Académique Documents

Professionnel Documents

Culture Documents

Klinger - Gasket Factors

Transféré par

Felip PrietoCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Klinger - Gasket Factors

Transféré par

Felip PrietoDroits d'auteur :

Formats disponibles

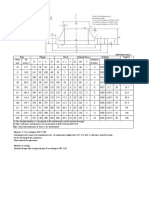

Gasket factors-E-Idstein-09:Dichtungskennwerte-E-G

17.11.2009

20:32 Uhr

Seite 1

Gasket factors

KLINGERSIL

Type

KLINGERSIL C-4300

KLINGERSIL C-4400

KLINGERSIL C-4409

KLINGERSIL C-4430

KLINGERSIL C-4500

KLINGERSIL C-4509

KLINGERSIL C-8200

VO Vu 0,1

BO (7.2.2)

DIN 28090/DIN 28091

thickness

mm

1

2

3

1

2

3

1

2

1

2

3

1

2

3

1

2

1

2

3

KLINGERtop-chem and top-graph

Type

thickness

mm

KLINGERtop-chem 2000

2

3

KLINGERtop-chem 2003

2

KLINGERtop-chem 2005

2

KLINGERtop-graph 2000

2

MPa

25C

158

120

48

240

240

63

240

240

>240

>240

133

220

180

100

280

180

225

150

75

MPa

25C

15

18

20

18

23

24

39

43

22

29

29

23

26

28

24

28

17

19

21

VO Vu 0,1

MPa

50C

120

80

40

195

110

53

215

110

260

240

97

195

110

80

195

110

160

110

55

MPa

100C

63

52

29

95

80

41

176

80

145

120

65

120

110

55

140

110

70

53

26

MPa

200C

39

33

18

50

42

24

120

42

81

73

40

68

59

33

120

59

44

34

17

BO (7.2.2)

MPa

300C

38

30

80

30

65

56

31

51

43

23

97

43

DIN 28090/DIN 28091

MPa

25C

210

100

>110

>110

>160

MPa

25C

21

21

13

28

25

MPa

50C

185

87

110

50

120

MPa

100C

150

60

28

35

80

MPa

200C

125

50

15

22

70

MPa

250C

75

33

10

15

60 *

DIN 2505

ASTM

k1 KO x KD

mm (N/mm)

1.1 x bD 22 x bD

1.1 x bD 22 x bD

1.1 x bD 22 x bD

1.1 x bD 22 x bD

1.1 x bD 22 x bD

1.1 x bD 22 x bD

1.1 x bD 28 x bD

1.1 x bD 28 x bD

1.1 x bD 22 x bD

1.1 x bD 22 x bD

1.1 x bD 22 x bD

1.1 x bD 22 x bD

1.1 x bD 22 x bD

1.1 x bD 22 x bD

1.1 x bD 28 x bD

1.1 x bD 28 x bD

1.1 x bD 22 x bD

1.1 x bD 22 x bD

1.1 x bD 22 x bD

m yStress

factor

MPa

2.7

15.0

3.0

15.0

3.3

15.0

3.2

20.0

3.5

20.0

3.9

20.0

3.2

30.0

3.5

30.0

4.5

25.0

5.0

25.0

5.5

25.0

3.5

25.0

4.0

25.0

4.5

25.0

3.5

30.0

4.0

30.0

3.5

22.5

4.0

22.5

4.5

22.5

DIN 2505

ASTM

k1 KO x KD

mm (N/mm)

1.1 x bD 25 x bD

1.1 x bD 25 x bD

1.1 x bD 22 x bD

1.1 x bv 22 x bD

m yStress

factor

MPa

3.5

10.0

5.0

12.0

2.8

5.0

3.5

10.0

4.0

25.0

DIN 2505

ASTM

* 300C

KLINGERgraphite Laminate

Type

PSM 100

PSM 200

PSM 300

SLS 100

SLS 200

SLS 300

VO Vu 0,1

BO (7.2.2)

DIN 28090/DIN 28091

thickness

mm

1

2

3

1

2

3

The evaluation of these characteristic

datas are based on the rules of DIN

28090. The use of this values will not

guarantee the performance of the

gasket. Application conditions not in

the control of the gasket material

manufacturer can influence the

operation of the gasket. A deducation

of liability claims of any nature is

therefore not possible. As further

investigations are continuousely

carried out we reserve the right of

appropriate updates.

