Académique Documents

Professionnel Documents

Culture Documents

Prefunctional Checklists

Transféré par

renjithv_4Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Prefunctional Checklists

Transféré par

renjithv_4Droits d'auteur :

Formats disponibles

1. Installation Checks Check if Okay. Enter N/A if not applicable. Enter Note number if deficient.

Check Equip Ta Cabinet and !eneral Installation "ermanent labels affi#ed$ includin for fans Casin condition ood% no dents$ leaks$ door installed Access doors close ti htly & no leaks 'oot bet(een duct and unit ti ht and in ood condition )ibration isolation equipment installed * released from shippin locks +aintenance access acceptable for unit and components ,ound attenuation installed Thermal insulation properly installed and accordin specification to askets

Contr.

Instrumentation installed accordin to specification -thermometers$ pressure a es$ flo( meters$ etc.. Clean up of equipment completed per contract documents /ilters installed and replacement type and efficiency permanently affi#ed to housin "ipin and Coils No leakin apparent around refri erant fittin s All coils are clean and fins are in ood condition All condensate drain pans clean and slope to drain per spec O,AT$ +AT$ ,AT$ 0AT sensors properly located and secure -related O,AT sensor shielded. ,ensors calibrated -,ee calibration section belo(. If split system$ refri erant pipin in ood condition and suction insulated "/T plu s and isolation 1al1es installed per dra(in s /ans and 2ampers ,upply fan and motor ali nment appear correct ,upply fan belt tension * condition ood ,upply fan protecti1e shrouds for belts in place and secure ,upply fan area clean ,upply fan and motor properly lubricated 0eturn/e#haust fan and motor ali ned 0eturn/e#haust fan belt tension * condition ood 0eturn/e#haust fan protecti1e shrouds for belts in place and secure 0eturn/e#haust fan area clean 0eturn/e#haust fan and motor lube lines installed and lubed /ilters installed and replacement type and efficiency permanently affi#ed to housin &&construction filters remo1ed CITYWIDE PUBLIC SAFETY BOND PROGRAM PREFUNCTIONAL CHECKLISTS RAMPART REPLACEMENT STATION

01813-1

Check Equip Ta /ilter pressure differential measurin de1ice installed and functional -ma nahelic$ inclined manometer$ etc.. All dampers close ti htly All damper linka es ha1e minimum play +otors% premium efficiency 1erified$ if specified3 Compressor and Condenser 0efri erant si ht lass clear of bubbles -if O,AT 4 56/. +oisture indicator sho(s no moisture Correct oil le1el -check site lass durin operation. Compressors and pipin (ere leak tested$ as required Crankcase heater on (hen unit is off Condenser coils clean and in ood condition -air cooled. Adequate clearance for airflo( around condenser 2ucts -preliminary check. ,ound attenuators installed 2uct 7oint sealant properly installed No apparent se1ere duct restrictions Turnin 1anes in square elbo(s as per dra(in s O,A intakes located a(ay from pollutant sources * e#haust outlets "ressure leaka e tests completed 'ranch duct control dampers operable 'alancin dampers installed as per dra(in s and TA'8s site 1isit Electrical and Controls "o(er disconnects in place and labeled All electric connections ti ht "roper roundin installed for components and unit ,afeties in place and operable Current o1erload heaters installed and correct si9e Au#iliary heaters installed ,ensors calibrated -see section belo(. All buildin control system interlocks hooked up (ith packa ed controls and functional Enthalpy control and sensor properly installed -if applicable. 0elated thermostats are installed 0elated buildin automation system points are installed All control de1ices and (irin complete TA' Installation of system and balancin de1ices (ill allo( balancin to be done per specified NE'' or AA'C procedures * contract docs /inal CITYWIDE PUBLIC SAFETY BOND PROGRAM PREFUNCTIONAL CHECKLISTS RAMPART REPLACEMENT STATION

Contr.

01813-2

Check Equip Ta ,afeties installed and safe operatin ran es are established /unctional test procedures for this equipment re1ie(ed and appro1ed by installin contractor If unit is started and (ill be runnin durin construction% ha1e quality filters on 0A rills$ etc. to minimi9e dirt in the duct(ork and coils and in any finished areas. )erify moisture mi ration is not a problem due to improper pressures bet(een spaces. Checklist items of "art : are all successfully completed for i1en trade; <<<<=es

Contr.

<<<<No

CITYWIDE PUBLIC SAFETY BOND PROGRAM PREFUNCTIONAL CHECKLISTS RAMPART REPLACEMENT STATION

01813-3

:. Operational Checks -These au ment manufacturer8s list. This is not a functional performance test. Check if Okay. Enter N/A if not applicable. Enter Note number if deficient. Check Equip Ta Contr. ,upply fan rotation correct 0eturn / e#haust fan rotation correct No unusual noise or 1ibration in supply and e#haust fans Condenser fan rotation correct -air cooled. Condenser fan acceptable noise and 1ibration -air cooled. +easure line to line 1olta e imbalance for 1/> of the compressors% Compressor 1 "hase% -?Imbalance @ 166 # -a1 . & lo(est. / a1 .. 0ecord in cell$ all three phase 1olta es. Imbalance less than :?3 Compressor : "hase% -?Imbalance @ 166 # -a1 . & lo(est. / a1 .. 0ecord in cell$ all three phase 1olta es. Imbalance less than :?3 0ecord full load runnin amps for each compressor. <<<<<rated /A amps # <<<<<<sr1c factor @ <<<<<<< -+a# amps.. 0unnin less than ma#3 0ecord full load runnin amps for each condenser fan. <<<<<rated /A amps # <<<<<<sr1c factor @ <<<<<<< -+a# amps.. 0unnin less than ma#3 /ans 4 B hp "hase Checks% -? imbalance @ 166 # -a1 . & lo(est. / a1 .. Aist fan * record all > 1olta es in cell. Imbalance less than :?3 0ecord full load runnin amps for each fan. <<<<<rated /A amps # <<<<<<sr1c factor @ <<<<<<< -+a# amps.. 0unnin less than ma#3 Inlet 1anes ali ned in housin $ actuator spanned$ modulate smoothly and proportional to input si nal and E+, readout. All dampers -O,A$ 0A$ EA$ etc.. stroke fully (ithout bindin and spans calibrated and 'A, readin site 1erified -follo( procedure in Calibration and Aeak&by Test "rocedures.. Aist dampers checked% <<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<< <<<< )al1es stroke fully and easily and spannin is calibrated -follo( procedure in Calibration and Aeak&by Test "rocedures.. Aist each actuated 1al1e here (hen spanned% <<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<< <<<< )al1es 1erified to not be leakin throu h coils (hen closed at normal operatin pressure -follo( procedure in Calibration and Aeak&by Test "rocedures.. The COA s(itch properly acti1ates and deacti1ates the unit CITYWIDE PUBLIC SAFETY BOND PROGRAM PREFUNCTIONAL CHECKLISTS RAMPART REPLACEMENT STATION

01813-4

Check Equip Ta ,afeties installed and safe operatin ran es for this equipment pro1ided to the commissionin a ent ,pecified sequences of operation and operatin schedules ha1e been implemented (ith all 1ariations documented ,pecified point&to&point checks ha1e been completed and documentation record submitted for this system Checklist items of "art > are all successfully completed for i1en trade; <<<=es <<<No

Contr.

