Académique Documents

Professionnel Documents

Culture Documents

Life Saving Composite Lamp Posts

Transféré par

Matthew TurnerTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Life Saving Composite Lamp Posts

Transféré par

Matthew TurnerDroits d'auteur :

Formats disponibles

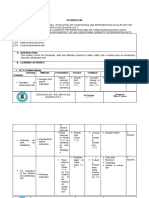

Performance engineering

Saving lives with

safer lamp posts

Collisions with steel or concrete lamp posts account for

nearly 100 deaths and more than 800 injuries annually in the

UK. Eureka project E! 2534 Thermopole, led by UK company

Euro-Projects Ltd, has developed a safer, energy-absorbing

and maintenance-free alternative which promises to

significantly reduce this carnage.

A conventional lamp post made of glass fibres to form hollow shapes that

concrete or galvanised steel acts like a are stronger than steel, faster to produce

cheese-cutter when hit at high speed, and more environmentally friendly. The

cutting a car in half and invariably killing result is a lamp post or column which not

or seriously injuring the occupants. The only withstands the full force of the

team of British, Danish, German and elements but crumples or, thanks to a

Canadian companies collaborating on strategically placed access hatch, hinges

Eureka project Thermopole set out to when a car hits it, absorbing the impact.

develop a safer alternative which would Led by Euro-Projects Ltd from

be capable of absorbing much of the Rothley, near Leicester, specialists in the

force of a crash and save the car’s development and processing of

occupants from the full impact. thermoplastic composite materials and

The Thermopole lamp post is made processes, the team researched,

from glass fibre reinforced thermoplastic developed and tested a number of

composite materials; the thermoplastic technological developments ranging from

composites are solid at room new jointing techniques to specialist

temperature but melt on heating, and can software for designing fibre preforms

be moulded and remoulded around the that taper in length and vary in thickness.

14 www.globalwatchservice.com JUNE 2005

Performance engineering

‘Nine lives were saved economies of scale as the production the dye is released and can be spotted

process continues to be refined and the as an engineer drives past.’

following four serious crashes

fact that they are maintenance-free and Given the global nature of the

at a pilot site testing one of last twice as long as conventional concept, which Euro-Projects is also

the earlier prototype columns. columns, and it becomes evident that the applying to wide-based street signs,

We’ve had a car hitting one of initial investment soon starts paying off. utility poles and traffic lights, the

potential rewards are considerable. There

our composite poles at 90

Easy to replace are 6.5 million lamp posts in the UK

miles an hour and the driver Also, when council highways alone, for example, of which 200,000-

walked away from the crash’ departments install steel columns, health 300,000 columns annually need

and safety regulations dictate that a replacing or refurbishing, representing 2-

Gerry Boyce

Euro-Projects Ltd protective barrier is placed in front of 2.5 percent of the overall market. To

them, or that they are positioned further market the column, the company has

from the roadside and therefore need to teamed up with Newark,

The Thermopole column has a number be taller. Composite columns, on the Nottinghamshire-based Poletech

of key advantages over the conventional other hand, being ‘passively safe’, can be Systems Limited, manufacturer of the

steel or concrete column. Its greater positioned close to the road without a ground units into which columns are

strength enables it to take the full force of protective barrier, representing a inserted. ‘Without Eureka’s support and

high winds and vehicular impacts, and it is measurable cost saving. Being funding we would not have got as far as

also corrosion-resistant - unlike steel remarkably light, they are also cheaper to we have, and in the time we have,’ says

columns for example, which are easily transport and install, and if a column is Gerry Boyce.

corroded by road salts and dog’s urine. The knocked down it is very easy to unclip

column is fully recyclable at the end of its and replace it.

lifetime – potentially 40-50 years, compared ‘The composite column has already ‘Eureka endorsement has

with a traditional column’s 10-25 years – proved itself a lifesaver,’ says Gerry enabled us to partner with

and as its method of manufacture doesn’t Boyce, Director of Euro-Projects. ‘Nine three key companies from

require the use of solvent-based resins, it lives were saved following four serious

Europe and Canada to bring

also meets strict European directives for crashes at a pilot site testing one of the

reduction in solvent emissions. earlier prototype columns. We’ve had a our skills together and take

Composite columns are currently car hitting one of our composite poles at forward a technology which we

more expensive to produce than 90 miles an hour and the driver walked know will save many lives’

traditional columns. However, factor in away from the crash.’

