Académique Documents

Professionnel Documents

Culture Documents

Loading Test

Transféré par

Htet Mrak AungCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Loading Test

Transféré par

Htet Mrak AungDroits d'auteur :

Formats disponibles

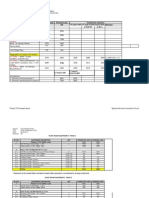

E - Load testing

1) Cable tray to IEC 61537 standard All TOLMEGA products are tested according to type 2 - Cable trays fixed onto supports - Uniformly distributed load - Deflection is measured at 3 points along the line midway between the supports and at right angles to the center of the tray.The 3 points measurements shall be under each edges or side beam and under the center. Load test -span pitch: 500 mm -Safe working load (SWL) is determined according to type 2 test instructions.

Results are selected according to : - the L/100 maximum deflection. - the 1.7 safety factor on the resistance while breaking. Usually deflection is < L/300 for cable trays and L/200 for wire mesh cable trays. Transversal deflection < L/20 for both cable trays and wire cable trays. For width > 200 mm, we recommend to fit a junction on the bottom of the cable trays.

L/2 Junction

A/B L L 0,4L

Tests are achieved with an L (or X) end span, an L middle span and a 0.4 L cantilever. SWL Safe Working Load / Span In compliance with the IEC 61537 standard, the manufacturer can select the load test type.

Manufacturers specifications Type I

Junctions are located anywhere on the routing

Comment

Results

This test includes an end span junction. However, a routing start SWL are inferior to the selected with usual 3 m length conventional cable trays, so there is never test. end span junction on site.This is an useless requirement. This is the usual application.There is never end span junction on site.This is the TOLMEGA selected test. This is an unusual on-site configuration, except for T-SCOPIC 4 m length cable trays in a 2 m span configuration: we recommend a L/5 junction: 400 mm to support for an easier installation. For conventional 3 m length cable trays, the manufacturer requires the installer to assemble the junctions on a 1,5 or 3 m span.This is not convenient on site at all, but the results are profitable. TOLMEGA selected test (50x150 mm steel wire cable trays and cable trays on span support 1,5 m). SWL are superior to the selected test : profitable results.

Type II

There must not have any junction on the end span Span must be equivalent or multiple to the standard length product and the junction location is specified.

Type III

Type IV Type V

Weak parts location onto the cable tray Specific products Span > 4 m Special cable ladders heavy duty applications 2) Cable tray to Nema VE 1-2002 All cable trays are subjected to loading to residual deflection (Method B) - Single beam span with free unrestrained ends - Uniformly distributed load - Vertical deflection measured on 3 points along the midway between the supports and the 3 points of measurement shall be under each side rail and at the centre of the tray. Load application - The residual deflection is measured according to 5.2.9.2 and 5.2.9.3 Sections after loading until the minimum test load minimum test load = 1,5 x L x w where 1,5 = safety factor L = span length (m) w = rated load (kg/m) - Historical load/span class designation.

Span (m) Load (kg/m) 37 67 74 97 112 149 179 299 2,4 3 3,7 4,9 6 D 20A 20B 20C

SWL Safe Working Load / Supports The IEC 61537 standard specifies that the SWL is the load limited by : The L/20 maximum deflection at the end of the bracket The 1.7 safety factor . SWL values : daN ( brackets) daN.m ( hanging systems) Bends /Supports

L

L/20

8A C 8B 8C D E

12A 12B 12C

16A 16B 16C

Vous aimerez peut-être aussi

- 500 Kva OFTC L-1 - 220920 - 124238Document3 pages500 Kva OFTC L-1 - 220920 - 124238rameshPas encore d'évaluation

- Trfo Voltage DropDocument16 pagesTrfo Voltage Dropshivvaram100% (1)

- EDS 06-0016 LV Network Earthing Design PDFDocument25 pagesEDS 06-0016 LV Network Earthing Design PDFRajendra Prasad ShuklaPas encore d'évaluation

- Emergency D.G. Sizing 16.11.07Document3 pagesEmergency D.G. Sizing 16.11.07mahesh_sali2003Pas encore d'évaluation

