Académique Documents

Professionnel Documents

Culture Documents

Cement Plaster, Pointing Work, Washing Work

Transféré par

Engr SwapanTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Cement Plaster, Pointing Work, Washing Work

Transféré par

Engr SwapanDroits d'auteur :

Formats disponibles

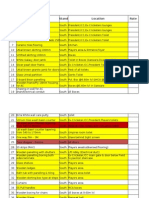

SHORT FORM

ANNEXURE - A

OF PWD SCHEDULE OF RATES, 16TH OCTOBER, 2002 (10TH EDITION) DETAIL DESCRIPTION OF THE ITEMS CORRESPOND TO THE RESPECTIVE ITEM IN THE SCHEDULE OF RATES

19. CEMENT PLASTER, POINTING WORK, WASHING WORK

Item No. 123(a-i) (i) (ii) (iii) iv) (a-ii) (a-iii) (i) (ii) (iii) iv) (b). (i) (ii) (iii) (iv) (c) (i) (ii) (iii) (iv) (d) Ground floor. Add for each additional floor up to 5

th th

Description of items Minimum 12 mm thick cement plaster (1:4) on walls.

Unit

Unit Rate

sqm floor. sqm sqm sqm sqm

Tk. Tk. Tk. Tk. Tk.

98.00 4.26 6.38 8.51 113.00

Add for each additional floor above 5 floor and upto 9th floor Add for each additional floor above 9th floor Minimum 12 mm thick cement plaster with neat cement finishing to plinth wall and upto 150 mm below ground level (1:4). Minimum 12 mm thick cement plaster with neat cement finishing to dado and plinth wall (1:4). Ground floor and upto 150 mm below ground level Add for each additional floor up to 5th floor. Add for each additional floor above 5th floor and upto 9th floor Add for each additional floor above 9th floor Minimum 12 mm thick cement plaster (1:6) to wall. Ground floor. Add for each additional floor up to 5

th th

sqm sqm sqm sqm sqm sqm sqm sqm sqm sqm sqm sqm sqm

Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk.

122.00 4.26 6.38 8.51 89.00 4.26 6.38 8.51 80.00 4.26 6.38 8.51 85.00 4.26 6.38 8.51 50.00 4.26 6.38 8.51 63.00

floor.

Add for each additional floor above 5 floor and upto 9th floor Add for each additional floor above 9th floor Minimum 6 mm thick cement plaster (1:4) on RCC surfaces. Ground floor. Add for each additional floor up to 5

th th

floor.

Add for each additional floor above 5 floor and upto 9th floor Add for each additional floor above 9th floor do-do cement plaster (1:3) in walls -do-doGround floor. Add for each additional floor up to 5

th th

floor.

sqm sqm sqm sqm sqm sqm sqm sqm

Add for each additional floor above 5 floor and upto 9th floor Add for each additional floor above 9th floor 124 (i) (ii) (iii) (iv) 125 (i) Flush pointing to brick wall with cement mortar (1:2). Ground floor. Add for each additional floor up to 5

th th

floor.

Add for each additional floor above 5 floor and upto 9th floor Add for each additional floor above 9th floor Rule pointing to brick wall with cement mortar (1:2). Ground floor.

ahsan/aqa

(196)

SHORT FORM

ANNEXURE - A

OF PWD SCHEDULE OF RATES, 16TH OCTOBER, 2002 (10TH EDITION) DETAIL DESCRIPTION OF THE ITEMS CORRESPOND TO THE RESPECTIVE ITEM IN THE SCHEDULE OF RATES

Item No. (ii) (iii) (iv) 126 (i) (ii) (iii) (iv) 127 i) ii) iii) iv) 128 129

Description of items Add for each additional floor up to 5th floor. Add for each additional floor above 5th floor and upto 9th floor Add for each additional floor above 9th floor Raised / tack pointing work to brick wall with cement mortar (1:2). Ground floor. Add for each additional floor up to 5

th th

Unit sqm sqm sqm sqm sqm sqm sqm

Unit Rate Tk. Tk. Tk. Tk. Tk. Tk. Tk. 4.26 6.38 8.51 154.00 4.26 6.38 8.51

floor.

Add for each additional floor above 5 floor and upto 9th floor Add for each additional floor above 9th floor Providing drip course/ nosing/ throating at the edge of sunshade or cornice. Ground floor. Add for each additional floor up to 5th floor Add for each additional floor above 5th floor and upto 9th floor Add for each additional floor above 9th floor White washing by three coats. Colour wash with yellow orchred/any otherr colour pigment by two coats over a prime coat of white wash.

rm rm rm rm sqm sqm

Tk. Tk. Tk. Tk. Tk. Tk.

37.00 1.30 1.95 2.59 6.35 7.43

20. PAINTING, DISTEMPERING, POLISHING & VARNISHING

130 131 132. 133. 134. Cement Paint of approved quality and colour. Painting to door and window frames and shutters in two coats with best quality approved colour of synthetic enamel paint. Synthetic polyvinyl distempering to wall & ceiling in 2 coats over a coat of brand specified primer or sealer. Plastic emulsion painting of best quality and approved colour to wall and ceiling two coats over a coat of brand specified primer or sealer. Acrylic emulsion painting (silky finish) of best quality and approved colour to wall and ceiling two coats over a coat of brand specified primer or sealer. Textured of best quality and approved colour paint to wall and ceiling. Jesoline clorinated rubber painting of best quality and approved colour to concrete surfaces & steel structures. French polishing to door and window frames and shutters three coats over a coat of priming. Wood varnishing using brand specified thinner to door and window frame and shutter three coats. Varnish (Yacht) Varnish (Egg shell) Varnish (Matt) sqm sqm sqm sqm Tk. Tk. Tk. Tk. 57.00 82.00 69.00 76.00

sqm sqm

Tk. Tk. Tk. Tk.

80.00 288.00 122.00 75.00

135. 136. 137. 138. (a) (b) (c)

sqm sqm

sqm sqm sqm

Tk. Tk. Tk.

68.00 72.00 65.00

ahsan/aqa

(197)

SHORT FORM

ANNEXURE - A

OF PWD SCHEDULE OF RATES, 16TH OCTOBER, 2002 (10TH EDITION) DETAIL DESCRIPTION OF THE ITEMS CORRESPOND TO THE RESPECTIVE ITEM IN THE SCHEDULE OF RATES

Item No.

Description of items

Unit

Unit Rate

21. DRAIN AND APRON

139. 140. 141. 142.(a) (b) Constructing surface drain of 300 mm clear width and depth up to 300 mm in brick masonry. Constructing surface drain of 600 mm (Av) depth and 225 mm clear width. Providing apron with 50 mm thick cement concrete (1:2:4). Supplying, laying, fitting and best quality fixing 225 mm dia (internal) machine made R.C.C. pipe. -do- with 300 mm dia ( (internal) R.C.C. pipe. rm rm sqm rm rm Tk. Tk. Tk. Tk. Tk. 541.00 1,117.00 387.00 792.00 1,103.00

22. FALSE CEILING, WALL PANELING

143.(a) (b) Supplying, fitting and fixing plain particle board ceiling of 12 mm thick with best quality and well seasoned Garjan wood frame. For auditorium and other type of tall structures beyond 4 m up to 8 m which do not cover the above item (Item No.143(a). sqm (c) 144. Supplying, fitting and fixing of 12 mm thick melamine board. (a) Supplying fitting and fixing gypsum board ceiling of 12 mm thick board. (b) -do- with 12 mm thick veneered board. (a) Supplying, fitting and fixing 12 mm thick BT Veneered board in walling. -do- 12 mm thick particle board sqm sqm sqm sqm sqm Tk. Tk. Tk. Tk. Tk. Tk. 1,206.00 752.00 1,151.00 1,124.00 1,652.00 954.00 sqm Tk. 1,129.00

145. (b)

23. COLLAPSIBLE GATE, M.S. GATE, ROLLING SHUTTER ETC.

146(a) 146 (b) Manufacturing, supplying, fitting and fixing collapsible gate of any design & shape made of 3/4" x 3/8" x 1/8" channel . - do - -do- collapsible gate made of 3/4" x 3/4" x 1/8" M.S. angle as vertical member and 3/4" x 1/8" F.I bar as scissors sqm 146 (c) 147.(a) 147.(b) 148. - do - -do- collapsible gate made of 1" x 1" x 1/8" M.S. angle as vertical member and 1" x 1/8" F.I bar as scissors Supplying, fitting, fixing, and installation of ordinary type M.S. gate (double leaf). Supplying, fitting, fixing, and installation of ordinary type M.S. security gate. Supplying, fitting, fixing and installation of ordinary type M.S. gate (double leaf). sqm sqm sqm sqm Tk. Tk. Tk. Tk. Tk. 1,382.00 1,644.00 2,017.00 3,534.00 1,780.00 sqm Tk. 1,200.00

ahsan/aqa

(198)

SHORT FORM

ANNEXURE - A

OF PWD SCHEDULE OF RATES, 16TH OCTOBER, 2002 (10TH EDITION) DETAIL DESCRIPTION OF THE ITEMS CORRESPOND TO THE RESPECTIVE ITEM IN THE SCHEDULE OF RATES

Item No. 149. 150. 151.

Description of items Supplying, fitting, fixing and installation ordinary type M.S. gate (double leaf). Manufacturing, supplying, fitting and fixing G.I. pipe gate. Supplying. fitting and fixing of rolling shutterof.

Unit sqm sqm sqm

Unit Rate Tk. Tk. Tk. 2,691.00 3,924.00 1,744.00

24. STAIR RAILING & VERANDAH RAILING

152. 153. 154. (a) (b) 155.(a) (b) Manufacturing, supplying, fitting and fixing stair railing with 3/4" x 3/4" M.S. square box. Manufacturing, supplying, fitting and fixing stair railing with 1" x 1" M.S. square box. Supplying, fitting and fixing 12 mm dia G.I pipe stair railing. With Hnadrail (150 x 62 mm) (finished) With Handrail (112 x 62 mm) Providing veranda railing with 38 mm dia G.I. Pipe hand rail. -do- with 50 mm dia G.I. Pipe hand rail sqm sqm sqm sqm Tk. Tk. Tk. Tk. 1,401.00 1,589.00 1,665.00 1,863.00 sqm sqm Tk. Tk. 1,357.00 2,217.00

25. GRILL FENCING, BARBED WIRE FENCING

156. 157. 158 Supplying, fitting and fixing steel grill fencing in bundary wall of any design & shape with 31 x 6 mm F.I. Bar. Supplying, fitting and fixing steel grill fencing of any design & shape made with 19 mm x 3 mm tube. Manufacturing, supplying, fitting and fixing M.S. grill fencing as per desin with outer frames having 38 x 38 x 6 mm M.S. angle and inner members having 6 mm dia M.S. rod. Manufacturing, supplying, fitting and fixing M.S. tube (angle box) post (bottom end bifurcated) made by thorough welding of two nos. 38 x 38 x 6 mm M.S. angle. Providing barbed wire fencing with R.C.C (1:2:4) pillars. Providing barbed wire fencing with average 100 mm dia best quality local bullah post. Supplying, fitting and fixing 12 BWG barbed wire (2 ply, 4 points) in fencing work @ 150 mm c/c in both horizontally and vertically, supported by 38 x 38 x 6 mm M.S. angle post. sqm sqm Tk. Tk. 655.00 1,532.00

sqm

Tk.

793.00

159

rm sqm sqm

Tk. Tk. Tk.

318.00 39.00 69.00

160 161 162

sqm

Tk.

