Académique Documents

Professionnel Documents

Culture Documents

Masterseal 550 El v3

Transféré par

rangarajan1989Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Masterseal 550 El v3

Transféré par

rangarajan1989Droits d'auteur :

Formats disponibles

MASTERSEAL 550 EL

An elastomeric, cementitious, waterproof coating for concrete and masonry Description MASTERSEAL 550 EL is an elastomeric flexible, two component polymers modified cementitious system that requires only on site mixing forming ideal waterproof coating on concrete, masonry, and most other construction materials. When cured, a 2mm thick MASTERSEAL 550 EL membrane shall accommodate movements up to 0.5mm, or up to 1.2mm when reinforced with 100% virgin polypropylene woven fabric. Uses Water-retaining structures subjected to movements Basement-waterproofing To protect concrete from water, carbonation and deicing salts. Waterproofing of roofs, sunken floors in bathrooms, WC, etc. Waterproofing coating for drinking water tanks, sumps, etc. Advantages Retains flexible when submerged Good chemical resistance against soft water, domestic waste water, manure or other liquids moderately aggressive to mineral substrates. Resist to occasional foot traffic Water vapour permeable CO 2 barrier, provides anticarbonation benefits Excellent adhesion. Bonds to porous and nonporous surfaces. Non toxic-suitable for contact with potable water. Saves time - Can be applied to 24 hour-old concrete Typical properties Mixed Density Mixing Ratio, by weight Pot Life Recoatable % elongation Tensile strength Water penetration (DIN 1048) Standard compliance BS 1881 Part 5 1983 - I.S.A.T. DIN 1048 Water Penetration Test Specification clause Treat the surface using MASTERSEAL 550 EL, an elastomeric flexible, two component polymers modified cementitious composite system that requires no addition of water at the site. The product shall be applied in minimum two coats to achieve total DFT of 1mm. The material shall be mixed and applied fully in accordance with the manufacturer's instructions. The product shall exhibit at least 40% elongation at ambient & 30% elongation in under water condition with tensile strength greater then 20 2 Kg/cm . The product shall resist 1.5 bars pressure when tested as per DIN 1048 at 2mm DFT. When applied at 2mm DFT, elastomeric coating shall be able to bridge crack up to 0.5mm width. Directions for use Surface preparation: The surface to be coated must be clean and sound. Remove all traces of formwork, release agents, previous coatings, laitance and any other contaminants that may affect the bond adversely. Suitable cleaning methods include high pressure water jetting and grit blasting. Mechanical wire brushing may be appropriate for small areas. After the above surface preparation, surfaces must be thoroughly washed with clean potable water to remove all dust and loose particles. Spalled concrete should be cut back to sound concrete and made good with a suitable cementitious repair mortar such as EMACO S48C T. All cracks and bolt holes must be cut out and filled solid with MASTERSEAL 505 or Emaco S48C T. Mixing MASTERSEAL 550 EL is supplied in premeasured units and should be mixed on site utilising clean containers. Slowly add the powder to the liquid and mix, using a slow speed drill fitted with a suitable paddle. Leave the mixed material to stand for 5 minutes to allow for full saturation to take place. Remix to restore the consistency. Do not mix more material than can be used in half an hour. DO NOT RE-TEMPER WITH WATER.

: 1850 kg/m : 3 (powder) : 1(liquid) o : 120 Minutes at 25 C o : 30 Minutes at 40 C : 8 12 Hours : >42% (Ambient) : >30% (under water) 2 : > 20 kg/cm : 1.5 bars - no leakage (at 2mm DFT)