Gerry Boyce

Euro-Projects Ltd

Low-cost inspection

One interesting issue raised by

maintenance engineers has formed the Further information

basis of a new project under the DTI

Technology Programme which comprises For further information about project

a consortium of eight companies. ‘If a Thermopole, please contact Gerry Boyce,

car hits a composite column at low Director, Euro-Projects Ltd

speed and then drives off, maintenance t: 0116 237 6693

engineers need to know if the column e: g.boyce@europrojects.co.uk

has been damaged,’ says Gerry Boyce. www.europrojects.co.uk

‘A steel or concrete column will have a

dent or the paint will be chipped, while a For further information about Eureka,

composite pole may have internal the European collaborative R&D scheme,

damage which isn’t obvious externally, please contact Robert Cameron,

but which may compromise its DTI Eureka Unit

resistance to the wind or another impact. t: 0207 215 1707

So we’ve put together a project to e: robert.cameron@dti.gsi.gov.uk

develop a low-cost inspection technique

based on ‘bruisable composites’, which For information about the DTI

involves applying an outer coating which Technology Programme, please visit

contains a dye. If a car hits the column www.dti.gov.uk/technologyprogramme

JUNE 2005 www.globalwatchservice.com 15

Vous aimerez peut-être aussi

- Essentials For A Good Night'S Sleep: Mattresses, Duvets and PillowsDocument4 pagesEssentials For A Good Night'S Sleep: Mattresses, Duvets and PillowselizondomaruPas encore d'évaluation

- A Comprehensive Guide to Composites: Processes & Procedures from the ProfessionalsD'EverandA Comprehensive Guide to Composites: Processes & Procedures from the ProfessionalsÉvaluation : 5 sur 5 étoiles5/5 (2)

- Brochure Combined Wall Systems - 2019 - Digital - SingleDocument40 pagesBrochure Combined Wall Systems - 2019 - Digital - SinglelazcanoPas encore d'évaluation

- Solutions For The Protection of Offshore Wind Farm CablingDocument6 pagesSolutions For The Protection of Offshore Wind Farm CablingJACK100% (1)

- Keller Phi - 1000 12E - Retaining Structures PDFDocument16 pagesKeller Phi - 1000 12E - Retaining Structures PDFluisPas encore d'évaluation

- CAT SealsDocument40 pagesCAT SealsMohammed NiyamatullahPas encore d'évaluation

- L P - The Dear Departed-Drama-10thDocument5 pagesL P - The Dear Departed-Drama-10thVritika Shorie100% (2)

- Principles of Curtain WallingDocument16 pagesPrinciples of Curtain Wallingjewon100% (1)

- EML3500 CH 8 SlidesDocument134 pagesEML3500 CH 8 SlidesGanesh Dongre100% (1)

- Vietnam ProjosDocument271 pagesVietnam Projosjbart252Pas encore d'évaluation

- Arcelor Mittal - Bridges PDFDocument52 pagesArcelor Mittal - Bridges PDFShamaPas encore d'évaluation

- Comflor Composite Floor Deck Brochure UK PDFDocument92 pagesComflor Composite Floor Deck Brochure UK PDFducke100% (1)

- WavePro LT Busway GE CatalogDocument40 pagesWavePro LT Busway GE CatalogWei Jiang NgPas encore d'évaluation

- MVVNL RGGVY Approved Vendor List: S.NO. Name of Material Vendor Name AddressDocument10 pagesMVVNL RGGVY Approved Vendor List: S.NO. Name of Material Vendor Name AddressELMEF LaboratoryPas encore d'évaluation