234.00

ahsan/aqa

(199)

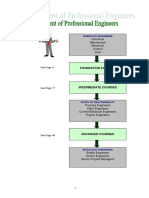

Analysis of rates of P.W.D. Schedule, May 2002 (10th Edition, Ist Revision) (For Dhaka P.W.D. Circle-1/2/3/4/Savar/Maintenance)

BASIS AND CONSIDERATION MARK-UPS 1. 2. 3. Contractor's profit Overhead expenses VAT MATERIAL AND LABOUR Head mason Mason Skilled labour Ordinary labour Carpenter Helper to carpenter Machine operator Skilled technician Plumber Helper to plumber Painter Helper to painter Welder Helper to welder Point welding Line welding Scaffolding Hire charge of paint spray machine Ordinary portland grey cement: 50 kg bag 0.8 F.M. fine local sand 1.2 F.M. coarse sand 2.5 F.M. sylhet sand Colour pigment Pumic stone Garjan/ Jam / local Shal timber Chittagong teak M.S. sheet/plate M.S. angle, T and Z-section, M.S. channel etc. M.S. bar and F.I. bar (non-structural) M.S. rod: 40 grade M.S. rod: 60 grade 2" dia G.I. pipe 1.5" dia G.I/ pipe 3/4" G.I. pipe 1/2" dia G.I. pipe Polythene sheet G. I. wire Nails Nut-bolt screw 9" dia RCC pipe 12" dia RCC pipe 12 mm thick Plain particle board Malamine Board (8 mm thick): 8' -0" x 4'-0" size 12 mm thick gypsum board 12 mm thick laminated vinyle board 12 mm thick B.T. veneered board Aluminium T-section (main Tee) for false ceiling Aluminium T-section (cross Tee) for false ceiling Aluminium L-section for false ceiling 12 BWG barbed wire Rivet, washer, wire nails etc. 1.5" dia M.S. wheel for collapsible gate 3" - 6" M.S. clamp 10.00% 3.50% 4.50% 18.6075% Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. 180.00 150.00 120.00 100.00 160.00 120.00 160.00 250.00 160.00 120.00 160.00 120.00 160.00 120.00 1.50 2.00 3.00 1.00 250.00 625.00 990.00 1,330.00 30.00 140.00 710.00 1,400.00 23,920.00 19,195.00 17,010.00 22,660.00 24,120.00 80.00 72.00 33.00 25.00 117.00 50.00 40.00 60.00 89.94 120.12 22.97 1,150.00 48.00 45.85 75.00 11.00 9.00 8.00 1,450.00 40.00 10.00 10.00 Per day Per day Per day Per day Per day Per day Per day Per day Per day Per day Per day Per day Per day Per day Per point Per inch Per sft. Per sft. Per bag Per % cft. Per % cft. Per % cft. Per Ib. Each Per cft. Per cft. Per Ton Per ton Per ton Per ton Per ton Per rft. Per rft. Per rft. Per rft. Per % sft. Per kg Per kg Per kg. Per rft. Per rft. Per sft. Per pc. Per sft. Per sft. Per sft. Per rft. Per rft. Per rft. Per cwt. Per kg Each Each

(200)

Analysis of rates of P.W.D. Schedule, May 2002 (10th Edition, Ist Revision) (For Dhaka P.W.D. Circle-1/2/3/4/Savar/Maintenance)

Electrodes in/c electricity Greese/lubricant etc. 1.5 inch dia heavy type gate wheel Clamp with huskel dumney Heavy duty gate locking arrangement 5" M.S. hinges 5/8" socket bolt China made spring for rlling shutter Spring box for rolling shutter 1/2 dia nut-bolt 1.5" screw Rowl plug Wall bit Slaked lime Gum Blue Pigment for colour washing PAINTS Cement paint S.E paint Paint Under-coat Thinner for oil-based paint S.P. Distemper Distemper Primer /sealer Acrylic Plastic Paint Acrylic Plastic paint Acrylic Plastic Paint sealer Acrylic Emulsion Paint Acrylic Emulsion Paint Acrylic Emulsion Paint Primer/under-coat Chlorinated Rubber Paint Chlorinated Rubber Paint Chlorinated Rubber Paint Sealer Chlorinated Rubber Paint Thinner Texured Paint (Bontile) Texured paint Wood varnishing: Yacht Yacht Egg-shell Matt Thinner French-polishing work French powder Spirit Gala Mostaki Karpa Sand paper Putty Markin cloth Cotton Earth work in excavation: Brick-flat soling: Cement concrete (1:3:6): Cement concrete (1:2:4): 5" thick brick work (1:4):

Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk.

Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk.

4.00 40.00 80.00 70.00 125.00 15.00 100.00 10.00 60.00 5.00 8.00 0.25 25.00 5.00 35.00 85.00 90.00

Each Per Ib. Each Each Each Each Each Per rft. Each Each doz. Each Each Per kg Per kg Per kg Per kg.

52.00 Per kg 151.00 Per liter 126.50 Per liter 45.00 Per liter 80.00 Per liter 148.00 Per liter 150.00 Per liter 150.00 Per liter 160.00 Per liter 153.00 Per liter 260.00 Per liter 240.00 Per liter 106.00 Per liter 155.00 Per liter 170.00 170.00 130.00 42.00 Per liter Per liter Per liter Per liter

Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk.

120.00 30.00 350.00 75.00 110.00 6.00 40.00 20.00 35.00 1,475.00 1,171.25 7,491.10 8,991.10 2,971.80

Per kg Per Ib. Per kg Per kg Per kg Each Per kg Per Yard Per Ib. % 0 cft. % sft. % cft. % cft. % sft.

(201)

Analysis of rates of P.W.D. Schedule, May 2002 (10th Edition, Ist Revision) (For Dhaka P.W.D. Circle-1/2/3/4/Savar/Maintenance)

1/2" thick cement plast:er (1:4) 1/2" thick cement plast:er (1:4) with neat cement finish: S.E. Paint French polishing

Tk. Tk. Tk. Tk.

694.50 882.00 642.50 587.63

% sft. % sft. Per % sft. % sft.

(202)

Analysis of Rates of PWD Schedule (10th Edition), 16th October 2002

18. CEMENT PLASTER, POINTING WORK, WASHING WORK

ANALYSIS FOR ITEM No. 123(a-i) Minimum 1/2" thick cement plaster (1:4) to walls (average of 1/2" on one side and 3/4" on other side of

the walls).

A. 1/2" thick cement plaster (1:4) on one side of the walls. Considering 100 sft. of work a) b) c) Sand (F.M. 1.2) Cement Labour i ) Head mason ii) Mason iii) Ordinary labour d) 0.25 No. @ 1.00 No. @ 1.00 No. @ Tk. Tk. Tk. 180.00 150.00 100.00 5.00 cft. 1.00 Bag @ @ Tk. Tk. 990.00 250.00 Per % cft. = Tk. Per bag = Tk. = each = Tk. each = Tk. each = Tk. L.S. = Tk. Total = Tk. Contractor's profit Overhead expenses VAT 10.00% = Tk. 3.50% = Tk. Tk. 4.50% = Tk. Grand total = Tk. B. 3/4" thick cement plaster (1:4) on other side of the walls. Considering 100 sft. of work a) b) c) Sand (F.M. 1.2) 7.50 cft. @ Tk. Cement 1.50 Bags @ Tk. Labour i ) Head mason 0.25 No. @ Tk. ii) Mason 1.00 No. @ Tk. iii) Ordinary labour 1.00 No. @ Tk. Washing of sand, local carriage, scaffolding, curing, & sundries etc. 990.00 250.00 180.00 150.00 100.00 Per % cft. = Tk. Per bag = Tk. = each = Tk. each = Tk. each = Tk. L.S. = Tk. Total = Tk. 10.00% = Tk. 74.25 375.00 45.00 150.00 100.00 100.00 844.25 84.43 45.00 150.00 100.00 100.00 694.50 69.45 24.31 788.26 35.47 823.73 49.50 250.00

Washing of sand, local carriage, scaffolding, curing, & sundries etc.

d)

Contractor's profit

- 347 -

Analysis of Rates of PWD Schedule (10th Edition), 16th October 2002

Overhead expenses

3.50% = Tk. Tk. VAT 4.50% = Tk. Grand total = Tk. Average of A & B = Tk. Rate per sft. = Tk. Rate per sqm. = Tk.

29.55 958.23 43.12 1,001.35 912.54 9.13 98.28

i)

ii) iii) iv)

For ground floor

Say,

Tk.

98 .00 Per sqm.

Per sqm = Tk. Per sqm = Tk. Per sqm = Tk. 4.26 6.38 8.51

Add for each addl. floor up to 5th floor (1/3 lab. per % sft.) in/c charges Add for each addl. from 6th floor to 9th floor (1/2 lab. per % sft.) in/c charges Add for each addl. floor above 9th floor (2/3 lab. per % sft.) in/c charges

ANALYSIS FOR ITEM No. 123(a-ii) Minimum 1/2" thick cement plaster (1:4) with neat cement finishing to plinth walls upto 150 mm below ground level. Considering 100 sft. of work a) b) c) Sand (F.M. 1.2) 5 cft. @ Cement 1.5 Bag @ Labour i ) Head mason 0.25 No. @ ii) Mason 1.25 Nos. @ iii) Ordinary labour 1.25 Nos. @ Washing of sand, local carriage, curing, & sundries etc. Tk. Tk. Tk. Tk. Tk. 990.00 250.00 180.00 150.00 100.00 Per % cft. = Tk. Per bag = Tk. each each each L.S. = = = = Tk. Tk. Tk. Tk. 49.50 375.00 45.00 187.50 125.00 100.00

d)

Total = Tk. 882.00 Contractor's profit 10.00% = Tk. 88.20 Overhead expenses 3.50% = Tk. 30.87 Tk. 1,001.07 VAT 4.50% = Tk. 45.05 Grand total = Tk. 1,046.12 Rate per sft. = Tk. 10.46 Rate per sqm. = Tk. 112.59 Say, Tk. 113 .00 Per sqm.

- 348 -

Analysis of Rates of PWD Schedule (10th Edition), 16th October 2002

ANALYSIS FOR ITEM No. 123(a-iii) Minimum 1/2" thick cement plaster (1:4) with neat cement finishing to dado (average of 1/2" on one side

and 3/4" on other side).

For 3/4" thick plaster with neat cement finish on walls Considering 100 sft. of work a) b) c) Sand (F.M. 1.2) 7.5 cft. @ Cement 2 Bags @ Labour i ) Head mason 0.25 No. @ ii) Mason 1.25 Nos. @ iii) Ordinary labour 1.25 Nos. @ Washing of sand, local carriage, curing, & sundries etc. Tk. Tk. Tk. Tk. Tk. 990.00 250.00 180.00 150.00 100.00 Per % cft. = Tk. Per bag = Tk. = each = Tk. each = Tk. each = Tk. L.S. Total 10.00% 3.50% 74.25 500.00 45.00 187.50 125.00

d)

= Tk. 100.00 = Tk. 1,031.75 Contractor's profit = Tk. 103.18 Overhead expenses = Tk. 36.11 Tk. 1,171.04 VAT 4.50% = Tk. 52.70 Grand total = Tk. 1,223.74 Average of 1/2"[from item No. 123 (a-ii)] and 3/4" = Tk. 1,134.93 Rate per sft. = Tk. Rate per sqm. = Tk. 11.35 122.17

i)

Ground floor

Say,

Tk.

122 .00 Per sqm.

ii) iii) iv)

Add for each addl. floor up to 5th floor (1/3 lab. per % sft.) in/c charges Add for each addl. from 6th floor to 9th floor (1/2 lab. per % sft.) in/c charges Add for each addl. floor above 9th floor (2/3 lab. per % sft.) in/c charges

Per sqm = Tk. Per sqm = Tk. Per sqm = Tk.

4.26 6.38 8.51

ANALYSIS FOR ITEM No. 123(b) Min 1/2" thick cement plaster (1:6) to walls (average of 1/2" on one side and 3/4" on other side). Considering 100 sft. of work A. For 1/2" thick cement plaster (1:6) to walls a) Sand (F.M. 1.2) 6 cft. b) Cement 0.75 Bag c) Labour

@ @

Tk. Tk.

990.00 250.00

Per % cft. = Tk. Per bag = Tk.

59.40 187.50

- 349 -

Analysis of Rates of PWD Schedule (10th Edition), 16th October 2002

d)

i ) Head mason 0.25 No. @ Tk. 180.00 ii) Mason 1.00 No. @ Tk. 150.00 iii) Ordinary labour 1.00 No. @ Tk. 100.00 Washing of sand, local carriage, scaffolding, curing, & sundries etc. Contractor's profit Overhead expenses VAT

each each each L.S. Total 10.00% 3.50%

= = = = =

= =

4.50% = Grand total =

Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk.

45.00 150.00 100.00 100.00 641.90 64.19 22.47 728.56 32.79 761.35

B. For 3/4" thick cement plaster (1:6) to walls a) b) c) Sand (F.M. 1.2) 8.25 cft. @ Tk. Cement 1.1 Bag @ Tk. Labour i ) Head mason 0.25 No. @ Tk. ii) Mason 1.00 No. @ Tk. iii) Ordinary labour 1.00 No. @ Tk. Washing of sand, local carriage, scaffolding, curing, & sundries etc. Per % cft. = Tk. Per bag = Tk. = 180.00 each = Tk. 150.00 each = Tk. 100.00 each = Tk. L.S. = Tk. Total = Tk. Contractor's profit 10.00% = Tk. Overhead expenses 3.50% = Tk. Tk. VAT 4.50% = Tk. Grand total = Tk. Average of A & B = Tk. Rate per sft = Tk. Rate per sqm. = Tk. Say,

ii) iii) iv) Add for each addl. floor up to 5th floor (1/3 lab. per % sft.) in/c charges Add for each addl. from 6th floor to 9th floor (1/2 lab. per % sft.) in/c charges Add for each addl. floor above 9th floor (2/3 lab. per % sft.) in/c charges

990.00 250.00

81.68 275.00 45.00 150.00 100.00 100.00 751.68 75.17 26.31 853.16 38.39 891.55 826.45 8.26 88.91

d)

i)

Ground floor

Tk.

89 .00 Per sqm.

