Académique Documents

Professionnel Documents

Culture Documents

Refrigerant Dryer Catalog

Transféré par

Manny MendozaCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Refrigerant Dryer Catalog

Transféré par

Manny MendozaDroits d'auteur :

Formats disponibles

04

REFRIGERANT AIR DRYERS

Compressed air treatment for quality and efficiency

F2C F1200C+

INTELLIGENT AIR TECHNOLOGY

REFRIGERANT DRYERS F2C F1200C+

WHY TREAT COMPRESSED AIR?

Modern production systems and production processes require high-quality compressed air. This is defined by the ISO 8573.1:2001 international standard and can only be achieved by filtration, water separation and drying. Compressed air quality and energy efficiency Often, attention is only paid to the quality of the air and not the resultant running costs. CompAir not only delivers compressed air of the necessary quality, but also supplies complete energy-efficient compressed air systems consisting of compressors, filters, dryers and air receivers, at minimal running costs.

NEW

MONO-BLOCK 3-IN-1 HEAT EXCHANGER

The compact dryers contain a unique Mono-Block 3-in-1 heat exchanger with Air-to-air heat exchanger to pre-cool the incoming warm air with the outgoing cold air and in turn heat and further dry the outgoing compressed air Air-to-refrigerant heat exchanger which cools the air to pressure dew point temperature Integrated cyclone separator which effectively separates the condensate and collects the condensed water by slowing and reversing the air flow even when the machine is operating at part load The state-of-the-art design features very low pressure loss, delivering real energy savings.

Dry air

AIR DRYER SCHEMATIC DIAGRAM

All dryers are equipped with an expansion valve which is working constantly to maintain the correct liquid refrigerant quantity in the heat exchanger to achieve the optimum pressure dew point. The hot gas bypass valve in the refrigerant circuit and the expansion valve allow a constant dew point temperature of 3C and a very fast reaction time under varying operating conditions.

Air/air heat exchanger Air/refrigerant exchanger Moisture separator Automatic condensate drain Expansion valve controlled by refrigerant pressure or temperature

Hot air

ESD ENERGY SAVING CONTROL

Like speed-regulated compressors, CompAir dryers with ESD control only use energy when the system actually needs compressed air unlike conventional dryers which continue to consume energy even when the system is off load.

Energy saving with ESD control

54 %

Energy saving (%)

36 %

21 %

9%

0% 20 % 40 % 60 % Idling hours per year 80 %

With the ESD control if the dryer is off load, the energy consumption/year can be reduced by as much as 54 %. The ESD control is fitted as standard on all 3-phase dryers and is available as an option on all 1-phase dryers. Quite simply a reduction in air demand means a reduction of energy requirement. 3-phase dryers are also available with the optional ESD3 digital plain text display.

CONDENSATE DRAIN

The F2C to F84C models have a timer-controlled solenoid valve. NO-LOSS CONDENSATE DRAIN + The 3-phase dryers are equipped with a BEKOMAT electronic level-controlled condensate drain. Also available as option for 1-phase dryers. A pre-filter must be fitted upstream of all refrigerant dryers of types F2C to F84C. The models F105C+ to F1200C+ have an integrated 5 m pre-filter.

FEATURES BENEFITS

Highly efficient heat exchanger with low pressure loss High level of efficiency for maximum energy savings Environmentally-friendly R134a and R404a refrigerant Pressure dew point reliably low Optimum condensate separation Minimum space requirements Easy installation, operation and maintenance ESD energy saving control

WARRANTY TO ENSURE YOUR PEACE OF MIND!

CompAir offers comprehensive service and warranty programmes. All you need to do is register for the programme, use genuine CompAir parts and adhere to the recommended service schedule.

A Gardner Denver Company

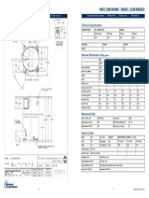

TECHNICAL SPECIFICATIONS

REFRIGERANT COMPRESSED AIR DRYER, AIR-COOLED, 1-PHASE CONNECTION

MODEL Volume flow Total power 50Hz Total power 60Hz m/min kW kW F2C 0.183 0.25 0.28 10 F3C 0.264 0.25 0.28 10 1/2" 500 360 460 30 30 32 32 53 54 F5C 0.48 0.25 0.28 20 F7C 0.732 0.25 0.36 30 F11C 1.14 0.28 0.36 20 F16C 1.62 0.35 0.40 50 3/4" 715 410 535 56 59 86 F22C 2.22 0.58 0.63 60 F26C 2.58 0.66 0.79 80 F36C 3.6 0.80 0.91 130 F45C 4.5 1.10 1.14 160 1 1/4" 715 490 750 93 93 F54C 5.4 1.30 1.48 225 F72C 7.2 1.17 1.56 260 1 1/2" 570 690 985 127 163 F84C 8.4 1.37 1.56 330 F105C+ 10.5 1.48 1.65 180 2" 715 765 1235 214 233 F133C+ 13.3 1.95 2.44 250