- Case - Study On Recruitment and SelectionDocument29 pagesCase - Study On Recruitment and SelectionDonasian Mbonea Elisante Mjema100% (1)

- EcoCast BrochureDocument4 pagesEcoCast BrochurePeterLOW0218Pas encore d'évaluation

- JPCL Transpipe EbookDocument82 pagesJPCL Transpipe Ebookvincent.w.stone6724Pas encore d'évaluation

- Introduction To Sea & Land ProjectsDocument40 pagesIntroduction To Sea & Land ProjectsbjlozadaPas encore d'évaluation

- Side Sealing Machine Operation GuideDocument30 pagesSide Sealing Machine Operation GuideRocio GimenezPas encore d'évaluation

- ComFlor Manual PDFDocument92 pagesComFlor Manual PDFSofija KekezPas encore d'évaluation

- Kotler Mm15e Inppt 22Document28 pagesKotler Mm15e Inppt 22SHAKTI KARPas encore d'évaluation

- Stirling Lloyd - Tunnels BrochureDocument8 pagesStirling Lloyd - Tunnels BrochureRaul Radu100% (1)

- Bridges: With Rolled SectionsDocument52 pagesBridges: With Rolled SectionsFRANCISCO CUBA H.Pas encore d'évaluation

- MB Concrete Solutions Wind Towers Nov10Document12 pagesMB Concrete Solutions Wind Towers Nov10jeovanPas encore d'évaluation

- 2013 Glasby-Earth Friendly Concrete - A Sustainable Option For Tunnels Requiring High DurabilityDocument11 pages2013 Glasby-Earth Friendly Concrete - A Sustainable Option For Tunnels Requiring High DurabilityChi ĐặngPas encore d'évaluation

- 001CorrosionArticleAntiCorrosionTechWEIQ PDFDocument3 pages001CorrosionArticleAntiCorrosionTechWEIQ PDFJACK100% (1)

- 2021 JEC Composites Innovation Awards Finalists 2021JUNE02Document31 pages2021 JEC Composites Innovation Awards Finalists 2021JUNE02Kang HsiehPas encore d'évaluation

- Lightweight Composite Monocoque Heavy Goods Vehicle TrailerDocument4 pagesLightweight Composite Monocoque Heavy Goods Vehicle TrailerMatthew TurnerPas encore d'évaluation

- OSNA10 Sheathing MTL Group EN 2019Document6 pagesOSNA10 Sheathing MTL Group EN 2019David RobsonPas encore d'évaluation

- Key Apps UtilitiesDocument12 pagesKey Apps UtilitiesDamodharan Chandran100% (1)

- Port of Great Yarmouth - Heavy Duty Concrete Block PavementsDocument4 pagesPort of Great Yarmouth - Heavy Duty Concrete Block Pavementsamir365Pas encore d'évaluation

- Monocoque ThesisDocument5 pagesMonocoque Thesisaflpaftaofqtoa100% (2)

- Intergard 343 - Marine CoatingsDocument9 pagesIntergard 343 - Marine CoatingsSerggie TabanaoPas encore d'évaluation

- Trimapanel® Brochure PDFDocument36 pagesTrimapanel® Brochure PDFyasserPas encore d'évaluation

- Insulated FormworkDocument2 pagesInsulated FormworkhimanshuPas encore d'évaluation

- Low Carbon Lining For Tunnelling Precast Segment - How Dramix® Fibre Reinforced Concrete Could Facilitate This AchievementDocument8 pagesLow Carbon Lining For Tunnelling Precast Segment - How Dramix® Fibre Reinforced Concrete Could Facilitate This AchievementDeyuan GuoPas encore d'évaluation

- Friction Stir Welding For Railway Rolling StockDocument8 pagesFriction Stir Welding For Railway Rolling StockHandri YantoPas encore d'évaluation

- Pressrelease CTE Wind Bilbao 2022Document6 pagesPressrelease CTE Wind Bilbao 2022basemPas encore d'évaluation

