Académique Documents

Professionnel Documents

Culture Documents

Advanced Kiln Optimization

Transféré par

Ehab SabryDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Advanced Kiln Optimization

Transféré par

Ehab SabryDroits d'auteur :

Formats disponibles

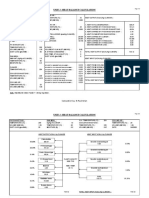

Training Department

Advanced Kiln Optimization

Duration

5 days

Objectives:

Clinker is the component that after grinding with gypsum gives the cement its

desired properties.

Therefore clinkerization of raw meal in Cement Rotary kilns is considered the most

important step in the process of cement production.

Operation of Cement Rotary Kilns requires a very Professional attitude and

knowledge, deep and profound experience on the part of rotary kiln manager,

besides understanding of kiln operation techniques, dedication and discipline on

behalf of kiln operators.

Their job during kiln operation is to operate the kiln in such a way to achieve it

nominal capacity with the lowest fuel and electrical energy consumption and with

the highest clinker quality.

In addition to this the operator is responsible for the safety of equipment and to

protect plant equipment from any damage during operation that can be caused by

shortage of training that can cause misunderstanding of kiln operation techniques.

If the techniques applied in kiln operation are not efficient; the product will be of no

market value due to low quality and plant will lose its reliability and efficiency and

consequently productivity will suffer.

Participants:

This course addresses professionals working as supervisors in rotary kiln system

and for kiln operation staff (kiln managers, operators) with a minimum of 3 year of

kiln operation experience.

Course contents:

Course outline

1.

Raw materials impact on Cement Rotary Kiln Operation

2.

Combustion of fuel in Rotary Cement Kilns

3.

Sulfur & Chlorine and Alkalis in Rotary Cement Kilns

4.

Kiln Operation

5.

Kiln Start up Techniques

6.

Kiln Shutdown Techniques

7.

Cement Rotary kiln Operation

8.

Troubleshooting in Rotary Cement Kilns

9.

Kiln Supervisor Roll in Rotary Cement Kilns

Training Department

Duration

days

:

.

.

.

:

:

.1

.2

.3

.4

.5

.6

.7 )(

.8

.9

Vous aimerez peut-être aussi

- Cooling Cement Clinker Exercise2.3.4Document2 pagesCooling Cement Clinker Exercise2.3.4Mohammed AbdoPas encore d'évaluation

- Brown ClinkerDocument21 pagesBrown ClinkerTamer Fathy0% (1)

- Technological Advancement in Cement Manufacturing Industry: System Length DiameterDocument16 pagesTechnological Advancement in Cement Manufacturing Industry: System Length Diameterfaran100% (3)

- Clinker CoolersDocument12 pagesClinker CoolersAkhilesh Pratap SinghPas encore d'évaluation

- RCA - IV Cyclone Blockage 11.12.14Document6 pagesRCA - IV Cyclone Blockage 11.12.14Visnu SankarPas encore d'évaluation

- Calculation of The Formation Process of Clinker inDocument7 pagesCalculation of The Formation Process of Clinker inYounas BugtiPas encore d'évaluation

- Energy Auditing and Recovery For Dry Type Cement Rotary Kiln Systems A Case StudyDocument12 pagesEnergy Auditing and Recovery For Dry Type Cement Rotary Kiln Systems A Case Study1977julPas encore d'évaluation

- By Pass SystemDocument56 pagesBy Pass SystemIrshad Hussain100% (2)

- 7-Mineral Phases of Portland CementDocument28 pages7-Mineral Phases of Portland CementzamriseramikPas encore d'évaluation

- Lucie MillDocument50 pagesLucie MillJoko DewotoPas encore d'évaluation

- Cement KilnDocument2 pagesCement Kilnamir100% (2)

- Presentasi Build UpDocument13 pagesPresentasi Build UpJoko Dewoto100% (1)

- VDZ - Optimising The Clinker Burning ProcessDocument2 pagesVDZ - Optimising The Clinker Burning ProcessfoxmancementPas encore d'évaluation

- 1.0 General Plant Information: Existing Cement Mill Process Data SheetDocument6 pages1.0 General Plant Information: Existing Cement Mill Process Data SheetBùi Hắc HảiPas encore d'évaluation

- Hasler Process Performance Engineer at HolcimDocument10 pagesHasler Process Performance Engineer at Holcimvikubhardwaj9224Pas encore d'évaluation

- 3500TPD Cement Plant Heat BalanceDocument2 pages3500TPD Cement Plant Heat BalanceIrshad HussainPas encore d'évaluation