Pressure drop at rated load mbar Compressed air connection RP Dimensions Length mm Width mm Height mm Weight, packaged in box Electrical connection kg V/Ph/Hz

230 / 1 / 50 & 230 / 1 / 60

REFRIGERANT COMPRESSED AIR DRYER, AIR-COOLED, 3-PHASE CONNECTION

MODEL Volume flow Total power 50Hz Total power 60Hz m/min kW kW F72CT+ F84CT+ F105CT+ F133CT+ F156C+ F183C+ F210C+ F240C+ F285C+ F348C+ F384C+ F444C+ F522C+ F678C+ F780C+ F930C+ F1050C+ F1200C+ 7.20 1.12 1.39 260 1 1/2" 570 690 985 130 166 8.40 1.42 1.73 330 10.5 1.46 1.77 180 2" 715 765 1235 217 236 278 720 820 1440 280 324 433 435 13.3 1.93 2.44 250 15.6 2.47 3.20 320 18.3 2.62 3.29 380 21.0 2.62 3.29 280 24.0 3.08 3.84 360 3" 1140 1020 1537 489 491 666 1020 1140 1925 703 897 996 1520 2000 1489 1573 28.5 4.30 5.56 380 34.8 5.02 6.44 380 38.4 5.64 6.88 420 44.4 6.20 8.14 400 52.2 6.98 8.54 380 4" 1140 1820 67.8 10.12 13.10 400 78.0 12.47 15.30 420 93.0 12.62 15.30 400 105.0 14.21 17.20 400 120.0 16.29 19.69 420

Pressure drop at rated load mbar Compressed air connection RP/Flange Dimensions Length mm Width mm Height mm Weight, packaged in box Electrical connection kg V/Ph/Hz

DN150 1520 2180 2039 1770

400 / 3 / 50 & 440 / 3 / 60 To obtain the necessary drying capacity, multiply the volume flow by the correction factors (volume flow x A x B x C). The correction factors given here are guide values. To choose the right product for the installation conditions, please use the dryer selection program. The performance of the dryer (pressure dew point, power consumption, pressure drop etc.) depends mainly on the volume flow and pressure of the compressed air to be dried and the condenser refrigerant temperature. Volume flows refer to an intake temperature of 20C, an intake pressure of 1 bar (ISO1217, C) and the following operating conditions: Operating pressure 7 bar, Inlet temperature 35C, Ambient temperature 25C

Volume ow correction factors for different operating conditions

Operating pressure bar (g) A) Inlet temperature C B) Ambient temperature C C) 5 0.86 30 1.18 22 1.00 6 0.94 35 1.00 25 1.00 7 1.00 8 1.04 40 0.85 30 0.90 9 1.08 45 0.72 35 0.81 10 1.11 50 0.60 40 0.73 11 1.14 12 1.16 55 0.57 45 0.66 13 1.19 60 0.48 50 0.59

Type F2C F240C+ with refrigerant R134a

Height

Type F285C+ F1200C+ with refrigerant R404a Max. operating pressure 16 bar g F105CW+ F1200CW+ optionally with water cooling

Length

Width

INTERNET: www.compair.com sales@compair.com

CompAir makes a point of continually improving its products and we therefore reserve the right to alter specications and prices without prior notice. All products are sold subject to the Companys conditions of sale. Ref. No. 91005-065E 02/11 B&N

DIN ISO 9001/ EN 29001 Certificate: 5168

Vous aimerez peut-être aussi

- Sworks Enduro 2021 ManualDocument28 pagesSworks Enduro 2021 ManualManny MendozaPas encore d'évaluation

- July 2014 GEARSDocument76 pagesJuly 2014 GEARSRodger BlandPas encore d'évaluation

- Emerson TXV Superheat Adjustment ChartDocument1 pageEmerson TXV Superheat Adjustment Chartzeropoint_romeoPas encore d'évaluation