Page 1 of 2

Application Always apply MASTERSEAL 550 EL to pre-dampened surface. High-suction substrates require more dampening then dense substrates. However, make sure there is no free-standing water. Apply by brush or broom. Mixed material must be used with in 30 to 45 minutes, or less under hot weather conditions. First Coat: Brush or broom the mix firmly onto the predampened, prepared surface. Care must be taken not to spread the material too thinly. When the material begins to drag or ball, do not add more liquid/water but dampen the surface again. Second Coat: Allow at least overnight to cure before applying subsequent coats. Dampen the first coat and remove excess moisture. Brush or broom the mix onto the surface (as above) finishing in the opposite direction to the first coat. With reinforcing mesh: 100% virgin polypropylene woven mesh is used to reinforce MASTERSEAL 550EL. Embed the mess in thick base layer of approximately 0.5 mm thickness, covered with the first coat of MASTERSEAL 550 EL while base coat is still wet. Ensure that the mesh is a minimum of 200 mm wide when treating existing cracks, joints, junctions. Curing Under hot or excessive drying conditions fog-spray after the initial set has taken place for as long as practicable. In cold, humid or unventilated areas it may be necessary to leave the application for a longer time curing period or to introduce forced air movement. Never use dehumidifiers during curing periods. Equipment Cleaning Not hardened material may simply be removed with water. Coverage Each square metre will require minimum of 0.9 Kg of mixed material per layer. The coverage rate for each layer will be strongly influenced by the roughness of the substrate. 1.8 kg / m in two coats to achieve 1 mm thickness. 3.6 kg / m in three coats to achieve 2 mm thickness.

Packaging MASTERSEAL 550 is available in 20kg pack and in white and grey colours. Storage and Shelf life Store under cover, out of direct sunlight and protect from extremes of temperature. In tropical climates the product must be stored in an air-conditioned environment. Shelf life of the powder is 6 months and liquid is 12 months when stored as recommended. Failure to comply with the recommended storage conditions may result in premature deterioration of the product or packaging. For specific storage advice please consult BASF's Technical Services Department. Safety precautions As with all chemical products, care should be taken during use and storage to avoid contact with eyes, mouth, skin and foodstuffs (which can also be tainted with vapour until product fully cured or dried). Treat splashes to eyes and skin immediately. If accidentally ingested, seek immediate medical attention. Keep away from children and animals. Reseal containers after use. Do not reuse containers for storage of consumable item. For further information refer to the material safety data sheet. MSDS available on demand or on BASF construction chemicals web site. Note All BASF Technical Data Sheets are updated on regular basis; it is the user's responsibility, to obtain the most recent issue. Field services where provided, does not constitute supervisory responsibility, for additional information contact your local BASF representative. Disclaimer Whilst any information contained herein is true, accurate and represents our best knowledge and experience, no warranty is given or implied with any recommendations made by us, our representatives or distributors, as the conditions of use and the competence of any labour involved in the application are beyond our control.

TDS Ref. no.: Msl550EL/03/0507 BASF India Limited Construction Chemicals Division Plot No.37, Chandivali Farm Road, Chandivali ,Andheri(East) Mumbai 400072 India Tel: +91 22 28580200, Fax: +91 22 28478381 www.basf-cc.co.in Page 2 of 2 e-mail: basfcc@vsnl.net

Vous aimerez peut-être aussi

- MASTERSEAL 550 EL v3 PDFDocument2 pagesMASTERSEAL 550 EL v3 PDFRajesh KumarPas encore d'évaluation

- MASTERSEAL 550 v6Document2 pagesMASTERSEAL 550 v6Mohiuddin MuhinPas encore d'évaluation

- MASTERTOP 1110 - v1Document2 pagesMASTERTOP 1110 - v1Sumit KiratPas encore d'évaluation

- 05 - TDS - Thoroseal FX100Document4 pages05 - TDS - Thoroseal FX100s.skumar1Pas encore d'évaluation

- MR - DRY 830EL-v4Document4 pagesMR - DRY 830EL-v4Ankita Baban GavadePas encore d'évaluation

- WPM 300 TDSDocument2 pagesWPM 300 TDSPetrus PaulusPas encore d'évaluation

- ULTRAMIX Tds en 0619Document3 pagesULTRAMIX Tds en 0619Dorian BugejaPas encore d'évaluation

- PELELITE FINISH Tds en 0222Document3 pagesPELELITE FINISH Tds en 0222Leak DetectionPas encore d'évaluation

- ConcreteDocument3 pagesConcreteTran DtrungPas encore d'évaluation

- LeafSeal-WP 503 EN - Rev 0221Document5 pagesLeafSeal-WP 503 EN - Rev 0221Le Tuan VietPas encore d'évaluation

- Eco-friendly protective coatingDocument2 pagesEco-friendly protective coatingRaed Naim KhammashPas encore d'évaluation