- 7 Most Common Problem in PyroProcessing For Kiln and CoolerDocument5 pages7 Most Common Problem in PyroProcessing For Kiln and CoolerbudiPas encore d'évaluation

- Circulation of Inorganic Elements in Combustion of Alternative Fuels in Cement PlantsDocument85 pagesCirculation of Inorganic Elements in Combustion of Alternative Fuels in Cement PlantsBetonÇimento100% (3)

- V5 Process Technology 3Document441 pagesV5 Process Technology 3Pavel ParfenovPas encore d'évaluation

- Pet Coke Fuel Experience in Rotary KilnDocument7 pagesPet Coke Fuel Experience in Rotary KilnP.S.J.Sarma100% (1)

- A Better Kiln CoatingDocument2 pagesA Better Kiln Coatingamir100% (4)

- Rotaflam Presentation 2004: Pillard Burner Tip RepairDocument11 pagesRotaflam Presentation 2004: Pillard Burner Tip RepairmustafPas encore d'évaluation

- Difference Between Alk Sulphate Ratio and MSO3Document2 pagesDifference Between Alk Sulphate Ratio and MSO3avisgop100% (2)

- Coal Flames For Cement KilnsDocument62 pagesCoal Flames For Cement KilnsvvijaybhanPas encore d'évaluation

- The Effects of Limestone Addition, Clinker Type and Fineness PDFDocument5 pagesThe Effects of Limestone Addition, Clinker Type and Fineness PDFHazem DiabPas encore d'évaluation

- Kfui (K F U I) : Chapter II - A Iln Eed Niformity NdexDocument25 pagesKfui (K F U I) : Chapter II - A Iln Eed Niformity NdexFranciscoCorreaJara100% (2)

- How To Measure False Air PDFDocument3 pagesHow To Measure False Air PDFharyantoaditPas encore d'évaluation

- Quality & Composition of Cement Clinker - INFINITY FOR CEMENT EQUIPMENT PDFDocument74 pagesQuality & Composition of Cement Clinker - INFINITY FOR CEMENT EQUIPMENT PDFSiddharth Singh100% (1)

- Alkali Khaled PDFDocument21 pagesAlkali Khaled PDFbulentbulut100% (1)

- Cement Mill: History Materials Ground Temperature Control Ball MillsDocument5 pagesCement Mill: History Materials Ground Temperature Control Ball MillsAli HadiPas encore d'évaluation

- Heat Consumption Mastery Standard: CementDocument16 pagesHeat Consumption Mastery Standard: CementJunaid Mazhar100% (3)

- The Effects of Oxygen Enrichment On ClinkerDocument9 pagesThe Effects of Oxygen Enrichment On ClinkerNael100% (1)

- Clinker Vs Kiln Feed FactorDocument3 pagesClinker Vs Kiln Feed Factorvvijaybhan100% (6)

- Duoflex BurnerDocument6 pagesDuoflex Burnersinghite100% (1)

- Click Here To Download Holcim, , Lafarge, Most Importnant Manuals, Most Important ExcelDocument26 pagesClick Here To Download Holcim, , Lafarge, Most Importnant Manuals, Most Important ExcelhamedPas encore d'évaluation

- Cement IndustryDocument27 pagesCement IndustryAhmed Mahmoud100% (1)

- Vade MecumDocument162 pagesVade MecumAdnan Nawaz100% (1)

- CTEO Chapter II C Process EffectsDocument12 pagesCTEO Chapter II C Process EffectsFranciscoCorreaJaraPas encore d'évaluation

- Ring Formation in KilnDocument12 pagesRing Formation in KilnAbul Qasim100% (2)

- Infinity For Cement Equipment: Quality & Composition of Cement ClinkerDocument48 pagesInfinity For Cement Equipment: Quality & Composition of Cement ClinkerYhanePas encore d'évaluation

- Heat Balance DiagramDocument29 pagesHeat Balance Diagramsanju_cgh100% (2)

- Cement Separator & Ball Mill OptimizationDocument29 pagesCement Separator & Ball Mill OptimizationAdelezzat OmranPas encore d'évaluation

- Factor Affecting Cement StrengthDocument13 pagesFactor Affecting Cement StrengthGirma TesemaPas encore d'évaluation

- PREHEATER BLOCKAGES Problem Diagnosis and Solution - INFINITY FOR CEMENT EQUIPMENTDocument19 pagesPREHEATER BLOCKAGES Problem Diagnosis and Solution - INFINITY FOR CEMENT EQUIPMENTali100% (2)

- Rotaflam PillardDocument34 pagesRotaflam PillardRogério CorreiaPas encore d'évaluation

- Ask DR. CLARK - OdtDocument50 pagesAsk DR. CLARK - Odtmauryaraj200750% (2)