MPa

MPa

MPa

k1 KO x KD

m yStress*

MPa

MPa

MPa

mm (N/mm) factor

25C

25C 50C 100C 200C 300C

MPa

3 x bD 30 x bD

210

30

190

3.0

210

30.0

200

195

2 x bD 10 x bD

140

20

110

2.0

140

10.0

130

120

2 x bD

7 x bD

95

20

80

2.0

95

6.0

90

85

2 x bD

6 x bD

195

20

110

2.0

180

6.0

160

130

2 x bD

6 x bD

125

20

75

2.0

110

6.0

100

90

2 x bD

6 x bD

80

20

50

2.0

75

6.0

70

60

*For practical application we recommend a minimum assembling gasket load of approx. 35 MPa

The design factors m and y

according to the ASME Code are

based on a maximum leakage rate of

1 ml/min. approx. 0.1 mg/sec x m

measured according to DIN 28090 at

different gas pressures and different

gasket stresses.

The DIN 2505 and the y and m

concept itself now being questioned

as a valid design tool.

Subject to technical alterations.

Issue: November 2009

Certified according to

DIN EN ISO 9001:2000

KLINGER GmbH

Rich.-Klinger-Strae 37

D-65510 Idstein

Phone +49 (0) 6126 4016-0

Fax +49 (0) 6126 4016-11/ -22

e-mail: mail@klinger.de

http://www.klinger.de

Gasket factors-E-Idstein-09:Dichtungskennwerte-E-G

17.11.2009

20:32 Uhr

Seite 2

Gasket Factors

according to EN13555

Gasket factor Qmin(L)

The gasket factor Qmin(L) is defined in

the EN13555 as the required

minimum surface stress on the

gasket at installation at room

temperature so that the adaptation of

the gasket to the flange surface is

sufficient to achieve tightness class L

for a given internal pressure.

Gasket factor QSmax

In the EN13555 the gasket factor

QSmax is defined as the maximum

surface stress with which the gasket

may be loaded at the given

temperature without collapsing or

failure due to over compression.

Gasket factor PQR

This gasket factor is defined to

consider the relaxation of the gasket

Gasket factor QSmin(L)

The gasket factor QSmin(L) is defined

load after tightening the bolts and the

as the required minimum surface

long-term influence of the operating

stress under operating conditions, i.e. temperature.

after release at operating temperature,

so that the required tightness class L

is achieved for the given internal

pressure.

Validity of the test result

The validity of the test result for

QSmax is dependant on the factor PQR

which is mentioned in the EN 13555

section 8.4.5. This can then be

applied to the QSmax for different

gasket materials.

However there is no information

in the standard which PQR values

confirm a QSmax value. This means it

is not easy for the user to determine

which gasket materials will work

properly at a given operating

temperature and surface pressure or

are already overrated as quoted in the

standard.

For KLINGER gasket materials

KLINGER recommends the use of the

values determined with the gasket

calculation software KLINGERexpert

for the maximum permissible and

minimum required surface stress for

a given application.

Gasket factors-E-Idstein-09:Dichtungskennwerte-E-G

17.11.2009

20:32 Uhr

Seite 3

Gasket factors

according EN 13555:2005-02

All values for thickness 2.0 mm

Material

KLINGERSIL C-4300

KLINGERSIL C-4324

KLINGERSIL C-4400

KLINGERSIL C-4430

KLINGERSIL C-4500

KLINGERSIL C-8200

KLINGERtop-graph 2000

KLINGERtop-sil-ML1

KLINGERtop-chem 2000

KLINGERtop-chem 2003

KLINGERtop-chem 2005

KLINGERtop-chem 2006

KLINGERQuantum

Qsmax

[N/mm 2]

Qsmin [N/mm 2], pi = 40 bar

QA [N/mm 2]

