Académique Documents

Professionnel Documents

Culture Documents

Machinery Lubrication Oilers

Transféré par

satstar0 évaluation0% ont trouvé ce document utile (0 vote)

126 vues0 pageF

Copyright

© Attribution Non-Commercial (BY-NC)

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentF

Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

126 vues0 pageMachinery Lubrication Oilers

Transféré par

satstarF

Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 0

66 July - August 2004 www.machinerylubrication.

com Machinery Lubrication

BY JEFF MALINOWSKI, TRICO MANUFACTURING CORP.

C

onstant level oilers are designed to maintain

a predetermined oil level in a sump, which is

necessary for proper lubrication. If the oil level

drops below this point, the depleted oil is auto-

matically replenished by the lubricator, returning

it to its original level. Constant level oilers can

also help increase maintenance efficiencies and

decrease maintenance costs and loss of produc-

tion time. Even though constant level oilers are

simplistic and easy to install, problems can still

arise. Care should be taken when installing,

applying and refilling these units.

Installation and Application

Prior to installing a constant level oiler, shaft

rotation direction must be determined. If a

side-mounted connection is required, the

recommended placement is on the side of the

equipment, facing the direction of shaft rotation

(Figure 1). This positioning protects the oiler

from oil sump surges that can occur during start-

up, which may cause the oiler to overfeed. If

frequent start-ups are necessary, the bottom-

mount configuration is recommended (Figure

2). In some cases, eddy currents and oil turbu-

lence can form due to slinger rings, discs and

high rotating speeds. These currents can

temporarily alter the level of the oil and ulti-

mately cause the oiler to overfeed. When these

rings or discs are present, mount the lubricator

LUBRICANT APPLICATION

Constant Level Oilers

Seven Mistakes to Avoid When

Installing, Applying and Refilling

Figure 1. Side-mounted Connection

Figure 2. Bottom-mounted Connection Continued on Page 68

LUBRICANT APPLICATION

using the bottom fitting, and connect it to the

bottom of the equipments sump (Figure 2).

Check lubricant levels periodically to ensure

proper application.

Many oilers contain a small vertical stem.

Some are fixed to the unit, and others are part of

a leveling assembly (Figure 3). The purpose of

this stem is to break the meniscus, allowing the

oil to feed properly through the unit. Often

times, when these stems are part of a removable

assembly, they are discarded during mainte-

nance, causing the oiler to misfeed or not feed at

all. Prior to installation, or after maintenance,

verify that all parts of the lubricator are present.

When using a constant level oiler that is

vented to the outside atmosphere, it is impor-

tant to keep the oiler and/or the breather vent

away from any air flow near the equipment.

This air flow can come from any type of fan,

such as a blower or motor fan. Fans create an air

flow over the breather vent or the oiler, causing

a pressure differential between the bearing

housing and the oiler, leading to misfeeding.

To prevent this, install an extension pipe

nipple on either the breather vent or the oiler

connection. Replacing the vented constant

level oiler with a nonvented or closed system

oiler is another solution that also eliminates

contaminant ingression.

A closed system oilers operation and installa-

tion considerations are similar to those of a

vented oiler. However, the closed system

requires a vent tube to be connected from the

lubricator to the bearing housing for pressure

equalization. Also available are additional types

of closed systems oilers that mount directly on

equipment that has a port at the centerline of

the oil level. This type of mounting does not

allow the fluid level to adjust, thus eliminating

potential installation errors.

Improper Filling Methods

Care should be taken when replenishing

fluids to predetermined levels. Understanding

proper filling methods is important in

preventing overfilling of the sump. Although

Figure 4. Cross-section of Optomatic

Figure 3. Level Adjustment Assembly

Figure 5. Pressure Differential from Air Flow

Continued from Page 66

68 July - August 2004 www.machinerylubrication.com Machinery Lubrication

Stem

Desired Oil Level

Lock Against

Top Arm

Air Flow

constant level oilers are simplistic in function,

several mistakes are often made, such as filling

through the top or the surge body and refilling

too frequently.

When filling through the top of the equip-

ment, knowing the required oil volume is

necessary to achieve the preset level. If the oil

quantity is known, then this method is consid-

ered to be a safe filling procedure. However,

more times then not, the oil quantity is

unknown and the oil is haphazardly poured

through the top, using a sight gauge to deter-

mine the level. Unfortunately, this will result in

a high fluid level due to residual lubricant

draining from the internal components such as

a shaft or gear.

Proper oil volume can be achieved through

the surge body when a sight gauge is present.