- DP 900T00A ENU TrainerHandbookDocument288 pagesDP 900T00A ENU TrainerHandbookAndré baungatnerPas encore d'évaluation

- BD+ CD+ XD+ - tcm833-3534072Document20 pagesBD+ CD+ XD+ - tcm833-3534072MisterMMPas encore d'évaluation

- RTP 3 25 TR For Rooftoppackage 1Document52 pagesRTP 3 25 TR For Rooftoppackage 1GeorgePas encore d'évaluation

- Technical Data: RefrigerationDocument15 pagesTechnical Data: RefrigerationIvanPas encore d'évaluation

- Pre Post and Infix NotationsDocument12 pagesPre Post and Infix NotationsGolla GirijaPas encore d'évaluation

- Valvula Expansao Te5 PDFDocument6 pagesValvula Expansao Te5 PDFJosé Edgard Pereira BarrettoPas encore d'évaluation

- 2749 - Carrier 30 GH 095Document16 pages2749 - Carrier 30 GH 095Mohammad Amer100% (2)

- Chiller Compressor MaintenanceDocument90 pagesChiller Compressor MaintenanceBabak GhavidelPas encore d'évaluation

- Global User GuideDocument107 pagesGlobal User GuideManny MendozaPas encore d'évaluation

- SS 525 2006 Roof Drainage CodeDocument73 pagesSS 525 2006 Roof Drainage CodeManny MendozaPas encore d'évaluation

- The Maisotsenko CycleDocument10 pagesThe Maisotsenko Cyclenishith_soni100% (1)

- No Oil Pump - No Pre Lubrification - Low Oil Quantity: Ep - 68.1 Psig Ep - 470 KpaDocument1 pageNo Oil Pump - No Pre Lubrification - Low Oil Quantity: Ep - 68.1 Psig Ep - 470 KpaKashif VeeraPas encore d'évaluation

- Storage Tank Design Calculation - Api 650: Close Floating RoofDocument32 pagesStorage Tank Design Calculation - Api 650: Close Floating RoofhgagPas encore d'évaluation

- CLCP Euro - Commercial May 09: Quick Selection ProcedureDocument2 pagesCLCP Euro - Commercial May 09: Quick Selection ProcedurehfrankiePas encore d'évaluation

- Hankison - Secador Adsorcion HPD 300-3200 SCFM - EsDocument8 pagesHankison - Secador Adsorcion HPD 300-3200 SCFM - EsrobertohugosanchezPas encore d'évaluation

- Brochure Exterior LightingDocument49 pagesBrochure Exterior Lightingmurali_227Pas encore d'évaluation

- Screw Compressors: Model: VD55-10DGDocument20 pagesScrew Compressors: Model: VD55-10DGVoştinar IoanPas encore d'évaluation

- RDJ-GG-008-040 (En)Document41 pagesRDJ-GG-008-040 (En)fouad kerkarPas encore d'évaluation

- Fd60hz Secador Atlas Copco - ManualDocument8 pagesFd60hz Secador Atlas Copco - ManualEdvaldo França100% (1)

- Air Compressor ASK-27TDocument5 pagesAir Compressor ASK-27TJonson CaoPas encore d'évaluation

- FDbrochureDocument13 pagesFDbrochureAyman Mohammed Ibrahim AbdouPas encore d'évaluation

- Air DryerDocument4 pagesAir Dryerrashm006ranjanPas encore d'évaluation

- Standard Procedure For Vacuum Decay Test (Advisory Procedure)Document7 pagesStandard Procedure For Vacuum Decay Test (Advisory Procedure)Jonathan MoralesPas encore d'évaluation

- Service Manual HaierDocument259 pagesService Manual HaierManuel Clemente Cañamero Alonso100% (5)

- Operation, Installation & Maintenance Manual: Vertical Liquid Separator FPVS-SHDocument12 pagesOperation, Installation & Maintenance Manual: Vertical Liquid Separator FPVS-SHMehdi Hajd KacemPas encore d'évaluation

- Gacl-Dahej Captive Co-Generation Power Plant Corrected Gas Turbines Output Calculation On Site ConditionDocument8 pagesGacl-Dahej Captive Co-Generation Power Plant Corrected Gas Turbines Output Calculation On Site Conditionakulahtu78Pas encore d'évaluation

- TR Diss 1672 PDFDocument302 pagesTR Diss 1672 PDFsalamrefighPas encore d'évaluation