>. ,ensor and Actuator Calibration DContr. @ <<<<<< E All field&installed temperature$ relati1e humidity$ CO$ CO : and pressure sensors and a es$ and all actuators -dampers and 1al1es. on this piece of equipment shall be calibrated usin the methods and tolerances i1en in the Calibration and Aeak&by Test "rocedures document. All test instruments shall ha1e had a certified calibration (ithin the last 1: months% =/N<<<<<<. ,ensors installed in the unit at the factory (ith calibration certification pro1ided need not be field calibrated. 1st !a e or 'A, /inal !a e or 1st !a e or 'A, /inal !a e or , Aoc& )alue Instr. 'A, Aoc& )alue Instr. 'A, e atio +eas8d )alue "ass , atio +eas8d )alue "ass n n )alue =/N3 e n )alue =/N3 s OF n OF o s r o o r r * A A ct o u c a a t ti o o r n * A o c a ti o n

!a e readin @ readin of the permanent a e on the equipment. 'A, @ buildin automation system. Instr. @ testin instrument. )isual @ actual obser1ation. The Contractor8s o(n sensor check& out sheets may be used in lieu of the abo1e$ if the same recordin fields are included and the referenced procedures are follo(ed. All sensors are calibrated (ithin required tolerances ; <<<<=es <<<<No

CITYWIDE PUBLIC SAFETY BOND PROGRAM PREFUNCTIONAL CHECKLISTS RAMPART REPLACEMENT STATION

01813-5

&& EN2 O/ CCECFAI,T &&

CITYWIDE PUBLIC SAFETY BOND PROGRAM PREFUNCTIONAL CHECKLISTS RAMPART REPLACEMENT STATION

01813-6

,ample "refunctional Checklist E#haust /ans$ Gnit I2 H8s% <<<<<<<<<<<<<<<<<<<<<<<<<<<<<< 1. ,ubmittals / Appro1als ,ubmittal. The abo1e equipment and systems inte ral to them are complete and ready for functional testin . The checklist items are complete and ha1e been checked off only by parties ha1in direct kno(led e of the e1ent$ as marked belo($ respecti1e to each responsible contractor. This prefunctional checklist is submitted for appro1al$ sub7ect to an attached list of outstandin items yet to be completed. A ,tatement of Correction (ill be submitted upon completion of any outstandin areas. None of the outstandin items preclude safe and reliable functional tests bein performed. <<< Aist attached. <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< +echanical Contractor 2ate <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< Electrical Contractor 2ate <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< TA' Contractor 2ate <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< Controls Contractor 2ate <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< ,heet +etal Contractor 2ate <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< !eneral Contractor 2ate

"refunctional checklist items are to be completed as part of startup * initial checkout$ preparatory to functional testin . This checklist does not take the place of the manufacturer8s recommended checkout and startup procedures or report. Items that do not apply shall be noted (ith the reasons on this form -N/A @ not applicable$ 'O @ by others.. If this form is not used for documentin $ one of similar ri or shall be used. The Contractors (ho are assi ned responsibility for sections of the checklist shall also be responsible to see that checklist items by their subcontractors are completed and checked off. IContr.J column or abbre1iations in brackets to the ri ht of an item refer to the contractor responsible to 1erify completion of this item. A/E @ architect/en ineer$ All @ all contractors$ CA @ commissionin a ent$ CC @ controls contractor$ EC @ electrical contractor$ !C @ eneral contractor$ +C @ mechanical contractor$ ,C @ sheet metal contractor$ TA' @ test and balance contractor.

Appro1als. This filled&out checklist has been re1ie(ed. Its completion is appro1ed (ith the e#ceptions noted belo(. <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< Commissionin A ent 2ate <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< O(ner8s 0epresentati1e 2ate

CITYWIDE PUBLIC SAFETY BOND PROGRAM PREFUNCTIONAL CHECKLISTS RAMPART REPLACEMENT STATION

01813-

:. Installation Checks Check if Okay. Enter N/A if not applicable. Enter Note number if deficient. Check Equip Ta Cabinet and !eneral Installation "ermanent labels affi#ed Casin condition ood% no dents or leaks +ountin s checked and shippin bolts remo1ed )ibration isolators installed Equipment uards installed "ulleys ali ned 'elt tension correct "lenums clear of debris /ans rotate freely /ire and balance dampers installed 'ack draft dampers installed per dra(in s and operate freely 2uct system complete Electrical Electrical connections complete 2isconnect s(itch installed O1erload heaters in place Control connections complete Checklist items of "art : are all successfully completed for i1en trade; <<<<=es >. Operational Checks -These au ment mfr8s list. This is not a functional performance test. Check if Okay. Enter N/A if not applicable. Enter Note number if deficient. Check Equip Ta /an rotation correct Electrical interlocks 1erified Any fan status indicators functionin No unusual 1ibration or and noise 0ecord full load runnin amps for each fan. <<<<<rated /A amps # <<<<<<sr1c factor @ <<<<<<< -+a# amps.. 0unnin less than ma#3 Check 1olta e% 0ate @ <<<<< Actual @ <<<<<< Kithin B?3 The disconnect s(itch properly operates After :L hours of operation$ recheck belt tension and ali nment Checklist items of "art > are all successfully completed for i1en trade; <<<=es && EN2 O/ CCECFAI,T &&

Contr.

<<<<No

Contr.

<<<<No

CITYWIDE PUBLIC SAFETY BOND PROGRAM PREFUNCTIONAL CHECKLISTS RAMPART REPLACEMENT STATION

01813-8

,ample "refunctional Checklist "umps$ Gnit I2 H8s% <<<<<<<<<<<<<<<<<<<<<<<<<<<<<< L. ,ubmittals / Appro1als ,ubmittal. The abo1e equipment and systems inte ral to them are complete and ready for functional testin . The checklist items are complete and ha1e been checked off only by parties ha1in direct kno(led e of the e1ent$ as marked belo($ respecti1e to each responsible contractor. This prefunctional checklist is submitted for appro1al$ sub7ect to an attached list of outstandin items yet to be completed. A ,tatement of Correction (ill be submitted upon completion of any outstandin areas. None of the outstandin items preclude safe and reliable functional tests bein performed. <<< Aist attached. <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< +echanical Contractor 2ate <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< Electrical Contractor 2ate <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< TA' Contractor 2ate <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< Controls Contractor 2ate <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< "lumbin Contractor 2ate <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< !eneral Contractor 2ate

"refunctional checklist items are to be completed as part of startup * initial checkout$ preparatory to functional testin . This checklist does not take the place of the manufacturer8s recommended checkout and startup procedures or report. Items that do not apply shall be noted (ith the reasons on this form -N/A @ not applicable$ 'O @ by others.. If this form is not used for documentin $ one of similar ri or shall be used. The Contractors (ho are assi ned responsibility for sections of the checklist shall also be responsible to see that checklist items by their subcontractors are completed and checked off. IContr.J column or abbre1iations in brackets to the ri ht of an item refer to the contractor responsible to 1erify completion of this item. A/E @ architect/en ineer$ All @ all contractors$ CA @ commissionin a ent$ CC @ controls contractor$ EC @ electrical contractor$ !C @ eneral contractor$ +C @ mechanical contractor$ ,C @ sheet metal contractor$ TA' @ test and balance contractor.