Per sqm = Tk. Per sqm = Tk. Per sqm = Tk. 4.26 6.38 8.51

ANALYSIS FOR ITEM No. 123(c) 1/4" thick cement plaster (1:4) to ceiling, column, beams etc. and all other RCC surfaces Considering 100 sft. of work a) Sand (F.M. 1.2) 2.5 cft. @ Tk. 990.00 Per % cft. = Tk. 24.75

- 350 -

Analysis of Rates of PWD Schedule (10th Edition), 16th October 2002

b) c) d)

Cement 0.5 Extra cement for grouting 0.125 Labour i ) Head mason 0.25 ii) Mason 1.00 iii) Ordinary labour 1.00 (iv) Extra labour for chiping RCC surface

Bag Bag

@ @

Tk. Tk. Tk. Tk. Tk.

250.00 250.00 180.00 150.00 100.00 100.00

Per bag = Tk. Per bag = Tk. each = Tk. each = Tk. each = Tk. each L.S. Total 10.00% 3.50% = Tk. = Tk. = Tk. = Tk. = Tk. Tk. = Tk. = Tk. = Tk. = Tk.

125.00 31.25 45.00 150.00 100.00 50.00 100.00 626.00 62.60 21.91 710.51 31.97 742.48 7.42 79.87

No. @ No. @ No. @

e)

0.50 No. @ Tk. Washing of sand, scaffolding, curing, sundries, local carriage etc.

Contractor's profit Overhead expenses VAT

4.50% Grand total Rate per sft. Rate per sqm.

i)

ii) iii) iv)

For ground floor

Say,

Tk.

80 .00 Per sqm.

Per sqm = Tk. Per sqm = Tk. Per sqm = Tk. 4.26 6.38 8.51

Add for each addl. floor up to 5th floor (1/3 lab. per % sft.) in/c charges Add for each addl. from 6th floor to 9th floor (1/2 lab. per % sft.) in/c charges Add for each addl. floor above 9th floor (2/3 lab. per % sft.) in/c charges

ANALYSIS FOR ITEM No. 123(d) Min 1/4" thick cement plaster (1:3) to walls Considering 100 sft. of work A. For 1/2" thick cement plaster (1:3) to walls a) Sand (F.M. 1.2) 4.7 b) Cement 1.25 c) Labour i ) Head mason 0.25 ii) Mason 1.00 iii) Ordinary labour 1.00 d)

cft. Bag

@ @

Tk. Tk. Tk. Tk. Tk.

990.00 250.00 180.00 150.00 100.00

Per % cft. = Tk. Per bag = Tk. each = Tk. each = Tk. each = Tk. L.S. = Tk. Total = Tk. 10.00% = Tk.

46.53 312.50 45.00 150.00 100.00 100.00 754.03 75.40

No. @ No. @ No. @

Washing of sand, local carriage, scaffolding, curing, & sundries etc. Contractor's profit

- 351 -

Analysis of Rates of PWD Schedule (10th Edition), 16th October 2002

Overhead expenses

3.50% = Tk. Tk. VAT 4.50% = Tk. Grand total = Tk.

26.39 855.82 38.51 894.33

B. For 1/4" thick cement plaster (1:3) to walls a) Sand (F.M. 1.2) 2.35 b) Cement 0.625 c) Labour i ) Head mason 1/4 ii) Mason 1.00 iii) Ordinary labour 1.00 d)

cft. Bag

@ @

Tk. Tk. Tk. Tk. Tk.

990.00 250.00 180.00 150.00 100.00

Per % cft. = Tk. Per bag = Tk. each = Tk. each = Tk. each = Tk. L.S. Total 10.00% 3.50%

23.27 156.25 45.00 150.00 100.00 100.00 574.52 57.45 20.11 652.08 29.34 681.42 787.88 7.88 84.82

No. @ No. @ No. @

Washing of sand, local carriage, scaffolding, curing, & sundries etc.

= Tk. = Tk. Contractor's profit = Tk. Overhead expenses = Tk. Tk. VAT 4.50% = Tk. Grand total = Tk. Average of A & B = Tk. Rate per sft = Tk. Rate per sqm. = Tk.

i)

Ground floor

Say,

ii) iii) iv) Add for each addl. floor up to 5th floor (1/3 lab. per % sft.) in/c charges

Tk.

85 .00 Per sqm.

Per sqm = Tk. Per sqm = Tk. Per sqm = Tk. 4.26 6.38 8.51

Add for each addl. from 6th floor to 9th floor (1/2 lab. per % sft.) in/c charges Add for each addl. floor above 9th floor (2/3 lab. per % sft.) in/c charges

ANALYSIS FOR ITEM No. 124 Flush pointing with cement mortar (1:2) to walls Considering 100 sft. of work a) b) c) Sand (F.M. 1.2) Cement Labour I ) Head mason 1.0 cft. 0.4 Bag @ @ Tk. Tk. Tk. 990.00 250.00 180.00 Per % cft. = Tk. Per bag = Tk. each = Tk. 9.90 100.00 45.00

0.25 No. @

- 352 -

Analysis of Rates of PWD Schedule (10th Edition), 16th October 2002

d)

ii) Mason 0.5 No. @ Tk. iii) Ordinary labour 1 No. @ Tk. Washing of sand, scaffolding, curing, sundries, local carriage etc.

150.00 100.00

each = Tk. each = Tk. L.S. = Tk. Total = Tk. 10.00% = Tk.

75.00 100.00 60.00 389.90 38.99 13.65 442.54 19.91 462.45 4.62 49.73

Contractor's profit Overhead expenses

3.50% = Tk. Tk. VAT 4.50% = Tk. Grand total = Tk. Rate per sft. = Tk. Rate per sqm. = Tk. 50 .00 Per sqm.

Per sqm = Tk. Per sqm = Tk. Per sqm = Tk.

i)

ii) iii) iv)

For ground floor

Say,

Tk.

Add for each addl. floor up to 5th floor (1/3 lab. per % sft.) in/c charges Add for each addl. from 6th floor to 9th floor (1/2 lab. per % sft.) in/c charges Add for each addl. floor above 9th floor (2/3 lab. per % sft.) in/c charges

4.26 6.38 8.51

ANALYSIS FOR ITEM No. 125 Ruled pointing with cement mortar (1:2) to walls Considering 100 sft. of work a) b) c) Sand (F.M. 1.2) 1.5 cft. @ Tk. Cement 0.5 Bag @ Tk. Labour I ) Head mason 0.25 No. @ Tk. ii) Mason 1 No. @ Tk. iii) Ordinary labour 1 No. @ Tk. d) Washing of sand, scaffolding, curing, sundries, local carriage etc. 990.00 250.00 180.00 150.00 100.00 Per % cft. = Tk. Per bag = Tk. each each each L.S. Total 10.00% 3.50% = = = = = Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. 14.85 125.00 45.00 150.00 100.00 60.00 494.85 49.49 17.32 561.66 25.27 586.93 5.87 63.18

Contractor's profit Overhead expenses VAT

= = =

= = =

4.50% Grand total Rate per sft. Rate per sqm.

i)

For ground floor

Say,

Tk.

63 .00 Per sqm.

- 353 -

Analysis of Rates of PWD Schedule (10th Edition), 16th October 2002

ii) iii) iv)

Add for each addl. floor up to 5th floor (1/3 lab. per % sft.) in/c charges Add for each addl. from 6th floor to 9th floor (1/2 lab. per % sft.) in/c charges Add for each addl. floor above 9th floor (2/3 lab. per % sft.) in/c charges

Per sqm = Tk. Per sqm = Tk. Per sqm = Tk.

4.26 6.38 8.51

ANALYSIS FOR ITEM No. 126 Raised / Tack pointing with cement mortar (1:2) to walls Considering 100 sft. of work a) b) c) d) Sand (F.M. 1.2) 3 cft. @ Tk. Cement 1 Bag @ Tk. Cost of pumic stone 0.25 No. @ Tk. Labour I ) Head mason 0.5 No. @ Tk. ii) Mason 2 Nos. @ Tk. iii) Skilled labour 2 Nos. @ Tk. iv) Ordinary labour 2 Nos. @ Tk. Washing of sand, scaffolding, curing, sundries, local carriage etc. 990.00 250.00 140.00 180.00 150.00 120.00 100.00 Per % cft. = Tk. Per bag = Tk. each Tk. each each each each L.S. Total 10.00% 3.50% 29.70 250.00 35.00

e)

Contractor's profit Overhead expenses VAT

4.50% Grand total Rate per sft. Rate per sqm.

= Tk. 90.00 = Tk. 300.00 Tk. 240.00 = Tk. 200.00 = Tk. 60.00 = Tk. 1,204.70 = Tk. 120.47 = Tk. 42.16 Tk. 1,367.33 = Tk. 61.53 = Tk. 1,428.86 = Tk. 14.29 = Tk. 153.82

i)

For ground floor

Say,

Tk.

154 .00 Per sqm.

ii) iii) iv)

Add for each addl. floor up to 5th floor (1/3 lab. per % sft.) in/c charges Add for each addl. from 6th floor to 9th floor (1/2 lab. per % sft.) in/c charges Add for each addl. floor above 9th floor (2/3 lab. per % sft.) in/c charges

Per sqm = Tk. Per sqm = Tk. Per sqm = Tk.

4.26 6.38 8.51

- 354 -

Analysis of Rates of PWD Schedule (10th Edition), 16th October 2002

ANALYSIS FOR ITEM No. 127

Providing drip course / noising / throating with cement mortar (1:2). Considering 25 rft. of work a) b) c) Sand (F.M. 1.2) 0.52 cft. @ Tk. Cement 0.08 Bag @ Tk. Labour i) Mason 1.0 No. @ Tk. ii) Ordinary labour 0.5 No. @ Tk. Washing of sand, scaffolding, curing, sundries, local carriage etc. 990.00 250.00 150.00 100.00 Per % cft. = Tk. Per bag = Tk. each = Tk. each = Tk. L.S. = Tk. 5.15 20.00 150.00 50.00 10.00 235.15 23.52 8.23 266.90 12.01 278.91 11.16 36.62

d)

Total = Tk. Contractor's profit 10.00% = Tk. Overhead expenses 3.50% = Tk. Tk. VAT 4.50% = Tk. Grand total = Tk. Rate per rft. = Tk. Rate per rm. = Tk. Say, Tk. 37 .00 Per rm.

ii) iii) iv)

Add for each addl. floor up to 5th floor (1/3 lab. per % rft.) in/c charges Add for each addl. from 6th floor to 9th floor (1/2 lab. per % rft.) in/c charges Add for each addl. floor above 9th floor (2/3 lab. per % rft.) in/c charges

Per rm = Tk. Per rm = Tk. Per rm = Tk.

1.30 1.95 2.59

ANALYSIS FOR ITEM No. 128 White washing: 3 coats Considering 1000 sft. of work a) b) c) d) Slaked lime Gum Blue Labour i) Mason 18.66 Kg 0.3 Kg 0.2 Kg @ @ @ Tk. Tk. Tk. Tk. 5.00 35.00 85.00 150.00 Per kg. = Tk. Per kg. = Tk. Per kg. = Tk. each = Tk. 93.30 10.50 17.00 225.00

1.5 Nos. @

- 355 -

Analysis of Rates of PWD Schedule (10th Edition), 16th October 2002

e)

ii) Ordinary labour Scaffolding, sundries, local carriage etc.

1 No. @

Tk.

100.00

Contractor's profit Overhead expenses VAT

each L.S. Total 10.00% 3.50%

4.50% Grand total Rate per sft. Rate per sqm.

= Tk. = Tk. = Tk. = Tk. = Tk. Tk. = Tk. = Tk. = Tk. = Tk.

100.00 50.00 495.80 49.58 17.35 562.73 25.32 588.05 0.59 6.35

Say,

Tk.

6.35 Per sqm.

ANALYSIS FOR ITEM No. 129 Colour washing: 3 coats Considering 1000 sft. of work

a) b) c) d) e)

f)

Slaked lime Gum Blue Colour pigment Labour i) Mason ii) Ordinary labour Scaffolding, sundries, local carriage

18.66 0.3 0.2 1

Kg Kg Kg Kg

@ @ @ @

Tk. Tk. Tk. Tk. Tk. Tk.

5.00 35.00 85.00 90.00 150.00 100.00

Per kg. Per kg. Per kg. Per kg. each each L.S. Total 10.00% 3.50%

= = = = = = = =

Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk.

93.30 10.50 17.00 90.00 225.00 100.00 50.00 585.80 58.58 20.50 664.88 29.92 694.80 0.69 7.43

1.5 Nos. @ 1 No. @

Contractor's profit Overhead expenses VAT

= = =

= = =

4.50% Grand total Rate per sft. Rate per sqm.

Say,

Tk.

