Académique Documents

Professionnel Documents

Culture Documents

Mechanical Equations

Transféré par

Paramveer PablaCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Mechanical Equations

Transféré par

Paramveer PablaDroits d'auteur :

Formats disponibles

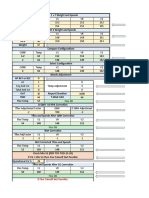

S

ut

(ksi) SQ(a) (in

0.5

)

50 0.130

55 0.118

60 0.108

70 0.093

80 0.080

90 0.070

100 0.062

110 0.055

120 0.049

130 0.044

140 0.039

160 0.310

180 0.024

200 0.018

220 0.013

240 0.009

Chapter 4: Stress, Strain, and Deflection

Maximum Bending Stress Straight Beams (4.9)

max

Mc

I

=

Transverse Shear Stress in Beams (4.9)

1

c

xy

y

V

ydA

Ib

=

max

3

2

V

A

=

max

4

3

V

A

=

Torsion (4.12)

max

Tr

J

=

Tl

JG

=

Chapter 5: Static Failure Theories

Von Mises Effective Stress for 3 Dimensions (5.1)

( ) ( ) ( ) ( )

2

6

2 2 2 2 2 2

3 1 3 2 2 1

2

3

2

2

2

1

zx yz xy x z z y y x

+ + + + +

=

+ + =

Von Mises Effective Stress for 2 Dimensions (5.1)

2 2 2

2

3 3 1

2

1

3

xy y x y x

+ + =

+ =

Safety Factor for Ductile Materials under Static Loading

(5.1)

=

y

S

N

1 3

max

:

2 2

y

S

MSS

N

=

Shear Yield Strength as a Function of Tensile Yield Strength

(5.1)

3

ys y

S S =

Modified-Mohr Effective Stress for 3 Dimensions (5.2)

( )

( )

( )

1 1 2 1 2

2 2 3 2 3

2 3 1 3 1

2

1

2

2

1

2

2

1

2

ut uc

uc

ut uc

uc

ut uc

uc

S S

C

S

S S

C

S

S S

C

S

(

= + +

(

(

(

= + +

(

(

(

= + +

(

(

1 2 3 1 2 3

( , , , , , ) MAX C C C = 0 = if MAX<0

Safety Factor for Brittle Materials under Static Loading (5.2)

ut

S

N=

Stress Intensity Factor (5.2)

nom

K a =

Safety Factor for Crack Propagation (5.2)

C

FM

K

N

K

=

Chapter 6: Fatigue Failure Theories

Fluctuating Stress Components (6.4)

max min

=

min

max

R

=

a

m

A

=

max min

2

a

=

max min

2

m

+

=

Uncorrected Fatigue Strength Estimates (6.5)

Steels:

0.5 1400

700 1400

e ut ut

e ut

S S S Mpa

S MPa S MPa

<

`

>

)

Irons:

0.4 400

700 400

e ut ut

e ut

S S S Mpa

S MPa S MPa

<

`

>

)

Aluminums:

@5 8

@5 8

0.5 330

700 330

E

E

f ut ut

f ut

S S S Mpa

S MPa S MPa

<

`

>

)

Correction Factors for Fatigue Strength (6.6)

Bending: C

load

=1

Axial loading: C

load

=0.70

2

95

0.0766 A d =

2

95

0.010462 A d =

95

0.05 A bh =

For d<8mm: C

size

=1

For 8mm<d<250mm: C

size

=1.189d

-0.097

C

surf

=A(S

ut

)

b

if C

surf

>1.0, set C

surf

=1.0

For T<450C: C

temp

=1

For 450<T<550C: C

temp

=1-0.0058(T-450)

Corrected Fatigue Strength Estimates (6.6)

S

e

=C

load

C

size

C

surf

C

temp

C

reliab

S

e

S

f

=C

load

C

size

C

surf

C

temp

C

reliab

S

f

Approximate Strength @ 1,000 cycles (6.6)

Bending: S

m

=0.9 S

ut

Axial loading: S

m

=0.75 S

ut

S-N Diagram (6.6)

log log log

n

S a b N = +

b

n

S aN =

1

log

m

e

S

b

z S

| |

=

|

\ .