Appro1als. This filled&out checklist has been re1ie(ed. Its completion is appro1ed (ith the e#ceptions noted belo(. <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< Commissionin A ent 2ate <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< O(ner8s 0epresentati1e 2ate

CITYWIDE PUBLIC SAFETY BOND PROGRAM PREFUNCTIONAL CHECKLISTS RAMPART REPLACEMENT STATION

01813-!

B. Installation Checks Check if Okay. Enter N/A if not applicable. Enter Note number if deficient. Check Equip Ta !eneral Installation Aabel permanently affi#ed "umps installed in place and properly routed$ bases filled )ibration isolation de1ices installed and functional /actory ali nment checked and appears correct /ield ali nment$ if required$ completed ,eismic anchorin installed Temperature and pressure au es and sensors installed "ump and motor lubricated "ipin -immediately around pump$ see full pipin checklist. "ipe fittin s completed and pipin properly supported No leaks in pipe fittin s and accessories at pump3 "ipin and pump properly insulated ,trainers in place and cleaned out "ipin system properly flushed )al1es properly ta ed Electrical and Controls 2isconnect s(itches in place and labeled Electrical connections ti ht "roper roundin installed for components and unit +otor o1erloads calibrated Control system interlocks hooked up and functional Control de1ices$ tubin and (irin complete )/2 )/2 po(ered up and (ired to controlled equipment )/2 interlocked to control system "ressure or other controllin sensor properly located and per dra(in s and calibrated Controller location not sub7ect to e#cessi1e temperatures Controller location not sub7ect to e#cessi1e moisture or dirt Controller si9e matches motor si9e Internal settin s desi natin the application are correct Input of motor /AA represents 16B? to 11B? of motor /AA ratin Appropriate )olts 1s C9 cur1e is bein usedM ener y sa1er on3 Accel and decel times are around 16&B6 seconds$ e#cept for special applications. Actual decel @ Actual accel @ Gpper frequency limit set at 166?$ unless e#plained other(ise Gnit is pro rammed (ith (ritten pro rammin record a1ailable )/2 kK demand at panel matches 'A, readout TA' CITYWIDE PUBLIC SAFETY BOND PROGRAM PREFUNCTIONAL CHECKLISTS RAMPART REPLACEMENT STATION

Contr.

01813-10

Check Equip Ta Installation of system and balancin de1ices permits balancin to be completed follo(in specified NE'' or AA'C procedures and contract documents /inal ,tartup report completed (ith this checklist attached ,afety controls tested$ calibrated and safe operatin ran es for this equipment pro1ided to the commissionin a ent Internal settin s desi natin the application are correct Checklist items of "art : are all successfully completed for i1en trade; <<<<=es N. Operational Checks -These au ment mfr8s list. This is not a functional performance test. Check if Okay. Enter N/A if not applicable. Enter Note number if deficient. Check Equip Ta The COA s(itch properly acti1ates and deacti1ates the unit under manual and automatic control. "ump rotation 1erified correct No unusual noise or 1ibration No leakin apparent around fittin s +easure line to line 1olta e phase imbalance for each pump% -?lmbalance @ 166 # -a1 . & lo(est. / a1 .. 0ecord imbalance of each pump in cell. Imbalance less than :?3 0ecord full load runnin amps for each pump. /A amps # factor -+a# amps.. 0unnin less than ma#3 ,pecified sequences of operation and operatin schedules ha1e been implemented (ith 1ariations documented ,pecified point&to&point checks ha1e been completed and documentation record submitted for this system Checklist items of "art > are all successfully completed for i1en trade; <<<=es

Contr.

<<<<No

Contr.

<<<<No

1. ,ensor and Actuator Calibration DContr. @ <<<<<< E /ield&installed temperature$ CO$ and pressure sensors and a es on this piece of equipment are calibrated. Test instruments NI,T certified for calibration (ithin the last 1: months% =/N<<<<<<. ,ensors installed in the unit at the factory (ith NI,T calibration certificates pro1ided need not be field calibrated.

CITYWIDE PUBLIC SAFETY BOND PROGRAM PREFUNCTIONAL CHECKLISTS RAMPART REPLACEMENT STATION

01813-11

,ensor Aoc&ation or 1st !a eInstr. )alue +eas8d /inal !a e )alue A OF )alue ct u a t o r * A o c a ti o n

"ass =/N3

,ensor Aoc&ation or 1st !a eInstr. )alue +eas8d /inal !a e )alue A OF )alue ct u a t o r * A o c a ti o n

"ass =/N3

!a e readin @ readin of the permanent a e on the equipment. Instr. @ testin instrument. )isual @ actual obser1ation. ,ensors are calibrated (ithin required tolerances ; <<<<=es <<<<No

EN2 O/ CCECFAI,T O

CITYWIDE PUBLIC SAFETY BOND PROGRAM PREFUNCTIONAL CHECKLISTS RAMPART REPLACEMENT STATION

01813-12

,ample "refunctional Checklist Cydronic Cot Kater 'oiler-s.$ Gnit I2 H8s% <<<<<<<<<<<<<<<<<<<<<<< Associated Checklists% "ipin -Cydronic. :. ,ubmittals / Appro1als ,ubmittal. The abo1e equipment and systems are installed and ready for functional testin . The checklist items are completed and ha1e been checked off by parties ha1in direct kno(led e of the e1ent$ as marked belo($ respecti1e to each responsible contractor. This prefunctional checklist is submitted sub7ect to an attached list of outstandin items yet to be completed. A ,tatement of Correction (ill be submitted upon completion of outstandin areas. <<< Aist attached. <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< "lumbin Contractor 2ate <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< Electrical Contractor 2ate <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< !eneral Contractor 2ate <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< +echanical Contractor 2ate

"refunctional checklist items must be completed as part of startup * initial checkout$ preparatory to functional testin . This checklist does not take the place of the manufacturer8s recommended startup procedures or reports. Note items that do not apply (ith the reasons on this form -N/A @ not applicable$ 'O @ by others.. If this form is not used for documentin prefunctional testin $ one of similar ri or shall be used. The Contractors (ho are assi ned responsibility for sections of the checklist shall also be responsible to see that checklist items by their subcontractors are completed and checked off. IContr.J column or abbre1iations in brackets to the ri ht of an item refer to the contractor responsible to 1erify completion of this item. A/E @ architect/en ineer$ All @ all contractors$ !C @ eneral contractor$ "C @ plumbin contractor$ +C @ mechanical contractor$ CC @ controls contractor$ ,+ @ sheet metal contractor$ TA' @ test and balance contractor$ EC @ electrical contractor$ CA @ commissionin a ent.