The sight gauge is a visual aid for achieving the

predetermined fluid level in the sump. Filling

without a sight gauge can cause overfilling of

the oil sump and surge body. An indication of

overfilling is that fluid begins flowing from the

surge body once the reservoir is replaced. To

adjust for overfilling, drain the lubricant from

the sump until the constant level oiler begins

feeding, and reaches the preset level.

In addition, excessive refilling of the reser-

voir will also have a negative effect on the oil

level. Each time the reservoir is removed and

replaced, a small amount of lubricant is added

to the oil sump level. Over time, this will

increase the fluid level. To combat this, refill

the reservoir only when it is half full or less.

This will help minimize unnecessary filling.

Constant level oilers are an easy and effective

method of maintaining proper oil level in

equipment. Proper installation and usage will

provide optimum performance of the lubricator

as well as the equipment it supplies. By imple-

menting the recommended guidelines,

efficient and effective lubrication management

can be achieved.

About the Author

Jeff Malinowski is a product development engineer for

Trico Manufacturing Corporation, a provider of lubrication

products for industrial equipment.

Figure 6. Installation of Extension Pipe

Note: When installing an extension pipe on the vented oiler in a

side-mount configuration, do not use an elbow fitting, because

this will change the fluid level in the oil sump.

Machinery Lubrication www.machinerylubrication.com July - August 2004 69

Air Flow

Air Flow

Correct

Incorrect

Figure 7. Closed System Opto-Matic

Figure 8. Watchdog Constant Level Oiler

Vous aimerez peut-être aussi

- Effective Constant Level LubricationDocument6 pagesEffective Constant Level Lubricationdaniel adamPas encore d'évaluation

- Constant Level Oilers - 7 Mistakes To AvoidDocument7 pagesConstant Level Oilers - 7 Mistakes To Avoiddaniel adamPas encore d'évaluation

- Practices For Lurbricating Bearing in APIDocument6 pagesPractices For Lurbricating Bearing in APINguyen ChuyenPas encore d'évaluation

- Best Practices For Lubing API Centrifugal Pump Bearing HousingsDocument7 pagesBest Practices For Lubing API Centrifugal Pump Bearing HousingsguluuPas encore d'évaluation

- Constant Level Oiler - Vented or NonventedDocument7 pagesConstant Level Oiler - Vented or Nonventedpeach5Pas encore d'évaluation

- Understanding Oil AnalysisDocument8 pagesUnderstanding Oil AnalysisTim ku100% (1)

- Brief Introduction To Oil Analysis: Click To Edit Master Subtitle StyleDocument29 pagesBrief Introduction To Oil Analysis: Click To Edit Master Subtitle StyleRoket StarterPas encore d'évaluation

- Hydrocarbon Turbo ExpandersDocument20 pagesHydrocarbon Turbo ExpandersPakde NdokPas encore d'évaluation

- The Dual Seal ArrangementDocument17 pagesThe Dual Seal Arrangementnyuvaraj1981Pas encore d'évaluation

- Condition Monitoring and Assessment For Rotating MachineryDocument22 pagesCondition Monitoring and Assessment For Rotating MachineryMohamed KhaledPas encore d'évaluation

- Balance LineDocument0 pageBalance Linewsjouri2510Pas encore d'évaluation

- Bearingfailure PDFDocument22 pagesBearingfailure PDFMohamed Altaf Jaffer100% (1)

- Api 23Document3 pagesApi 23sapu11jagat5855Pas encore d'évaluation

- Advanced Bearing MaterialsDocument8 pagesAdvanced Bearing Materialsthrashco69Pas encore d'évaluation

- Full Load Test ExpanderDocument8 pagesFull Load Test Expanderdhanu_aquaPas encore d'évaluation

- Grease BasicsDocument6 pagesGrease BasicsnagbabuiPas encore d'évaluation

- Types of Lubrication: BoundaryDocument20 pagesTypes of Lubrication: BoundaryAbishek Abi100% (1)

- Flushing and The Voice Within Your OilDocument4 pagesFlushing and The Voice Within Your OilHunab379Pas encore d'évaluation

- A Review of Tilting Pad Bearing TheoryDocument31 pagesA Review of Tilting Pad Bearing TheoryJose Luis RattiaPas encore d'évaluation

- Troubleshooting Rotating Machinery: Including Centrifugal Pumps and Compressors, Reciprocating Pumps and Compressors, Fans, Steam Turbines, Electric Motors, and MoreD'EverandTroubleshooting Rotating Machinery: Including Centrifugal Pumps and Compressors, Reciprocating Pumps and Compressors, Fans, Steam Turbines, Electric Motors, and MorePas encore d'évaluation

- Turbine Oil AnalysisDocument12 pagesTurbine Oil Analysismanuelsum100% (2)