where

1 2

log log z N N = N

1

=1,000

( ) ( ) ( ) ( )

1

log log log log 3

m m

a S b N S b = =

Notch Sensitivity (6.7)

1

1

q

a

r

=

+

Fatigue Stress-concentration factors (6.7 & 6.10)

( ) 1 1

f t

K q K = +

Safety Factor Fully Reversed Stresses (6.9)

n

f

S

N

Modified Goodman Diagram (6.10)

1

m a

yc yc

S S

+ = 1

m a

ut f

S S

+ =

a f

S = 1

m a

y y

S S

+ =

Safety Factor Fluctuating Stresses (6.10)

Case 1 (mean increase): 1

y

a

f

m y

S

N

S

| |

= |

|

\ .

Case 2 (amp increase): 1

f

m

f

a ut

S

N

S

| |

=

|

\ .

Case 3 (ratio constant):

f ut

f

a ut m f

S S

N

S S

=

+

Case 4 (independent):

f

OZ ZS

N

OZ

+

=

( ) ( )

2 2

a m

OZ = +

( ) ( )

2 2

@ @ a a S m m S

ZS = +

SEQA Method for Complex Multiaxial Stresses in Fatigue

(6.11)

1

2 2 2 4

3 3 9

1 2 1 2 cos 2 2

4 2 16 2

SEQA

(

| | | | | |

(

= + + + +

| | |

(

\ . \ . \ .

Fracture Mechanics in Fatigue (6.5)

( )

( )

max min

max min

n

K a a

a

da

A K

dN

=

=

=

Reliability %Creliab

50 1

90 0.897

99 0.814

99.9 0.753

99.99 0.702

99.999 0.659

Roller > Slider

static

dynamic

Supports radial & thrust

Lubrication less critical

No self-excited

instabilities

Low Temp

Sealed lubricant

Less space axially

Slider > Roller

Less fatigue

Less space radially

Better damping

Lower noise

Lessened alignment

Lower cost

Lower friction

Beam Bending (4.10)

1

1 2

2

1 2 3

3 2

1 2 3 4

V qdx C

M Vdx C x C

M

dx C x C x C

EI

y dx C x C x C x C

= +

= + +

= + + +

= + + + +

Stress Concentrations (6.11)

max

nom

f y

K S <

fm f

K K =

max

nom

f y

K S >

nom

nom

y f a

fm

m

S K

K

=

max min

2

nom nom

f y

K S > 0

fm

K =

Chapter 9: Shafts, Keys, and Couplings

Power-Torque Relationship (9.4)

avg avg avg

P T =

Shaft Stresses (9.6)

a

a f

M c

k

I

=

m

m fm

M c

k

I

=

axial

z

m fm

F

k

A

=

a

a fs

T r

k

J

=

m

m fsm

T r

k

J

=

b

t

r

K A

d

| |

=

|

\ .

2

d

c r = =

4

64

d

I

=

4

32

d

J

=

D/d A b

3.00 0.90720 -0.33333

2.00 0.93232 -0.30304

1.30 0.95880 -0.27269

1.20 0.99590 -0.23829

1.10 1.01650 -0.21548

1.05 1.02260 -0.19156

1.01 0.96689 -0.15417

ASME Shaft-Design Eqn. (9.8)

2

2

1

a m

f f

e ys

N N

S S

| |

| |

+ = |

|

|

\ .

\ .

1

1

3

2 2

2

32

3

4

f

a m

f

f y

N

M T

d k

S S

(

| | | |

(

= + | |

`

| |

(

\ . \ .

)

General Shaft-Design Eqn. (9.8)

2 2

3

a a a

= +

( )

2

2

3

axial

m m m m

= + +

1

a m

f f ut

N S S

= +

( ) ( ) ( ) ( )

1

3

2 2 2 2

3 3

32

4 4

f a fs a fm m fsm m

f

f ut

k M k T k M k T

N

d

S S

(

+ +

(

(

= +

`

(

(

)

Shaft Torsional Deflection (9.9)

Tl

GJ

=

Chapter 10: Bearings and Lubrication

Load-Life Relationship (10.10)

Ball bearings:

3

C

L

P

| |

=

|

\ .