- Pam Spec Guide Intro Overview SectionDocument11 pagesPam Spec Guide Intro Overview Sectiondurrant bilankuluPas encore d'évaluation

- Grace Strux Beton PDFDocument33 pagesGrace Strux Beton PDFmpilgirPas encore d'évaluation

- 8 - SOG Company Profile - 2018Document3 pages8 - SOG Company Profile - 2018Masood KhanPas encore d'évaluation

- Development of FRP Composites in Building ConstructionDocument11 pagesDevelopment of FRP Composites in Building ConstructionSingletonicPas encore d'évaluation

- Factory PanelformDocument1 pageFactory PanelformMatthew TurnerPas encore d'évaluation

- Svetsaren 1 2009Document72 pagesSvetsaren 1 2009João Diego FeitosaPas encore d'évaluation

- EPS System CVL Reference DocumentDocument6 pagesEPS System CVL Reference DocumentAnil KumarPas encore d'évaluation

- Fulltext01 PDFDocument105 pagesFulltext01 PDFPrasen ChaudhariPas encore d'évaluation

- EcoShield VpCI 380 PRDocument3 pagesEcoShield VpCI 380 PRdalt.guniPas encore d'évaluation

- RELIX BrochureDocument20 pagesRELIX BrochureAlpesh ValaPas encore d'évaluation

- C: T F F: Orrosion AND Abrasion HE Inal RontierDocument3 pagesC: T F F: Orrosion AND Abrasion HE Inal Rontier1977julPas encore d'évaluation

- Pre - Cast Concrete-Designer Perspective Including Customisation of Design by Shri Alok BhowmickDocument28 pagesPre - Cast Concrete-Designer Perspective Including Customisation of Design by Shri Alok BhowmickSreekanth SattirajuPas encore d'évaluation

- Creating Economic Value in The Supply ChainDocument36 pagesCreating Economic Value in The Supply ChainimetallurgyPas encore d'évaluation

- Sika-Trocal Single Ply RoofingDocument12 pagesSika-Trocal Single Ply Roofingp2pnow2005Pas encore d'évaluation

- BGLDocument4 pagesBGLjulioalexcmPas encore d'évaluation

- An Innovative Solution For Small Span Bridges - Precobeam: June 2014Document13 pagesAn Innovative Solution For Small Span Bridges - Precobeam: June 2014Miguel Angel Contreras OrtizPas encore d'évaluation

- Contemporary Building MaterialsDocument23 pagesContemporary Building MaterialsShif renPas encore d'évaluation

- Indonesia-PT Apora Indusma An Experience of Holding IPR in A Market With Fierce CompetitionDocument7 pagesIndonesia-PT Apora Indusma An Experience of Holding IPR in A Market With Fierce CompetitionALANKARPas encore d'évaluation

- Literature Review Fly Ash BricksDocument7 pagesLiterature Review Fly Ash Bricksafdtbflry100% (1)

- Bridges Brochure Nov 2022Document11 pagesBridges Brochure Nov 2022Jim XUPas encore d'évaluation

- Research Paper On Eot CraneDocument4 pagesResearch Paper On Eot Craneadyjzcund100% (1)

- Tuerk PERE ProsthesisDocument12 pagesTuerk PERE ProsthesisHua Hidari YangPas encore d'évaluation

- Final Year Project TopicsDocument41 pagesFinal Year Project TopicsJulia MichalowPas encore d'évaluation

- Current Trends and Industrial Applications of Polymer CompositesDocument85 pagesCurrent Trends and Industrial Applications of Polymer CompositesSampath PSPas encore d'évaluation

- Atritor Fly Ash LeafletDocument2 pagesAtritor Fly Ash LeafletnmarquesPas encore d'évaluation

- Steel Structures Design Based on Eurocode 3D'EverandSteel Structures Design Based on Eurocode 3Évaluation : 3 sur 5 étoiles3/5 (1)

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965D'EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Pas encore d'évaluation