Qmin

[N/mm 2]

pi = 40 bar, RT

20

< 10.0

L 0.1

L 0.01

L 0.001

L 0.0001

L 0.1

L 0.01

L 0.001

L 0.0001

L 0.1

L 0.01

L 0.001

L 0.0001

L 0.00001

L 0.1

L 0.01

L 0.001

L 0.0001

L 0.00001

18.0

28.2

36.6

48.5

17.2

27.0

37.7

51.2

18.1

29.4

41.6

54.8

71.0

20.5

32.6

44.7

56.8

73.4

L 0.1

L 0.01

L 0.001

L 0.0001

L 0.00001

L 0.000001

L 0.1

L 0.01

L 0.001

L 0.0001

L 0.1

L 0.01

L 0.001

L 0.0001

L 0.00001

17.5

25.6

34.0

43.7

56.4

93.7

17.0

26.5

36.7

49.3

19.3

32.5

47.1

63.3

81.9

< 10.0

L 0.1

L 0.01

L 0.001

L 0.0001

L 0.00001

19.2

32.2

45.7

59.3

80.4

16.4

L 0.1

L 0.01

L 0.001

L 0.0001

< 10.0

19.7

51.8

84.8

L 0.1

L 0.01

L 0.001

L 0.0001

L 0.1

L 0.01

L 0.001

L 0.0001

L 0.1

L 0.01

L 0.001

L 0.0001

L 0,1

L 0,01

L 0,001

L 0,0001

L 0,00001

< 10.0

14.7

23.7

38.4

< 10.0

12.0

21.0

36.0

30.0

41.0

51.8

66.0

14.0

25.0

35.0

49.0

72.0

< 10.0

< 10.0

40

< 10.0

< 10.0

30.1

< 10.0

< 10.0

27.5

< 10.0

< 10.0

60

< 10.0

< 10.0

< 10.0

< 10.0

< 10.0

< 10.0

< 10.0

17.4

< 10.0

< 10.0

< 10.0

18.9

80

< 10.0

< 10.0

< 10.0

< 10.0

< 10.0

< 10.0

< 10.0

< 10.0

< 10.0

< 10.0

< 10.0

< 10.0

24.9

< 10.0

< 10.0

< 10.0

< 10.0

28.0

< 10.0

< 10.0

< 10.0

< 10.0

< 10.0

31.8

< 10.0

< 10.0

13.1

< 10.0

< 10.0

< 10.0

< 10.0

34.9

< 10.0

< 10.0

< 10.0

< 10.0

15.7

< 10.0

< 10.0

16.7

< 10.0

< 10.0

< 10.0

12.5

< 10.0

< 10.0

12.6

< 10.0

< 10.0

< 10.0

< 10.0

< 10.0

< 10.0

< 10.0

16.0

< 10.0

11.0

< 10.0

< 10.0

12.1

56.8

< 10.0

< 10.0

< 10.0

15.1

< 10.0

19.0

< 10.0

< 10.0

< 10.0

< 10.0

39.5

< 10.0

< 10.0

< 10.0

< 10.0

< 10.0

< 10.0

< 10.0

< 10.0

23.9

< 10.0

< 10.0

< 10.0

18.0

< 10.0

< 10.0

< 10.0

< 10.0

< 10.0

< 10.0

< 10.0

< 10.0

10.5

< 10.0

< 10.0

< 10.0

< 10.0

16.8

< 10.0

< 10.0

< 10.0

< 10.0

10.6

< 10.0

< 10.0

13.0

RT

100C

175C

200C

RT

100C

175C

200C

RT

100C

175C

200C

250C

RT

100C

175C

200C

250C

300C

RT

100C

175C

200C

250C

300C

RT

100C

175C

200C

RT

100C

175C

200C

250C

300C

RT

100C

175C

200C

250C

300C

RT

100C

175C

200C

250C

RT

100C

150C

PQR

Stiffness

500 kN/mm

> 200

> 200

> 200

> 200

> 200

> 200

> 200

> 200

> 200

> 200

> 200

> 200

> 200

> 200

> 200

> 200

> 200

> 200

> 200

> 200

> 200

> 200

> 200

> 200

> 200

> 200

> 200

> 200

> 200

> 200

> 200

> 200

> 200

> 200

> 200

> 160

> 160

140

120

100

80

> 200

> 180

> 160

140

50

80

30

20

0.87

0.80

0.78

0.84

0.76

0.75

0.92

0.84

0.84

0.83

0.93

0.91

0.90

0.88

0.85

0.87

0.79

0.80

0.77

0.74

0.67

0.60

0.54

0.92

0.84

0.83

0.77

0.76

0.87

0.76

0.78

0.72

0.70

0.73

0.77

0.67

0.93

0.65

0.70

120

RT

< 10.0

0.90

40

100C

< 10.0

0.92

20

175C

< 10.0

0.90

20

200C

< 10.0

100

RT

< 10.0

0.86

40

100C

< 10.0

0.82

20

175C

< 10.0

< 10.0

0.99

> 200

RT

< 10.0

< 10.0

0.77

> 200

100C

< 10.0

< 10.0

0.72

120

200C

< 10.0

< 10.0

0.64

100

300C