7.43 Per sqm.

- 356 -

Analysis of Rates of P.W.D. Schedule (10th Edition), 16th October 2002

19. PAINTING, DISTEMPERING, POLISHING & VARNISHING

ANALYSIS FOR ITEM No. 130 Cement paint 3 coats (one coat is for priming) Considering 100 sft. of work 1. Skilled labour for cleaning, washing and wetting etc. 0.10 No. 2. Painter for applying paint 3. Helper to painter 4. Labour for 7 days curing: 5. Scaffolding, local carriage, sundries etc. 6. Cement paint 3.25 kg. @ Tk. 52.00 0.50 No. 0.50 No. 1.00 No. @ Tk. 120.00 @ Tk. 160.00 @ Tk. 120.00 @ Tk. 100.00 each = Tk. each = Tk. each = Tk. each = Tk. L.S. = Tk. Per kg. = Tk. Tk. Contractor's profit Overhead expenses VAT 10.00% = 3.50% = 4.50% = Tk. Tk. Tk. Tk. Tk. Tk. Tk. Grand total = Rate per sft. = Rate per sqm. = Say, Tk. 57 .00 Per sqm. 12.00 80.00 60.00 100.00 25.00 169.00 446.00 44.60 15.61 506.21 22.78 528.99 5.29 56.94

ANALYSIS FOR ITEM No. 131 Painting to doors and windows frame and shutters with synthetic enamel paint two coats over a coat of priming Considering 100 sft. of work 1. 2. 3. 4. 5. 6. Painter Ordinary labour Scaffolding, sundries etc. Paint Sealer Thinner 1.00 1.00 1.00 1.00 1.00 No. No. liter liter liter @ @ @ @ @ Tk. 160.00 Tk. 100.00 Tk. 151.00 Tk. 126.50 Tk. 45.00 each each L.S. Per liter Per liter Per liter = = = = = = Tk. Tk. Tk. Tk. Tk. Tk. 160.00 100.00 60.00 151.00 126.50 45.00

- 357 -

Analysis of Rates of P.W.D. Schedule (10th Edition), 16th October 2002

Contractor's profit Overhead expenses

10.00% = 3.50% =

VAT 4.50% Grand total Rate per sft. Rate per sqm. Say, Tk.

=

= = =

Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk.

642.50 64.25 22.49 729.24 32.82 762.06 7.62 82.02

82 .00 Per sqm.

ANALYSIS FOR ITEM No. 132 Synthetic polyvinyl distempering 2 coats over a coat of priming Considering 100 sft. of work 1. 2. 3. 4. 5. Painter Painter helper Scaffolding, sundries etc. Distemper Under-coat/sealer 1.00 1.00 1.00 1.00 No. No. liter liter @ @ @ @ Tk. 160.00 Tk. 120.00 Tk. 80.00 Tk. 148.00 Contractor's profit Overhead expenses each each L.S. Per liter Per liter Total 10.00% 3.50% = = = = = = Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. 160.00 120.00 33.33 80.00 148.00 541.33 54.13 18.95 614.41 27.65 642.06 6.42 69.10

= = =

= = =

VAT 4.50% Grand total Rate per sft. Rate per sqm. Say, Tk.

69 .00 Per sqm.

ANALYSIS FOR ITEM No. 133 Plastic emulsion paint to walls and ceiling 2 coats over a coat of primer Considering 100 sft. of work 1. Painter 2. Painter helper 1.00 1.00 No. No.

- 358 -

@ @

Tk. 160.00 Tk. 120.00

each = Tk. each = Tk.

160.00 120.00

Analysis of Rates of P.W.D. Schedule (10th Edition), 16th October 2002

3. Scaffolding, sundries etc. 4. Plastic emulsion paint 5. Sealer / under-coat

1.00 0.90

Litre Litre

@ @

Tk. 150.00 Tk. 150.00 Contractor's profit Overhead expenses

L.S. Per litre Per litre Total 10.00% 3.50%

= = = =

= = =

= = =

VAT 4.50% Grand total Rate per sft. Rate per sqm. Say, Tk.

Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk.

30.00 150.00 135.00 595.00 59.50 20.83 675.33 30.39 705.72 7.06 75.99

76 .00 Per sqm.

ANALYSIS FOR ITEM No. 134 Acrylic emulsion paint to walls and ceiling 2 coats over a coat of acrylic sealer Considering 100 sft. of work 1. Painter 2. Painter helper 3. Scaffolding, sundries etc. 4. Acrylic emulsion paint 5. Sealer / under-coat 1.00 1.00 1.00 1.00 No. No. Litre Litre @ @ @ @ Tk. 160.00 Tk. 120.00 Tk. 160.00 Tk. 153.00 Contractor's profit Overhead expenses each = Tk. each = Tk. L.S. = Tk. Per litre = Tk. Per litre = Tk. Total = Tk. 10.00% = 3.50% = Tk. Tk. Tk. Tk. Tk. Tk. Tk. 160.00 120.00 30.00 160.00 153.00 623.00 62.30 21.81 707.11 31.82 738.93 7.39 79.55

VAT 4.50% = Grand total = Rate per sft. = Rate per sqm. = Say, Tk. 80 .00 Per sqm.

ANALYSIS FOR ITEM No. 135 Textured painting with sealer coat, texure coat and top coat Considering 100 sft. of work

- 359 -

Analysis of Rates of P.W.D. Schedule (10th Edition), 16th October 2002

1. 2. 3. 4. 5.

Machine operator 1.00 Helper 1.00 Cost of electricity, machinery hire charges Scaffolding, sundries etc. Texured paint 12.12

No. No.

@ @

Tk. 160.00 Tk. 120.00

liters

Tk. 155.00 Contractor's profit Overhead expenses

each each L.S. L.S. Per liter

= = = = =

10.00% = 3.50% =

VAT 4.50% Grand total Rate per sft. Rate per sqm. Say, Tk.

=

= = =

Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk.

160.00 120.00 70.00 30.00 1,878.60 2,258.60 225.86 79.05 2,563.51 115.36 2,678.87 26.79 288.37

288 .00 Per sqm.

ANALYSIS FOR ITEM No. 136 Chlorinated rubber painting of best quality & approved colour. Considering 100 sft. of work

1. Painter 2. Painter helper 3. Scaffolding, sundries etc. 4. Chlorinated rubber paint 5. Sealer / under-coat 6. Thinner : T-2

1.00 1.00 1.10 1.10 0.60

No. No. Litre Litre Liter

@ @ @ @ @

Tk. 160.00 Tk. 120.00 Tk. 260.00 Tk. 240.00 Tk. 106.00 Contractor's profit Overhead expenses

each = Tk. each = Tk. L.S. = Tk. Per litre = Per litre = Per litre = Total= 10.00% = 3.50% =

160.00 120.00 60.00

VAT 4.50% Grand total Rate per sft. Rate per sqm. Say, Tk.

=

= = =

Tk. 286.00 Tk. 264.00 Tk. 63.60 Tk. 953.60 Tk. 95.36 Tk. 33.38 Tk. 1,082.34 Tk. 48.71 Tk. 1,131.05 Tk. 11.31 Tk. 121.74

122 .00 Per sqm.

ANALYSIS FOR ITEM No. 137

- 360 -

Analysis of Rates of P.W.D. Schedule (10th Edition), 16th October 2002

French polishing 3 coats Considering 100 sft. of work a) b) c) d) e) f) g) h) i) j) k) l) French powder Spirit Gala Mostaki Karpa Sand paper Putty Markin cloth Cotton Painter Helper Scaffolding, sundries etc. 0.25 4 0.15 0.15 0.05 4 0.5 0.5 0.03 1 1 kg. Ibs. kg. kg. kg. Nos. kg. yard Ibs. Nos. Nos. @ @ @ @ @ @ @ @ @ @ @ Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. 120.00 30.00 350.00 75.00 110.00 6.00 40.00 20.00 35.00 160.00 120.00 Per kg = Per Ib. = Per kg = Per kg = Per kg = each = Per kg = Per yard = Per Ib. = each = each = L.S. = Total= 10.00% = 3.50% = Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. 30.00 120.00 52.50 11.25 5.50 24.00 20.00 10.00 1.05 160.00 120.00 30.00 584.30 58.43 20.45 663.18 29.84 693.02 6.93 74.59

Contractor's profit Overhead expenses VAT

4.50% = Grand total Rate per sft.= Rate per sqm.=

Say, Tk. ANALYSIS FOR ITEM No. 138(a) Wood varnishing with varnish (Yacht) Considering 100 sft. of work 1. 2. 3. 4. 5. 6. 7. Sand paper Markin cloth Painter Ordinary labour Scaffolding, sundries, T & P etc. Cost of varnish: Yacht Thinner 4 0.5 1 1 1.00 0.91 Nos. Yard. Nos. Nos. Litre Litre @ @ @ @ @ @

75 .00 Per sqm.

Tk. 6.00 Tk. 20.00 Tk. 160.00 Tk. 100.00 Tk. 170.00 Tk. 42.00 Contractor's profit Overhead expenses

each Per yard each each L.S. Per litre Per litre

= = = = = = =

Tk. Tk. Tk. Tk. Tk. Tk. Tk.

24.00 10.00 160.00 100.00 30.00 170.00 38.22

Total = Tk.

10.00% = Tk. 3.50% = Tk. Tk.

532.22

53.22 18.63 604.07

- 361 -

Analysis of Rates of P.W.D. Schedule (10th Edition), 16th October 2002

VAT

4.50% = Grand total Rate per sft.= Rate per sqm.=

Tk. Tk. Tk. Tk.

27.18 631.25 6.31 67.92

Say, Tk.

68 .00 Per sqm.

ANALYSIS FOR ITEM No. 138(b) Wood varnishing with varnish (Egg-shell) Considering 100 sft. of work 1. 2. 3. 4. 5. Sand paper Markin cloth Painter Ordinary labour Scaffolding, sundries, T & P etc. 4.00 0.50 1.00 1.00 1.33 0.34 Nos. Yard. No. No. Litre Litre @ @ @ @ @ @ Tk. 6.00 Tk. 20.00 Tk. 160.00 Tk. 100.00 Tk. 170.00 Tk. 42.00 Contractor's profit Overhead expenses each Per yard each each L.S. Per litre Per litre Total 10.00% = = = = = = = = = Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. 24.00 10.00 160.00 100.00 30.00 226.10 14.28 564.38 56.44 19.75 640.57 28.83 669.40 6.69 72.01

6. Cost of varnish: Egg-shell 7. Thinner

3.50% = Tk. Tk. VAT 4.50% = Tk. Grand total Tk. Rate per sft.= Tk. Rate per sqm.= Tk. 72 .00 Per sqm.

Say, Tk. ANALYSIS FOR ITEM No. 138(c) Wood varnishing with varnish (Matt) Considering 100 sft. of work Sand paper Markin cloth Painter Ordinary labour Scaffolding, sundries, T & P etc.

1. 2. 3. 4. 5.

4 0.5 1 1

Nos. Yard. No. No.

@ @ @ @

Tk. 6.00 Tk. 20.00 Tk. 160.00 Tk. 100.00

each Per yard each each L.S.

= = = = =

Tk. Tk. Tk. Tk. Tk.

24.00 10.00 160.00 100.00 30.00

- 362 -

Analysis of Rates of P.W.D. Schedule (10th Edition), 16th October 2002

6. Cost of varnish: Matt 7. Thinner

1.30 0.35

Litre Litre

@ @

Tk. 130.00 Tk. 42.00 Contractor's profit Overhead expenses VAT

Per litre Per litre Total 10.00% 3.50%

= = = = =

4.50% = Grand total Rate per sft.= Rate per sqm.=

Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk.

169.00 14.70 507.70 50.77 17.77 576.24 25.93 602.17 6.02 64.80

Say, Tk.

65 .00 Per sqm.

- 363 -

Analysis of Rates of PWD Schedule (10th Edition), 16th October 2002

20. DRAIN AND APRON

ANALYSIS FOR ITEM NO. 139 Construction of 1'-0" clear width and depth upto 1'-0" masonry surface drain Considering 10 rft. of work a) Earth work in excavation: 10'-0" x 1'-10" x 1'-3"(av.) = b) Brick-flat soling: 10'-0" x 1'-10"= 18.33 sft. @ c) Cement concrete (1:3:6): 10'-0" x 1'-10" x 0'-3"(av.) = 4.58 cft. @ d) 5" thick brick work (1:4): 2 x 10'-0" x 0'-9"= 15 sft. @ e) 1/2" thick cement plast:er (1:4) with neat cement finish: 10'-0" x 4'-0"= 40 sft. @ Tk. 1,171.25 Tk. 7,491.10 Tk. 2,971.80 Tk. 882.00 Per % sft. = Per % cft. = Per % sft. = Per % sft = Total = 10.00% = 3.50% = 4.50% Grand total Rate per rft.. Rate per rm = Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. 214.69 343.09 445.77 352.80 1,390.16 139.02 48.66 1,577.84 71.00 1,648.84 164.88 540.97

22.92 cft.

Tk. 1,475.00

Per % 0 cft. =

Tk.

33.81

Contractor's profit Overhead expenses VAT

= = =

Say,

Tk.

541 .00 Per rm.

ANALYSIS FOR ITEM NO. 140 Construction of surface drain of 2'-0" (av.) depth and 0'-9" clear width at bottom and 1'-0" at top having 5" thick cement concrete curb etc. masonry surface drain Considering 10 rft. of work a) Earth work in excavation: 10'-0" x (2'-7" + 1'-7")/2 x 2'-7"=

53.66 cft.

Tk. 1,475.00

Per % 0 cft. =

Tk.