Appro1als. This filled&out checklist has been re1ie(ed. Its completion is appro1ed (ith the e#ceptions noted belo(. <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< Commissionin A ent 2ate <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< O(ner8s 0epresentati1e 2ate

CITYWIDE PUBLIC SAFETY BOND PROGRAM PREFUNCTIONAL CHECKLISTS RAMPART REPLACEMENT STATION

01813-13

>. Installation Checks Check if Okay. Enter N/A if not applicable. Enter Note number if deficient. Check Equip Ta &4 !eneral Installation !eneral appearance ood$ no apparent dama e ,ite clean and ready for testin Equipment labels and ta s affi#ed Tube pull and access door space adequate 0equired seismic restraints in place /lue installed completely and sloped properly Combustion air supply pro1ided ,ystem filled (ith (ater and treatment chemicals "ressure a es installed Thermometers installed /lue /lue installed completely and sloped properly /lue is installed a(ay from combustible materials "roper flue connection (ith draft di1erter "roper flue termination$ 1ent cap$ and flashin "roper type flue O double (all penetration "ipin E+, instruments installed "IT plu s installed as per dra(in s 'oiler interlocks and controls completed "ipin Immediately at unit. Also see Cydronic and 2omestic "ipin . !as pipin installed and tested -supply is at proper pressure. Cydronic pipin complete$ includin makeup (ater pipin and safety relief 1al1es Cydronic system flushin complete$ strainers clean and treatment installed Isolation 1al1es and balancin 1al1es installed (ith e#tensions to clear insulation "ipe fittin s and accessories installed (ith e#tensions for insulation Test ports installed near control sensors and per spec /lo( s(itches installed as required /lo( meters installed as required /lo( directions labeled on pipin insulation Chemical treatment pot installed in proper direction A,+E pressure 1essel data sheet or certification ta posted and inspection complete for each e#pansion tank E#pansion tanks 1erified not (aterlo ed and system is completely full of (ater. Air 1ents and bleeds at hi h points of systems functional Electrical and Controls "o(er to disconnect s(itch and unit installed Electrical components rounded ,ensors calibrated -see belo(. Control system interlocks hooked up and functional CITYWIDE PUBLIC SAFETY BOND PROGRAM PREFUNCTIONAL CHECKLISTS RAMPART REPLACEMENT STATION

Contr.

01813-14

Check

Equip Ta &4

Contr.

Control de1ices$ pneumatic tubin and (irin complete +otori9ed 1al1es$ dampers and le1el s(itches functional /inal ,tartup report completed (ith this checklist attached ,tartup report includes (ritten certification from boiler manufacturer that specified features$ controls and safeties ha1e been installed and are functionin properly and that the installation and application complies (ith the manufacturer8s recommendations. ,afety controls installed and safe operatin ran es for this equipment pro1ided to the commissionin a ent Ceatin (ater pipin and pump prefunctional checklists completed 'oiler controls ener i9ed and safety controls tested ,tartup report includes optimal and actual percent CO :$CO$ O:$ stack temperatureM combustion efficiency and NO P ,pecified sequences of operation and operatin schedules ha1e been implemented (ith 1ariations documented ,pecified point&to&point checks ha1e been completed and documentation record submitted for this system Checklist items of "art : are all successfully completed for i1en trade; <<<=es <<<<No

L. ,ensor and Actuator Calibration DContr. @ <<<<<< E /ield&installed temperature$ CO$ and pressure sensors and a es on this piece of equipment are calibrated. Test instruments NI,T certified for calibration (ithin the last 1: months% =/N<<<<<<. ,ensors installed in the unit at the factory (ith NI,T calibration certificates pro1ided need not be field calibrated. ,ensor Aoc&ation or 1st !a eInstr. )alue +eas8d /inal !a e )alue ,ensor Aoc&ation or 1st !a eInstr. )alue +eas8d /inal !a e )alue A OF )alue "ass A OF )alue "ass ct =/N3 ct =/N3 u u a a t t o o r r * * A A o o c c a a ti ti o o n n

!a e readin @ readin of the permanent a e on the equipment. Instr. @ testin instrument. )isual @ actual obser1ation. ,ensors are calibrated (ithin required tolerances ; <<<<=es <<<<No

CITYWIDE PUBLIC SAFETY BOND PROGRAM PREFUNCTIONAL CHECKLISTS RAMPART REPLACEMENT STATION

01813-15

&& EN2 O/ CCECFAI,T &&

CITYWIDE PUBLIC SAFETY BOND PROGRAM PREFUNCTIONAL CHECKLISTS RAMPART REPLACEMENT STATION

01813-16

,ample "refunctional Checklist 2omestic Cot Kater Ceater-s.$ Gnit I2 H8s% <<<<<<<<<<<<<<<<<<<<<<< Associated Checklists% "ipin -2omestic Kater. B. ,ubmittals / Appro1als ,ubmittal. The abo1e equipment and systems are installed and ready for functional testin . The checklist items are completed and ha1e been checked off by parties ha1in direct kno(led e of the e1ent$ as marked belo($ respecti1e to each responsible contractor. This prefunctional checklist is submitted sub7ect to an attached list of outstandin items yet to be completed. A ,tatement of Correction (ill be submitted upon completion of outstandin areas. <<< Aist attached. <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< "lumbin Contractor 2ate <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< Electrical Contractor 2ate <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< !eneral Contractor 2ate <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<<

"refunctional checklist items must be completed as part of startup * initial checkout$ preparatory to functional testin . This checklist does not take the place of the manufacturer8s recommended startup procedures or reports. Note items that do not apply (ith the reasons on this form -N/A @ not applicable$ 'O @ by others.. If this form is not used for documentin prefunctional testin $ one of similar ri or shall be used. The Contractors (ho are assi ned responsibility for sections of the checklist shall also be responsible to see that checklist items by their subcontractors are completed and checked off. IContr.J column or abbre1iations in brackets to the ri ht of an item refer to the contractor responsible to 1erify completion of this item. A/E @ architect/en ineer$ All @ all contractors$ !C @ eneral contractor$ "C @ plumbin contractor$ +C @ mechanical contractor$ CC @ controls contractor$ ,+ @ sheet metal contractor$ TA' @ test and balance contractor$ EC @ electrical contractor$ CA @ commissionin a ent.

Appro1als. This filled&out checklist has been re1ie(ed. Its completion is appro1ed (ith the e#ceptions noted belo(. <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< Commissionin A ent 2ate <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< O(ner8s 0epresentati1e 2ate

CITYWIDE PUBLIC SAFETY BOND PROGRAM PREFUNCTIONAL CHECKLISTS RAMPART REPLACEMENT STATION

01813-1

N. Installation Checks Check if Okay. Enter N/A if not applicable. Enter Note number if deficient. Check Equip Ta &4 !eneral Installation !eneral appearance ood$ no apparent dama e ,ite clean and ready for testin Equipment labels and ta s affi#ed 0equired seismic restraints in place Insulatin blanket installed -if necessary. Adequate combustion air supply pro1ided -air supply is si9ed and located properly. Gnit is protected from (eather Gnit is accessible and has manufacturer recommended clearances /lue /lue installed completely and sloped properly /lue is installed a(ay from combustible materials "roper flue connection (ith draft di1erter "roper flue termination$ 1ent cap$ and flashin "roper type flue O double (all penetration "ipin immediately at unit. -Also see Cydronic and 2omestic "ipin .. !as pipin installed and tested -supply is at proper pressure. "ipin complete$ includin safety relief 1al1es. ,ystem flushed and sterili9ed. ,trainers clean and installed ,hutoff 1al1es installed properly Ceat Trap properly installed 2ielectric connections installed correctly 2rain pipe is properly terminated ,mitty pan is properly installed -if required. Air 1ents and bleeds at hi h points of systems functional Electrical and Controls Electrical components rounded ,ensors calibrated -see belo(. Control de1ices and (irin complete ,hutoff de1ices and controls installed -if necessary. /lo( s(itches installed as required -if necessary. Checklist items of "art : are all successfully completed for i1en trade; <<<=es

Contr.