< 10.0

< 10.0

28.0

Gasket dimensions: DN40/ PN40 according EN 1514-1

Gasket factors-E-Idstein-09:Dichtungskennwerte-E-G

17.11.2009

20:32 Uhr

Seite 4

Gasket factors

according EN 13555:2005-02

All values for thickness 2.0 mm

Material

KLINGERgraphite Laminate

SLS 200

KLINGERgraphite Laminate

PSM 200

KLINGERgraphite Laminate

PDM 200

KLINGERgraphite Laminate

TSM 200

Qmin

[N/mm 2]

pi = 40 bar, RT

L 1.0

L 0.1

L 0.01

L 1.0

L 0.1

L 0.01

L 1.0

L 0.1

L 0.01

L 1.0

L 0.1

L 0.01

< 10.0

22.0

70.0

< 10.0

31.0

75.0

12.0

35.0

74.0

< 10.0

< 10.0

15.0

Qsmin [N/mm 2], pi = 40 bar

QA [N/mm 2]

20

< 10.0

40

< 10.0

< 10.0

< 10.0

< 10.0

15.0

< 10.0

< 10.0

21.0

< 10.0

< 10.0

< 10.0

< 10.0

< 10.0

< 10.0

Qsmax

[N/mm 2]

PQR

Stiffness

500 kN/mm

80

0.99

140

RT

< 10.0

0.94

120

300C

< 10.0

62.0

0.99

> 240

RT

< 10.0

< 10.0

0.99

200

300C

< 10.0

< 10.0

69.0

0.99

220

RT

< 10.0

< 10.0

0.94

160

300C

< 10.0

< 10.0

65.0

0.98

100

RT

< 10.0

< 10.0

0.94

120

300C

< 10.0

< 10.0

< 10.0

< 10.0

Gasket dimensions: DN40/ PN40 according EN 1514-1

60

< 10.0

< 10.0

Vous aimerez peut-être aussi

- ASTM A686 T72301 W1A 9.5 Steel Plate, ASTM T72301 W1A 9.5 Tool SteelDocument2 pagesASTM A686 T72301 W1A 9.5 Steel Plate, ASTM T72301 W1A 9.5 Tool SteelBernice JohnsonPas encore d'évaluation

- Pipe SpecDocument84 pagesPipe SpecAbdullahPas encore d'évaluation

- The Names of Allah and Their ReflectionsDocument98 pagesThe Names of Allah and Their ReflectionsSuleyman HldPas encore d'évaluation

- Minimess CouplingDocument39 pagesMinimess Couplingani_datPas encore d'évaluation

- Solution Manual-Statistical Physics of Particles by Meheran KardarDocument165 pagesSolution Manual-Statistical Physics of Particles by Meheran KardarDanielle Nguyen7% (14)

- A4-80 Stainless Steel Grade Specification - Midland Bright SteelsDocument4 pagesA4-80 Stainless Steel Grade Specification - Midland Bright SteelsramonagherghePas encore d'évaluation

- Catalog - Texas FlangesDocument76 pagesCatalog - Texas FlangesVicky GautamPas encore d'évaluation

- Manual CAT 345C LDocument20 pagesManual CAT 345C LRicardo SotoPas encore d'évaluation

- ASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound GasketsDocument5 pagesASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound Gasketserik aranaPas encore d'évaluation

- Turning The Mind Into An AllyDocument244 pagesTurning The Mind Into An AllyNic Sosa67% (3)

- 30 Risk and InsuranceDocument4 pages30 Risk and InsuranceSiti Nur Ain RamliPas encore d'évaluation

- Roark's FormulasDocument14 pagesRoark's FormulasDavide FerraresePas encore d'évaluation

- 22-Stainless Steel Aisi 316 (A4)Document1 page22-Stainless Steel Aisi 316 (A4)Paul OnionsPas encore d'évaluation

- Design of Obround Flange For Pressure Vessel Application by Analytical Method and FEA To Comply With ASME CodeDocument11 pagesDesign of Obround Flange For Pressure Vessel Application by Analytical Method and FEA To Comply With ASME CodeFelip PrietoPas encore d'évaluation