79.15

- 364 -

Analysis of Rates of PWD Schedule (10th Edition), 16th October 2002

b) c) d) e) f)

Brick-flat soling: 10'-0" x 1'-10"= 18.30 sft. Cement concrete (1:2:4): 10'-0" x 3'-7" x 0'-5"= 14.93 cft. 5" thick brick work (1:4): 2 x 10'-0" x 1'-0"= 20 sft. 1/2" thick cement plast:er (1:4) with neat cement finish: 10'-0" x 6'-7"= 65.83 sft. Cost of polythene: 10'-0" x 6'-0"= 50 sft. @ @ @ @ @ Tk. 1,171.25 Tk. 8,991.10 Tk. 2,971.80 Tk. Tk. 882.00 117.00 Per % sft. = Per % cft. = Per % sft. = Per % sft. = Per % sft. Total = 10.00% = 3.50% = 4.50% Grand total Rate per rft. Rate per rm. = Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. 214.34 1,342.37 594.36 580.62 58.50 2,869.34 286.93 100.43 3,256.70 146.55 3,403.25 340.33 1,116.62

Contractor's profit Overhead expenses VAT

=

= =

Say,

Tk.

1,117 .00 Per rm.

ANALYSIS FOR ITEM NO. 141 Providing apron with 2" or 50 mm thick cement concrete (1:2:4) and one layer brick flat soling at bottom. Considering 100 sft. of work A) For concrete of (1:2:4) 100 cft. @ Tk. 8,991.10 Per % cft. = Cost for 2" thick 100 sft. concrete = Tk. Tk. Tk. 150.00 100.00 250.00 each = each = Per bag = = = Per % sft. = Per % 0 cft. = (A+B+C) = 10.00% = 3.50% = Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. 8,991.10 1,498.52 75.00 100.00 125.00 300.00 1,798.52 1,171.25 61.46 3,031.23 303.12 106.09

Labour cost for 2" thick 100 sft. concrete i) Mason for neat finish 0.5 No. 1 No. ii) Ordinary lab. for neat finish iii) Extra cement for neat finish 0.5 bag.

@ @ @

B) C)

Total cost for 100 sft. concrete One layer brick flat soling 100 sft. @ Tk. 1,171.25 Earth work: 100 sft. x 0'-5"= 41.67 cft. @ Tk. 1,475.00 Total Contractor's profit Overhead expenses

- 365 -

Analysis of Rates of PWD Schedule (10th Edition), 16th October 2002

Tk. VAT 4.50% = Grand total = Rate per sft. = Rate per sqm. = Say, Tk. 387 .00 Per sqm. Tk. Tk. Tk. Tk.

3,440.44 154.82 3,595.26 35.95 386.97

ANALYSIS FOR ITEM NO. 142(a) Supplying and laying, fitting, fixing of 9" or 225 mm inside dia RCC pipe excluding cost of earth cutting & back filling. Considering 18 rft. of work a) Cost of machine made best quality 9" dia RCC pipe in/c all necessary fittings 18 rft. b) @ Tk. 89.94 each = Per % sft. = Tk. Tk. 1,618.92 438.52

One layer brick flat soling: 18'-0" x 2'-1"= 37.44 sft. @ Tk. 1,171.25 c) Cement concrete(1:3:6): bottom: 18'-0" x 2'-1" x 0'-4"= 12.48 cft. sides: 2 x 18'-0" x 10" x 10"/2= 6.25 cft. = 18.73 cft. @ Tk. 7,491.10 d) Labour charge for laying pipe maintaining proper slope in/c cost of gasket etc. 0.25 No. @ Tk. 180.00 i) Head mason ii) Mason 0.25 No. @ Tk. 150.00 iii) Skilled labour 1 No. @ Tk. 120.00 Contractor's profit Overhead expenses VAT

Per % cft. = each each each Total = = = =

Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk.

1,403.08 45.00 37.50 120.00 3,663.02 366.30 128.21 4,157.53 187.09 4,344.62 241.37 791.93

10.00% = 3.50% = 4.50% = Grand total = Rate per rft. = Rate per rm. =

Say,

Tk.

792 .00 Per rm.

- 366 -

Analysis of Rates of PWD Schedule (10th Edition), 16th October 2002

ANALYSIS FOR ITEM NO. 142(b) Supplying and laying, fitting, fixing of 12" or 300 mm inside dia RCC pipe excluding cost of earth cutting & back filling. Considering 18 rft. of work Cost of machine made best quality 12" dia RCC pipe in/c necessary fittings. 18 rft. @ Tk. 120.12 c) One layer brick flat soling: 1 x 18'-0" x 2'-8"= 48 sft. @ Tk. 1,171.25 d) Cement concrete(1:3:6): bottom: 1 x 18'-0" x 2'-8" x 0'-4"= 16.0 cft. sides: 2 x 18'-0" x 14" x 7"/2= 12.25 cft. = 28.25 cft. @ Tk. 7,491.10 e) Labour charge for laying pipe maintaining proper slope in/c cost of gasket etc. 0.25 No. @ Tk. 180.00 i) Head mason ii) Mason 0.25 No. @ Tk. 150.00 iii) Skilled labour 1.5 No. @ Tk. 120.00 a) Contractor's profit Overhead expenses VAT

each = Per % sft. =

Tk. Tk.

2,162.16 562.20

Per % cft. = each each each Total 10.00% 3.50% 4.50% Grand total Rate per rft. Rate per rm. = = = = = = =

Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk.

2,116.24 45.00 37.50 180.00 5,103.10 510.31 178.61 5,792.02 260.64 6,052.66 336.26 1,103.27

= = =

Say,

Tk.

1,103 .00 Per rm.

21. FALSE CEILING, WALL PANELING

ANALYSIS FOR ITEM NO. 143(a) 1/2" thick plain particle board ceiling screwed up with wooden frame for normal room height

Considering a panel of 12' x 16'= 192 sft. of work

- 367 -

Analysis of Rates of PWD Schedule (10th Edition), 16th October 2002

a)

Cost of Garjan wood: (7 x 16' + 9 x 12') x 3" x 2"= Add 5% wastage= 9.17 cft. cft. cft. sft. sft. sft. @ Tk. 710.00 Per cft. = Tk. 6,837.30 0.46 9.63 Cost of 1/2" thick plain particle board 12'-0" x 16'-0"= 192 Add 5% wastage= 9.6 201.6

b)

Tk.

22.97

Per sft. =

Tk.

4,630.75

c) Cost of G.I. wire, rowel plug, nails and screws etc. necessary for fabricating, hoisting and hanging frame and board

(7.5% of cost of wood and board)

d) Cost of fitting, fixing, levelling, finishing, scaffolding etc (upto 3.5 m height) i) Carpenter 10 Nos. @ Tk. 160.00 ii) Carpenter helper 10 Nos. @ Tk. 120.00 e) Painting 2 coats over a coat of priming (rate is 50% more than the normal rate) 192 sft. @ Tk. 963.75

Tk.

860.10

each = each = = = = = =

Tk. Tk. Tk. Tk. Tk. Tk.

1,600.00 1,200.00 1,850.40 16,978.55 1,697.86 594.25

Contractor's profit Overhead expenses VAT

Per %sft. Total 10.00% 3.50% 4.50% Grand total Rate per sft. Rate per sqm

= = =

Tk. 19,270.66 Tk. 867.18 Tk. 20,137.84 Tk. 104.88 Tk. 1,128.93

Say,

Tk.

1,129 .00 Per sqm.

ANALYSIS FOR ITEM NO. 143(b) 1/2" thick plain particle board ceiling screwed up with wooden frame for auditorium and other tall structures beyond 3.5 meter upto 6 meter height. Consider 1 No. panel Considering a panel of 12'-0" x 16'-0"= 192 sft. of work a) Cost of materials and labour

Same as item No. 143(a)

Tk.

16,978.55

- 368 -

Analysis of Rates of PWD Schedule (10th Edition), 16th October 2002

b)

Scaffolding beyond 12' upto 20' (double stage) 2 x 16'-0" x 12'-0"= 384 sft. @ Tk. 3.00 Per sft. = Total = Contractor's profit Overhead expenses VAT 10.00% = 3.50% = 4.50% = Grand total = Rate per sft. = Rate per sqm = Say, Tk. 1,206 .00 Per sqm. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. 1,152.00 18,130.55 1,813.06 634.57 20,578.18 926.02 21,504.20 112.00 1,205.57

ANALYSIS FOR ITEM NO. 143(c) Supplying, fitting and fixing of 8 mm thick melamine board laminated by mechanical hot press with a milk white PVC membrance with aluminum frame suspended from ceiling. Consider 16'-0" x 10'-0"= 160 sft. of work A. 1. MATERIAL Malamine board (8 mm thick) : 8' -0" x 4'-0" size 5 Pcs. 2. Aluminium section & accessories (a) 1" main T-section 64.00 rft. (b) 1" cross T-section 30.00 rft. (c) 1" L-section 63.00 rft. (d) Revit (e) G.I. wire 1.50 kg. (f) 1.5" screw 10.50 doz. (g) Rowl plug 120.00 Nos. (h) Wall bit 2.00 Nos. B. LABOUR i) Carpenter 6.00 Nos. ii) Helper to carpenter 6.00 Nos. iii) Carrying to site in/c sundries

@ @ @ @ @ @ @ @ @ @

Tk. 1,150.00 Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. 11.00 9.00 8.00 50.00 8.00 0.25 25.00 160.00 120.00

Per pc. = Per rft. Per rft. Per rft. L.S. Per sft. Per doz. each each each each L.S. Total 10.00% 3.50% = = = = = = = = = = = = = =

Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk.

5,750.00 704.00 270.00 504.00 75.00 75.00 84.00 30.00 50.00

Contractor's profit Overhead expenses

Tk. 960.00 Tk. 720.00 Tk. 200.00 Tk. 9,422.00 Tk. 942.20 Tk. 329.77 Tk. 10,693.97

- 369 -

Analysis of Rates of PWD Schedule (10th Edition), 16th October 2002

VAT

4.50% Grand total Rate per sft. Rate per sqm

= = =

Tk. Tk. Tk. Tk.

481.23 11,175.20 69.85 751.87

Say,

Tk.

752 .00 Per sqm.

ANALYSIS FOR ITEM NO. 144(a) Supplying, fitting and fixing of 12 mm thick gypsum board laminated by mechanical hot press with a milk white PVC membrance with aluminum frame suspended from ceiling. Consider 10'-0" x 10'-0"= 100 sft. of work a) Cost of materials i) Aluminium sections Main T-section: 4 x 10' - 0" = Coss T-section 4 x 10' - 0" = Angle or L-section: 4 x 10' - 0"=

40.00 rft. 40.00 rft. 40.00 rft.

@ @ @

Tk. Tk. Tk. Tk.

11.00 9.00 8.00 48.00 40.00%

Per rft. = Per rft. = Per rft. = Per sft. = of cost of aluminium sections = each each each Per sft. Total 10.00% 3.50% 4.50% Grand total Rate per sft. Rate per sqm = = = = = = = =

Tk. Tk. Tk. Tk.

440.00 360.00 320.00 4,800.00

ii) Gypsum board 100.00 sft. @ iii) Accessories, rowel bolts, G.I. wire, machine charges for 100.00 sft. @

Tk.

448.00

b) i) ii) iii) iv)

Cost of labour Skilled technician Skilled labour Ordinary labour Scaffolding

5.00 5.00 5.00 100.00

Nos. Nos. Nos. sft.

@ @ @ @

Tk. Tk. Tk. Tk.

250.00 120.00 100.00 3.00

Contractor's profit Overhead expenses VAT

= = =

Tk. 1,250.00 Tk. 600.00 Tk. 500.00 Tk. 300.00 Tk. 9,018.00 Tk. 901.80 Tk. 315.63 Tk. 10,235.43 Tk. 460.59 Tk. 10,696.02 Tk. 106.96 Tk. 1,151.32

Say,

Tk.

1,151 .00 Per sqm.

- 370 -

Analysis of Rates of PWD Schedule (10th Edition), 16th October 2002

ANALYSIS FOR ITEM NO. 144(b) Supplying, fitting and fixing of 12 mm thick vinyl board laminated by mechanical hot press with a milk white PVC membrance with aluminum frame suspended from ceiling. Consider ing 100 sft. of work a) b) Cost of false ceiling work excluding cost of board Cost of vinyle board 100.00 @ Same as item No. 144(a) 45.85 Per sft. Total Contractor's profit 10.00% Overhead expenses 3.50% Tk. VAT 4.50% Grand total Rate per sft. Rate per sqm = = = = = = Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. 4,218.00 4,585.00 8,803.00 880.30 308.11 9,991.41 449.61 10,441.02 104.41 1,123.87

= = =

Say,

Tk.

1,124 .00 Per sqm.

ANALYSIS FOR ITEM NO. 145(a) Supplying, fitting and fixing of 12 mm thick B.T. veneered board in walling. Consider 1 No. panel Consider 12'-0" x 10'-0"= 120 sft. of work a) Cost of materials i) Garjan wood: batten: 7 x 10'-0" x 3" x 1.5"= 6 x 12'-0" x 3.25" x 1.5"= = Add wastage 5%= = ii) Cost of 12 mm B.T. veneered board: 12'-0" x 10'-0"= 120.00 sft. Add wastage 5%= 6.00 sft.