- Cable Tray Size CalculationDocument3 pagesCable Tray Size Calculationtsraj10Pas encore d'évaluation

- 33kv Indoor VCB 3 Panel Sets and 5 Panel SetsDocument88 pages33kv Indoor VCB 3 Panel Sets and 5 Panel SetsAssistant Engineer SCM XTPas encore d'évaluation

- Blue Star Catalogue 2018 ChillerDocument20 pagesBlue Star Catalogue 2018 Chiller3nadhPas encore d'évaluation

- Calculation of Back Pressure of Silencer: Item # Silencer Name of Item # Silencer Name of Model Model Model ModelDocument1 pageCalculation of Back Pressure of Silencer: Item # Silencer Name of Item # Silencer Name of Model Model Model Modeluntung_susiloPas encore d'évaluation

- Project TrackerDocument11 pagesProject TrackerVivek Singh ChouhanPas encore d'évaluation

- WORK SCHEDULE at Unit-3 Area: Paiton III Expansion Project Construction Contractor: Mitsui Co., LTD and TOA CorporationDocument10 pagesWORK SCHEDULE at Unit-3 Area: Paiton III Expansion Project Construction Contractor: Mitsui Co., LTD and TOA CorporationJosua Ferry ManurungPas encore d'évaluation

- Annexure E2 - Electrical Load Details-R3 - (09!09!2011)Document10 pagesAnnexure E2 - Electrical Load Details-R3 - (09!09!2011)vinesh_viswanathan_3Pas encore d'évaluation

- Tagging Philosophy For Junction Boxes, Panels & CablesDocument7 pagesTagging Philosophy For Junction Boxes, Panels & CablesKarthikPas encore d'évaluation

- Electrical Materials Sizing CalculationDocument3 pagesElectrical Materials Sizing CalculationTayebASherifPas encore d'évaluation

- COOPER B LINE - Cable Tray Selection - Choosing The Proper Support SpacingDocument2 pagesCOOPER B LINE - Cable Tray Selection - Choosing The Proper Support SpacingReginald D. De GuzmanPas encore d'évaluation

- Calculate Cable Size and Voltage Drop Electrical Notes Articles PDFDocument10 pagesCalculate Cable Size and Voltage Drop Electrical Notes Articles PDFKamugasha Kagonyera100% (1)

- Cable Size Calculation For LT & HT Motors - Electrical TechnologyDocument15 pagesCable Size Calculation For LT & HT Motors - Electrical TechnologySaneesh SJPas encore d'évaluation

- Sandwhich BusductDocument5 pagesSandwhich BusductHarmandeep Ahluwalia100% (1)

- A&H Meyer - Low Res PDFDocument36 pagesA&H Meyer - Low Res PDFAnonymous MDkp0hnb3lPas encore d'évaluation

- Technology Park Development Project, Islamabad Electrical Load Estimation (Phase-1-1)Document2 pagesTechnology Park Development Project, Islamabad Electrical Load Estimation (Phase-1-1)Asad KhanPas encore d'évaluation

- HT Cable Voltage Drop CalculationDocument9 pagesHT Cable Voltage Drop CalculationPaul Goh Yngwie100% (1)

- RVT ElectricalDocument42 pagesRVT ElectricalAbdelmoneimPas encore d'évaluation

- Masterclad SwitchgearDocument16 pagesMasterclad Switchgeareshscribd123Pas encore d'évaluation

- Eee Electrical Reference Standards Electrical Codes and StandardsDocument4 pagesEee Electrical Reference Standards Electrical Codes and StandardsXozanPas encore d'évaluation

- Cable Ladder TrayDocument24 pagesCable Ladder TrayrocketvtPas encore d'évaluation

- Calculate Cable Size and Voltage Drop - Electrical Notes & ArticlesDocument10 pagesCalculate Cable Size and Voltage Drop - Electrical Notes & ArticlesCastiel Arthur100% (1)

- RTCC Cable ScheduleDocument11 pagesRTCC Cable SchedulearafinPas encore d'évaluation