- Kan FlexDocument3 pagesKan FlexSunny SinghPas encore d'évaluation

- FlexicreteDocument3 pagesFlexicreteapi-302611547Pas encore d'évaluation

- Mastertop 1110 TDocument4 pagesMastertop 1110 THaresh BhavnaniPas encore d'évaluation

- TDS - Mastertop 1740Document3 pagesTDS - Mastertop 1740Venkata RaoPas encore d'évaluation

- Masterseal 540Document2 pagesMasterseal 540Nguyen Chi Thanh100% (1)

- Betakril: Decorative Water-Based Exterior Product GroupDocument2 pagesBetakril: Decorative Water-Based Exterior Product Groupmaga2292Pas encore d'évaluation

- Thick Bed - WP555Document3 pagesThick Bed - WP555IB KPas encore d'évaluation

- Mastertop 1120tDocument3 pagesMastertop 1120themajsuryaPas encore d'évaluation

- MASTERSEAL 200H v3 PDFDocument2 pagesMASTERSEAL 200H v3 PDFRajesh KumarPas encore d'évaluation

- MASTERTILE 25 v6Document2 pagesMASTERTILE 25 v6AnandPrabuPas encore d'évaluation

- Description: Super Thoroseal Is A Blend of PortlandDocument2 pagesDescription: Super Thoroseal Is A Blend of Portlandqwerty_conan100% (1)

- Primer SC PDFDocument3 pagesPrimer SC PDFFrancois-Pas encore d'évaluation

- Elastocrete P8J Waterproofing Kit Technical Data SheetDocument3 pagesElastocrete P8J Waterproofing Kit Technical Data SheetZèlia FláviaPas encore d'évaluation

- Sikaseal - 105Document3 pagesSikaseal - 105Nader ToutounjiPas encore d'évaluation

- TDS - Mastertile 550 - DgroutDocument3 pagesTDS - Mastertile 550 - DgroutVenkata RaoPas encore d'évaluation

- TDS - Mastertop 1105Document3 pagesTDS - Mastertop 1105Venkata Rao100% (1)

- TDS - Mastertop 1710Document2 pagesTDS - Mastertop 1710Venkata RaoPas encore d'évaluation

- Masterflow - 410 PC T - v1Document2 pagesMasterflow - 410 PC T - v1kavi_prakash6992Pas encore d'évaluation

- MASTERSEAL - 501-502 - v5Document2 pagesMASTERSEAL - 501-502 - v5Parth GondaliaPas encore d'évaluation

- Sika Monotop®-160 Migrating: Product Data SheetDocument3 pagesSika Monotop®-160 Migrating: Product Data Sheetslavisa05Pas encore d'évaluation

- Flexible Cement Waterproof CoatingDocument2 pagesFlexible Cement Waterproof CoatingDharryl Dharryl DharrylPas encore d'évaluation

- Rapid Set Tds - NoRestrictionDocument4 pagesRapid Set Tds - NoRestrictionFloorkitPas encore d'évaluation

- Alpha Dry Adhesive Tds 843706Document2 pagesAlpha Dry Adhesive Tds 843706aruncg2Pas encore d'évaluation

- Specs Pull Off Cement Plaster General PurposeDocument3 pagesSpecs Pull Off Cement Plaster General PurposeKhan Shahzeb100% (2)

- 8 Bergermaster 00 en Intext WB Plaster Primer 2022 Rev5Document5 pages8 Bergermaster 00 en Intext WB Plaster Primer 2022 Rev5yoxan25808Pas encore d'évaluation

- Sahara Clear Masonry Sealer 2-2 DescriptionDocument3 pagesSahara Clear Masonry Sealer 2-2 DescriptionNathaniel Gutierez MangubatPas encore d'évaluation

- Method Statement:: Dr. Fixit Roofseal Top Coat - Insulating Elastomeric Waterproof Coating For RoofsDocument4 pagesMethod Statement:: Dr. Fixit Roofseal Top Coat - Insulating Elastomeric Waterproof Coating For RoofsSudarshan KamblePas encore d'évaluation

- Ficha Inscripcion SSDocument2 pagesFicha Inscripcion SSalexPas encore d'évaluation