- 371 -

2.19 cft. 2.25 cft. 4.44 cft. 0.22 cft. 4.66 cft. @ Tk. 710.0 Per cft. = Tk. 3,308.60

Analysis of Rates of PWD Schedule (10th Edition), 16th October 2002

= 126.00 sft.

Tk.

75.00

Per sft. = =

Tk. Tk.

9,450.00 330.86

iii) Cost of M.S. clamps, wooden block, screws, nails etc. (10% of cost of wooden frame) b) Cost of fitting, fixing, cutting to sizes, levelling, finishing, scaffolding i) Carpenter ii) Carpenter helper c) d) Local carriage French polishing 120.00 sft. @ Tk. 587.63 6.00 Nos. 6.00 Nos. @ @ Tk. Tk. 160.00 120.00

each = each = L.S = Per % sft. = Total = 10.00% = 3.50% = 4.50% = Grand total = Rate per sft. = Rate per sqm =

Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk.

960.00 720.00 50.00 705.16 15,524.62 1,552.46 543.36 17,620.44 792.92 18,413.36 153.44 1,651.63

Contractor's profit Overhead expenses VAT

Say,

Tk.

1,652 .00 Per sqm.

ANALYSIS FOR ITEM NO. 145(b)

Supplying, fitting and fixing of 12 mm thick particle board walling with wooden frame.

Consider 12'-0" x 10'-0"= 120 sft. of work a) b) Cost of walling excluding cost of board Cost of 12 mm thick particle board in/c 5% wastage 126 sft. @

Same as item No. 145(a) =

Tk. 22.97 Per sft. Total 10.00% 3.50% = = = =

Tk.

6,074.62

Contractor's profit Overhead expenses VAT

4.50% =

Tk. 2,894.22 Tk. 8,968.84 Tk. 896.88 Tk. 313.91 Tk. 10,179.63 Tk. 458.08

- 372 -

Analysis of Rates of PWD Schedule (10th Edition), 16th October 2002

Grand total = Rate per sft. = Rate per sqm = Say, Tk. 954 .00 Per sqm.

Tk. Tk. Tk.

10,637.71 88.65 954.23

- 373 -

Analysis of Rates of PWD Schedule (10th Edition), 16th October, 2002

22. COLLAPSIBLE GATE, M.S. GATE, ROLLING SHUTTER ETC.

ANALYSIS FOR ITEM NO. 146(a) Manufacturing, supplying, fitting and fixing of collapsible gate with 3/4" x 3/8" 1/8" size M.S. channel excluding cost of paint. Considering 1 No. collapsible gate Considering 8'-0" x 8'-0"= 64.00 sft. in two parts a) Cost of materials i) 3/4" x 3/8" x 1/8" channel: @ 0.53 Ibs per rft. 2 x 12 x 2 x 8'-6"= 384 rft. Add wastage 5%= 19.2 rft. = 403.2 rft. = 213.696 Ibs. @ ii) 3/4" x 1/8" M.S. flat bar diagonals at 3 levels of length 1'0" to 2'-0": @ 0.32 Ibs per rft. 2 x 9 x 2 x 3 x 2'-0"= 2 x 2 x 2 x 3 x 1'-9"= = Add wastage 5%= = 216.00 rft. 42.00 rft. 258.00 rft. 12.90 rft. 270.90 rft. 7.71 Per Ib. = Tk. 668.38

Tk.

8.71

Per Ib. = Tk.

1,861.29

= 86.69 Ibs. @ Tk. iii) 2" x 1/4" F.I. bar to make Tee (top & bottom rail) and locking arrangement: @ 1.70 Ibs per rft. 34 rft. 2 rft. 36 rft. Add wastage 5%= 1.8 rft. = 37.8 rft. = 64.26 Ibs. @ Tk. iv) 3/4" x 3/16" F.I. bar for making handle: @ 0.48 Ibs per rft. 4 x 0'-10"= Add wastage 5%= = = b) Hardwares, fittings and consumables: i) Rivet and washer ii) 1.5" dia M.S. wheel 2.00 kg. 6.00 Nos.

- 374 -

4 x 8'-6"= 2 x 2 x 0'-6"=

7.71

Per Ib. = Tk.

495.44

3.30 rft. 0.17 rft. 3.47 rft. 1.67 Ibs. @ @ @ Tk. Tk. Tk. 7.71 40.00 10.00 Per Ibs = Tk. Per kg. = Tk. each = Tk. 12.88 80.00 60.00

Analysis of Rates of PWD Schedule (10th Edition), 16th October, 2002

iii) M.S. clamp: iv) Locking arrangement v) Electrodes vi) Greese c) Making gate in work-shop i) Welder/ fabricator ii) Helper to welder iii) Ordinary labour d)

10 Nos. 2 pairs 20 Pc. 0.5 Ibs. 3.5 Nos. 3.5 Nos.

@ @ @ @ @ @

Tk. Tk. Tk. Tk. Tk. Tk. Tk.

10.00 20.00 4.00 40.00 160.00 120.00 100.00

each = Tk. each pair = Tk. Per pc. = Tk. Per kg. = Tk. each = Tk. each = Tk. each = Tk. L.S. = Tk. Sub-total = Tk. 10% = Tk. Total = Tk.

100.00 40.00 80.00 20.00 560.00 420.00 350.00 150.00 4,897.99 489.80 5,387.79 84.00 48.00 89.91 166.68 105.84 75.00 60.00 6,017.22 601.72 210.60 6,829.54 307.33 7,136.87 111.51 1,200.29

3.5 Nos. @ Carrying cost: steel materials from market to workshop & finished gate from workshop to site. Workshop charge Ancillary work for fitting-fixing the gate: i) Making holes ii) Making groove (channel) on floor: 1 x 8'-0"= iii) Cost of CC (1:2:4): 14 x 6" x 4" x 4"= iv) 1/2" thick plaster (1:4) 3 x 8'-0" x 1'-0"= 1 x 8'-0" x 1'-6"= 14.00 Nos. 8.00 rft. 1.00 cft (say) 24.00 sft. 12.00 sft. 0.5 No. 0.5 No. @ @ @ @ @ @ @

e) f)

Tk. Tk.

6.00 6.00

each = Tk. Per rft. = Tk. Per % cft. = Tk. Per % sft. = Tk. Per % sft. = Tk. each = Tk. each = Tk. Total = Tk. 10.00% = Tk. 3.50% = Tk. Tk. 4.50% = Tk. Grand total = Tk. Rate per sft. = Tk. Rate per sqm. = Tk.

Tk. 8,991.10 Tk. Tk. Tk. Tk. 694.50 882.00 150.00 120.00

v) Repairing floor and plaster with neat cement finish: g) Labour for fitting-fixing the gate: iii) Mason iv) Skilled labour

Contractor's profit Overhead expenses VAT

Say,

Tk.

1,200 .00 Per sqm.

- 375 -

Analysis of Rates of PWD Schedule (10th Edition), 16th October, 2002

ANALYSIS FOR ITEM NO. 146(b) Manufacturing, supplying, fitting and fixing of collapsible gate with 3/4" x 3/4" x 1/8" M.S. angle excluding cost of paint. Considering 1 No. collapsible gate Considering 8'-0" x 8'-0"= 64.00 sft. in two parts a) Cost of materials i) 3/4" x 3/4" x 1/8" angle: @ 0.585 Ibs per rft. 2 x 12 x 2 x 8'-6"= 384 rft. Add wastage 5%= 19.2 rft. = 403.2 rft. = 235.872 Ibs. @ ii) 3/4" x 1/8" M.S. flat bar diagonals at 3 levels of length 1'0" to 2'-0": @ 0.32 Ibs per rft. 2 x 9 x 2 x 3 x 2'-0"= 2 x 2 x 2 x 3 x 1'-9"= = Add wastage 5%= = = 216.00 rft. 42.00 rft. 258.00 rft. 12.90 rft. 270.90 rft. 86.69 Ibs. @ Tk. 7.71 Per Ib. = Tk. 668.38

Tk.

8.71

Per Ib. = Tk.

2,054.45

iii) 2" x 1/4" F.I. bar to make Tee (top & bottom rail) and locking arrangement: @ 1.70 Ibs per rft. 4 x 8'-6"= 2 x 2 x 0'-6"= Add wastage 5%= = = b) Hardwares, fittings and consumables: i) Rivet and washer ii) 1.5" dia M.S. wheel iii) M.S. clamp: iv) Locking arrangement v) Handle with 5/8" dia M.S rod v) Electrodes vi) Greese 2.50 kg. 6.00 Nos. 10 Nos. 2 pairs 4 Nos 70 pcs. 0.5 Ibs. @ @ @ @ @ @ @ Tk. Tk. Tk. Tk. Tk. Tk. Tk. 40.00 10.00 10.00 20.00 12.00 4.00 40.00 Per kg. = Tk. each = Tk. each = Tk. each pair = Tk. each = Tk. Per pc. = Tk. Per kg. = Tk. 100.00 60.00 100.00 40.00 48.00 280.00 20.00 34 rft. 2 rft. 36 rft. 1.8 rft. 37.8 rft. 64.26 Ibs.

Tk.

7.71

Per Ib. = Tk.

495.44

- 376 -

Analysis of Rates of PWD Schedule (10th Edition), 16th October, 2002

c)

Making gate in work-shop i) Welder/ fabricator ii) Helper to welder iii) Ordinary labour 4.5 Nos. 4.5 Nos. 4.5 Nos. @ @ @ Tk. Tk. Tk. 160.00 120.00 100.00 each = Tk. each = Tk. each = Tk. L.S. Sub-total 10% Total @ @ @ @ @ @ @ Tk. Tk. 6.00 6.00 = = = = Tk. Tk. Tk. Tk. 720.00 540.00 450.00 150.00 5,726.27 572.63 6,298.90 84.00 48.00 89.91 166.68 105.84 75.00 60.00 6,928.33 692.83 242.49 7,863.65 353.86 8,217.51 128.40 1,382.10

d) e)

Carrying cost: materials & finished gate. Workshop charge

f) Anciliary work for fitting-fixing the gate: i) Making holes 14.00 Nos. ii) Making groove (channel) on floor: 1 x 8'-0"= 8.00 rft. iii) Cost of CC (1:2:4): 14 x 6" x 4" x 4"= 1.00 cft (say) iv) 1/2" thick plaster (1:4) 3 x 8'-0" x 1'-0"= 24.00 sft. v) Repairing floor and plaster with neat cement finish: 1 x 8'-0" x 1'-6"= 12.00 sft. Labour for fitting-fixing the gate: iii) Mason 0.5 No. iv) Skilled labour 0.5 No. each = Tk. Per rft. = Tk. Per % cft. = Tk. Per % sft. = Tk. Per % sft. = Tk. each each Total 10.00% = = = = Tk. Tk. Tk. Tk. Tk. VAT 4.50% = Tk. Grand total = Tk. Rate per sft. = Tk. Rate per sqm. = Tk. Say, Tk. 1,382 .00 Per sqm.

Tk. 8,991.10 Tk. Tk. Tk. Tk. 694.50 882.00 150.00 120.00

g)

Contractor's profit Overhead expenses

3.50% = Tk.

ANALYSIS FOR ITEM NO. 146(c) Manufacturing, supplying, fitting and fixing of collapsible gate with 1" x 1" x 1/8" M.S. angle excluding cost of paint. Considering 1 No. collapsible gate Considering 8'-0" x 8'-0"= 64.00 sft. in two parts

- 377 -

Analysis of Rates of PWD Schedule (10th Edition), 16th October, 2002

a)

Cost of materials i) 1" x 1" x 1/8" angle: @ 0.8 Ibs per rft. 2 x 12 x 2 x 8'-6"= Add wastage 5%= =

384 rft. 19.2 rft. 403.2 rft. Per Ib. = Tk. 2,809.50

= 322.56 Ibs. @ Tk. 8.71 ii) 1" x 1/8" M.S. flat bar diagonals at 3 levels of length 1'-0" to 2'-0": @ 0.43 Ibs per rft. 2 x 9 x 2 x 3 x 2'-0"= 2 x 2 x 2 x 3 x 1'-9"= = Add wastage 5%= = 216.00 rft. 42.00 rft. 258.00 rft. 12.90 rft. 270.90 rft. 7.71

= 116.49 Ibs. @ Tk. iii) 2" x 1/4" F.I. bar to make Tee (top & bottom rail) and locking arrangement: @ 1.70 Ibs per rft. 4 x 8'-6"= 2 x 2 x 0'-6"= Add wastage 5%= = = b) Hardwares, fittings and consumables: i) Rivet and washer ii) 1.5" dia M.S. wheel iii) M.S. clamp: iv) Locking arrangement v) Handle with 5/8" dia M.S rod v) Electrodes c) vi) Greese Making gate in work-shop i) Welder/ fabricator ii) Helper to welder d) e) iii) Ordinary labour Carrying cost: materials & finished gate. Workshop charge 34 2 36 1.8 rft. rft. rft. rft. @ @ @ @ @ @ @ @ @ @ @ Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk.

