad FarhanPas encore d'évaluation

- RVCE Study on Tool Maker's MicroscopeDocument9 pagesRVCE Study on Tool Maker's Microscopevenkateshaiah ktPas encore d'évaluation

- 10 Surface Finish MeasurementDocument12 pages10 Surface Finish Measurementsomu_amuPas encore d'évaluation

- Power Plant EngineeringDocument14 pagesPower Plant Engineeringsomu_amuPas encore d'évaluation

- 10 Surface Finish MeasurementDocument12 pages10 Surface Finish Measurementsomu_amuPas encore d'évaluation

- Liquid Metal Fast Breeder Reactors: Mohammed NawazDocument11 pagesLiquid Metal Fast Breeder Reactors: Mohammed Nawazsomu_amuPas encore d'évaluation

- Power Plant Engineering 1Document7 pagesPower Plant Engineering 1somu_amuPas encore d'évaluation

- 8 Bevel ProtractorsDocument4 pages8 Bevel Protractorssomu_amuPas encore d'évaluation

- 10 Surface Finish - TerminologiesDocument8 pages10 Surface Finish - Terminologiessomu_amuPas encore d'évaluation

- Power Plant Engineering - 2Document29 pagesPower Plant Engineering - 2somu_amuPas encore d'évaluation

- Human Baam Appusamy-BrDocument12 pagesHuman Baam Appusamy-BrAkila Anganan100% (1)

- Hydro Electric Power PlantsDocument11 pagesHydro Electric Power Plantssomu_amuPas encore d'évaluation

- Enge Pookiraai ChoDocument66 pagesEnge Pookiraai ChormgowrinarayanPas encore d'évaluation

- Thabu Sankar-Devadhaikalin DevadhaiDocument47 pagesThabu Sankar-Devadhaikalin Devadhaikarthik93% (27)

- Amman Pathakkam Sujatha k3Document26 pagesAmman Pathakkam Sujatha k3heidi1982Pas encore d'évaluation

- Using Microscopes to Examine SpecimensDocument1 pageUsing Microscopes to Examine SpecimensMarian Alexis Fernandez100% (1)

- Relevant Lamps ReportDocument27 pagesRelevant Lamps ReportSai ChesettiPas encore d'évaluation

- Ophthalmic Lenses: Single Vision Lenses Bi-Focal LensesDocument26 pagesOphthalmic Lenses: Single Vision Lenses Bi-Focal LensesSuman MandalPas encore d'évaluation

- The Compound Light Microscope InstructionsDocument3 pagesThe Compound Light Microscope InstructionsReisel RegioPas encore d'évaluation

- ACTIVITY 3 The MicroscopeDocument4 pagesACTIVITY 3 The MicroscopeBien PresasPas encore d'évaluation

- PV Module List - CEC Aug 2010Document116 pagesPV Module List - CEC Aug 2010SolarShop Australia100% (1)

- Uv Visible SpectrosDocument6 pagesUv Visible SpectrosSnape the PrincePas encore d'évaluation

- Adi Wijaya Project - Vc0-ReportDocument7 pagesAdi Wijaya Project - Vc0-Reportryhz0410Pas encore d'évaluation

- Device Performance of Emerging Photovoltaic MateriDocument41 pagesDevice Performance of Emerging Photovoltaic MateriVebry YudiaPas encore d'évaluation

- Marco (Hubbell) Product Catalog 1992Document276 pagesMarco (Hubbell) Product Catalog 1992Alan Masters100% (2)

- KS4 Waves: Reflection: © Boardworks LTD 2003Document34 pagesKS4 Waves: Reflection: © Boardworks LTD 2003Isabel Iglesias QuintanaPas encore d'évaluation

- Float GlassDocument9 pagesFloat GlassA. KARUNYA BHARGAVIPas encore d'évaluation

- Jeep110 PDFDocument7 pagesJeep110 PDFJitendra TiwariPas encore d'évaluation

- Float Glass Manufacturing PlantDocument4 pagesFloat Glass Manufacturing PlantOgre MagiPas encore d'évaluation

- Science: B6D1E1-Devices Used To Overcome The Limitation of Sight and HearingDocument14 pagesScience: B6D1E1-Devices Used To Overcome The Limitation of Sight and HearingvonashPas encore d'évaluation

- Stadium LightingDocument24 pagesStadium LightingKalyani KaleshPas encore d'évaluation

- IndustriDocument6 pagesIndustriOm AlfiPas encore d'évaluation

- SI Brochure Oct081Document30 pagesSI Brochure Oct081Mohan PrasadPas encore d'évaluation

- EGL Neon Tube NewsDocument1 pageEGL Neon Tube Newsjohnnie2610Pas encore d'évaluation

- USHIO Lamparas Equipos MedicosDocument16 pagesUSHIO Lamparas Equipos MedicosIvan Villena ChumanPas encore d'évaluation

- Selum AutolampsDocument42 pagesSelum AutolampsGeorge IstratePas encore d'évaluation

- 430 ZXM6-NH156 158.75 - 420-445W - 35×35 - 20200623 - E - 350mmcable - 430Document2 pages430 ZXM6-NH156 158.75 - 420-445W - 35×35 - 20200623 - E - 350mmcable - 430steven6diaz-2Pas encore d'évaluation

- The Sinarf2: A Versatile, High-Performance View Camera in a Compact DesignDocument8 pagesThe Sinarf2: A Versatile, High-Performance View Camera in a Compact DesignDocPas encore d'évaluation

- Medium FormatDocument33 pagesMedium FormatjcecilPas encore d'évaluation

- Light Reflection & MirrorsDocument16 pagesLight Reflection & MirrorsBelinda LapsitPas encore d'évaluation

- Future Scope of Dual Axis Solar Tracking SystemDocument1 pageFuture Scope of Dual Axis Solar Tracking SystemArun GuptaPas encore d'évaluation

- CFL & LED Bulbs: A ComparisonDocument4 pagesCFL & LED Bulbs: A Comparisonjoel_goh_3Pas encore d'évaluation