Académique Documents

Professionnel Documents

Culture Documents

Damper NFPA Code

Transféré par

Nedunuri.Madhav MurthyCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Damper NFPA Code

Transféré par

Nedunuri.Madhav MurthyDroits d'auteur :

Formats disponibles

YOURE SAFE WITH US

8 OUT OF 10 non-healthcare facilities have NOT inspected their dampers

*

do you know what the nfpa code is to test and repair fire and smoke dampers? nfpa 80 states that:

19.4.1 each damper shall be tested and inspected 1 year after installation. 19.4.1.1 the test and inspection frequency shall then be every 4 years, except in hospitals where the frequency shall then be every 6 years. 19.4.4 If the damper is equipped with a fusible link, the link shall be removed for testing to ensure full closure and lock-in-place if so equipped. 19.4.5 The operational test of the damper shall verify that there is no damper interference due to rusted, bent, misaligned, or damaged frame or blades, or defective hinges or other moving parts. 19.4.8 The fusible link shall be reinstalled after testing is complete. 19.4.9 All inspections and testing shall be documented indicating the location of the fire damper or combination fire/smoke damper, date of inspection, name of inspector, and deficiencies discovered. 19.4.10 All documentation shall be maintained and made available for review by the AHJ.

nfpa 105 states that:

6.5.1 smoke dampers for dedicated and non-dedicated smoke control systems shall be inspected and tested in accordance with NFPA 92A, Standard for Smoke-Control Systems Utilizing Barriers and Pressure Differences. 6.5.2 each damper shall be tested and inspected one year after installation. the test and inspection frequency shall then be every 4 years, except in hospitals, where the frequency shall be every 6 years. 6.5.5 The damper shall be actuated and cycled as part of the associated smoke detector testing in accordance with NFPA 72, National Fire Alarm Code. Where a fusible link is installed on a combination fire/smoke damper, the fusible link shall be removed for testing the damper for full closure simulating a fire condition per the requirements and frequencies of 19.5.4 of NFPA 80, Standard for Fire Doors and Other Opening Protectives. 6.5.6 The test shall be conducted with normal HVAC airflow. 6.5.7 The operation of the damper shall verify that there is no damper interference due to rust or bent, misaligned, or damaged frame or blades, or defective hinges or other moving parts. 6.5.10 The fusible link shall be reinstalled after testing is complete, If the link is damaged or painted, it shall be replaced with a link of the same size, temperature rating, and load rating. 6.5.11 All inspections and testing shall be documented indicating the location of the damper, date of inspection, name of inspector, and deficiencies discovered. The documentation shall have a space to indicate when and how the deficiencies were corrected 6.5.12 All documentation shall be maintained by the property owner and available for review by the authority having jurisdiction

* Deficiencies compiled from LSS Life Safety Services data

TOLL FREE 1-888-675-4519 FAX 1-502-964-1337 EMAIL: INFO@LIFESAFETYSERVICES.COM

WWW.LIFESAFET YSERVICES.COM

YOURE SAFE WITH US

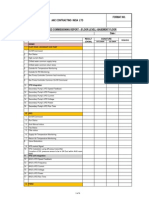

top ten fire and smoke damper deficiencies

Top Fire and Smoke Damper Deficiencies

1. 2. 3. 4. 5. Inoperable Actuator No Power to Actuator No Power Wired to Actuator No Air to Actuator No Airline to Actuator 6. Not Enough Air to Actuator 7. Screw in track 8. Linkage out of Alignment or Broken 9. Bound in tracks (racking) 10. Damper rusted

Approximately 10% of dampers fail during inspection

damper type: fire damper deficiency: damper rusted open

damper type: fire damper deficiency: damper being held open by metal and mastic gluing damper open and blocking tracks

damper type: fire damper deficiency: no actuator for damper

damper type: fire damper deficiency: damper wired open

TOLL FREE 1-888-675-4519 FAX 1-502-964-1337 EMAIL: INFO@LIFESAFETYSERVICES.COM

WWW.LIFESAFET YSERVICES.COM

Vous aimerez peut-être aussi

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- 1B 2 1 Types Fire PumpsDocument25 pages1B 2 1 Types Fire Pumpsharoub_nasPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5795)