Per Ib. = Tk.

898.14

37.8 rft. 64.26 Ibs. 3.00 6.00 10 2 kg. Nos. Nos. pairs

7.71 40.00 10.00 10.00 20.00 12.00 4.00 40.00 160.00 120.00 100.00

Per Ib. = Tk. Per kg. each each each pair = = = = Tk. Tk. Tk. Tk.

495.44 120.00 60.00 100.00 40.00 48.00 280.00 20.00 800.00 600.00 500.00 150.00 6,921.08 692.11 7,613.19

4 Nos 70 pcs. 0.5 Ibs. 5 Nos. 5 Nos. 5 Nos.

each = Tk. Per pc. = Tk. Per kg. = Tk. each = each = each = L.S. = Sub-total = 10% = Total = Tk. Tk. Tk. Tk. Tk. Tk. Tk.

- 378 -

Analysis of Rates of PWD Schedule (10th Edition), 16th October, 2002

f)

Anciliary work for fitting-fixing the gate: i) Making holes ii) Making groove (channel) on floor: 1 x 8'-0"= iii) Cost of CC (1:2:4): 14 x 6" x 4" x 4"= iv) 1/2" thick plaster (1:4) 3 x 8'-0" x 1'-0"= 8.00 rft. 1.00 cft (say) 24.00 sft. @ @ @ @ @ @ Tk. 6.00 Per rft. = Tk. Per % cft. = Tk. Per % sft. = Tk. Per % sft. = Tk. each each Total 10.00% 3.50% Tk. Tk. Tk. Tk. Tk. Tk. 4.50% = Tk. = = = = = 48.00 89.91 166.68 105.84 75.00 60.00 8,242.62 824.26 288.49 9,355.37 420.99 9,776.36 152.76 1,644.31 14.00 Nos. @ Tk. 6.00 each = Tk. 84.00

Tk. 8,991.10 Tk. Tk. Tk. Tk. 694.50 882.00 150.00 120.00

v) Repairing floor and plaster with neat cement finish : 1 x 8'-0" x 1'-6"= 12.00 sft. g) Labour for fitting-fixing the gate: iii) Mason iv) Skilled labour 0.5 No. 0.5 No.

Contractor's profit Overhead expenses VAT

Grand total = Tk. Rate per sft. = Tk. Rate per sqm. = Tk. Say, Tk. 1,644 .00 Per sqm.

ANALYSIS FOR ITEM NO. 147(a) Manufacturing, supplying, fitting and fixing of ordinary type M.S.gate (double leaf) with 5/8" dia M.S. rod and 1.5" x 1.5" x 1/4" angle frame excluding cost of painting. Considering 1 No. of gate Considering 10'-0" x 6'-8"= 66.67 sft. in two parts a) Cost of materials i) 1.5" x 1.5" x 1/4" angle for frame: @ 2.34 Ibs per rft. 2 x 2 x 6'-0"= 2 x 3 x 5'-0"= 1 x 3'-6"= 2 x 2'-0"= 2 x 3-6"= 24.0 rft. 30.0 rft. 3.5 rft. 4.0 rft. 7.0 rft.

- 379 -

Analysis of Rates of PWD Schedule (10th Edition), 16th October, 2002

68.5 rft. Add wastage 5%= = = 2 x 2 x 5'-7"= 2 x 2'-6"= 2 x 5'-0"= = Add wastage 5%= = = 2 x 3.142 x 10'-0"/4= Add wastage 5%= 3.425 rft. 71.93 rft. 168.32 Ibs. 22.32 rft. 5.00 rft. 10.00 rft. 37.32 rft. 1.866 rft. 39.19 rft. 50.16 Ibs. 15.71 rft. 0.79 rft. 16.50 rft. 28.05 Ibs. @ Tk. 7.71 Per Ib = Tk. 216.27 @ Tk. 7.71 Per Ib. = Tk. 386.73 @ Tk. 8.71 Per Ib. = Tk. 1,466.07

ii) 1.5" x 1/4" M.S. flat bar: @ 1.28 Ibs per rft.

iii) 2" x 1/4" F.I. bar for rails: @ 1.7 Ibs per rft.

= iv) 5/8" M.S. rod: @ 1.043 Ibs per rft.: 2 x 21 x 0'-8"= 28.14 rft. 2 x 19 x 3'-6"= 133.00 rft. 19.00 180.14 Add wastage 5%= 9.01 = 189.15 = 197.28 v) 1/8" thick M.S. plate: @ 5.10 lbs per sft. 4.00 1 5.00 Add wastage 5%= 0.25 = 5.25 = 26.78 vi) 1/4" thick M.S. plate: @ 10.2 Ibs per sft. 2 x 0-6" x 0'-6"= 0.50 Add wastage 5%= 0.03 = 0.53 = 5.41 vii) 18 BWG M.S. plate: 2.04 Ibs per sft. 2 x 5'-0" x 2'-6"= 2 x 2 x 1'-0" x 1'-0"= 2 x 1'-0" x 6" = 2 x 38 x 0'-3"=

rft. rft. rft. rft. Ibs. sft. sft. sft. sft. sft. Ibs. sft. sft. sft. Ibs.

Tk.

7.71

Per Ib. = Tk.

1,521.03

Tk.

10.85

Per Ib. = Tk.

290.56

Tk.

10.85

Per Ib. = Tk.

58.70

25.00 sft.

- 380 -

Analysis of Rates of PWD Schedule (10th Edition), 16th October, 2002

b)

Add wastage 5%= = = Fittings and consumables i) Hinges for pocket gate: ii) 1.5" dia heavy duty wheel iii) Locking arrangement iv) Clamp with huskel dumney v) Clamp for rails vi) Electrodes

1.25 sft. 26.25 sft. 53.55 Ibs. 2 Nos. 2 Nos. 3 Nos. 6 Nos. 16 Nos. 200 Pc. 6 Nos. 5 Nos. 5 Nos.

@ @ @ @ @ @ @ @ @ @

Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk.

10.85 15.00 80.00 125.00 70.00 10.00 4.00 160.00 120.00 100.00

Per Ib. = Tk. each = Tk. each = Tk. each = Tk. each = Tk. each = Tk. each = Tk. each = Tk. each = Tk. each = Tk. L.S. = Tk. Sub-total = Tk. 10% = Tk. Total = Tk.

581.02 30.00 160.00 375.00 420.00 160.00 800.00 960.00 600.00 500.00 150.00 8,675.38 867.54 9,542.92 30.00

c)

Making steel gate in work-shop i) Welder / fabricator ii) Helper iii) Ordinary labour

d) e) f)

Carrying materials to work-shop & gate to site Work-shop charges Ancillary work for fitting -fixing the gate: i) Making holes 6 Nos. ii) Plain concrete: (1:2:4) 6 x 10" x 6" x 6"= 1.25 cft. 16'-0" x 6" x 4"= 2.67 cft. 2 x 4 x 6" x 4"= 1.33 cft. 5.25 cft. Labour charge for hoisting the gate in position i) Mason 1 No. ii) Mason helper iii) Ordinary labour 2 No. 1 No.

Tk.

5.00

each = Tk.

@ @ @ @

Tk. 8,991.10 Tk. Tk. Tk. 150.00 120.00 100.00

Per % cft. = Tk. each = Tk. each = Tk.

472.03 150.00 240.00

g)

each = Tk. 100.00 Total = Tk. 10,534.95 10.00% = Tk. 3.50% = Tk. 1,053.50 368.72

Contractor's profit Overhead expenses VAT

Tk. 11,957.17 4.50% = Tk. 538.07 Grand total = Tk. 12,495.24 Rate per sft. = Tk. Rate per sqm. = Tk. 187.42 2,017.39

- 381 -

Analysis of Rates of PWD Schedule (10th Edition), 16th October, 2002

Say,

Tk.

2,017 .00 Per sqm.

ANALYSIS FOR ITEM NO. 147(b) Manufacturing, supplying, fitting and fixing of security door with 7/8" dia M.S. rod and 2" x 2" x 1/4" angle frame excluding cost of painting. Considering 1 No. of gate Considering 3'-4" x 7'-0"= 23.31 sft. in two parts a) Cost of materials i) 2" x 2" x 1/4" angle for frame: @ 3.19 Ibs per rft. Vertical: 2 x 7'-0"= Horizontal: 2 x 3'-4"= Clamp: 4 x 1'-6"= = Add wastage 5%= = = ii) 7/8" M.S. rod: @ 2.04 Ibs per rft.: 10 x 6'-11.5"= Add wastage 5%= = = iii) 2" x 1/4" F.I. bar: @ 1.7 Ibs per rft. Horizontal: 4 x 3'-3.5= Rails: 2 x 3.142 x 3'-4"=

14.0 6.67 6.00 26.67 1.33 28.00 89.32

rft. rft. rft. rft. rft. rft. Ibs.

Tk.

8.71

Per Ib. = Tk.

777.98

69.60 3.48 73.08 149.08

rft. rft. rft. Ibs.

Tk.

7.71

Per Ib. = Tk.

1,149.41

b)

15.71 20.93 36.64 Add wastage 5%= 1.83 38.47 = 65.40 v) 1/8" thick M.S. plate: @ 5.10 lbs per sft. 1 x 2'-0" x 3'-0"= 6.00 Add wastage 5%= 0.3 = 6.30 = 32.13 Fittings and consumables i) Hinges for pocket gate:

rft. rft. rft. rft. rft. Ibs. sft. sft. sft. Ibs.

Tk.

7.71

Per Ib = Tk.

504.23

@ @

Tk. Tk.

10.85 15.00

Per Ib. = Tk. each = Tk.

348.61 30.00

2 Nos.

- 382 -

Analysis of Rates of PWD Schedule (10th Edition), 16th October, 2002

ii) 1.5" dia heavy duty wheel iii) Locking arrangement iv) Clamp with huskel dumney v) Clamp for rails vi) Electrodes c) Making steel gate in work-shop i) Welder / fabricator ii) Helper iii) Ordinary labour d) e) f)

2 Nos. 2 Nos. 3 Nos. 6 Nos. 98 Pc. 3 Nos. 3 Nos. 3 Nos.

@ @ @ @ @ @ @ @

Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk.

80.00 125.00 70.00 10.00 4.00 160.00 120.00 100.00

each = Tk. each = Tk. each = Tk. each = Tk. each = Tk. each = Tk. each = Tk. each = Tk. L.S. = Tk. Sub-total = Tk. 10% = Tk. Total = Tk.

160.00 250.00 210.00 60.00 392.00 480.00 360.00 300.00 53.00 5,075.23 507.52 5,582.75 400.00

Carrying materials to work-shop & gate to site Work-shop charges Ancillary work for fitting -fixing the gate: i) Making holes ii) Plain concrete: (1:2:4) 2 x 10" x 6" x 6"= 3'-4" x 6" x 4"= 2 x 3 x 6" x 4"= 80 Nos. @ Tk. 5.00

each = Tk.

g)

0.41 cft. 0.55 cft. 0.99 cft. 1.95 cft. Labour charge for hoisting the gate in position i) Mason 0.5 No. ii) Mason helper 1 No. iii) Ordinary labour 1 No.

@ @ @ @

Tk. 8,991.10 Tk. Tk. Tk. 150.00 120.00 100.00

Per % cft. = Tk. each each each Total 10.00% 3.50% 4.50% Grand total Rate per sft. Rate per sqm. = = = = = = = Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk.

175.33 75.00 120.00 100.00 6,453.08 645.31 225.86 7,324.25 329.59 7,653.84 328.35 3,534.36

Contractor's profit Overhead expenses VAT

=

= =

Say,

Tk.

3,534 .00 Per sqm.

ANALYSIS FOR ITEM NO. 148

- 383 -

Analysis of Rates of PWD Schedule (10th Edition), 16th October, 2002

Manufacturing, supplying, fitting and fixing of ordinary type M.S. gate (double leaf) with 1 x 1/4" F.I. bar, M.S. plate and 1.5" x 1.5" x 1/4" angle outer frame (without pocket gate) excluding cost of paint. Considering 1 No. of gate Considering 10'-0" x 6'-8"= 66.67 sft. in two parts a) Cost of materials i) 1.5" x 1.5" x 1/4" angle for frame: @ 2.34 Ibs per rft. 2 x 2 x 6'-8"= 2 x 4 x 5'-0"= 26.70 rft. 40.00 rft. 66.70 rft. Add wastage 5%= 3.34 rft. = 70.04 rft. = 163.89 Ibs. ii) 1.5" x 1/4" M.S. flat bar: @ 1.28 Ibs per rft. 2 x 5'-0"= 2 x 3'-4"= 2 x 2 x 4'-8.5" Add wastage 5%= = 10.00 rft. 6.70 rft. 18.80 rft. 35.50 rft. 1.775 rft. 37.28 rft. @ Tk. 7.71 Per Ib. = Tk. 367.92

Tk.