Roller bearings:

10

3

C

L

P

| |

=

|

\ .

Equivalent Load for Rolling Bearings (10.10)

r a

P XVF YF = +

1

in

V = 1.2

out

V =

Bearing Life:

For catalog (C

10

)

1

10

10

a

D

D

L

C F

L

| |

=

|

\ .

a: - 3 ball bearings

a: - 10/3 roller bearings

For given reliability

( ) ( )

1

10 1

0 0

1

a

D

D

b

D

C F

R

(

(

=

(

+

(

10

D

D

L

L

=

0

, (-

0) and b

weibull parameters

D a e

F f F = f

a

=load app. factor

F

e

equivalent radial load

For combined radial (F

r

) & thrust (F

a

) loading

e R

F VF =

a

R

F

e

VF

2 2 e R a

F X VF Y F = +

a

R

F

e

VF

>

F

a

=applied constant thrust load

Chapter 14: Screws and Fasteners

Torque required to raise the load with a power screw (14.2)

( )

( )

cos

2 2

cos

u

p

p

c

u s c c

p

d L

Pd

d

T T T P

d L

+

= + = +

Self-locking of a power screw will occur if (14.2)

cos

p

L

d

or tan cos

Efficiency of a power screw (14.2)

2

out

in

W PL

e

W T

= =

Spring constant of a threaded fastener (14.7)

1

t t t s

b t b b b t b b b

l l l l l

k A E A E A E A E

= + = +

Spring constant of the clamped material (14.7)

m m

m

A E

k

l

=

Approximate effective area of a clamped material around one

fastener (14.8)

2

2 2 3

4 2

m

d d

A d

(

+ | |

(

|

\ . (

Load taken by a preloaded bolt and the joint constant C

(14.7)

b

b

m b

k

P P

k k

=

+

or

b

P CP = where

b

m b

k

C

k k

=

+

Load taken by the preloaded material (14.7)

( ) 1

m

m

m b

k

P P C P

k k

= =

+

Minimum load in material and maximum load in bolt (14.7)

( ) 1

m i

F F C P =

b i

F F CP = +

Load required to separate a preloaded bolt (14.7)

( )

0

1

i

F

P

C

=

Mean and alternating loads felt by a preloaded bolt (14.7)

2

b i

mean

F F

F

+

=

2

b i

alt

F F

F

=

Mean and alternating stresses in a preloaded bolt (14.7)

mean

m fm

t

F

K

A

=

alt

a f

t

F

K

A

=

Preload stress in a bolt (14.7)

i

i fm

t

F

K

A

=

Fatigue safety factor for a preloaded bolt (14.7)

( )

( )

e ut i

f

e m i ut a

S S

N

S S

=

+

Approximate torque needed to preload a bolt (14.9)

0.21

i i

T Fd

Centroid of a group of fasteners (14.10)

1

1

n

i i

n

i

A x

x

A

=

1

1

n

i i

n

i

A y

y

A

=

Forces of fasteners eccentrically loaded in shear (14.10)

1

i

P

F

n

=

0

2

2 2

1 1

i

i i

n n

j j

j j

Mr Plr

F

r r

= =

= =

Vous aimerez peut-être aussi

- VescosityDocument6 pagesVescosityParamveer PablaPas encore d'évaluation

- Lab Report Charles' LawDocument6 pagesLab Report Charles' LawParamveer PablaPas encore d'évaluation

- Steamengine PablaDocument3 pagesSteamengine PablaParamveer PablaPas encore d'évaluation

- Math 625 Spring 2013 HWK 2 SolutionsDocument15 pagesMath 625 Spring 2013 HWK 2 SolutionsParamveer PablaPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Chapter 3Document12 pagesChapter 3Raymond LeoPas encore d'évaluation

- Create Login Application In Excel Macro Using Visual BasicDocument16 pagesCreate Login Application In Excel Macro Using Visual Basicfranklaer-2Pas encore d'évaluation

- Jack of All Trades ArchetypeDocument2 pagesJack of All Trades ArchetypeGwazi MagnumPas encore d'évaluation

- 942 FullDocument9 pages942 FullZulfah MidahPas encore d'évaluation

- A320 Flex CalculationDocument10 pagesA320 Flex CalculationMansour TaoualiPas encore d'évaluation