<<<<No

CITYWIDE PUBLIC SAFETY BOND PROGRAM PREFUNCTIONAL CHECKLISTS RAMPART REPLACEMENT STATION

01813-18

5. ,ensor and Actuator Calibration DContr. @ <<<<<< E /ield&installed temperature$ CO$ and pressure sensors and a es on this piece of equipment are calibrated. Test instruments NI,T certified for calibration (ithin the last 1: months% =/N<<<<<<. ,ensors installed in the unit at the factory (ith NI,T calibration certificates pro1ided need not be field calibrated. ,ensor Aoc&ation or 1st !a eInstr. )alue +eas8d /inal !a e )alue ,ensor Aoc&ation or 1st !a eInstr. )alue +eas8d /inal !a e )alue A OF )alue "ass A OF )alue "ass ct =/N3 ct =/N3 u u a a t t o o r r * * A A o o c c a a ti ti o o n n

!a e readin @ readin of the permanent a e on the equipment. Instr. @ testin instrument. )isual @ actual obser1ation. ,ensors are calibrated (ithin required tolerances ; <<<<=es <<<<No

&& EN2 O/ CCECFAI,T &&

CITYWIDE PUBLIC SAFETY BOND PROGRAM PREFUNCTIONAL CHECKLISTS RAMPART REPLACEMENT STATION

01813-1!

,ample "refunctional Checklist 'uildin -22C. Automation ,ystem$ Gnit I2 H8s% <<<<<<<<<<<<<<<<<<<<<<< 1. ,ubmittals / Appro1als ,ubmittal. The abo1e equipment and systems are installed and ready for functional testin . The checklist items are completed and ha1e been checked off by parties ha1in direct kno(led e of the e1ent$ as marked belo($ respecti1e to each responsible contractor. This prefunctional checklist is submitted sub7ect to an attached list of outstandin items yet to be completed. A ,tatement of Correction (ill be submitted upon completion of outstandin areas. <<< Aist attached. <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< Controls Contractor 2ate <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< Electrical Contractor 2ate <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< !eneral Contractor 2ate <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< +echanical Contractor 2ate

"refunctional checklist items must be completed as part of startup * initial checkout$ preparatory to functional testin . This checklist does not take the place of the manufacturer8s recommended startup procedures or reports. Note items that do not apply (ith the reasons on this form -N/A @ not applicable$ 'O @ by others.. If this form is not used for documentin prefunctional testin $ one of similar ri or shall be used. The Contractors (ho are assi ned responsibility for sections of the checklist shall also be responsible to see that checklist items by their subcontractors are completed and checked off. IContr.J column or abbre1iations in brackets to the ri ht of an item refer to the contractor responsible to 1erify completion of this item. A/E @ architect/en ineer$ All @ all contractors$ !C @ eneral contractor$ "C @ plumbin contractor$ +C @ mechanical contractor$ CC @ controls contractor$ ,+ @ sheet metal contractor$ TA' @ test and balance contractor$ EC @ electrical contractor$ CA @ commissionin a ent. A si nificant part of the 'A, functional testin requirements is the successful completion of the functional tests of equipment the 'A, controls or interlocks (ith. Gncompleted equipment functional tests or outstandin deficiencies in those tests lend the required 'A, functional testin incomplete. Inte ral or stand&alone controls are functionally tested (ith the equipment they are attached to$ includin any interlocks (ith other equipment or systems and thus are not co1ered under the 'A, testin requirements$ e#cept for any inte rated functions or interlocks listed belo(. In addition to the controlled equipment testin $ the follo(in tests are required for the 'A,$ (here features ha1e been specified. The follo(in testin requirements are in addition to and do not replace any testin requirements else(here in the specifications.

Appro1als. This filled&out checklist has been re1ie(ed. Its completion is appro1ed (ith the e#ceptions noted belo(. <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< Commissionin A ent 2ate <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< O(ner8s 0epresentati1e 2ate

CITYWIDE PUBLIC SAFETY BOND PROGRAM PREFUNCTIONAL CHECKLISTS RAMPART REPLACEMENT STATION

01813-20

:. Installation Checks Check if Okay. Enter N/A if not applicable. Enter Note number if deficient. Check Equip Ta &4 Cabinet and !eneral Installation !eneral appearance ood$ no apparent dama e Equipment labels affi#ed Aayout and location of control panels matches dra(in s Areas or equipment panels ser1e clear in control dra(in s Kirin labeled inside panels -to controlled components. Controlled components labeled/ta ed 'A, connection made to labeled terminal-s. as sho(n on dra(in s ,hielded (irin used on electronic sensors 116 1olt AC po(er a1ailable to panel 'attery backup in place and operable "anels properly rounded En1ironmental conditions accordin to manufacturer8s requirements 2ate and time correct +isc. /unctions "ro1ide a 1erbal discussion of specified functions and features that are set up$ debu ed and fully operable 2emonstrate po(er failure and battery backup and po(er&up restart functions ,pecified trendin and raphin features demonstration 2emonstrate lobal commands features 2emonstrate security and access codes 2emonstrate occupant o1er&rides -manual$ telephone$ key$ keypad$ etc.. 2emonstrate O*+ schedules and alarms ,chedulin features fully functional and setup$ includin holidays 2emonstrate date and time settin in central computer and 1erify field panels are the same. 2emonstrate included features not specified to be setup are installed -list. 2emonstrate occupancy sensors and controls 2emonstrate functionality of 166? of field panels usin local operator keypads and 16? of local ports -plu &ins. usin portable computer/keypad 2emonstrate raphic screens and 1alue readouts completed 2urin equipment testin demonstrate set&point chan in features and functions 2emonstrate communications to remote sites Throu h samplin durin equipment tests 1erify sensor calibrations /inal as&builts or redlines -per spec. control dra(in s$ final points list$ pro ram code$ set&points$ schedules$ (arranties$ etc. per specs$ submitted for O*+s. )erify that points that are monitored only$ ha1in no control function$ are checked for proper reportin to 'A,.

Contr.

CITYWIDE PUBLIC SAFETY BOND PROGRAM PREFUNCTIONAL CHECKLISTS RAMPART REPLACEMENT STATION

01813-21

>.

Installation% Checks & 2e1ice and "oint Checkout

Contr. @ D

The follo(in procedures are required to be performed and documented for each and e1ery point in the control system. The follo(in procedures are minimum requirements. The control contractor is encoura ed to identify better and more comprehensi1e checkout procedures in their submitted plan. These procedures are not a substitute for the manufacturer8s recommended start&up and checkout procedures$ but are to be combined (ith them$ as applicable. The documentation may be pro1ided on the 1endor8s stock form$ as lon as all the information in the sample table belo( can be clearly documented on the form. ,imilar checkout and calibration requirements are found on the equipment prefunctional checklists. 0edundant documentation is not required. Cross reference$ by name and form number$ to other forms that contain documentation left blank on the current form. "rocedures% a. b. c. d. e. DKireE )erify that the (irin is correct to each point. DActuE If the de1ice is or has an actuator$ 1erify full free mo1ement throu h its full ran e. DAddrE )erify that the soft(are address is correct. DAoadE /or de1ices (ith a controller$ 1erify that current soft(are pro ram (ith proper setpoints has been do(nloaded. D2e1CalE 2e1ice stroke/ran e calibration. This applies to all controlled 1al1es$ dampers$ fans$ pumps$ actuators$ etc. ,imulate ma#imum and minimum transmitter si nal 1alues and 1erify minimum and ma#imum controller output 1alues and positi1ely 1erify each and e1ery control de1ice minimum and ma#imum stroke and capacity ran e. D,ensAocE )erify that all sensor locations are appropriate and a(ay from causes of erratic operation. D,ensCalE ,ensor calibration. Calibrate or 1erify calibration of all sensors and thermostats$ includin temperature$ pressure$ flo($ current$ kK$ rpm$ Cert9$ etc. )erify that the sensor readin s in the control system are (ithin the sensor accuracies specified in this section$ usin hand&held or other e#ternal measurin instruments. DOperCkE /or controlled de1ices -dampers$ 1al1es$ actuators$ )A) bo#es$ etc..$ after mechanical equipment control becomes operational$ perform an operational test of each control loop. /ollo( procedure N.: belo(. Operational checks are preparatory to the later functional testin . Other Abbre1iations% D'A,E 'uildin automation system or a e&read 1alueM DInstruE Instrument -calibrated. read 1alueM DOfsetE Offset pro rammed into the point to correct the calibration. <<<<No

f. .

h.

i.