- Bearing Defect Inspection Based On Machine VisionDocument20 pagesBearing Defect Inspection Based On Machine VisionArun Kumar100% (1)

- Intro To Centrifugal Compressor ComponentsDocument7 pagesIntro To Centrifugal Compressor ComponentsMuhammad Ridhwan100% (2)

- Evaluation of Tilting Pad Thrust Bearings PDFDocument10 pagesEvaluation of Tilting Pad Thrust Bearings PDFVILLANUEVA_DANIEL2064Pas encore d'évaluation

- Hy-Pro Gearbox Filtration OverviewDocument4 pagesHy-Pro Gearbox Filtration OverviewlubangjarumPas encore d'évaluation

- Mobil Product Guide South Pacific May09Document23 pagesMobil Product Guide South Pacific May09Arimbi GembiekPas encore d'évaluation

- Sealing Sense: Where Mechanical Seals Meet Pumps: What Is The Next Generation?Document3 pagesSealing Sense: Where Mechanical Seals Meet Pumps: What Is The Next Generation?madairkifPas encore d'évaluation

- Dry Gas Seal ContaminationDocument12 pagesDry Gas Seal ContaminationnguyennhatbaoPas encore d'évaluation

- Maintenance Engineering Lecture Module I PDFDocument52 pagesMaintenance Engineering Lecture Module I PDFAnandaKrishnan NairPas encore d'évaluation

- 070 Seal Piping Plan ReviewDocument100 pages070 Seal Piping Plan Reviewvlcmstne04Pas encore d'évaluation

- 6 Centrifugal Compressor IDocument40 pages6 Centrifugal Compressor IBassam AmirPas encore d'évaluation

- Top 10 Rotating Equipment Engineer Interview Questions and AnswersDocument17 pagesTop 10 Rotating Equipment Engineer Interview Questions and AnswersSathishkumar VeluPas encore d'évaluation

- 100 Ways To Improve Lubrication ProgramDocument21 pages100 Ways To Improve Lubrication ProgramTalha NizamiPas encore d'évaluation

- P178Document9 pagesP178keepmoshingPas encore d'évaluation

- A Study On Failure of Mechanical PumpDocument34 pagesA Study On Failure of Mechanical PumpAzif Ali MoothantevileyilPas encore d'évaluation

- VUD Vacuum DehydratorsDocument7 pagesVUD Vacuum DehydratorsZaqueu Santos OliveiraPas encore d'évaluation

- API Flush Plan 54Document2 pagesAPI Flush Plan 54hurrikenPas encore d'évaluation

- Cylinder Lubrication SystemDocument8 pagesCylinder Lubrication SystemSilvio RodriguezPas encore d'évaluation

- 3-Day Gen Open 112003 1a (Compatibility Mode)Document84 pages3-Day Gen Open 112003 1a (Compatibility Mode)api-3703348100% (1)

- Cavitation in Centrifugal PumpDocument22 pagesCavitation in Centrifugal Pumpnastyn-1Pas encore d'évaluation

- Advanced Strategies For Selecting Oil Analysis Alarms and LimitsDocument6 pagesAdvanced Strategies For Selecting Oil Analysis Alarms and Limitsho-fa100% (1)

- Trane SemiHermetic CompressorsDocument169 pagesTrane SemiHermetic CompressorsGerson RomeroPas encore d'évaluation

- Understanding Basic Oil AnalysisDocument24 pagesUnderstanding Basic Oil AnalysisArslan Hamid100% (2)

- Technical Presentation - Mechanical SealsDocument54 pagesTechnical Presentation - Mechanical SealsAlen Koo100% (2)

- Gear Pump DiscussionDocument2 pagesGear Pump DiscussionSlim ShaddysPas encore d'évaluation

- Wet SealsDocument8 pagesWet Sealsasadiqbal127100% (1)

- Complete - Nicholson Designers Guide - 3rd EditionDocument177 pagesComplete - Nicholson Designers Guide - 3rd Editionwdelgado2011Pas encore d'évaluation

- Mechanical Seal ProblemsDocument5 pagesMechanical Seal Problemschazz29hkPas encore d'évaluation

- Pumps Course MaterialDocument222 pagesPumps Course Materialarkan1976Pas encore d'évaluation

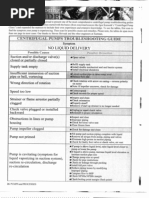

- Centrifugal Pump Troubleshooting GuideDocument10 pagesCentrifugal Pump Troubleshooting GuideSteve Sund100% (1)

