Académique Documents

Professionnel Documents

Culture Documents

Marc-Powell Resume

Transféré par

marcpowell2011Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Marc-Powell Resume

Transféré par

marcpowell2011Droits d'auteur :

Formats disponibles

Marc Powell

Production, Warehouse Supervisor

100 Alert Rd - Louisburg, NC 27549 marcpowell2011@gmail.com - 919-426-8092 Strong and rewarding professional experience with consistent promotions based on lean, team and goal oriented achievements. * Customer Service, Inventory Control, Shipping, Receiving, Warehouse, and Manufacturing Production Supervision Management experience. * A diversified professional background in Adult Education; Customer Service, Operations Management; Supervision; Safety and Policy Procedure Development; Training Skill Sets and Document Development. * Formal training in 5s, Lean Manufacturing, Continuous Improvement (Train the Trainer), HPWT, People Oriented Management, Total Quality Management (Facilitator/Trainer), Good Manufacturing Practices, Team Leadership, ISO 9000, FDA policies. * Excellent Computer Skills, CompTia A+ and Network + certifications, proficient with MS Windows 8/ 7/ 98/ NT/2K/XP SP2 and MS Office. * Class A CDL OTR driver securing and hauling specialized commodities on flatbed, single and double-drop and other specialized 53-foot trailers in all 48 states and Canada.

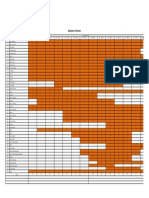

WORK EXPERIENCE

Warehouse, Production Supervisor/Lead

Pacific Coast Feather Co - Henderson, NC - October 2011 to September 2013 Managing associates manufacturing comforters and pillows by filling (down, feathers or synthetic fiber), sewing single or double needle, packaging and inventory control. Also managed 3 satellite warehouses.

OTR Class A CDL Driver

Maverick Transportation - Specialized Division - November 2010 to February 2011 Glass). Securing and hauling specialized commodities on flatbed, single and double-drop and other specialized 53foot trailers in all 48 states and Canada.

Production Supervisor

Kflex-USA - May 2005 to March 2010 Responsible for training lean continuous improvement teams in 6S and 8D decision making processes and supervising forty-five technical support staff, including safety, operations, and quality of production and assuring customer requirements.

Systems Customer Service Representative

Document Messaging Technology Div. -Pitney Bowes Inc - January 2002 to May 2005

Maintaining and servicing the High Speed Mail Inserter and Sorter machines. My responsibilities also include all customer communications, services, sales and training.

CompTia A+ Certification Teacher

Nash Community College - July 2001 to January 2002 Instructor for the Continuing Education Department teaching CompTia A+ Guide to "Managing and Maintaining your PC." Preparing adult students for the CompTia A+ Certification Core Hardware and OS exams. Responsible for curriculum, material and lesson plans. Contract position

Network Technician

Triton Management - January 2001 to July 2001 Total responsibility for migrating a thirty-station Novell two site LAN to a new Compaq Server utilizing Microsoft Windows 2000 Server and infrastructure and customer communications, and training. Contract position

Process Technician - Wheaton Plastics Operations

Operation and Maintenance - 1998 to December 2000 of 20-injection blow and 1 stretch blow-molding machines including support and packaging equipment. Responsible for production, quality and customer requirements.

Molding Supervisor

Granville Plastics - 1995 to 1998 Supervising and training technical support staff for 25 Custom injection molding and packaging lines. Training and implementation of Safety, ISO 9000, TQM and GMP procedures.

Molding Supervisor

Tenax/Bespak - 1993 to 1995 Training of technical support staff for 20 injection machines and molds. Training and enforcement of FDA GMP requirements, Safety, writing, training ISO 9000 procedures, SOPs and GMPs.

Operations Consultant

Revlon Inc - 1993 to 1993 Development of procedures for training, machinery, safety, and operations for the blow molding, high-speed decorating and packaging departments. Six month Contract position.

Production Manager

Creative Printworks, Inc - 1989 to 1993 Responsible for staff of skilled craftsmen, inspection, quality control, and plant maintenance for specialized printing of Polycarbonate machine panels, bar codes and flexography generated labels.

Department Supervisor

Advanced Components Manufacturing Company - 1984 to 1989 Supervision and production of high speed plastic blow molding and silk screening equipment, maintenance and quality control and supervision of other department personnel.

Production Supervisor

Hoover Universal Corp. and Amoco Container Corp and Coca Cola of Oklahoma - 1973 to 1984 Assisted with the development of the PET Beverage Bottle from initial prototype to standard manufacturing processes, equipment and quality standards resulting in the PET Bottle replacing Glass Bottles as the cost effective product of choice.