- What Is A Process ControlDocument17 pagesWhat Is A Process ControlpashaPas encore d'évaluation

- Burner Basic TheoryDocument10 pagesBurner Basic Theoryehtisham zaibPas encore d'évaluation

- FLSmidth - Cement Training Catalogue 2018 PDFDocument12 pagesFLSmidth - Cement Training Catalogue 2018 PDFbertawan bastiarPas encore d'évaluation

- PetroSync - Coiled Tubing Operation 2023 Oil Gas TrainingDocument11 pagesPetroSync - Coiled Tubing Operation 2023 Oil Gas TrainingPetro SyncPas encore d'évaluation

- Kiln Trouble ShootingDocument3 pagesKiln Trouble Shootingemad sabriPas encore d'évaluation

- Operator Training and Simulation Fundamentals Distillation OperationDocument2 pagesOperator Training and Simulation Fundamentals Distillation OperationshakPas encore d'évaluation

- Curriculum For Knitting Machine Operator-QA PDFDocument51 pagesCurriculum For Knitting Machine Operator-QA PDFNaveed ShoukatPas encore d'évaluation

- Ots 0009 at en Des 544 r000 Rev01 0 Operator Training and Simulation Fun PDFDocument2 pagesOts 0009 at en Des 544 r000 Rev01 0 Operator Training and Simulation Fun PDFWahaj ShafiPas encore d'évaluation

- Syllabus 2013.updateDocument27 pagesSyllabus 2013.updatemaspanuciPas encore d'évaluation

- CVDocument3 pagesCVMansoor Khanali100% (1)

- ResumeDocument5 pagesResumeVaibhav Vithoba NaikPas encore d'évaluation

- Intrajan2021 - Presentation 53211117470 Afiq Faizul Bin Zulkiflee-Umw AerospaceDocument15 pagesIntrajan2021 - Presentation 53211117470 Afiq Faizul Bin Zulkiflee-Umw AerospaceasfafasfPas encore d'évaluation

- Centrifugal Service and Repair 2018Document4 pagesCentrifugal Service and Repair 2018Black SmithPas encore d'évaluation

- Presentation 1Document12 pagesPresentation 1Amirul AmriPas encore d'évaluation

- Kalina Cycle and Cement IndustryDocument8 pagesKalina Cycle and Cement IndustryEhab SabryPas encore d'évaluation

- Condition Monitoring Benefits For Cement ManufacturingDocument12 pagesCondition Monitoring Benefits For Cement ManufacturingEhab SabryPas encore d'évaluation

- Low Grade Waste Heat Recovery For Optimized Energy Efficiencies and Enhanced Sustainability in Process Industries A Comprehensive ReviewDocument12 pagesLow Grade Waste Heat Recovery For Optimized Energy Efficiencies and Enhanced Sustainability in Process Industries A Comprehensive ReviewEhab Sabry100% (1)

- Inventor Level 1Document7 pagesInventor Level 1Ehab SabryPas encore d'évaluation

- Central Jet Pulse FilterDocument4 pagesCentral Jet Pulse FilterEhab Sabry100% (1)

- Op Amp TutorialDocument41 pagesOp Amp Tutorialpuliking123Pas encore d'évaluation

- Inova T3Document1 pageInova T3Ehab SabryPas encore d'évaluation

- Blaine Fineness ASTM C 204Document9 pagesBlaine Fineness ASTM C 204Angel NazPas encore d'évaluation

- At 89 S 52Document38 pagesAt 89 S 52Long NguyenPas encore d'évaluation

- Home AutomationDocument25 pagesHome AutomationEhab Sabry50% (2)

- Brinell Hardness TestDocument3 pagesBrinell Hardness TestEhab SabryPas encore d'évaluation

- Example Technical ReportDocument2 pagesExample Technical ReportEhab SabryPas encore d'évaluation

- Overview and Tutorial On Artificial Intelligence Systems: Eric ConradDocument6 pagesOverview and Tutorial On Artificial Intelligence Systems: Eric ConradEhab SabryPas encore d'évaluation

- Basic PLCDocument127 pagesBasic PLCEhab Sabry100% (3)

- Numerical Reasoning Test2 QuestionsDocument11 pagesNumerical Reasoning Test2 QuestionsvarshnnhPas encore d'évaluation

- Meo Class II ElectricalDocument1 pageMeo Class II ElectricalArpit GoyalPas encore d'évaluation

- Difense University Institute of Technology: By: Dr. Milkias B. (PH.D.) Adama Science and Technology UniversityDocument52 pagesDifense University Institute of Technology: By: Dr. Milkias B. (PH.D.) Adama Science and Technology UniversityyaredPas encore d'évaluation