Items of "arts : and > are all successfully completed for i1en trade; <<<=es

L. ,ensor and Actuator Calibration CITYWIDE PUBLIC SAFETY BOND PROGRAM PREFUNCTIONAL CHECKLISTS RAMPART REPLACEMENT STATION

DContr. @ <<<<<< E

01813-22

/ield&installed temperature$ CO :$ CO$ and pressure sensors and a es on this piece of equipment are calibrated. Test instruments NI,T certified for calibration (ithin the last 1: months% =/N<<<<<<. ,ensors installed in the unit at the factory (ith NI,T calibration certificates pro1ided need not be field calibrated. ,A+"AE /O0+% Controls Checkout 2ocumentation Table Card(are Checks /ield 2e1ice ,enscal /inal Check

,ensors are calibrated (ithin required tolerances ;

<<<<=es

<<<<No

&& EN2 O/ CCECFAI,T &&

CITYWIDE PUBLIC SAFETY BOND PROGRAM PREFUNCTIONAL CHECKLISTS RAMPART REPLACEMENT STATION

01813-23

,ample "refunctional Checklist Test * Air 'alance -TA'.$ 0e1ie( Checklist Components Included% <<<< Airside$ <<<< Katerside The purpose of this checklist is to 1erify that necessary components for TA' ha1e been included. 1. ,ubmittals / Appro1als ,ubmittal. The TA' "lan has been de1eloped and re1ie(ed a ainst the checklist belo(. This plan is submitted for appro1al$ sub7ect to the attached list of outstandin items yet to be completed. <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< TA' Contractor 2ate <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< !eneral Contractor 2ate

The TA' "lan checklist does not take the place of the recommended formats or procedures in standards referenced in the specifications$ but it is intended to au ment them. Items that do not apply shall be noted (ith the reasons on this form -N/A @ not applicable$ 'O @ by others.. This filled&out checklist and the TA' "lan ha1e been re1ie(ed. appro1ed (ith the e#ceptions noted belo(. Their completion is

Appro1als.

<<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< Commissionin A ent 2ate

<<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< O(ner8s 0epresentati1e 2ate

:. TA' "lan Checklist Check if included in "lan. Krite N/A if not applicable. Enter Note number if deficient. Chilled Kater Ceatin Kater Check ,pecified qualifications and certifications of parties performin TA' (ork (ere submitted TA' contractor has re1ie(ed dra(in s$ (alked throu h the site and 1erified that there are sufficient balancin dampers$ 1al1es$ isolation dampers and 1al1es and test ports installed to perform TA' per spec. 2eficiencies in desi n or installation that (ill ad1ersely affect or preclude proper TA' ha1e been reported. TA' contractor has re1ie(ed the construction documents and the systems (ith the desi n en ineers and contractors to sufficiently understand the desi n intent for each system and outlet. "rior to plan$ TA' contractor met (ith controls contractor to become familiar (ith usin the terminal unit pro rammer for TA' /ield checkout sheets and lo s pro1ided as part of plan "roposed final test report sheets pro1ided as part of plan /ield and final test report sheets list each piece of equipment to be tested$ ad7usted and balanced (ith the data cells to be athered for each 2iscussion of (hat notations and markin s (ill be made on the duct and pipin dra(in s. CITYWIDE PUBLIC SAFETY BOND PROGRAM PREFUNCTIONAL CHECKLISTS RAMPART REPLACEMENT STATION

01813-24

Chilled Kater Ceatin Kater Check Aist of air flo(s$ (ater flo(s$ sound le1els$ system capacities and efficiency measurements to be performed$ and a description of specific test procedures$ parameters$ formulas and test instrument type to be used for the measurements ha1e been pro1ided. ,ample forms ha1e been included. 2etailed step&by&step procedures for TA' (ork% Terminal flo( calibration -for each terminal type.$ diffuser proportionin $ branch/sub&main proportionin $ total flo( calculations$ recheckin $ and others. ,imilar for (ater side. 2etails of ho( total flo( (ill be determined -Air% ,um of terminal flo(s 1ia 'A, calibrated readin s or 1ia hood read of terminals$ supply -,A. and return air -0A. pitot tra1erse$ ,A or 0A flo( stations. Kater% pump cur1es$ circuit setter$ flo( station$ ultrasonic meter.. ,pecific procedures that (ill ensure -and (hich can be 1erified. that both air side and (ater side are operatin at the lo(est possible pressures and ener y consumption. Outside air 1entilation criteria under clearly understood by TA' contractor 2etails of if and ho( minimum outside air cfm (ill be 1erified and set and for (hat le1el -total bld $ 9one$ other.. 2etails of ho( buildin static and e#haust fan/relief damper capacity (ill be checked. The identification and types of measurement instruments to be used and their most recent calibration date "roposed selection points for sound measurements 2etails of any TA' (ork to be done in phases$ by floor$ or of areas to be built out later 2etails re ardin specified deferred or seasonal TA' (ork 2etails of specified false loadin of systems to complete TA' (ork 2etails of e#haust fan balancin and capacity 1erifications$ includin required room pressure differentials. "lan for hand&(ritten field technician lo s of discrepancies$ deficient or uncompleted (ork by others$ contract interpretation requests and lists of completed tests -scope and frequency. "lan for formal pro ress reports -scope and frequency. "lan for formal deficiency reports -scope$ frequency and distribution. Checklist items of "art : are successfully completed ; <<<<=es <<<<No

N/A

N/A

&& EN2 O/ CCECFAI,T &&

CITYWIDE PUBLIC SAFETY BOND PROGRAM PREFUNCTIONAL CHECKLISTS RAMPART REPLACEMENT STATION

01813-25

,ample "refunctional Checklist Ai htin ,ystem -and Controls.$ <<<< Entire 'l $ <<<< /loor H 1. ,ubmittals / Appro1als ,ubmittal. The abo1e equipment and systems inte ral to them are complete and ready for functional testin . The checklist items are complete and ha1e been checked off only by parties ha1in direct kno(led e of the e1ent$ as marked belo($ respecti1e to each responsible contractor. This prefunctional checklist is submitted for appro1al$ sub7ect to an attached list of outstandin items yet to be completed. A ,tatement of Correction (ill be submitted upon completion of any outstandin areas. None of the outstandin items preclude safe and reliable functional tests bein performed. <<< Aist attached. <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< Electrical Contractor 2ate <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< !eneral Contractor 2ate

"refunctional checklist items are to be completed as part of startup * initial checkout$ preparatory to functional testin . This checklist does not take the place of the manufacturer8s recommended checkout and startup procedures or report. Items that do not apply shall be noted (ith the reasons on this form -N/A @ not applicable$ 'O @ by others.. If this form is not used for documentin $ one of similar ri or shall be used. The Contractors (ho are assi ned responsibility for sections of the checklist shall also be responsible to see that checklist items by their subcontractors are completed and checked off. IContr.J column or abbre1iations in brackets to the ri ht of an item refer to the contractor responsible to 1erify completion of this item. A/E @ architect/en ineer$ All @ all contractors$ CA @ commissionin a ent$ CC @ controls contractor$ EC @ electrical contractor$ !C @ eneral contractor.