- Design of Obround Flange For Pressure Vessel Application by Analytical Method and FEA To Comply With ASME CodeDocument11 pagesDesign of Obround Flange For Pressure Vessel Application by Analytical Method and FEA To Comply With ASME CodeFelip PrietoPas encore d'évaluation

- DIN 3015 ClampsDocument20 pagesDIN 3015 ClampsRasheshPas encore d'évaluation

- Design of Fillet Weld (As Per Bs en 1993 1 8, CL 4.5.3) : KN M KN KN M KN KN MMDocument2 pagesDesign of Fillet Weld (As Per Bs en 1993 1 8, CL 4.5.3) : KN M KN KN M KN KN MMGiri DharanPas encore d'évaluation

- 12 Point Flange ScrewsDocument1 page12 Point Flange ScrewsstugwynnePas encore d'évaluation

- JIS SectionDocument2 pagesJIS SectionthakrarhitsPas encore d'évaluation

- Bs7531 Grade y MasterDocument1 pageBs7531 Grade y Masterheena jainPas encore d'évaluation

- Pressure Equipment - European Commission NORMASDocument23 pagesPressure Equipment - European Commission NORMASFelip PrietoPas encore d'évaluation

- 4991 2004 PDFDocument9 pages4991 2004 PDFsskamalakannanPas encore d'évaluation

- The Sword and The Exquisiteness PDFDocument1 437 pagesThe Sword and The Exquisiteness PDFTaruna UnitaraliPas encore d'évaluation

- AS NZS 4680-2006 Hot-Dip Galvanized - Zinc - CoatingsDocument33 pagesAS NZS 4680-2006 Hot-Dip Galvanized - Zinc - Coatingsasaram1Pas encore d'évaluation

- BS 3799 (74) Specification For Steel Pipe Fittings, Screwed and Socket-Welding For The Petroleum Industry PDFDocument32 pagesBS 3799 (74) Specification For Steel Pipe Fittings, Screwed and Socket-Welding For The Petroleum Industry PDFjodasi300% (1)

- Bisalloy: Bunge Industrial Steels Pty. LimitedDocument65 pagesBisalloy: Bunge Industrial Steels Pty. Limitedramaus100% (1)

- Asme b16.20 StandardsDocument1 pageAsme b16.20 StandardsJakir HossainPas encore d'évaluation

- Asme Sec Viii D2 Art D-2 PDFDocument10 pagesAsme Sec Viii D2 Art D-2 PDFDieguitoOmarMoralesPas encore d'évaluation

- High Strength Structural Bolt Assemblies To As/nzs 1252Document4 pagesHigh Strength Structural Bolt Assemblies To As/nzs 1252Josh Maizidian100% (1)

- Star Core 6Document2 pagesStar Core 6jmur10Pas encore d'évaluation

- Metric DIN 434 Square Taper Washers: Visit Our For Product AvailabilityDocument4 pagesMetric DIN 434 Square Taper Washers: Visit Our For Product AvailabilityRodrigoPas encore d'évaluation

- Jis g3456 Grade STPT 410 Pipes PDFDocument1 pageJis g3456 Grade STPT 410 Pipes PDFMitul MehtaPas encore d'évaluation

- B Jack Nos For Cs Ss MaterialDocument12 pagesB Jack Nos For Cs Ss MaterialfahadfiazPas encore d'évaluation

- Knife Gate Valve - AVKCMSDocument2 pagesKnife Gate Valve - AVKCMSjuantamad02Pas encore d'évaluation

- Garlock GYLON Style 3501 - Spec Sheet - (NA) 2016-12 enDocument1 pageGarlock GYLON Style 3501 - Spec Sheet - (NA) 2016-12 ennmosilvaPas encore d'évaluation

- Catalogo GASKET General Measurement TablesDocument20 pagesCatalogo GASKET General Measurement TablescastibraPas encore d'évaluation

- Mechanical Properties Min. 0,2 % Yield Strength Values at Increased TemperaturesDocument4 pagesMechanical Properties Min. 0,2 % Yield Strength Values at Increased TemperaturesJarek CieslakPas encore d'évaluation

- Pre-Load For BoltDocument6 pagesPre-Load For BoltJ.GuerhardPas encore d'évaluation

- Hinge DesignDocument2 pagesHinge Designpare222Pas encore d'évaluation

- AMS 5699, Inconel X-750Document1 pageAMS 5699, Inconel X-750Khai HuynhPas encore d'évaluation

- Material Conversion TableDocument3 pagesMaterial Conversion TableNo PersonPas encore d'évaluation