- Site Test Procedure and Report For Transformer: Commissioning FormDocument14 pagesSite Test Procedure and Report For Transformer: Commissioning Formimrankhan zPas encore d'évaluation

- Tce Consulting Engineers Limited Quality Assurance Compliance Report For Enquiry SpecificationsDocument2 pagesTce Consulting Engineers Limited Quality Assurance Compliance Report For Enquiry SpecificationsMathivanan AnbazhaganPas encore d'évaluation

- Phase Shifting TransformersDocument7 pagesPhase Shifting Transformerse06001Pas encore d'évaluation

- MV Switchgear 24kV PDFDocument4 pagesMV Switchgear 24kV PDFmira100% (1)

- 014 - CRT With OLTC - 2500 KVA - 33-0.433 KV - GODAVARI PROJECTS PRIVATE LIMITED - Dt. 13.04.2021Document4 pages014 - CRT With OLTC - 2500 KVA - 33-0.433 KV - GODAVARI PROJECTS PRIVATE LIMITED - Dt. 13.04.2021Ajay MedikondaPas encore d'évaluation

- Coordination With Other DepartmentDocument3 pagesCoordination With Other Departmentdanishsaifi2007Pas encore d'évaluation

- Electrical Engineering Portal Com Electrical Thumb Rules You Must Follow Part 1Document10 pagesElectrical Engineering Portal Com Electrical Thumb Rules You Must Follow Part 1m khPas encore d'évaluation

- Major ProjectDocument30 pagesMajor ProjectRakesh YadavPas encore d'évaluation

- BIM DiaLux SoftwareDocument17 pagesBIM DiaLux SoftwarenhatvpPas encore d'évaluation

- Electrical Design Course - R0Document11 pagesElectrical Design Course - R0Malik malikPas encore d'évaluation

- Instructions To Users: A Run 500 M Sq. MM 3 Allow V DropDocument26 pagesInstructions To Users: A Run 500 M Sq. MM 3 Allow V DropjjspencePas encore d'évaluation

- Panel Design & Calculate Size of Bus Bar: 20 CommentsDocument9 pagesPanel Design & Calculate Size of Bus Bar: 20 CommentspvamanPas encore d'évaluation

- General Notes On Cable TraysDocument5 pagesGeneral Notes On Cable TraysPeter AntonyPas encore d'évaluation

- 6.6kV CABLES Steady State Voltage DropDocument1 page6.6kV CABLES Steady State Voltage Dropmahesh_sali2003Pas encore d'évaluation

- Abb 1hc0075853-Revaa en Surge Arrester Polim-DDocument5 pagesAbb 1hc0075853-Revaa en Surge Arrester Polim-Drobert_rjcPas encore d'évaluation

- 04 Refer A Friend For A Job Email TemplateDocument1 page04 Refer A Friend For A Job Email TemplateJANKI PATELPas encore d'évaluation

- 000 EE 153 CAD For EEE PDFDocument35 pages000 EE 153 CAD For EEE PDFStampinusStephanoPas encore d'évaluation

- Cable Glands Selectin ChartDocument11 pagesCable Glands Selectin Chartcherif yahyaouiPas encore d'évaluation

- Cable Tray Selection 2Document7 pagesCable Tray Selection 2Mwp MadushankaPas encore d'évaluation

- DWG Cable Trench - 850x800Document1 pageDWG Cable Trench - 850x800Anshuman PandeyPas encore d'évaluation

- Ahp HT Load List Is-4-Dc-691-300-E002Document4 pagesAhp HT Load List Is-4-Dc-691-300-E002Rukma Goud ShakkariPas encore d'évaluation

- TB Cable TrayDocument275 pagesTB Cable Traycrazy devilPas encore d'évaluation

- 254624-400-SP-ELE-007-Rev C-FINALDocument37 pages254624-400-SP-ELE-007-Rev C-FINALEmma NuPas encore d'évaluation

- CV - Electrical Engineer-Design-VigneshDocument2 pagesCV - Electrical Engineer-Design-VigneshvigneshPas encore d'évaluation

- 6.6kV CABLES Starting Voltage DropDocument1 page6.6kV CABLES Starting Voltage Dropmahesh_sali2003Pas encore d'évaluation