- Annulus - Second Moment of Area and Cantilever Beam StressDocument1 pageAnnulus - Second Moment of Area and Cantilever Beam StressMatthew TurnerPas encore d'évaluation

- Factory PanelformDocument1 pageFactory PanelformMatthew TurnerPas encore d'évaluation

- Factory PanelformDocument1 pageFactory PanelformMatthew TurnerPas encore d'évaluation

- Factory PanelformDocument1 pageFactory PanelformMatthew TurnerPas encore d'évaluation

- Suzuki 660 K6aDocument88 pagesSuzuki 660 K6aJames Wayne BarkerPas encore d'évaluation

- Session Plan (Julaps)Document10 pagesSession Plan (Julaps)Wiljhon Espinola JulapongPas encore d'évaluation

- 81/253/INF For IEC Use Only 2004-08-27 International Electrotechnical Commission Technical Committee No. 81: Lightning ProtectionDocument3 pages81/253/INF For IEC Use Only 2004-08-27 International Electrotechnical Commission Technical Committee No. 81: Lightning ProtectionAndres Felipe Muñoz APas encore d'évaluation

- Negotiation - Course Outline APR17Document8 pagesNegotiation - Course Outline APR17ravindrarao_mPas encore d'évaluation

- Healthbox - Mairi Johnson - HANDI at EHI Live - Nov 2013Document18 pagesHealthbox - Mairi Johnson - HANDI at EHI Live - Nov 2013EwanDavisPas encore d'évaluation

- Ligaya NG Buhay EnsembleDocument2 pagesLigaya NG Buhay EnsembleFrinzess VelascoPas encore d'évaluation

- Kawasaki 4 Cylinder Hyperpack Installation ManualDocument8 pagesKawasaki 4 Cylinder Hyperpack Installation ManualJuan Carlos RojasPas encore d'évaluation

- Pasundan United FC - Anggaran Dasar Dan Rumah Tangga Pasundan United FCDocument1 231 pagesPasundan United FC - Anggaran Dasar Dan Rumah Tangga Pasundan United FCdondo lambaPas encore d'évaluation

- PSR 640Document188 pagesPSR 640fer_12_328307Pas encore d'évaluation

- Utmost TFT Training Part1Document96 pagesUtmost TFT Training Part1gideontargrave7Pas encore d'évaluation

- Libro Desarrollo Organizacional Xady Nieto - AntiCopy - CompressedDocument190 pagesLibro Desarrollo Organizacional Xady Nieto - AntiCopy - Compressedleandro cazarPas encore d'évaluation

- Anderson PDFDocument7 pagesAnderson PDFChristian MavarezPas encore d'évaluation

- Group 6 - Chapter 1 RevisedDocument15 pagesGroup 6 - Chapter 1 RevisedJAMES ELIJAH BALDERRAMAPas encore d'évaluation

- M.tech Lab Manual JNTUHDocument80 pagesM.tech Lab Manual JNTUHSivarama Prasad PamarthyPas encore d'évaluation

- Netsh Wlan Start HostednetworkDocument3 pagesNetsh Wlan Start HostednetworkM Nanda KumarPas encore d'évaluation

- Rate CardDocument1 pageRate CardSalvato HendraPas encore d'évaluation

- K2225 MosfetDocument7 pagesK2225 MosfetDavid Eduardo Drew PerezPas encore d'évaluation

- Example Problem Solutions - Chapter 8Document18 pagesExample Problem Solutions - Chapter 8Nguyen Tien DungPas encore d'évaluation

- First Law of ThermodynamicsDocument21 pagesFirst Law of ThermodynamicsMariam50% (2)

- 1 - Censorship Lesson Plan F451Document4 pages1 - Censorship Lesson Plan F451Julia MaturoPas encore d'évaluation

- Machine Design ME 314 Shaft DesignDocument14 pagesMachine Design ME 314 Shaft DesignMohammed AlryaniPas encore d'évaluation

- Liftformslabconstruction 160907075019 PDFDocument12 pagesLiftformslabconstruction 160907075019 PDFishikaPas encore d'évaluation