Appro1als. This filled&out checklist has been re1ie(ed. Its completion is appro1ed (ith the e#ceptions noted belo(. <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< Commissionin A ent 2ate <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< O(ner8s 0epresentati1e 2ate

CITYWIDE PUBLIC SAFETY BOND PROGRAM PREFUNCTIONAL CHECKLISTS RAMPART REPLACEMENT STATION

01813-26

:. Installation Checks Check if Okay. Enter N/A if not applicable. Enter Note number if deficient -attach notes.. Complete table for each room. Check 0ooms Contr. Ai htin fi#tures and s(itches Ai ht s(itches are located per plans Ai ht s(itches are labeled (ith proper I2 to match dra(in s or field chan es Ai ht s(itch is controllin the fi#tures in the area indicated on desi n dra(in s /i#tures are properly supported for seismic 9one )erify proper lamp type is installed in each fi#ture to match fi#ture schedule and specifications Ai htin controls Ai htin control is installed per manufacturer recommendations -attached recommendations to this checklist. Ai htin control is calibrated per manufacturer checklist Check if Okay. for each room. Enter N/A if not applicable. Enter Note number if deficient -attach notes.. Complete table Check Ai htin fi#tures and s(itches Ai ht s(itches are located per plans Ai ht s(itches are labeled (ith proper I2 to match dra(in s or field chan es Ai ht s(itch is controllin the fi#tures in the area indicated on desi n dra(in s /i#tures are properly supported for seismic 9one )erify proper lamp type is installed in each fi#ture to match fi#ture schedule and specifications Ai htin controls Ai htin control is installed per manufacturer recommendations -attached recommendations to this checklist. Ai htin control is calibrated per manufacturer checklist 0ooms Contr.

CITYWIDE PUBLIC SAFETY BOND PROGRAM PREFUNCTIONAL CHECKLISTS RAMPART REPLACEMENT STATION

01813-2

Check if Okay. for each room.

Enter N/A if not applicable. Enter Note number if deficient -attach notes.. Complete table 0ooms Contr.

Check Ai htin fi#tures and s(itches

Ai ht s(itches are located per plans Ai ht s(itches are labeled (ith proper I2 to match dra(in s or field chan es Ai ht s(itch is controllin the fi#tures in the area indicated on desi n dra(in s /i#tures are properly supported for seismic 9one )erify proper lamp type is installed in each fi#ture to match fi#ture schedule and specifications Ai htin controls Ai htin control is installed per manufacturer recommendations -attached recommendations to this checklist. Ai htin control is calibrated per manufacturer checklist Check if Okay. for each room. Enter N/A if not applicable. Enter Note number if deficient -attach notes.. Complete table Check Ai htin fi#tures and s(itches Ai ht s(itches are located per plans Ai ht s(itches are labeled (ith proper I2 to match dra(in s or field chan es Ai ht s(itch is controllin the fi#tures in the area indicated on desi n dra(in s /i#tures are properly supported for seismic 9one )erify proper lamp type is installed in each fi#ture to match fi#ture schedule and specifications Ai htin controls Ai htin control is installed per manufacturer recommendations -attached recommendations to this checklist. Ai htin control is calibrated per manufacturer checklist Checklist items of "art : are all successfully completed for i1en trade; <<<=es && EN2 O/ CCECFAI,T && <<<<No 0ooms Contr.

CITYWIDE PUBLIC SAFETY BOND PROGRAM PREFUNCTIONAL CHECKLISTS RAMPART REPLACEMENT STATION

01813-28

,ample "refunctional Checklist "ipin -2# 0efri eration. Components Include% <<<<<pipin specialties <<<<<"ipin $ <<<<<2# coils$ <<<<<<Condensin units$

Associated Checklists% "acka ed 0ooftop AC Gnit 1. ,ubmittals / Appro1als ,ubmittal. The abo1e equipment and systems inte ral to them are complete and ready for functional testin . The checklist items are complete and ha1e been checked off only by parties ha1in direct kno(led e of the e1ent$ as marked belo($ respecti1e to each responsible contractor. This prefunctional checklist is submitted for appro1al$ sub7ect to an attached list of outstandin items yet to be completed. A ,tatement of Correction (ill be submitted upon completion of any outstandin areas. None of the outstandin items preclude safe and reliable functional tests bein performed. <<< Aist attached. <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< +echanical Contractor 2ate <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< Electrical Contractor 2ate <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< TA' Contractor 2ate <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< Controls Contractor 2ate <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< ,heet +etal Contractor 2ate <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< !eneral Contractor 2ate

"refunctional checklist items are to be completed as part of startup * initial checkout$ preparatory to functional testin . This checklist does not take the place of the manufacturer8s recommended checkout and startup procedures or report. Items that do not apply shall be noted (ith the reasons on this form -N/A @ not applicable$ 'O @ by others.. If this form is not used for documentin $ one of similar ri or shall be used. The Contractors (ho are assi ned responsibility for sections of the checklist shall also be responsible to see that checklist items by their subcontractors are completed and checked off. IContr.J column or abbre1iations in brackets to the ri ht of an item refer to the contractor responsible to 1erify completion of this item. A/E @ architect/en ineer$ All @ all contractors$ CA @ commissionin a ent$ CC @ controls contractor$ EC @ electrical contractor$ !C @ eneral contractor$ +C @ mechanical contractor$ ,C @ sheet metal contractor$ TA' @ test and balance contractor.

Appro1als. This filled&out checklist has been re1ie(ed. Its completion is appro1ed (ith the e#ceptions noted belo(. <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< Commissionin A ent 2ate <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< O(ner8s 0epresentati1e 2ate

CITYWIDE PUBLIC SAFETY BOND PROGRAM PREFUNCTIONAL CHECKLISTS RAMPART REPLACEMENT STATION

01813-2!

:. Installation Checks Check if Okay. Enter N/A if not applicable. Enter Note number if deficient. Check "ipin -line sets. "ipe fittin s complete$ properly supported$ not kinked or trapped "ipes properly labeled "ipes properly insulated "ipin properly (eather protected 2# specialties in place and clean Isolation 1al1es installed Test ports -"/T. installed "ipin pressure tested accordin -report attached. "ipe penetrations properly sealed No leakin apparent around fittin s )al1es -e#cept coil 1al1e. Coil )al1e checklists are (ith the unit checklist. )al1e labels permanently affi#ed )al1es installed in proper direction No leaks "ressure relief 1al1es tested 0efri erant fully char ed )al1es that require a positi1e shut&off are 1erified to not be leakin (hen closed at normal operatin pressure. Aist% <<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<< < ,ensors and !a es Temperature$ pressure and flo( a es and sensors installed Checklist items of "art : are all successfully completed for i1en trade; <<<<=es to contract documents

Contr.