8.71

Per Ib. = Tk.

1,427.48

= 47.72 Ibs. iii) 2" x 1/4" F.I. bar for rails: @ 1.7 Ibs per rft. 2 x 3.142 x 10'-0"/4= Add wastage 5%= = iv) 1" x 1/4" F.I. bar : 0.85 Ib per rft. 2 x 2 x 9 x 1'-8"= Add wastage 5%= = 15.71 rft. 0.79 rft. 16.50 rft. 28.05 Ibs. 60.12 rft. 3.01 rft. 63.13 rft.

Tk.

7.71

Per Ib = Tk.

216.27

= 53.66 Ibs. v) 1/8" thick M.S. plate: @ 5.10 lbs per sft. 4 x 1'-0" x 1'-0"= Add wastage 5%= 4.00 sft. 0.2 sft.

Tk.

7.71

Per Ib. = Tk.

413.72

= 4.20 sft. = 21.42 Ibs. vi) 1/4" thick M.S. plate as gusset plate

Tk.

10.85

Per Ib. = Tk.

232.41

- 384 -

Analysis of Rates of PWD Schedule (10th Edition), 16th October, 2002

2 x 0-6" x 0'-6"= Add wastage 5%= =

0.50 sft. 0.03 sft. 0.53 sft. @ Tk. 10.85 Per Ib. = Tk. 58.70

= 5.41 Ibs. vii) 18 BWG M.S. plate: @ 2.04 Ibs per sft. 2 x 5'-0" x 3'-4"= 33.30 sft. Add wastage 5%= 1.67 sft. = = b) Fittings and consumables i) Locking arrangement ii) 1.5" dia heavy duty wheel iii) Clamp with huskel dumney iv) Clamp for rails v) Electrodes Making steel gate in work-shop i) Welder / fabricator 2 Nos. 2 6 16 160 Nos. Nos. Nos. Pc. 34.97 sft. 71.3388 Ibs.

@ @ @ @ @ @ @ @ @

Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk.

10.85 125.00 80.00 70.00 10.00 4.00 160.00 120.00 100.00

Per Ib. = Tk. each = Tk. each each each each = = = = Tk. Tk. Tk. Tk.

774.03 250.00 160.00 420.00 160.00 640.00 960.00 720.00 600.00 150.00 7,550.53 755.05 8,305.58 30.00

c)

6 Nos.

each = Tk. each each L.S. Sub-total = = = = Tk. Tk. Tk. Tk.

d) e) f)

ii) Helper 6 Nos. iii) Ordinary labour 6 Nos. Carrying materials to work-shop & gate to site Work-shop charges Ancillary work for fitting-fixing the gate: i) Making holes 6 ii) Plain concrete: (1:2:4) 6 x 10" x 6" x 6"= 1.25 16'-0" x 6" x 4"= 2.67 2 x 4 x 6" x 4"= 1.33

10% = Tk. Total = Tk. Nos. cft. cft. cft. @ @ @ @ Tk. 8,991.10 Tk. Tk. Tk. 150.00 120.00 100.00 Per % cft. = Tk. each = Tk. each = Tk. each = Tk. Total = Tk. @ Tk. 5.00 each = Tk.

g)

5.25 cft. Labour charge for hoisting the gate in position i) Mason ii) Mason helper iii) Ordinary labour 1 No. 2 No. 1 No.

472.03 150.00 240.00 100.00 9,297.61

Contractor's profit Overhead expenses VAT

- 385 -

10.00% = Tk. 929.76 3.50% = Tk. 325.42 Tk. 10,552.79 4.50% = Tk. 474.88

Analysis of Rates of PWD Schedule (10th Edition), 16th October, 2002

Grand total = Tk. 11,027.67 Rate per sft. = Tk. Rate per sqm. = Tk. Say, Tk. 1,780 .00 Per sqm. 165.41 1,780.47

ANALYSIS FOR ITEM NO. 149 Manufacturing, supplying, fitting and fixing of ordinary type M.S. gate (double leaf) with 1.5" x 1.5" x 1/4" M.S. angle box and channel. Considering 1 No. of gate Considering 13'-8" x 5'-2"= 70.67 sft. in two parts a) Cost of materials i) 1.5" x 1.5" x 1/4" angle for frame: @ 2.34 Ibs per rft. 2 x 2 x 2 x 6'-10"= 2 x 3 x 2 x 5'-2"= = Add wastage 5%= = 54.64 62.04 116.68 5.83 122.51 rft. rft. rft. rft. rft. @ Tk. 8.71 Per Ib. = Tk. 2,496.90

= 286.67 Ibs. ii) 1" x 2" x 1" x 3/16" M.S. channel: @ 2.32 Ibs per rft. Horizontal: 2 x 19 x 1'-3"= 47.50 rft. 0 217.14 rft. 45 inclined: 2 x 21 x 5'-2"(av)= 264.64 rft. Add wastage 5%= 13.232 rft. = = 277.87 rft. 644.66 Ibs.

Tk.

8.71

Per Ib. = Tk.

5,614.99

iii) 2" x 1/4" F.I. bar for rails: @ 1.7 Ibs per rft . 2 x 3.142 x 13'-8"/4= 21.46 rft. Add wastage 5%= 1.07 rft. @ Tk. 7.71 Per Ib = Tk. 295.29 22.53 rft. = 38.30 Ibs. iv) 1/8" thick M.S. plate: @ 5.10 lbs per sft. 4 x 1'-0" x 1'-0"= Add wastage 5%= = 4.00 sft. 0.2 sft. 4.20 sft.

- 386 -

Analysis of Rates of PWD Schedule (10th Edition), 16th October, 2002

= b) Fittings and consumables i) Locking arrangement ii) 1.5" dia heavy duty wheel iii) Clamp with huskel dumney iv) Clamp for rails v) Electrodes c) Making steel gate in work-shop i) Welder / fabricator ii) Helper iii) Ordinary labour d) e) f)

21.42 Ibs. 2 Nos. 2 6 8 240 Nos. Nos. Nos. Pc.

@ @ @ @ @ @ @ @ @

Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk.

10.85 125.00 80.00 70.00 10.00 4.00 160.00 120.00 100.00

Per Ib. = Tk. each = Tk. each each each each = = = = Tk. Tk. Tk. Tk.

232.41 250.00 160.00 420.00 80.00 960.00 800.00 600.00 500.00 150.00

5 Nos. 5 Nos. 5 Nos.

each = Tk. each = Tk. each = Tk. L.S. = Tk.

Carrying materials to work-shop & gate to site Work-shop charges Ancillary work for fitting -fixing the gate: i) Making holes 6 Nos. ii) Plain concrete: (1:2:4) 6 x 10" x 6" x 6"= 1.25 cft. 22'-0" x 6" x 4"= 3.67 cft. 2 x 4 x 6" x 4"= 1.33 cft. @ @ @ @ Tk. 8,991.10 Tk. Tk. Tk. 150.00 120.00 100.00 6.25 cft. Labour charge for hoisting the gate in position i) Mason 1 No. ii) Mason helper 2 No. iii) Ordinary labour 1 No.

Sub-total = Tk. 12,559.59 10% = Tk. 1,255.96 Total = Tk. 13,815.55 @ Tk. 5.00 each = Tk. 30.00

Per % cft. = Tk. each each each Total 10.00% = = = = =

561.94

g)

Contractor's profit Overhead expenses VAT

Tk. 150.00 Tk. 240.00 Tk. 100.00 Tk. 14,897.49 Tk. 1,489.75 521.41

3.50% = Tk.

Tk. 16,908.65 4.50% = Tk. 760.89 Grand total = Tk. 17,669.54 Rate per sft. = Tk. 250.03 Rate per sqm. = Tk. 2,691.32

Say,

Tk.

2,691 .00 Per sqm.

ANALYSIS FOR ITEM NO. 150

- 387 -

Analysis of Rates of PWD Schedule (10th Edition), 16th October, 2002

Manufacturing, supplying, fitting and fixing of G.I. pipe gate excluding cost of painting. Considering 1 No. of gate Considering 10'-0" x 6'-8"= 66.67 sft. in two parts a) Cost of materials i) 1.5" dia G.I. pipe 2 x 4 x 5'-0"= 4 x 6'-8"= = Add wastage 5%= = ii) 3/4" dia G.I. pipe Vertical post: 2 x 19 x 6'-8"= Pocket gate: 2 x 2'-0"= 2 x 4'-5"= 1 x 2'-2"= = Add 5% wastage= 40.00 26.67 66.67 3.33 70.00 rft. rft. rft. rft. rft.

Tk.

72.00

Per rft. = Tk.

5,040.00

253.33 rft. 4.00 rft. 8.83 rft. 2.17 rft. 268.33 rft. 13.42 rft. 281.75 rft. @ iii) 18 BWG M.S. plate for middle part: @ 2.04 lbs per sft. 2 x 5'-0" x 3'-4"= Add wastage 5%= = = Fittings and consumables i) Locking arrangement ii) 5" long hinges iii) Clamp with huskel dumney iv) 5/8" dia M.S. socket bolt v) Electrodes c) Making steel gate in work-shop i) Welder / fabricator ii) Helper iii) Ordinary labour d) e) 33.33 1.67 35.00 71.40 sft. sft. sft. Ibs.

Tk.

33.00

Per rft. = Tk.

9,297.75

@ @ @ @ @ @ @ @ @

Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk.

10.85 125.00 15.00 70.00 100.00 4.00 160.00 120.00 100.00

Per Ib. = Tk. each = Tk. each = Tk. each = Tk. each = Tk. each = Tk. each = Tk. each = Tk. each = Tk.

774.69 250.00 30.00 420.00 200.00 480.00 640.00 480.00 400.00

b)

2 Nos. 2 Nos. 6 Nos. 2 Nos. 120 Pc. 4 Nos. 4 Nos. 4 Nos.

Carrying materials to work-shop & gate to site Work-shop charges

L.S. = Tk. 150.00 Sub-total = Tk. 18,162.44 10% = Tk. 1,816.24 Total = Tk. 19,978.68

- 388 -

Analysis of Rates of PWD Schedule (10th Edition), 16th October, 2002

f)

Ancillary work for fitting -fixing the gate: i) Making holes ii) Plain concrete: (1:2:4) 6 x 10" x 6" x 6"= 1.25 cft. @ @ @ @ Tk. 8,991.10 Tk. Tk. Tk. 150.00 120.00 100.00 Per % cft. = Tk. each each each Total 10.00% 3.50% 4.50% Grand total Rate per sft. Rate per sqm. = = = = = = = 112.39 6 Nos. @ Tk. 5.00 each = Tk. 30.00

g)

Labour charge for hoisting the gate in position i) Mason 1 No. ii) Mason helper 1 No. iii) Ordinary labour 1 No.

Contractor's profit Overhead expenses VAT

=

= =

Tk. 150.00 Tk. 120.00 Tk. 100.00 Tk. 20,491.07 Tk. 2,049.11 Tk. 717.19 Tk. 23,257.37 Tk. 1,046.58 Tk. 24,303.95 Tk. 364.54 Tk. 3,923.91

Say,

Tk.

3,924 .00 Per sqm.

ANALYSIS FOR ITEM NO. 151 Manufacturing, supplying, fitting and fixing of rolling shutter made of 24 SWG G.P. sheet excluding cost of painting. Considering 1 No. rolling shutter Considering 10'-0" x 6'-0"= 60 sft. of work a) Cost of materials: i) 24 SWG G.P. sheet with 1/2" dia folding at the other end (@ 1 Ibs per rft.) 44 (2.75"+3.14 x 0.5"+3.14 x 0.375) x 10'-0" = 121.00 sft. Side patty: 2 x 10'-0" x 0'-3"= 5.00 sft. 126.00 sft. Add 5% wastage= 6.05 sft. 132.05 sft. = 132.05 lbs @ Tk. 10.85 iii) 26 SWG cover sheet: @ 0.85 Ibs per sft. 6'-0" x 4'-0"= 24.0 sft. Add 5% wastage= 1.2 sft. = 25.2 sft. 21.42 Ibs. @ Tk. 10.85

Per Ib. = Tk.

1,432.74

Per Ib. = Tk.

232.41

- 389 -

Analysis of Rates of PWD Schedule (10th Edition), 16th October, 2002

iv) 1.5" dia G.I. pipe 1 x 6'-0"=

6.33 rft. 6 rft.

Tk.

72.00

Per rft. = Tk.

455.76

iii) 1" x 1" x 1/8" M.S. angle: @ 0.8 per rft.: = 4.8 lbs v) 1/4" thick M.S. plate: @ 10.21 lbs per sft. Side guide: 2 x 2 x 4" x 10'-6"= 14.0 sft. Mid guide: 2 x 6" x 10'-6"= 10.5 sft. 4 x 0'-2" x 0'-3"= = Add wastage 5%= 0.17 sft. 24.67 sft. 1.23 sft. @ Tk. 8.71 Per lb = Tk. 2,303.27 @ Tk. 8.71 Per Ib. = Tk. 41.81