- Masterseal 380Document2 pagesMasterseal 380Haresh BhavnaniPas encore d'évaluation

- 5.thomsit DX Self Levelling - 3-Aug-10Document2 pages5.thomsit DX Self Levelling - 3-Aug-10adchem123Pas encore d'évaluation

- SPLANDEK 2100v3Document4 pagesSPLANDEK 2100v3Ankita Baban GavadePas encore d'évaluation

- Polyglass Polyglass Polyglass Polyglass: Page 1 of 2Document2 pagesPolyglass Polyglass Polyglass Polyglass: Page 1 of 2aryopnPas encore d'évaluation

- Alpha Dry Base Coat Tds 114477Document3 pagesAlpha Dry Base Coat Tds 114477aruncg2Pas encore d'évaluation

- BASF MasterSeal M 790 TdsDocument9 pagesBASF MasterSeal M 790 TdsAmar WadoodPas encore d'évaluation

- MasterTile® 700 PDFDocument7 pagesMasterTile® 700 PDFJong Dollente Jr.Pas encore d'évaluation

- Uzin PE 360Document2 pagesUzin PE 360FloorkitPas encore d'évaluation

- MasterSeal - 551 v4Document2 pagesMasterSeal - 551 v4piyu114Pas encore d'évaluation

- Masterseal 380 TDSDocument2 pagesMasterseal 380 TDSArasu DonPas encore d'évaluation

- Aqua Stop+TDS+25kg+TubDocument4 pagesAqua Stop+TDS+25kg+Tubshess1Pas encore d'évaluation

- Uzin NC 152Document2 pagesUzin NC 152FloorkitPas encore d'évaluation

- Aqua StopDocument2 pagesAqua Stoppravi3434Pas encore d'évaluation

- Brushbond PDFDocument4 pagesBrushbond PDFpravi3434Pas encore d'évaluation

- Mastertop P10 TDSDocument2 pagesMastertop P10 TDSطه اللوذعيPas encore d'évaluation

- Bituaqua Prime Coat - AnionicDocument2 pagesBituaqua Prime Coat - AnionicSyed WusatPas encore d'évaluation

- TDS - Mastertop 503Document2 pagesTDS - Mastertop 503Venkata RaoPas encore d'évaluation

- Insulation Plaster TdsDocument3 pagesInsulation Plaster TdsaliPas encore d'évaluation

- Weberfloor - 630 - TSC - 01 (1) - 221109 - 183928Document3 pagesWeberfloor - 630 - TSC - 01 (1) - 221109 - 183928Pacific CoastPas encore d'évaluation

- Uzin L 3 Gold: Product Data SheetDocument2 pagesUzin L 3 Gold: Product Data SheetFloorkitPas encore d'évaluation

- Water Damage Restoration and Clean Up ChecklistD'EverandWater Damage Restoration and Clean Up ChecklistÉvaluation : 1 sur 5 étoiles1/5 (1)

- BS en 12390 8 2009 Testing Hardened Concrete Depth of Penetration of Water Under Pressure PDFDocument10 pagesBS en 12390 8 2009 Testing Hardened Concrete Depth of Penetration of Water Under Pressure PDFKING OF VIDEO GAMES xPas encore d'évaluation

- Method Statement For Raft & RC Wall Water Proofing WorksDocument2 pagesMethod Statement For Raft & RC Wall Water Proofing Worksrangarajan1989Pas encore d'évaluation

- Astm c403 16 Time of Setting of Concrete Mixtures by Penetration ResistanceDocument7 pagesAstm c403 16 Time of Setting of Concrete Mixtures by Penetration Resistancerangarajan1989Pas encore d'évaluation

- Weber - Tec MC1Document2 pagesWeber - Tec MC1rangarajan1989Pas encore d'évaluation

- Fosroc Thioflex 600 Gun Grade: Declaration of PerformanceDocument3 pagesFosroc Thioflex 600 Gun Grade: Declaration of Performancerangarajan1989Pas encore d'évaluation

- LicenseDocument1 pageLicenserangarajan1989Pas encore d'évaluation

- Method Statement For Terrace & Headroom Water Proofing..Document2 pagesMethod Statement For Terrace & Headroom Water Proofing..rangarajan1989Pas encore d'évaluation