- BS EvDocument2 pagesBS EvPradeesh Vijayan (v.prathi)Pas encore d'évaluation

- Electrical Sd-2020-2021-FinalDocument106 pagesElectrical Sd-2020-2021-Finalj11erryPas encore d'évaluation

- Schneider Power Control & Protection Products (Contactors) Pricelist 20.12.2013Document35 pagesSchneider Power Control & Protection Products (Contactors) Pricelist 20.12.2013Amit PatelPas encore d'évaluation

- HW-3514-OECDocument1 pageHW-3514-OECM.WAQAS MAZHERPas encore d'évaluation

- Cabelsizing Table Acceptable Running V Drop in % Acceptable Starting V Drop in %Document11 pagesCabelsizing Table Acceptable Running V Drop in % Acceptable Starting V Drop in %erkamlakar2234Pas encore d'évaluation

- 1-Conformite Aux Normes AnglaisDocument13 pages1-Conformite Aux Normes AnglaisJetn SrisuthumPas encore d'évaluation

- Multi-B Busduct FeaturesDocument30 pagesMulti-B Busduct FeaturesSourp VartanPas encore d'évaluation

- Electrical Power Transmission 4Document7 pagesElectrical Power Transmission 4FaisalSoPas encore d'évaluation

- Portland Bolt Bolt Torque ChartDocument6 pagesPortland Bolt Bolt Torque ChartHtet Mrak Aung100% (1)

- Phone Naing - KhineDocument301 pagesPhone Naing - KhineHtet Mrak Aung100% (2)

- Acto DCDocument20 pagesActo DCHtet Mrak AungPas encore d'évaluation

- 1 Technical Report: Customer: Royal GK Pte LTDDocument4 pages1 Technical Report: Customer: Royal GK Pte LTDHtet Mrak AungPas encore d'évaluation

- General Technical Report 05Document173 pagesGeneral Technical Report 05Htet Mrak AungPas encore d'évaluation

- General Technical Report 05Document173 pagesGeneral Technical Report 05Htet Mrak AungPas encore d'évaluation

- Sans 62444Document8 pagesSans 62444Htet Mrak AungPas encore d'évaluation

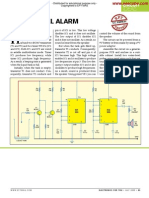

- Automated Alarm Circuits - OptDocument2 pagesAutomated Alarm Circuits - OptHtet Mrak AungPas encore d'évaluation

- General Index 03Document13 pagesGeneral Index 03Htet Mrak AungPas encore d'évaluation

- Liquid Level AlarmDocument1 pageLiquid Level AlarmHtet Mrak AungPas encore d'évaluation

- Anti Theft Alarm For Bikes - OptDocument1 pageAnti Theft Alarm For Bikes - OptHtet Mrak AungPas encore d'évaluation

- Sans 62444Document8 pagesSans 62444Htet Mrak AungPas encore d'évaluation

- Quartus 2 Operation Procedure v1Document5 pagesQuartus 2 Operation Procedure v1Htet Mrak AungPas encore d'évaluation

- 11 ICT For Development Lecture MyanmarDocument99 pages11 ICT For Development Lecture MyanmarHtet Mrak AungPas encore d'évaluation

- Myanmar EngDocument17 pagesMyanmar EngHtet Mrak AungPas encore d'évaluation

- The Potential For Biofuels From Algae: Algae Biomass Summit San Francisco, CA November 15, 2007Document22 pagesThe Potential For Biofuels From Algae: Algae Biomass Summit San Francisco, CA November 15, 2007Htet Mrak AungPas encore d'évaluation

- S 000 1378 001 - 1 - 0001Document53 pagesS 000 1378 001 - 1 - 0001sifoouPas encore d'évaluation

- Cable Reference Installation Methods - Open ElectricalDocument3 pagesCable Reference Installation Methods - Open ElectricalDoly DamanikPas encore d'évaluation