- Oil Free Scroll Compressors 2 30 KW Brochure NADocument8 pagesOil Free Scroll Compressors 2 30 KW Brochure NAKervin CoronadoPas encore d'évaluation

- Blue Star AHU DetailsDocument5 pagesBlue Star AHU DetailsdheerajdorlikarPas encore d'évaluation

- Control Air DryerDocument23 pagesControl Air DryerGeorgiPas encore d'évaluation

- Data Sheet PTCDocument8 pagesData Sheet PTCjjermanPas encore d'évaluation

- TecData SR SRM SRHDocument1 pageTecData SR SRM SRHAir Repair, LLCPas encore d'évaluation

- Copeland Compresor 2019 ECT2014DS78 PDFDocument166 pagesCopeland Compresor 2019 ECT2014DS78 PDFFrancisco Sanchez RPas encore d'évaluation

- 1413F001ADocument6 pages1413F001AMinh Tường NguyễnPas encore d'évaluation

- 1503F003ADocument6 pages1503F003AMinh Tường NguyễnPas encore d'évaluation

- Sporlan TXV PDFDocument72 pagesSporlan TXV PDFjorge castilloPas encore d'évaluation

- C-PAC Gas R22Document22 pagesC-PAC Gas R22Leed ENPas encore d'évaluation

- 30hxyhxc-High Cop 2012Document12 pages30hxyhxc-High Cop 2012Luciano Lopes Simões100% (2)

- 0-76150-BB0798A-13 - Rev.F DATASHEET GENE PDFDocument22 pages0-76150-BB0798A-13 - Rev.F DATASHEET GENE PDFPandiyanPas encore d'évaluation

- Specification ARX120HK EnglishDocument5 pagesSpecification ARX120HK Englishheruono sitorusPas encore d'évaluation

- H23A383DBEADocument1 pageH23A383DBEABruno Monteiro0% (1)

- General-Service Packaged Air Compressors and ReceiversDocument11 pagesGeneral-Service Packaged Air Compressors and ReceiversElie HajjPas encore d'évaluation

- Catalogue Air Cooled Chiller Uaa-St3m (R134) PDFDocument9 pagesCatalogue Air Cooled Chiller Uaa-St3m (R134) PDFNanda AulianaPas encore d'évaluation

- Superlon Technical SpecificationDocument8 pagesSuperlon Technical SpecificationSam Wing HongPas encore d'évaluation

- 38CKC Product DataDocument26 pages38CKC Product DataCarlos Enrique Godoy Sifontes0% (1)

- Parts List PC CompressorDocument20 pagesParts List PC CompressorSyed Ali KhanPas encore d'évaluation

- Copeland LubricantsDocument2 pagesCopeland LubricantsDanLorenaPas encore d'évaluation

- C-PAC Gas R22 PDFDocument22 pagesC-PAC Gas R22 PDFngocdhxd92Pas encore d'évaluation

- 369 EN-BI 201601 Air-treatment-DRYERS PDFDocument20 pages369 EN-BI 201601 Air-treatment-DRYERS PDFMuhammad JahanzaibPas encore d'évaluation

- Addl Att. Oct 2019Document22 pagesAddl Att. Oct 2019PolymerPas encore d'évaluation

- Rcu2e Ag2 & Rhu2e Ag2 PDFDocument192 pagesRcu2e Ag2 & Rhu2e Ag2 PDFKostas AstrinisPas encore d'évaluation

- Ceccato CSC 40-60 AC 400V 13bar 50Hz Technical Data ENDocument4 pagesCeccato CSC 40-60 AC 400V 13bar 50Hz Technical Data ENSegeyPas encore d'évaluation

- 40LX040 060 (Malaysia)Document8 pages40LX040 060 (Malaysia)Leed ENPas encore d'évaluation

- LN Electrical DataDocument7 pagesLN Electrical DataBen MusimanePas encore d'évaluation

- F-HS Dryers Brochure v4Document8 pagesF-HS Dryers Brochure v4Mulyono ReyonzPas encore d'évaluation

- Hallscrew Replacement Parts List: July 2006Document8 pagesHallscrew Replacement Parts List: July 2006Annika Cass100% (1)

- PARTS LITS Air Cooled Packaged Water ChillersDocument11 pagesPARTS LITS Air Cooled Packaged Water ChillersOng MatPas encore d'évaluation

