Académique Documents

Professionnel Documents

Culture Documents

Manual Micro Compound Table KT 70 No. 27 100

Transféré par

Joel MartzDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Manual Micro Compound Table KT 70 No. 27 100

Transféré par

Joel MartzDroits d'auteur :

Formats disponibles

Manual Micro Compound Table KT 70 No.

27 100

Fig. 1

Fig. 2

Fig. 3

Fig. 4 3

Fig. 4b

Fig. 5

Micro Compound Table KT 70 Dear Customer, The PROXXON Micro Compound Table KT 70 gives you the possibility of drilling to precise coordinates or performing small milling operations in conjunction with a bench drill press or a stationary milling machine. When working with the X-Y-table, please always observe the safety regulations for the drill press or mill, which is in use and please remember that the compound table is a precision tool and is also very sensitive. Therefore, please always work with due care. General view (Fig. 1): 1. Work table 2. Support 3. Hand wheel for X direction 4. Hand wheel for Y direction 5. Dial for X direction 6. Dial for Y direction 7. Adjustable scale 8. Adjusting screws 9. Base plate 10. Cutting guard Accessories supplied: for fixing the machine vise MS 4 (which is available as accessory no. 28 132, Fig. 2a); clamping claws (Fig. 2b); for fastening the compound table to a work surface (Fig. 2c);

Technical data: Work table: 7 7/8 x 2 3/4 (200 mm x 70 mm) Adjustment travel in X direction: 5 9/32 (134 mm) Adjustment travel in Y direction: 1 13/16 (46 mm) Weight: 1.65 lb (750 g) 3 T-slots in size 15/32 x 15/64 x 13/64 (12 x 6 x 5 mm) distance between grooves (center-to-center): 63/64 (25 mm)

Mounting the Micro Compound Table KT 70 The KT 70 was designed for use with PROXXON MB 140/S drill stand or the PROXXON bench drill press TBM 115. (Note: The TBM 115 bench drill press is suitable for coordinate drilling, but not for milling.) In order to fasten the coordinate table to the work surface, first cut two M4 threaded holes in the work surface according to Fig. 3. For this purpose, pre-drill the thread holes using a 3.3 mm drill and countersink the holes. Then cut the thread using a tap. The Micro Compound Table KT 70 can now be fastened to the work surface using the M4 threaded holes and the mounting stones (Fig. 2c). Mounting the clamping claws (4a): Especially in the case of milling operations, it is recommended that the work piece 1 (Fig. 4) is secured using the supplied clamping claws. For this purpose, place 2 blocks of an adequately stable material under the claws (2) as support. Please ensure that the blocks are at approximately the same height as the work piece to be secured. Setting the scale: The dials on the hand wheels are adjustable and can thus be set to zero without traversing the table. In addition to the dials, the Micro Compound Table KT 70 is equipped with an adjustable scale for adjustment in the X direction (7, Fig.1). Adjusting the guide play: If, after a certain time, the compound table guide is found to have too much or too little play, the play can be reset using the adjusting screws (Fig. 5). In order to adjust the play in the X-direction, first loosen the nut 1 (Fig. 5). Then adjust the play using the set screws 2. Lock by re-tightening the nut 1. (Note: Do not overtighten the set screws as the sensitive guide will be damaged.) Adjustment of play in the Y-direction is performed the same way. 5

Spare parts list Please order spare parts in writing from Proxxon Service center (adress on the back of this manual) PROXXON Micro Compound Table KT 70 Part no.: 27100 - 1 27100 - 2 27100 - 3 27100 - 4 27100 - 5 27100 - 6 27100 - 7 27100 - 8 27100 - 9 27100 - 10 27100 - 11 27100 - 12 27100 - 12a 27100 - 13 27100 - 14 27100 - 15 27100 - 16 27100 - 17 27100 - 18 27100 - 19 27100 - 20 27100 - 21 27100 - 22 27100 - 30 27100 - 30a 27100 - 31 27100 - 32 27100 - 33 27100 - 34 27100 - 35 27100 - 36 27100 - 37 37110 - 99 Designation Work table Support Base plate Cutting guard Cutting guard base Upper cover Lower cover Upper intermediate plate Lower intermediate plate X spindle Y spindle Spindle nut Spindle nut Handwheel Handle Dial Cap Upper adjusting plate Lower adjusting plate Scale Bushing Rivet Blade spring Nut Nut Washer Pin Screw Short set screw Long set screw Nut Screw Manual