- Method Statement For Terrace & Headroom Water Proofing..Document2 pagesMethod Statement For Terrace & Headroom Water Proofing..rangarajan1989Pas encore d'évaluation

- TDS Proofex 3000 Saudi ArabiaDocument3 pagesTDS Proofex 3000 Saudi Arabiarangarajan1989Pas encore d'évaluation

- Make Sure You'Re Covered.: Please Wear A Mask Before EnteringDocument1 pageMake Sure You'Re Covered.: Please Wear A Mask Before Enteringrangarajan1989Pas encore d'évaluation

- Tci-Hci I Content OutlineDocument1 pageTci-Hci I Content Outlinerangarajan1989Pas encore d'évaluation

- Method Statement For Terrace & Headroom Water Proofing..Document2 pagesMethod Statement For Terrace & Headroom Water Proofing..rangarajan1989Pas encore d'évaluation

- Media Bulletin 06 07 20 COVID 19 6 PMDocument25 pagesMedia Bulletin 06 07 20 COVID 19 6 PMbalajishivarajPas encore d'évaluation

- Project Management Professional Handbook PDFDocument43 pagesProject Management Professional Handbook PDFmohamedyosrymohamedPas encore d'évaluation

- Chartered Engg FormDocument3 pagesChartered Engg Formrangarajan1989Pas encore d'évaluation

- BHAVINI Site Assembly Shop TenderDocument2 pagesBHAVINI Site Assembly Shop Tenderrangarajan1989Pas encore d'évaluation

- ERRATA - November 2019: Manual of Standard PracticeDocument10 pagesERRATA - November 2019: Manual of Standard Practicerangarajan1989Pas encore d'évaluation

- Section - V: Index Part - ADocument6 pagesSection - V: Index Part - Arangarajan1989Pas encore d'évaluation

- Med Price BidDocument83 pagesMed Price Bidrangarajan1989Pas encore d'évaluation

- 5119 PDFDocument1 page5119 PDFrangarajan1989Pas encore d'évaluation

- BHAVINI Site Assembly Shop TenderDocument2 pagesBHAVINI Site Assembly Shop Tenderrangarajan1989Pas encore d'évaluation

- PriceBuildup Diesel Delhi As On 16 Jul-2020 PDFDocument1 pagePriceBuildup Diesel Delhi As On 16 Jul-2020 PDFrangarajan1989Pas encore d'évaluation

- Item 1 MTK 54 Iii TDDocument154 pagesItem 1 MTK 54 Iii TDrangarajan1989Pas encore d'évaluation

- Nitoflor HT HTSTDDocument4 pagesNitoflor HT HTSTDrajeshji_000Pas encore d'évaluation

- Scanned With CamscannerDocument1 pageScanned With Camscannerrangarajan1989Pas encore d'évaluation

- 1297074531452-Specification of Mechanically Procuced Blanket Meteria (GE - IRS-2 Final) July 2005Document24 pages1297074531452-Specification of Mechanically Procuced Blanket Meteria (GE - IRS-2 Final) July 2005yamanta_rajPas encore d'évaluation

- Media Bulletin 06 07 20 COVID 19 6 PMDocument25 pagesMedia Bulletin 06 07 20 COVID 19 6 PMbalajishivarajPas encore d'évaluation

- Item 2 MTK 63 Iii TDDocument157 pagesItem 2 MTK 63 Iii TDrangarajan1989Pas encore d'évaluation

- Media Bulletin 06 07 20 COVID 19 6 PMDocument25 pagesMedia Bulletin 06 07 20 COVID 19 6 PMbalajishivarajPas encore d'évaluation

- Is 14593 1998Document15 pagesIs 14593 1998rbs_75Pas encore d'évaluation

- MF AXIOM Cyber Brief PDFDocument2 pagesMF AXIOM Cyber Brief PDFluis demetrio martinez ruizPas encore d'évaluation

- Chapter 1: Introduction To Switched Networks: Routing and SwitchingDocument28 pagesChapter 1: Introduction To Switched Networks: Routing and SwitchingTsehayou SieleyPas encore d'évaluation

- Chapter 2 and 3 Exam HintsDocument16 pagesChapter 2 and 3 Exam HintsNga PhuongPas encore d'évaluation