- Avoiding Leakage Seals+Sealing Systems Machinery+Piping Chemengonline.cDocument3 pagesAvoiding Leakage Seals+Sealing Systems Machinery+Piping Chemengonline.cAnonymous nw5AXJqjdPas encore d'évaluation

- Stan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineD'EverandStan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineÉvaluation : 5 sur 5 étoiles5/5 (1)

- Turbine Oil QualityDocument13 pagesTurbine Oil QualityJagadish PatraPas encore d'évaluation

- Pure Oil Mist PresentationDocument20 pagesPure Oil Mist Presentationzackii90Pas encore d'évaluation

- TTI Turboexpander Description-RecDocument36 pagesTTI Turboexpander Description-Recgurguri5691100% (1)

- Lubrication Program Development - Brochure NoriaDocument12 pagesLubrication Program Development - Brochure NoriaWilmar LEON PEÑA100% (2)

- Mechanical SealDocument15 pagesMechanical SealTinu Paul Jepin100% (2)

- Fire Pump Vibration Acceptable LimitDocument2 pagesFire Pump Vibration Acceptable LimitsatstarPas encore d'évaluation

- Understanding Your Exam ResultsDocument1 pageUnderstanding Your Exam ResultssatstarPas encore d'évaluation

- 3 and 6 Sigma Standard DeviationDocument5 pages3 and 6 Sigma Standard DeviationMohammed AbdulPas encore d'évaluation

- 7037E Comparing PMBOK and ISO v1-1Document0 page7037E Comparing PMBOK and ISO v1-1eduardo_pl8256Pas encore d'évaluation

- Fire Pump Vibration Acceptable LimitDocument2 pagesFire Pump Vibration Acceptable LimitsatstarPas encore d'évaluation

- Management TheoriesDocument7 pagesManagement TheoriesMohammed AbdulPas encore d'évaluation

- Project Integration Management PDFDocument5 pagesProject Integration Management PDFnomanPas encore d'évaluation

- V005t16a008 82 GT 277Document10 pagesV005t16a008 82 GT 277satstarPas encore d'évaluation

- PMP Certification Exam Changes 2018 - PMIDocument2 pagesPMP Certification Exam Changes 2018 - PMIsatstarPas encore d'évaluation

- The PMP® Exam Changes After 11 January 2016Document11 pagesThe PMP® Exam Changes After 11 January 2016satstarPas encore d'évaluation

- V005t16a008 82 GT 277Document10 pagesV005t16a008 82 GT 277satstarPas encore d'évaluation

- Gerbera Vs CarnationDocument4 pagesGerbera Vs CarnationsatstarPas encore d'évaluation

- Difference Between ANSI & API PumpsDocument2 pagesDifference Between ANSI & API PumpsAnonymous KpVxNXs100% (3)

- PMP Mock Exams Set2Document11 pagesPMP Mock Exams Set2Eslam MansourPas encore d'évaluation

- Pump Formulas PDFDocument3 pagesPump Formulas PDFsatstarPas encore d'évaluation

- Project Scope Management3Document5 pagesProject Scope Management3Ankush JaggiPas encore d'évaluation

- Project Stakeholder Management11Document5 pagesProject Stakeholder Management11Ankush JaggiPas encore d'évaluation

- PMP Certification Prerequisites - PMP Eligibility RequirementsDocument4 pagesPMP Certification Prerequisites - PMP Eligibility RequirementssatstarPas encore d'évaluation

- PMP Mock Exams Set1Document15 pagesPMP Mock Exams Set1Bhushan PAwar100% (1)

- 8.project Quality ManagementDocument5 pages8.project Quality ManagementsatstarPas encore d'évaluation

- Ar Motor 01Document7 pagesAr Motor 01Sunil MotepalliPas encore d'évaluation

- International Flower Auction Bangalore (IFAB) Limited6Document31 pagesInternational Flower Auction Bangalore (IFAB) Limited6satstarPas encore d'évaluation

- Carnation Flower - Manufacturers, Suppliers & ExportersDocument14 pagesCarnation Flower - Manufacturers, Suppliers & ExporterssatstarPas encore d'évaluation

- 6.project Time Management PDFDocument5 pages6.project Time Management PDFsatstarPas encore d'évaluation

- Track E-Mail Messages That Require Follow Up - OutlookDocument8 pagesTrack E-Mail Messages That Require Follow Up - OutlooksatstarPas encore d'évaluation

- Water Dynamic LoadDocument27 pagesWater Dynamic LoadsolarpolPas encore d'évaluation

- 166 Twenty Principles For Good Spreadsheet PracticeDocument20 pages166 Twenty Principles For Good Spreadsheet PracticesatstarPas encore d'évaluation