12 VA

SERVICE AND REPAIR Your device does not work properly? Please read the operating instructions again carefully. If the unit is in fact defective, please send it to: Prox-Tech, Inc. Attn.: PROXXON Service Center 2555 Tate Blvd. S.E. Hickory, NC 28601 Please make sure, that your tool is carefully packaged and include a copy of your dated proof of purchase. You will help us to react even quicker, if you describe the problem in short and please dont forget to include your name, address and daytime telephone number. We will respond in a prompt and reliable manner. For any further information call us toll free at 1-877-PROXXON (1-877-776-9966) or visit us on the web at www.proxxon.com/us. Made in Japan. Distributed in the U. S. by Prox-Tech, Inc.

We reserve the right to make further alterations for the purpose of technical progress.

Vous aimerez peut-être aussi

- Introduction To Microelectronic Fabrication PDFDocument332 pagesIntroduction To Microelectronic Fabrication PDFChristy Moore92% (13)

- Full ManualDocument13 pagesFull ManualSteve Dowell80% (5)

- 2005-2010 Tacoma Bed Extender PT329-35050 Rev. A - PT329-35050Document8 pages2005-2010 Tacoma Bed Extender PT329-35050 Rev. A - PT329-35050kylemac123Pas encore d'évaluation

- Chapter 6 Strategy Analysis and Choice: Strategic Management: A Competitive Advantage Approach, 16e (David)Document27 pagesChapter 6 Strategy Analysis and Choice: Strategic Management: A Competitive Advantage Approach, 16e (David)Masum ZamanPas encore d'évaluation

- Installation of Submarine PE PipesDocument84 pagesInstallation of Submarine PE Pipeswaseemiqbal133100% (2)

- Off Grid Solar Hybrid Inverter Operate Without Battery: HY VMII SeriesDocument1 pageOff Grid Solar Hybrid Inverter Operate Without Battery: HY VMII SeriesFadi Ramadan100% (1)

- DIY Bench Top Tubing BenderDocument17 pagesDIY Bench Top Tubing BenderMalcolm DiamondPas encore d'évaluation

- Instruction Book Emcostar-EmcorexDocument45 pagesInstruction Book Emcostar-EmcorexJohan Leide80% (5)

- Kearney and Trecker Installation ManualDocument12 pagesKearney and Trecker Installation Manualaa987100% (1)

- WoodPlans Online - Universal Tablesaw JigDocument9 pagesWoodPlans Online - Universal Tablesaw JigHannes Michaelis100% (15)

- OPOS UpgradeManualDocument22 pagesOPOS UpgradeManualAndrew LobodaPas encore d'évaluation

- Iso Iec 25030 2007 eDocument44 pagesIso Iec 25030 2007 eAngélica100% (1)

- Expert 24lx ManualDocument140 pagesExpert 24lx ManualDiana ArghirPas encore d'évaluation

- Lynx Manual 24" Vinyl CutterDocument43 pagesLynx Manual 24" Vinyl Cutterpappu khanPas encore d'évaluation

- Expert 24 User ManualDocument38 pagesExpert 24 User ManualDonwBIMOSAPas encore d'évaluation

- Fitting Instructions For Resilient Mounting of Gensets L16/24 L21/31Document4 pagesFitting Instructions For Resilient Mounting of Gensets L16/24 L21/31Yafiz MalikPas encore d'évaluation

- Expert 52 ManualDocument58 pagesExpert 52 ManualDiana ArghirPas encore d'évaluation

- Deawst01 StandDocument16 pagesDeawst01 StandA D PiercePas encore d'évaluation

- Geometrical and Mechanical Drawing: Paper 2Document8 pagesGeometrical and Mechanical Drawing: Paper 2jayaseelan39Pas encore d'évaluation

- Gear Cutters 01Document4 pagesGear Cutters 01Raúl MuñizPas encore d'évaluation

- Demec Operating InstructionsDocument7 pagesDemec Operating InstructionsKudzai MushunjePas encore d'évaluation

- Mongoose PT Spare Parts (Less Control Panel)Document18 pagesMongoose PT Spare Parts (Less Control Panel)Anonymous gwldee5100% (1)

- M1 Jig Instructions PDFDocument8 pagesM1 Jig Instructions PDFAnonymous nMXXPvg1R2100% (1)

- TriumphDocument15 pagesTriumph1zmajPas encore d'évaluation

- Mod Squad 0204Document4 pagesMod Squad 0204afgalPas encore d'évaluation

- Design of Milling Fixture PDFDocument18 pagesDesign of Milling Fixture PDFgsudhanta1604Pas encore d'évaluation