- RRC 271 DDocument64 pagesRRC 271 Drfuentes73Pas encore d'évaluation

- The Definitive O Ring Design GuideDocument31 pagesThe Definitive O Ring Design GuideChezPas encore d'évaluation

- En 10025 S235JR SteelDocument2 pagesEn 10025 S235JR SteelAgung Nak OtomotifPas encore d'évaluation

- DIN 580 ISO 3266: Lifting Eye BoltsDocument2 pagesDIN 580 ISO 3266: Lifting Eye BoltsbloggerparthiPas encore d'évaluation

- Ccsviiid1 2260Document2 pagesCcsviiid1 2260DieguitoOmarMoralesPas encore d'évaluation

- Equivalent Steel GradesDocument6 pagesEquivalent Steel GradesPapaiPas encore d'évaluation

- DNV OS-H102 Marine Operations Design and Fabrication 2012-01Document12 pagesDNV OS-H102 Marine Operations Design and Fabrication 2012-01Marios DiasPas encore d'évaluation

- OPSS 906 - Nov12Document20 pagesOPSS 906 - Nov12umerfr2Pas encore d'évaluation

- Ameron FRP Fittings 7000MDocument8 pagesAmeron FRP Fittings 7000MNatchimuthu Durai BalanPas encore d'évaluation

- Valve MaterialsDocument9 pagesValve MaterialsVu Tung LinhPas encore d'évaluation

- Tightening Torque StableDocument5 pagesTightening Torque Stablemasmarkun4444Pas encore d'évaluation

- Din Flange Din 2627: (Dimensions in MM.)Document12 pagesDin Flange Din 2627: (Dimensions in MM.)Wisüttisäk PeäröönPas encore d'évaluation

- API5LDocument3 pagesAPI5LputrudePas encore d'évaluation

- API 650 Storage Tank HRD - SubDocument7 pagesAPI 650 Storage Tank HRD - SubBimal DeyPas encore d'évaluation

- Aluminium Alloy 6061Document3 pagesAluminium Alloy 6061choobyPas encore d'évaluation

- Flange GradesDocument8 pagesFlange Gradesaateka02Pas encore d'évaluation

- ErmetoDocument14 pagesErmetoJavier VespaPas encore d'évaluation

- Grade Chemical Composition (% by Mass - Max Unless Stated) Ferritic SteelsDocument15 pagesGrade Chemical Composition (% by Mass - Max Unless Stated) Ferritic SteelsSenthil KumarPas encore d'évaluation

- Csa-G40 350WLRDocument2 pagesCsa-G40 350WLRMario VenturaPas encore d'évaluation

- WEBFORGE - Grating CatalogueDocument10 pagesWEBFORGE - Grating CatalogueSaravan KumarPas encore d'évaluation

- NPS - 'Nominal Pipe Size' and DN - 'Diametre Nominal'Document3 pagesNPS - 'Nominal Pipe Size' and DN - 'Diametre Nominal'harisPas encore d'évaluation

- Global Marketing For Tube & Pipe: JIS G3457 Arc Welded Carbon Steel PipesDocument7 pagesGlobal Marketing For Tube & Pipe: JIS G3457 Arc Welded Carbon Steel PipesNurzed MunkhbayarPas encore d'évaluation

- Factores de JuntaDocument3 pagesFactores de JuntaBib GmzPas encore d'évaluation

- Minimess KatalogDocument39 pagesMinimess Kataloganeesh awasthiPas encore d'évaluation

- General Arrangement - Plan: 3300-15R-132 A 240K-C2-1:300Document1 pageGeneral Arrangement - Plan: 3300-15R-132 A 240K-C2-1:300Leo Unocc YauriPas encore d'évaluation

- 198 Faf2500 Flanged y Type StrainerDocument4 pages198 Faf2500 Flanged y Type Strainerinfo8176Pas encore d'évaluation

- MDFO UK LowDocument17 pagesMDFO UK Lowmsn86Pas encore d'évaluation

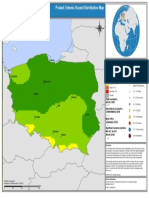

- Poland Seismic ZonesDocument1 pagePoland Seismic ZonesFelip PrietoPas encore d'évaluation

- Super-Sized Home EntertainmentDocument5 pagesSuper-Sized Home EntertainmentFelip PrietoPas encore d'évaluation