- Mel GiriDocument40 pagesMel GiriChethan ChaiPas encore d'évaluation

- Hilti GT Britain CP 636 Firestop Mortar Specifications Firestop Systems Binder CP 636 Firestop System DetailsDocument11 pagesHilti GT Britain CP 636 Firestop Mortar Specifications Firestop Systems Binder CP 636 Firestop System DetailsPraveen KanagarajPas encore d'évaluation

- Nitson Kymore CPP ERECTION DEVIATIONDocument61 pagesNitson Kymore CPP ERECTION DEVIATIONcvsrikalaPas encore d'évaluation

- Method Statement For Cable Tray InstallationDocument4 pagesMethod Statement For Cable Tray InstallationHafis Aikal Amran100% (1)

- Wire Mesh Cable Tray Technical Manual PDFDocument32 pagesWire Mesh Cable Tray Technical Manual PDFDuy ChuPas encore d'évaluation

- Cable Tray DetailsDocument2 pagesCable Tray Detailssomasreekanth4220% (1)

- Cable Trays PILGRIMDocument6 pagesCable Trays PILGRIMsabeerPas encore d'évaluation

- Fire Stop Work Installation & Application Method Statement: ScopeDocument22 pagesFire Stop Work Installation & Application Method Statement: ScopeWahid HusainPas encore d'évaluation

- Eaton B-Line Cable Management CT-13Document420 pagesEaton B-Line Cable Management CT-13Doug BoddyPas encore d'évaluation

- 331402DBQB16012 0Document37 pages331402DBQB16012 0AHMED AMIRAPas encore d'évaluation

- Time Schedule Projcet Pekerjaan Electrical & Instrument SemberahDocument5 pagesTime Schedule Projcet Pekerjaan Electrical & Instrument Semberahahmad yaniPas encore d'évaluation

- Ladder Tray Trunking CatalogDocument15 pagesLadder Tray Trunking CatalogRa ArPas encore d'évaluation

- U Li Catalogue 2023Document32 pagesU Li Catalogue 2023AGnes GiOkPas encore d'évaluation

- TJCL20001Document164 pagesTJCL20001i_m_pranayPas encore d'évaluation

- MEPF Material PricesDocument27 pagesMEPF Material PricesCarolie BacatanoPas encore d'évaluation

- Cable Tray Method StatementDocument8 pagesCable Tray Method StatementNidhin Mohan0% (1)

- Method Statement For Mep Installations PDFDocument24 pagesMethod Statement For Mep Installations PDFAnonymous j8lxlTlLk100% (11)

- Metal Cable TrayDocument2 pagesMetal Cable TrayGaurav KoliPas encore d'évaluation

- E Line CTK enDocument20 pagesE Line CTK enmarchentoPas encore d'évaluation

- Conectores TeckDocument50 pagesConectores TeckMario GuzmanPas encore d'évaluation

- Handout 22089 Handout MSF22089-L-Lien-MSF2016 Wip PDFDocument15 pagesHandout 22089 Handout MSF22089-L-Lien-MSF2016 Wip PDFBrandon ChoatePas encore d'évaluation

- CTME10Document272 pagesCTME10charleselitb92Pas encore d'évaluation

- THOMAS & BETTS Cable Tray CatalogueDocument24 pagesTHOMAS & BETTS Cable Tray CataloguemadhivananspPas encore d'évaluation

- Inmitto Solutions FRPDocument12 pagesInmitto Solutions FRPHansel FrancisPas encore d'évaluation

- Nvent MI Cable Installation Manual PDFDocument48 pagesNvent MI Cable Installation Manual PDFSivagurunathan SpPas encore d'évaluation

- 1986-0040-EL-SPE03-0001 RA Specification For Bulk MaterialsDocument16 pages1986-0040-EL-SPE03-0001 RA Specification For Bulk MaterialsjmohammadrezaPas encore d'évaluation

- Bprp1-Swyd 230kv Gis Boq r1Document16 pagesBprp1-Swyd 230kv Gis Boq r1Ae SuwaphanPas encore d'évaluation

- Cable Tray Manual: Based On The 2005 National Electrical CodeDocument59 pagesCable Tray Manual: Based On The 2005 National Electrical CodeSunil KumawatPas encore d'évaluation