- Craft & HobbyDocument14 pagesCraft & HobbyDjordje TasicPas encore d'évaluation

- Ornamental ManualDocument26 pagesOrnamental ManualКонстантин ГусевPas encore d'évaluation

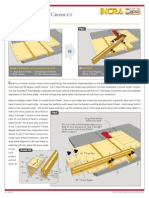

- Adjustable Angle Crosscut W/drop Panel: Fig.1 Fig.2Document1 pageAdjustable Angle Crosscut W/drop Panel: Fig.1 Fig.2Litus FendetestasPas encore d'évaluation

- User Manual T Model: V.1.2 MAYDocument35 pagesUser Manual T Model: V.1.2 MAYAndrés MorenoPas encore d'évaluation

- Bawn 004Document4 pagesBawn 004sike1977Pas encore d'évaluation

- 16-24 Press Brake ManualDocument8 pages16-24 Press Brake ManualJoel BecherPas encore d'évaluation

- Trabajo Con MaderaDocument2 pagesTrabajo Con MaderaMax VTPas encore d'évaluation

- 011-Repl of Kiln Shell Under TyreDocument32 pages011-Repl of Kiln Shell Under Tyremkpq100% (3)

- Instruction Manual: MIG210SDocument20 pagesInstruction Manual: MIG210SMani ShankerPas encore d'évaluation

- Adaptadores para Conectores DeutschDocument2 pagesAdaptadores para Conectores DeutschFrancisco Alvarado HuenquiaoPas encore d'évaluation

- Parts: RoebuckDocument6 pagesParts: RoebuckCary BriefPas encore d'évaluation

- Manual Troqueladra Lb201Document18 pagesManual Troqueladra Lb201Carlos Choton AbantoPas encore d'évaluation

- Components of 6V7898 Dial Bore Gauge Group: NoticeDocument5 pagesComponents of 6V7898 Dial Bore Gauge Group: NoticeMiguel GutierrezPas encore d'évaluation

- Cs 59 ManDocument22 pagesCs 59 ManLuis GpPas encore d'évaluation

- Press-Fit Technology: The New VaripinDocument3 pagesPress-Fit Technology: The New VaripinonafetsPas encore d'évaluation

- Homemade RF Step AttenuatorDocument8 pagesHomemade RF Step Attenuatorngt881Pas encore d'évaluation

- ShopNotes Issue 08Document32 pagesShopNotes Issue 08Correia Orlando100% (1)

- QWB8xxF1 User ManualDocument25 pagesQWB8xxF1 User ManualHenry EspinalPas encore d'évaluation

- Series: Compact SlideDocument17 pagesSeries: Compact SlideluisenriqueruizPas encore d'évaluation

- VB 214FMDocument10 pagesVB 214FMyu3zaPas encore d'évaluation

- BAJA - Chassis Fixture For ManufacturingDocument3 pagesBAJA - Chassis Fixture For ManufacturingIjaems JournalPas encore d'évaluation

- Is 3063-Spring WashersDocument11 pagesIs 3063-Spring Washerspbp2956Pas encore d'évaluation

- Power Tools: Operating and Maintenance InstructionsDocument16 pagesPower Tools: Operating and Maintenance InstructionsBill WidmerPas encore d'évaluation

- Flender Plate Pack Assembly InstructionDocument8 pagesFlender Plate Pack Assembly InstructionfahazumeePas encore d'évaluation

- EMCO F1 ManualDocument308 pagesEMCO F1 ManualClinton Koo100% (1)

- Table 1. Maximum Bearing Radial Play: Tri-Pivot ConnectionsDocument4 pagesTable 1. Maximum Bearing Radial Play: Tri-Pivot ConnectionsaugustinhodjPas encore d'évaluation

- Card Option: Installation and Setting InstructionDocument20 pagesCard Option: Installation and Setting Instructionaartb101Pas encore d'évaluation

- Construction of A Shaping MachineDocument16 pagesConstruction of A Shaping MachineHassan AzmiPas encore d'évaluation

- Geeetech A20M 3D Printer User Manual: Shenzhen Getech Technology Co., LTDDocument60 pagesGeeetech A20M 3D Printer User Manual: Shenzhen Getech Technology Co., LTDRene CastilloPas encore d'évaluation

- Guidelines For Collect DesignDocument24 pagesGuidelines For Collect DesignArun LelePas encore d'évaluation