- AD 2000-Merkblatt (B4 - Dished Heads)Document1 pageAD 2000-Merkblatt (B4 - Dished Heads)Felip PrietoPas encore d'évaluation

- VRF-SLB013-EN - 0805115 - Catalogo Ingles 2015 PDFDocument50 pagesVRF-SLB013-EN - 0805115 - Catalogo Ingles 2015 PDFJhon Lewis PinoPas encore d'évaluation

- Ashfaque Ahmed-The SAP Materials Management Handbook-Auerbach Publications, CRC Press (2014)Document36 pagesAshfaque Ahmed-The SAP Materials Management Handbook-Auerbach Publications, CRC Press (2014)surajnayak77Pas encore d'évaluation

- SafetyStock OverviewDocument3 pagesSafetyStock OverviewJosue FonsecaPas encore d'évaluation

- RG-RAP6260 (G) Hardware InstallationDocument26 pagesRG-RAP6260 (G) Hardware InstallationrazuetPas encore d'évaluation

- Math Cad 15Document3 pagesMath Cad 15Kim ChanthanPas encore d'évaluation

- Menu Planning in HospitalDocument4 pagesMenu Planning in HospitalERva Soelkarnaen100% (1)

- Introduction of Woman Role in SocietyDocument12 pagesIntroduction of Woman Role in SocietyApple DogPas encore d'évaluation

- Spring Newsletter 2014-LockedDocument4 pagesSpring Newsletter 2014-Lockedapi-244488788Pas encore d'évaluation

- How To Spend An Hour A Day in Prayer - Matthew 26:40-41Document1 pageHow To Spend An Hour A Day in Prayer - Matthew 26:40-41Steve GainesPas encore d'évaluation

- Stability TestDocument28 pagesStability TestjobertPas encore d'évaluation

- AA-SM-010 Stress Due To Interference Fit Bushing Installation - Rev BDocument3 pagesAA-SM-010 Stress Due To Interference Fit Bushing Installation - Rev BMaicon PiontcoskiPas encore d'évaluation

- How To Connect To iSCSI Targets On QNAP NAS Using MPIO On Windows 2008Document30 pagesHow To Connect To iSCSI Targets On QNAP NAS Using MPIO On Windows 2008Jazz OberoiPas encore d'évaluation

- Jo - Mc.Donough. ESP in Perspective A Practical Guide. London. Collin ELT. 1984. p.3Document6 pagesJo - Mc.Donough. ESP in Perspective A Practical Guide. London. Collin ELT. 1984. p.3Falihatul Kholidiyah100% (1)

- Enable Modern Authentication in Exchange OnlineDocument2 pagesEnable Modern Authentication in Exchange Onlinedan.artimon2791Pas encore d'évaluation

- Roles of Community Health NursingDocument2 pagesRoles of Community Health Nursingdy kimPas encore d'évaluation

- Ruby Onyinyechi Amanze - Werte Magazine - 2019Document2 pagesRuby Onyinyechi Amanze - Werte Magazine - 2019José LaertonPas encore d'évaluation

- Datasheet TBJ SBW13009-KDocument5 pagesDatasheet TBJ SBW13009-KMarquinhosCostaPas encore d'évaluation

- Marisa Wolf Final New ResumeDocument2 pagesMarisa Wolf Final New Resumeapi-403499166Pas encore d'évaluation

- Volcanic SoilsDocument14 pagesVolcanic SoilsVictor Hugo BarbosaPas encore d'évaluation

- CN Blue Love Rigt Lyrics (Romanized)Document3 pagesCN Blue Love Rigt Lyrics (Romanized)Dhika Halet NinridarPas encore d'évaluation

- Cyanocobalamin Injection Clinical Pharmacology Drug MonographDocument36 pagesCyanocobalamin Injection Clinical Pharmacology Drug MonographLaureyPas encore d'évaluation

- HH220i - JAN 11Document1 pageHH220i - JAN 11Achmad GazaliPas encore d'évaluation

- Two Occult Philosophers in The Elizabethan Age: by Peter ForshawDocument10 pagesTwo Occult Philosophers in The Elizabethan Age: by Peter ForshawFrancesco VinciguerraPas encore d'évaluation

- Design of A Low Cost Hydrostatic Bearing: Anthony Raymond WongDocument77 pagesDesign of A Low Cost Hydrostatic Bearing: Anthony Raymond WongRogelio DiazPas encore d'évaluation