- 574 914 PDFDocument1 page574 914 PDFDee RajaPas encore d'évaluation

- Fabrication Bill of MaterialDocument8 pagesFabrication Bill of MaterialHashemAliHashemPas encore d'évaluation

- DCDocument25 pagesDCaries26marchPas encore d'évaluation

- VCV WesperDocument12 pagesVCV Wesperciperu55Pas encore d'évaluation

- N10DC2432-4 NitrogenGenerationPlant NB216Document31 pagesN10DC2432-4 NitrogenGenerationPlant NB216ionut nicolaePas encore d'évaluation

- 0053Document1 page0053superowelPas encore d'évaluation

- Compressor Start-Up and Warranty ValidationDocument3 pagesCompressor Start-Up and Warranty ValidationAhmed SofaPas encore d'évaluation

- DV DVW Series - Catalog - For 2015Document39 pagesDV DVW Series - Catalog - For 2015adeel_akhtarPas encore d'évaluation

- SS 546-2009Document37 pagesSS 546-2009Manny MendozaPas encore d'évaluation

- dc19-09 - Rev To Landscape Deck GuideDocument6 pagesdc19-09 - Rev To Landscape Deck GuideManny MendozaPas encore d'évaluation

- Use of Lifts For Evacuation of Building OccupantsDocument11 pagesUse of Lifts For Evacuation of Building OccupantsManny MendozaPas encore d'évaluation

- SCDF Cop 1991Document77 pagesSCDF Cop 1991Manny MendozaPas encore d'évaluation

- dc19-12 - Simplication of Site CoverageDocument2 pagesdc19-12 - Simplication of Site CoverageManny MendozaPas encore d'évaluation

- As at Feb 2011 Handbook On Gross Floor Area: Urban Redevelopment AuthorityDocument109 pagesAs at Feb 2011 Handbook On Gross Floor Area: Urban Redevelopment AuthorityManny MendozaPas encore d'évaluation

- dc19-10 - Guide For Solar PanelDocument4 pagesdc19-10 - Guide For Solar PanelManny MendozaPas encore d'évaluation

- dc19-11 - Refinement To GFADocument5 pagesdc19-11 - Refinement To GFAManny MendozaPas encore d'évaluation

- Letter Template For Confirmation of Lift Details v2Document1 pageLetter Template For Confirmation of Lift Details v2Manny MendozaPas encore d'évaluation

- URA Exemption ListDocument11 pagesURA Exemption ListManny MendozaPas encore d'évaluation

- URA Fee Schedule 2013Document13 pagesURA Fee Schedule 2013Manny MendozaPas encore d'évaluation

- Worker DormitoryDocument19 pagesWorker DormitoryManny MendozaPas encore d'évaluation

- Ura Penalty FeeDocument2 pagesUra Penalty FeeManny MendozaPas encore d'évaluation

- Building Plans Submission To NEADocument16 pagesBuilding Plans Submission To NEAManny MendozaPas encore d'évaluation

- (Guide) +How+to+Apply+for+Electricity+Connection Sep+2016Document7 pages(Guide) +How+to+Apply+for+Electricity+Connection Sep+2016Manny MendozaPas encore d'évaluation

- Amendments To The Fire Code 2013 Fire Safety Requirements For ColdroomDocument6 pagesAmendments To The Fire Code 2013 Fire Safety Requirements For ColdroomManny MendozaPas encore d'évaluation

- URA Fee Schedule 2016Document15 pagesURA Fee Schedule 2016Manny MendozaPas encore d'évaluation

- Schematic Model Manager User GuideDocument244 pagesSchematic Model Manager User GuideManny Mendoza50% (2)

- CR V New Onlinebrochure 2020 - HighresDocument11 pagesCR V New Onlinebrochure 2020 - HighresManny MendozaPas encore d'évaluation

- Area Based ADP Administrator GuideDocument60 pagesArea Based ADP Administrator Guidealanluis2009Pas encore d'évaluation

- Concrete Design User GuideDocument340 pagesConcrete Design User GuideManny MendozaPas encore d'évaluation

- Metal, Metallurgy, Music, Husserl, Simondon Richard Pinhas: I Have Two Questions To Formulate Regarding The Last Session, Although WhatDocument13 pagesMetal, Metallurgy, Music, Husserl, Simondon Richard Pinhas: I Have Two Questions To Formulate Regarding The Last Session, Although WhatbluexpectroPas encore d'évaluation