- QCX Housing UKDocument4 pagesQCX Housing UKTomPas encore d'évaluation

- CD1116-20-25 TechnicalBulletin 20101018Document123 pagesCD1116-20-25 TechnicalBulletin 20101018dtolind smtpPas encore d'évaluation

- AD-360X2 Parts Manual PN - 450558 (Rev-1)Document32 pagesAD-360X2 Parts Manual PN - 450558 (Rev-1)naokito AkemiPas encore d'évaluation

- Cat EyeDocument2 pagesCat EyejaklaudiuszPas encore d'évaluation

- Workshop DIY PROJECTSDocument75 pagesWorkshop DIY PROJECTSEmijo.A100% (1)

- Linotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeD'EverandLinotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypePas encore d'évaluation

- Storage-Tanks Titik Berat PDFDocument72 pagesStorage-Tanks Titik Berat PDF'viki Art100% (1)

- CESCOM 10 - Aircraft Status Report: Maintenance InspectionsDocument78 pagesCESCOM 10 - Aircraft Status Report: Maintenance InspectionsAlejandro BarradasPas encore d'évaluation

- Free ConvectionDocument4 pagesFree ConvectionLuthfy AditiarPas encore d'évaluation

- S3 U4 MiniTestDocument3 pagesS3 U4 MiniTestĐinh Thị Thu HàPas encore d'évaluation

- HAF350A User ManualDocument14 pagesHAF350A User ManualUEEPas encore d'évaluation

- Yu ZbornikDocument511 pagesYu ZbornikВладимирРакоњацPas encore d'évaluation

- 1 AlarmvalveDocument9 pages1 AlarmvalveAnandPas encore d'évaluation

- Teaching PowerPoint Slides - Chapter 5Document19 pagesTeaching PowerPoint Slides - Chapter 5Azril ShazwanPas encore d'évaluation

- Handout Waste Catch BasinDocument2 pagesHandout Waste Catch BasinJonniel De GuzmanPas encore d'évaluation

- Brochure - OasisDocument24 pagesBrochure - OasisVivek RPas encore d'évaluation

- 3-Phase Short-Circuit Current (Isc) at Any Point Within A LV Installation - Electrical Installation GuideDocument6 pages3-Phase Short-Circuit Current (Isc) at Any Point Within A LV Installation - Electrical Installation GuideYuukinoriPas encore d'évaluation

- C103 - General Checklist - ISO-IEC 17025:2017 Accreditation of Field Testing and Field Calibration LaboratoriesDocument19 pagesC103 - General Checklist - ISO-IEC 17025:2017 Accreditation of Field Testing and Field Calibration LaboratorieshuidhyiuodghPas encore d'évaluation

- Questions 1 To 3 Are Based On The Following TextDocument7 pagesQuestions 1 To 3 Are Based On The Following TextHokage KumPas encore d'évaluation

- Week 1 Familiarize The VmgoDocument10 pagesWeek 1 Familiarize The VmgoHizzel De CastroPas encore d'évaluation

- EDAG0007Document5 pagesEDAG0007krunalPas encore d'évaluation

- 全新全真题库一 PDFDocument36 pages全新全真题库一 PDFTzarlene100% (1)

- Derivation Bragg's Snell Law PDFDocument4 pagesDerivation Bragg's Snell Law PDFVaswati BiswasPas encore d'évaluation

- Chapter 3 Extension - Game Theory-StDocument25 pagesChapter 3 Extension - Game Theory-StQuynh Chau TranPas encore d'évaluation

- Cella Di Carico Sartorius MP77 eDocument3 pagesCella Di Carico Sartorius MP77 eNCPas encore d'évaluation

- MSDS Leadframe (16 Items)Document8 pagesMSDS Leadframe (16 Items)bennisg8Pas encore d'évaluation

- 3DS 2017 GEO GEMS Brochure A4 WEBDocument4 pages3DS 2017 GEO GEMS Brochure A4 WEBlazarpaladinPas encore d'évaluation

- Entrepreneurial MotivationDocument18 pagesEntrepreneurial MotivationRagavendra RagsPas encore d'évaluation

- Oral Communication in ContextDocument19 pagesOral Communication in ContextAzory ZellePas encore d'évaluation

- Industrial Motor Control Part IDocument38 pagesIndustrial Motor Control Part Ikibrom atsbha100% (2)

- Ferroelectric RamDocument20 pagesFerroelectric RamRijy LorancePas encore d'évaluation