- Industrial Wire Cutting Machine: A Senior Capstone Design ProjectDocument17 pagesIndustrial Wire Cutting Machine: A Senior Capstone Design ProjectTruta IonutPas encore d'évaluation

- Exp# 1c Exec System Call Aim: CS2257 Operating System LabDocument3 pagesExp# 1c Exec System Call Aim: CS2257 Operating System LabAbuzar ShPas encore d'évaluation

- ADC MethodDocument16 pagesADC MethodPhilip K MathewPas encore d'évaluation

- Unit 30 WorkDocument2 pagesUnit 30 WorkThanh HàPas encore d'évaluation

- Eco 201Document23 pagesEco 201Tâm TítPas encore d'évaluation

- Planets Classification Malefic and BeneficDocument3 pagesPlanets Classification Malefic and Beneficmadhu77Pas encore d'évaluation

- Hydrocarbon TechnologyDocument21 pagesHydrocarbon Technologyghatak2100% (1)

- Cathodic Disbonding TesterDocument1 pageCathodic Disbonding TesterfelavinPas encore d'évaluation

- PDF Manual de Reparaciones Estructurales Del Airbus A 320 CompressDocument15 pagesPDF Manual de Reparaciones Estructurales Del Airbus A 320 CompressJosé LuisPas encore d'évaluation

- BSBCRT511 Project Portfolio - Revised - Answers IncludedDocument26 pagesBSBCRT511 Project Portfolio - Revised - Answers IncludedShivanee JhaumalPas encore d'évaluation

- Multiple Choice Bubble Sheet Template Customize This WordDocument3 pagesMultiple Choice Bubble Sheet Template Customize This WordAl Bin0% (1)

- LG - Week 1 - Operations - ManagementDocument4 pagesLG - Week 1 - Operations - ManagementMechaella Shella Ningal ApolinarioPas encore d'évaluation

- Generative NLP Robert DiltsDocument11 pagesGenerative NLP Robert DiltsTyler Durden100% (22)

- Friction WedgesDocument7 pagesFriction Wedgespericharla ravivarmaPas encore d'évaluation

- Microsoft Word - JOB DESCRIPTION Staff AccountantDocument2 pagesMicrosoft Word - JOB DESCRIPTION Staff Accountantanon-634050100% (3)

- What Is The Procedure For Graceful Shutdown and Power Up of A Storage System During Scheduled Power OutageDocument5 pagesWhat Is The Procedure For Graceful Shutdown and Power Up of A Storage System During Scheduled Power OutageNiraj MistryPas encore d'évaluation

- Sheet Metalworking 1 - Chapter 19Document99 pagesSheet Metalworking 1 - Chapter 19xharpreetxPas encore d'évaluation

- Types of Managers and Management Styles: Popmt@uoradea - Ro Dpop@uoradeaDocument7 pagesTypes of Managers and Management Styles: Popmt@uoradea - Ro Dpop@uoradeaJimnadominicPas encore d'évaluation

- Chapter 6 THE SECOND LAW OF THERMODYNAMICS5704685Document29 pagesChapter 6 THE SECOND LAW OF THERMODYNAMICS5704685bensonPas encore d'évaluation

- Calicut University: B. A PhilosophyDocument6 pagesCalicut University: B. A PhilosophyEjaz KazmiPas encore d'évaluation

- Chapter 2 - Key Themes of Environmental ScienceDocument34 pagesChapter 2 - Key Themes of Environmental ScienceJames Abuya BetayoPas encore d'évaluation

- Accomplishment Report - English (Sy 2020-2021)Document7 pagesAccomplishment Report - English (Sy 2020-2021)Erika Ikang WayawayPas encore d'évaluation

- C ProgDocument29 pagesC ProgaishwaryaPas encore d'évaluation

- Us00-000 831 01 02 02Document18 pagesUs00-000 831 01 02 02Cristian Camilo0% (1)

- Some Reading Problems of Arab EFL Students: Dr. Kamal R. MourtagaDocument17 pagesSome Reading Problems of Arab EFL Students: Dr. Kamal R. MourtagaANOOOSAPas encore d'évaluation