EDUCATION

Certification in CompTia A+ and Network+

Nash Community College 2001 to 2002

CERTIFICATIONS

CompTia A+

January 2001 to Present Computer Maintenance and Repair

CompTia Network+

January 2002 to Present Networking Basics

ADDITIONAL INFORMATION * Train the Trainer for Lean C I Teams which reduced downtime, scrap and increased safety for a major elastomeric rubber closed cell insulation manufacturer. * Taught Adult Community College students preparing for the CompTia A+ Certification Core Hardware and OS exams. Responsible for curriculum, material and lesson plans. * Facilitator for a T.Q.M. team that developed, wrote, and taught procedures to insure compliance with FDA clean room regulations and as a member of a T.Q.M. team developed and taught procedures per ISO 9000 standards resulting in certification. * As an Operations Consultant issued recommendations for the development and training of GMP procedures; equipment maintenance; safety, and production methods for the Blow Molding and high speed Container Decorating Departments for a Fortune 49 Cosmetics Manufacturer. * Developed GMPs and Quality Improvement Cycles to develop and train a team of skilled craftsmen [Printers and Die Cutters] for an OEM Membrane Switch Manufacturer resulting in the company being bought by a much larger competitor. * Assisted in the start-up of five injection, injection/blow and blow molding operations, including the development of GMP, Safety, Quality and Training procedures. * Assisted in the development of the first PET beverage bottle, including manufacturing processes, production, equipment, safety, quality standards, procedures, and training.

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Journey To Lean Continuous Improvement Supported byDocument12 pagesJourney To Lean Continuous Improvement Supported byprabhatchandra15Pas encore d'évaluation

- Extractive Metallurgy of Niobium PDFDocument2 pagesExtractive Metallurgy of Niobium PDFMarquise0% (1)

- Anti-Yellowing Inhibitor (Phenolic Yellowing)Document2 pagesAnti-Yellowing Inhibitor (Phenolic Yellowing)TrinhTruongPas encore d'évaluation

- Ct-Prephd - PDF Rrh-Prephd - PDF Rsmethod PDFDocument6 pagesCt-Prephd - PDF Rrh-Prephd - PDF Rsmethod PDFIkoka RiderPas encore d'évaluation

- BS 5750-8 Guide To Quality ManagementDocument28 pagesBS 5750-8 Guide To Quality Managementmythee100% (1)

- Project Monitoring and Control Expediting PDFDocument5 pagesProject Monitoring and Control Expediting PDFRebecca MariamPas encore d'évaluation

- Kotler Pom CW PPT Exp Ch13Document15 pagesKotler Pom CW PPT Exp Ch13uldsPas encore d'évaluation

- Helical Gearbox InstallationDocument8 pagesHelical Gearbox InstallationKUNALJAYPas encore d'évaluation

- Indonesia A&d IndustryDocument19 pagesIndonesia A&d Industrymy_new_diaryPas encore d'évaluation

- Roof Repair ProposalDocument17 pagesRoof Repair ProposalDen PaijoPas encore d'évaluation

- V4i DatasheetDocument2 pagesV4i DatasheetRyanK7686Pas encore d'évaluation

- ESAB Electrodes User ManualDocument44 pagesESAB Electrodes User ManualF. Alijani100% (1)

- 4S-02 02Document11 pages4S-02 02Claudio Hernández PobletePas encore d'évaluation

- WMBD Background of VoltasDocument2 pagesWMBD Background of VoltaschetnagawadePas encore d'évaluation

- Technical Data Sheet DECODALLEDocument2 pagesTechnical Data Sheet DECODALLEMaría Isabel CevallosPas encore d'évaluation

- Digimat To Abaqus AbaqusDocument2 pagesDigimat To Abaqus Abaqusdarebusi1100% (1)

- Brazilian Certification System For NDT and Welding InspectorsDocument4 pagesBrazilian Certification System For NDT and Welding Inspectorsjoaovitorsp_spPas encore d'évaluation

- Nist Handbook 105-1Document14 pagesNist Handbook 105-1Diego TobrPas encore d'évaluation

- Creusabro 4800Document8 pagesCreusabro 4800ravigurajapuPas encore d'évaluation

- MicroSoft Office Packages: Practical QuestionsDocument112 pagesMicroSoft Office Packages: Practical QuestionsMakaha Rutendo84% (69)

- Company ProfileDocument3 pagesCompany ProfileKoventhan RaviPas encore d'évaluation

- Manpower & Equipment ScheduleDocument1 pageManpower & Equipment ScheduleColitz D. KhenPas encore d'évaluation

- Sheet Metal FormingDocument4 pagesSheet Metal FormingYared AbebePas encore d'évaluation

- Business Development Manager Sample CVDocument3 pagesBusiness Development Manager Sample CVArnab100% (1)

- BackDocument19 pagesBackjadePas encore d'évaluation

- Oee PDFDocument5 pagesOee PDFsdvikkiPas encore d'évaluation

- Auckland Transport Material SpecificationsDocument190 pagesAuckland Transport Material SpecificationsBobNobbitsPas encore d'évaluation

- Deuterium Lamps PdfpricelistDocument16 pagesDeuterium Lamps PdfpricelistAnggun Teh PamegetPas encore d'évaluation

- Mivan DetailDocument57 pagesMivan DetailtapankumardasPas encore d'évaluation

- Lean Vs Six SigmaDocument23 pagesLean Vs Six SigmaTrichy MaheshPas encore d'évaluation