- DAU Program Managers ToolkitDocument157 pagesDAU Program Managers ToolkitMuzafar Shah Mosam ShahPas encore d'évaluation

- Dow Corning Success in ChinaDocument24 pagesDow Corning Success in ChinaAnonymous lSeU8v2vQJ100% (1)

- Pixar EssayDocument2 pagesPixar Essayapi-523887638Pas encore d'évaluation

- Questions from 1- 20 carry 2 marks eachDocument10 pagesQuestions from 1- 20 carry 2 marks eachJoramsugPas encore d'évaluation

- R 245Document2 pagesR 245Ravi RanjanPas encore d'évaluation

- Module 1 in ACC 80Document12 pagesModule 1 in ACC 80debate ddPas encore d'évaluation

- Jill Bush ResumeDocument3 pagesJill Bush ResumeAustinTalksPas encore d'évaluation

- Malaysia Technical Programme ScreenDocument36 pagesMalaysia Technical Programme ScreenMohd Zainee ZainalPas encore d'évaluation

- Ict - 7 For Cot DLL Wek 5Document3 pagesIct - 7 For Cot DLL Wek 5Leila ForioPas encore d'évaluation

- Atlassian Vladimir Yastreboff Sept21Document1 pageAtlassian Vladimir Yastreboff Sept21devk2011Pas encore d'évaluation

- Networks of Workstations: (Distributed Memory)Document19 pagesNetworks of Workstations: (Distributed Memory)aliha ghaffarPas encore d'évaluation

- CMBS World - Reremic PhenomenonDocument14 pagesCMBS World - Reremic PhenomenonykkwonPas encore d'évaluation

- OSV Part 4Document664 pagesOSV Part 4devbsl123Pas encore d'évaluation

- Scope and Nature of HotelDocument2 pagesScope and Nature of HotelJan Hidalgo LaroyaPas encore d'évaluation

- Centum VP 7 ENG Advanced Labs - GlobalDocument6 pagesCentum VP 7 ENG Advanced Labs - GlobalNikhilesh Muraleedharan100% (1)

- Electricity Markets and Renewable GenerationDocument326 pagesElectricity Markets and Renewable GenerationElimar RojasPas encore d'évaluation

- 7 Principles of Highly Effective Command CentersDocument11 pages7 Principles of Highly Effective Command CentersLuis OlavarrietaPas encore d'évaluation

- Masonry Bridge Assessment With Archie-M: Notes For A Masonry Bridge Masterclass Bill Harvey Associates LTD March 2011Document12 pagesMasonry Bridge Assessment With Archie-M: Notes For A Masonry Bridge Masterclass Bill Harvey Associates LTD March 2011Info Aviron LavalPas encore d'évaluation

- 2019 - 2020 Skills Gap Report FINAL PDFDocument12 pages2019 - 2020 Skills Gap Report FINAL PDFPradyumna DangewarPas encore d'évaluation

- Audio System and Pairing: Supplementary Rider's ManualDocument106 pagesAudio System and Pairing: Supplementary Rider's ManualSylvainsfcPas encore d'évaluation

- CTA RulingDocument12 pagesCTA RulingGhia TalidongPas encore d'évaluation

- RRV DC: 3.54 In. (90 MM)Document7 pagesRRV DC: 3.54 In. (90 MM)Trevor AdamsPas encore d'évaluation

- Setting Up A Virtual Switch For A HyperDocument5 pagesSetting Up A Virtual Switch For A Hyperaleksandar71Pas encore d'évaluation

- Faiq ResumeDocument3 pagesFaiq ResumeFoudziah SarinPas encore d'évaluation

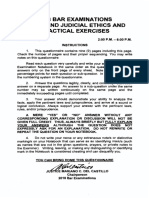

- 2018 Bar Examinations Practical Exercises: Legal and Judicial Ethics andDocument9 pages2018 Bar Examinations Practical Exercises: Legal and Judicial Ethics andrfylananPas encore d'évaluation

- OmniVision OV9716Document2 pagesOmniVision OV9716cuntadinPas encore d'évaluation

- Total Preventative Maintenance Program InitiationDocument20 pagesTotal Preventative Maintenance Program InitiationAji Beni LastomoPas encore d'évaluation