- Poradnik Hugha PiggottaDocument157 pagesPoradnik Hugha PiggottaMarian AriciucPas encore d'évaluation

- Sources of Radiant EnergyDocument1 pageSources of Radiant EnergyRjvm Net Ca Fe100% (1)

- Basic Principle II Second Class Dr. Arkan Jasim HadiDocument9 pagesBasic Principle II Second Class Dr. Arkan Jasim Hadimeilana23Pas encore d'évaluation

- Boost ProjectDocument13 pagesBoost ProjectAbdur RahmanPas encore d'évaluation

- Experiment 2 - DC Power SupplyDocument6 pagesExperiment 2 - DC Power SupplySam67% (3)

- Environmental Systems and Societies Paper 2 SL MarkschemeDocument6 pagesEnvironmental Systems and Societies Paper 2 SL MarkschemeAfra LamisaPas encore d'évaluation

- WECC Second Generation Wind Turbine Models 012314Document36 pagesWECC Second Generation Wind Turbine Models 012314SaeedAhmedKhanPas encore d'évaluation

- Datasheet Ps 10000 3u 15kw enDocument15 pagesDatasheet Ps 10000 3u 15kw engigel1980Pas encore d'évaluation

- European Marketscan: European Products ($/MT) ICE FuturesDocument9 pagesEuropean Marketscan: European Products ($/MT) ICE FuturesWallace YankotyPas encore d'évaluation

- Effizienzhausplus Elektromobil en Aufl1Document17 pagesEffizienzhausplus Elektromobil en Aufl1Wessel SimonsPas encore d'évaluation

- M6 TTT Course Posters Final1 PDFDocument1 pageM6 TTT Course Posters Final1 PDFJCAPas encore d'évaluation

- 3244cr Four Stroke Diesel Engine - 3 PDFDocument9 pages3244cr Four Stroke Diesel Engine - 3 PDFalulgamePas encore d'évaluation

- Emerson's Power Solution To AAI 19-Dec-11Document123 pagesEmerson's Power Solution To AAI 19-Dec-11oicfbdPas encore d'évaluation

- SG Unit6ProgressCheckMCQ 63fd8804e35951.63fd880808f2a9.47859323Document10 pagesSG Unit6ProgressCheckMCQ 63fd8804e35951.63fd880808f2a9.47859323vDraqPas encore d'évaluation

- Eocr SSDocument2 pagesEocr SStrngocnamPas encore d'évaluation

- CHEM2122 General Chemistry Week 11 - 19 by Querubin Cabalida GR12Document14 pagesCHEM2122 General Chemistry Week 11 - 19 by Querubin Cabalida GR12Cesar TuñacaoPas encore d'évaluation

- 1628172537BS-Curriculum-GEB 2019-2020 OnwordDocument113 pages1628172537BS-Curriculum-GEB 2019-2020 OnwordLuminous AudioBooksPas encore d'évaluation

- Thermofluids Exit ReviewDocument73 pagesThermofluids Exit Reviewben richPas encore d'évaluation

- Carnot Engine (Application of The Second Law of Thermodynamics) Problems and SolutionsDocument2 pagesCarnot Engine (Application of The Second Law of Thermodynamics) Problems and SolutionsFUN SCIENCEPas encore d'évaluation

- Cyber CafeDocument1 pageCyber Cafeindia4gPas encore d'évaluation

- Waste Incineration Heat Recovery at Roche IrelandDocument12 pagesWaste Incineration Heat Recovery at Roche IrelandidrieshamidiPas encore d'évaluation

- Earthing or Grounding MCQ Questions & Answers - Electrical EngineeringDocument4 pagesEarthing or Grounding MCQ Questions & Answers - Electrical EngineeringKhushal shendePas encore d'évaluation

- Combined Cycle GTW Specs - Rule of Thumb EstimationsDocument4 pagesCombined Cycle GTW Specs - Rule of Thumb EstimationsvankayalasuryaPas encore d'évaluation

- The Great Energy Rip OffDocument19 pagesThe Great Energy Rip OffRobert H HalfonPas encore d'évaluation

- UNCC 2013 WorkshopDocument241 pagesUNCC 2013 WorkshopRicardo HungriaPas encore d'évaluation

- Acoustic Energy HarvestingDocument2 pagesAcoustic Energy HarvestingBikram PantheePas encore d'évaluation

- SC3000 Line Voltage Fan Coil Relay Pack - Installation SheetDocument9 pagesSC3000 Line Voltage Fan Coil Relay Pack - Installation SheetLuis Oliver Neciosup VasquezPas encore d'évaluation