- Understanding The Difference Between NPV Vs IRRDocument3 pagesUnderstanding The Difference Between NPV Vs IRRsatstarPas encore d'évaluation

- Bank FD V - S. Bank RDDocument3 pagesBank FD V - S. Bank RDsatstarPas encore d'évaluation

- EMI Calculator IndiaDocument3 pagesEMI Calculator IndiasatstarPas encore d'évaluation

- Agricultural MeteorologyDocument25 pagesAgricultural MeteorologyAman IndwarPas encore d'évaluation

- Meteorology: Background ConceptsDocument98 pagesMeteorology: Background ConceptsPuja Kadam Ghadi100% (1)

- Waste Incineration Bref 0806Document638 pagesWaste Incineration Bref 0806Stullie100% (1)

- Siphonic Roof DrainageDocument2 pagesSiphonic Roof DrainagemichelefatecPas encore d'évaluation

- Public Talk On ToiletDocument1 pagePublic Talk On ToiletRichard LeongPas encore d'évaluation

- PollutionDocument13 pagesPollutionRahul VatsPas encore d'évaluation

- Manila Standard Today - August 09, 2012 IssueDocument12 pagesManila Standard Today - August 09, 2012 IssueManila Standard Today100% (1)

- Water Distribution NetworkDocument3 pagesWater Distribution NetworkLorie Mae IIPas encore d'évaluation

- Key Map PujapitiyaDocument1 pageKey Map PujapitiyaPradeep KumaraPas encore d'évaluation

- 10 Point Checklist To Find The Right Mineral Water Plant Manufacturers For Your MineralDocument3 pages10 Point Checklist To Find The Right Mineral Water Plant Manufacturers For Your MineralSoumitra GhotikarPas encore d'évaluation

- MatthewsDocument50 pagesMatthewsДрагана Скоко100% (1)

- NMR - WATER Exploration, Presentation - Water - ProjectDocument35 pagesNMR - WATER Exploration, Presentation - Water - Projectmichel louis friedmanPas encore d'évaluation

- Factors Which May Influence Air ContentDocument4 pagesFactors Which May Influence Air ContentAnonymous ouZFaSBRPas encore d'évaluation

- Surface WaterDocument22 pagesSurface WaterLuis MenendezPas encore d'évaluation

- Hormuz Strait Dam Futuristic MacroprojectDocument14 pagesHormuz Strait Dam Futuristic MacroprojectMariabelen MalagaPas encore d'évaluation

- Leopold, L. T. 1968 Hydrology For Urban Planning - A Guide Book On TheDocument26 pagesLeopold, L. T. 1968 Hydrology For Urban Planning - A Guide Book On TheFiguraDesfiguraPas encore d'évaluation

- AcknowledgementDocument35 pagesAcknowledgementSaba HafeezPas encore d'évaluation

- Sources of Energy Mind MapDocument1 pageSources of Energy Mind Mapravichandran50% (2)

- U3Test Unit 7 StandardDocument4 pagesU3Test Unit 7 StandardCristina MorilloPas encore d'évaluation

- gb5 & fb80: U.S. Installation GuidelineDocument2 pagesgb5 & fb80: U.S. Installation GuidelineAnatoliy RozenbljumPas encore d'évaluation

- (5167) Sheet Ionic Equilibrium Elementary Theory eDocument19 pages(5167) Sheet Ionic Equilibrium Elementary Theory eSunny MethaniPas encore d'évaluation

- Side View Front View: Edgecomm IncorporatedDocument1 pageSide View Front View: Edgecomm IncorporatedMarvin VinaraoPas encore d'évaluation

- Septic Tank Size TableDocument4 pagesSeptic Tank Size Tablepersona100% (5)

- Aquaguard INFINITI UserManualDocument19 pagesAquaguard INFINITI UserManualBalaram Rath25% (4)

- D D Module The War Rafts of Kron PDFDocument38 pagesD D Module The War Rafts of Kron PDFS75% (4)

- MPDPMDocument181 pagesMPDPMvenkateshbitraPas encore d'évaluation

- Course of Flexible PipesDocument67 pagesCourse of Flexible PipesEd Mulford100% (1)

- Amphibious Architecture DissertationDocument60 pagesAmphibious Architecture DissertationnivedaaPas encore d'évaluation

- AFIL Eng Capability - RevisedDocument5 pagesAFIL Eng Capability - RevisedArunprasad MurugesanPas encore d'évaluation

- Oily Water Separators: Dissolved Air Flotation Units (DAF)Document2 pagesOily Water Separators: Dissolved Air Flotation Units (DAF)blondtumbalaPas encore d'évaluation