- 02-Construction Manager Civil BuildingsDocument2 pages02-Construction Manager Civil BuildingsNedunuri.Madhav MurthyPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Answer Key of Revision Worksheet TA-2Document6 pagesAnswer Key of Revision Worksheet TA-2Nedunuri.Madhav MurthyPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Toilet No 15MM 20MM 15Mm Insulation T1 T2 T3 T4 T5 T6 T7 T8 T9 T10 T11 T12 T13 T14 T15 T16 Actual Rate of Each Toilet From Old MeasurementDocument1 pageToilet No 15MM 20MM 15Mm Insulation T1 T2 T3 T4 T5 T6 T7 T8 T9 T10 T11 T12 T13 T14 T15 T16 Actual Rate of Each Toilet From Old MeasurementNedunuri.Madhav MurthyPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Dongre Associates Balance Work/snag List 10th Floor: Tower QC 2, Gift CityDocument6 pagesDongre Associates Balance Work/snag List 10th Floor: Tower QC 2, Gift CityNedunuri.Madhav MurthyPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Accoustic Results SummaryDocument1 pageAccoustic Results SummaryNedunuri.Madhav MurthyPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Draft Letter - High RiseDocument1 pageDraft Letter - High RiseNedunuri.Madhav MurthyPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- ETA SummeryDocument1 pageETA SummeryNedunuri.Madhav Murthy100% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Balance Works Planning-Qc2Document2 pagesBalance Works Planning-Qc2Nedunuri.Madhav MurthyPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Order Details: Order ID: SAP14050587113 Order Date: Mon 5th May 2014 12:26pmDocument1 pageOrder Details: Order ID: SAP14050587113 Order Date: Mon 5th May 2014 12:26pmNedunuri.Madhav MurthyPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- BMT Check List - XLSXDocument6 pagesBMT Check List - XLSXNedunuri.Madhav MurthyPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- MOM of MEP Meeting 16 11 2012 - XLSXDocument2 pagesMOM of MEP Meeting 16 11 2012 - XLSXNedunuri.Madhav MurthyPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- 18th Floor Snag ListDocument1 page18th Floor Snag ListNedunuri.Madhav MurthyPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Response by ETA Response by HAIL Response by ANCDocument14 pagesResponse by ETA Response by HAIL Response by ANCNedunuri.Madhav MurthyPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- BMS IO Summary For QC2 R1 20.02.2013Document9 pagesBMS IO Summary For QC2 R1 20.02.2013Nedunuri.Madhav Murthy100% (2)

- Madhava ResumeDocument5 pagesMadhava ResumeNedunuri.Madhav MurthyPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Trane Chiller CatalogoDocument2 pagesTrane Chiller CatalogojcqadrosPas encore d'évaluation

- HP Operations Orchestration: Concepts GuideDocument25 pagesHP Operations Orchestration: Concepts Guidejhf281192Pas encore d'évaluation

- Project Automation IndustryDocument94 pagesProject Automation Industryleaking_brainsPas encore d'évaluation

- Viko Genel Katalog EN PDFDocument200 pagesViko Genel Katalog EN PDFManvitha GPas encore d'évaluation

- Posteriop4ir - Stara2022 07 04Document1 pagePosteriop4ir - Stara2022 07 04Jakub PękPas encore d'évaluation

- Hariom AutomationDocument25 pagesHariom AutomationTecky Pan YadPas encore d'évaluation

- A Project On Management of Theja FortDocument29 pagesA Project On Management of Theja FortShahjahanPas encore d'évaluation