- Conventional and Box-Shaped Piled RaftsDocument6 pagesConventional and Box-Shaped Piled RaftsAdrian VechiuPas encore d'évaluation

- Chuck Eesley - Recommended ReadingDocument7 pagesChuck Eesley - Recommended ReadinghaanimasoodPas encore d'évaluation

- Switch RotatoriosDocument12 pagesSwitch RotatoriosRoberto AndrésPas encore d'évaluation

- p-100 Vol2 1935 Part5Document132 pagesp-100 Vol2 1935 Part5Matias MancillaPas encore d'évaluation

- A Microscope For Christmas: Simple and Differential Stains: Definition and ExamplesDocument4 pagesA Microscope For Christmas: Simple and Differential Stains: Definition and ExamplesGwendolyn CalatravaPas encore d'évaluation

- Entrepreneurial BehaviourDocument16 pagesEntrepreneurial Behaviournonalyn tomboconPas encore d'évaluation

- C57.12.29 Pad-Mounted Equipment-Enclosure Integrity For Coastal EnvironmentsDocument26 pagesC57.12.29 Pad-Mounted Equipment-Enclosure Integrity For Coastal EnvironmentsSureshKumarPas encore d'évaluation

- Question 1: As Shown in Figure 1. A 6-Pole, Long-Shunt Lap-Wound CompoundDocument4 pagesQuestion 1: As Shown in Figure 1. A 6-Pole, Long-Shunt Lap-Wound Compoundالموعظة الحسنه chanelPas encore d'évaluation

- Prescriptions For Closing The Seven Service Quality GapsDocument1 pagePrescriptions For Closing The Seven Service Quality GapsReema NegiPas encore d'évaluation

- Guide For H Nmr-60 MHZ Anasazi Analysis: Preparation of SampleDocument7 pagesGuide For H Nmr-60 MHZ Anasazi Analysis: Preparation of Sampleconker4Pas encore d'évaluation

- Mini Riset Bahasa Inggris BisnisDocument10 pagesMini Riset Bahasa Inggris BisnissyahsabilahPas encore d'évaluation

- Jurong Junior College: Preliminary Examination 2009Document16 pagesJurong Junior College: Preliminary Examination 2009cjcsucksPas encore d'évaluation

- Rail Inspection Vehicle Using Ir Sensor and Spot Marking SystemDocument63 pagesRail Inspection Vehicle Using Ir Sensor and Spot Marking SystemNarayananNanuPas encore d'évaluation

- Theoretical Grammar of EnglishDocument132 pagesTheoretical Grammar of EnglishMisarabbit NguyenPas encore d'évaluation

- PQA824 ManualDocument100 pagesPQA824 ManualElkin AguasPas encore d'évaluation

- 17 Safety InventoryDocument47 pages17 Safety Inventorymishrakanchan 2396Pas encore d'évaluation

- Tank Top Return Line Filter Pi 5000 Nominal Size 160 1000 According To Din 24550Document8 pagesTank Top Return Line Filter Pi 5000 Nominal Size 160 1000 According To Din 24550Mauricio Ariel H. OrellanaPas encore d'évaluation

- Amanuel MekonnenDocument125 pagesAmanuel Mekonnenabata yohannesPas encore d'évaluation

- Examen Inglés de Andalucía (Ordinaria de 2019) (WWW - Examenesdepau.com)Document2 pagesExamen Inglés de Andalucía (Ordinaria de 2019) (WWW - Examenesdepau.com)FREESTYLE WORLDPas encore d'évaluation

- Low Invasion CoringDocument4 pagesLow Invasion CoringKHALEDFEKAIRPas encore d'évaluation

- Metascope An/Pas-6 (5855-790-6197) : Technical ManualDocument38 pagesMetascope An/Pas-6 (5855-790-6197) : Technical ManualDens VillaPas encore d'évaluation

- Unit 8 - A Closer Look 2Document3 pagesUnit 8 - A Closer Look 2Trần Linh TâmPas encore d'évaluation

- Product Matrix: Network Security Platform - Top Selling Models MatrixDocument6 pagesProduct Matrix: Network Security Platform - Top Selling Models MatrixWashington CárdenasPas encore d'évaluation

- Evaluation of A Systematic Approach To Matrix Acidizing On An Oil Producing WellDocument6 pagesEvaluation of A Systematic Approach To Matrix Acidizing On An Oil Producing WellTrần Hoàng ChươngPas encore d'évaluation