- Solar Powered Seed Planter Controlled by Using BluetoothDocument6 pagesSolar Powered Seed Planter Controlled by Using Bluetoothha2012ma2013Pas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- DUB Diagnostic Unit: Brake Diagnostics Through Function and Wear Analysis For Preventive MaintenanceDocument2 pagesDUB Diagnostic Unit: Brake Diagnostics Through Function and Wear Analysis For Preventive MaintenancemeganPas encore d'évaluation

- Scanner de Segurança PDFDocument108 pagesScanner de Segurança PDFThiago BortolozzoPas encore d'évaluation

- 3 - Bharadiya2532023JERR100807Document20 pages3 - Bharadiya2532023JERR100807Ing Edwin Alarcon MarquezPas encore d'évaluation

- MOD Acronyms and Abbreviations PDFDocument402 pagesMOD Acronyms and Abbreviations PDFnileshranePas encore d'évaluation

- Bicol University College of Science Capstone 1Document3 pagesBicol University College of Science Capstone 1Vince DabucolPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- 09-Ap 1Document5 pages09-Ap 1mostafaabdelrazikPas encore d'évaluation

- Refrigrator WorkingDocument6 pagesRefrigrator WorkingNagendra PalPas encore d'évaluation

- 42wkn 1pdDocument16 pages42wkn 1pdClaudiaFerrioliPas encore d'évaluation

- The Pulse of Automation: Ultrasonics by Pepperl+FuchsDocument70 pagesThe Pulse of Automation: Ultrasonics by Pepperl+FuchspallinalvitesPas encore d'évaluation

- Desigo™ PX: Building TechnologiesDocument12 pagesDesigo™ PX: Building Technologieskev YPas encore d'évaluation

- Red Stack Attack! Algorithms, Capital and The Automation of The Common - Tiziana Terranova (2014)Document9 pagesRed Stack Attack! Algorithms, Capital and The Automation of The Common - Tiziana Terranova (2014)didadosPas encore d'évaluation

- Refrigeration and Air ConditioningDocument52 pagesRefrigeration and Air ConditioningYashawantha Gowda100% (1)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Analisa Kebutuhan Make Up Water Cooling Tower Rsg-Gas Pada Daya 30 MW Setelah RevitalisasiDocument7 pagesAnalisa Kebutuhan Make Up Water Cooling Tower Rsg-Gas Pada Daya 30 MW Setelah RevitalisasiArin pashadiera mellinaPas encore d'évaluation

- Desigo Building Automation System 6.0 SPDocument416 pagesDesigo Building Automation System 6.0 SPnaveedfndPas encore d'évaluation

- Exercise 4Document3 pagesExercise 4Sreeprada ChowduruPas encore d'évaluation

- Is Technology Our FriendDocument3 pagesIs Technology Our FriendSuryasree BhattacharyyaPas encore d'évaluation

- SAP IBP Product Roadmap February 2019Document52 pagesSAP IBP Product Roadmap February 2019vishnuPas encore d'évaluation

- Accenture Tech Vision 2021 Full ReportDocument107 pagesAccenture Tech Vision 2021 Full ReportKevin HanleyPas encore d'évaluation

- Cyber Security in Industrial AutomationDocument113 pagesCyber Security in Industrial Automationchandra100% (2)

- Untitled-1 - Mumbai-Expo-BROCHURE-2024Document4 pagesUntitled-1 - Mumbai-Expo-BROCHURE-2024nikhil indoreinfolinePas encore d'évaluation

- Natural Evaporative CoolingDocument5 pagesNatural Evaporative CoolingCM SoongPas encore d'évaluation

- rth2510b1000 U 7 Day Programmable Thermostat PDFDocument52 pagesrth2510b1000 U 7 Day Programmable Thermostat PDFtarik859Pas encore d'évaluation

- Real Life: Construction Management Guide from A-ZD'EverandReal Life: Construction Management Guide from A-ZÉvaluation : 4.5 sur 5 étoiles4.5/5 (4)

- Bulk Material Handling: Practical Guidance for Mechanical EngineersD'EverandBulk Material Handling: Practical Guidance for Mechanical EngineersÉvaluation : 5 sur 5 étoiles5/5 (1)