<<<<No

&& EN2 O/ CCECFAI,T &&

CITYWIDE PUBLIC SAFETY BOND PROGRAM PREFUNCTIONAL CHECKLISTS RAMPART REPLACEMENT STATION

01813-30

,ample "refunctional Checklist "ipin -Condensate. Associated Checklists% "acka ed 0ooftop AC Gnits 1. ,ubmittals / Appro1als ,ubmittal. The abo1e equipment and systems inte ral to them are complete and ready for functional testin . The checklist items are complete and ha1e been checked off only by parties ha1in direct kno(led e of the e1ent$ as marked belo($ respecti1e to each responsible contractor. This prefunctional checklist is submitted for appro1al$ sub7ect to an attached list of outstandin items yet to be completed. A ,tatement of Correction (ill be submitted upon completion of any outstandin areas. None of the outstandin items preclude safe and reliable functional tests bein performed. <<< Aist attached. <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< "lumbin Contractor 2ate <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< +echanical Contractor 2ate <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< !eneral Contractor 2ate <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<<

"refunctional checklist items are to be completed as part of startup * initial checkout$ preparatory to functional testin . This checklist does not take the place of the manufacturer8s recommended checkout and startup procedures or report. Items that do not apply shall be noted (ith the reasons on this form -N/A @ not applicable$ 'O @ by others.. If this form is not used for documentin $ one of similar ri or shall be used. The Contractors (ho are assi ned responsibility for sections of the checklist shall also be responsible to see that checklist items by their subcontractors are completed and checked off. IContr.J column or abbre1iations in brackets to the ri ht of an item refer to the contractor responsible to 1erify completion of this item. A/E @ architect/en ineer$ All @ all contractors$ !C @ eneral contractor$ "C @ plumbin contractor$ +C @ mechanical contractor$ CC @ controls contractor$ TA' @ test and balance contractor$ EC @ electrical contractor$ CA @ commissionin a ent.

Appro1als. This filled&out checklist has been re1ie(ed. Its completion is appro1ed (ith the e#ceptions noted belo(. <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< Commissionin A ent 2ate <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< O(ner8s 0epresentati1e 2ate

CITYWIDE PUBLIC SAFETY BOND PROGRAM PREFUNCTIONAL CHECKLISTS RAMPART REPLACEMENT STATION

01813-31

:. Installation Checks Check if Okay. Enter N/A if not applicable. Enter Note number if deficient. Check "ipin "ipe fittin s complete and pipes properly supported allo(in for thermal e#pansion and contraction and buildin e#pansion 7oints. "ipe 7oints properly installed 0equired seismic anchorin installed "ipes properly labeled "ipes properly insulated "ipes properly sloped Trap and 1ent properly installed No leakin apparent around fittin s "roper primary drain termination "roper secondary drain termination "lastic pipe e#posed on roof /ire rated penetration properly sealed

Contr.

Checklist items of "art : are all successfully completed for i1en trade <<<<=es

<<<<No

END OF CHECKLIST

CITYWIDE PUBLIC SAFETY BOND PROGRAM PREFUNCTIONAL CHECKLISTS RAMPART REPLACEMENT STATION

01813-32

,ample "refunctional Checklist "ipin -Cydronic and 2omestic Kater. Associated Checklists% 'oiler and Cot Kater Ceater-s. 1. ,ubmittals / Appro1als ,ubmittal. The abo1e equipment and systems inte ral to them are complete and ready for functional testin . The checklist items are complete and ha1e been checked off only by parties ha1in direct kno(led e of the e1ent$ as marked belo($ respecti1e to each responsible contractor. This prefunctional checklist is submitted for appro1al$ sub7ect to an attached list of outstandin items yet to be completed. A ,tatement of Correction (ill be submitted upon completion of any outstandin areas. None of the outstandin items preclude safe and reliable functional tests bein performed. <<< Aist attached. <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< "lumbin Contractor 2ate <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< !eneral Contractor 2ate

"refunctional checklist items are to be completed as part of startup * initial checkout$ preparatory to functional testin . This checklist does not take the place of the manufacturer8s recommended checkout and startup procedures or report. Items that do not apply shall be noted (ith the reasons on this form -N/A @ not applicable$ 'O @ by others.. If this form is not used for documentin $ one of similar ri or shall be used. The Contractors (ho are assi ned responsibility for sections of the checklist shall also be responsible to see that checklist items by their subcontractors are completed and checked off. IContr.J column or abbre1iations in brackets to the ri ht of an item refer to the contractor responsible to 1erify completion of this item. A/E @ architect/en ineer$ All @ all contractors$ !C @ eneral contractor$ "C @ plumbin contractor$ +C @ mechanical contractor$ CC @ controls contractor$ TA' @ test and balance contractor$ EC @ electrical contractor$ CA @ commissionin a ent.

Appro1als. This filled&out checklist has been re1ie(ed. Its completion is appro1ed (ith the e#ceptions noted belo(. <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< Commissionin A ent 2ate <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< O(ner8s 0epresentati1e 2ate

CITYWIDE PUBLIC SAFETY BOND PROGRAM PREFUNCTIONAL CHECKLISTS RAMPART REPLACEMENT STATION

01813-33

:. Installation Checks Check if Okay. Enter N/A if not applicable. Enter Note number if deficient. Check "ipin "ipe fittin s complete and pipes properly supported allo(in for thermal e#pansion and contraction and buildin e#pansion 7oints. "ipe 7oints properly installed 0equired seismic anchorin installed "ipes properly labeled "ipes properly insulated "ipin properly sloped "roper construction isolation ,trainers in place and clean Isolation 1al1es and balancin 1al1es installed Test ports -"/T. installed near all control sensors and as per spec "ipin system properly flushed and cleaned and temporary pipin remo1ed -report attached. 16? of strainers and O(ner&selected lo(&point drains opened and (itnessed by O(ner to be clean. -Aist points checked belo(.. "ipin hydrostatic pressure test completed accordin to contract documents -report attached. No leakin apparent around fittin s A,+E pressure 1essel data sheet or certification ta posted and inspection complete for each e#pansion tank and stora e tank E#pansion tanks 1erified to not be air bound and system completely full of (ater. ,ystem pur ed of air. Air 1ents and bleeds at hi h points of systems functional Kater hammer arrestors installed and tested 'ackflo( pre1enter proper location Adequate depth of bury for ser1ice pipin Cross connection protection )al1es )al1e ta s permanently affi#ed )al1es installed in proper direction "ressure reducin 1al1es set at proper pressure No leaks /le#ible connections at equipment installed 2ielectric fittin s for dissimilar metals installed )ibration Isolation installed /ire&rated pipe penetrations installed properly )al1es that require a positi1e shut&off are 1erified to not be leakin (hen closed at normal operatin pressure. Aist% <<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<< CITYWIDE PUBLIC SAFETY BOND PROGRAM PREFUNCTIONAL CHECKLISTS RAMPART REPLACEMENT STATION

Contr.

01813-34

Check ,ensors and !a es Temperature$ pressure and flo( a es and sensors installed. Aist % <<<<<<<<<<<< <<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<< TA' Installation of system and balancin de1ices allo(ed balancin to be completed follo(in specified NE'' or AA'C procedures and contract documents Checklist items of "art : are all successfully completed for i1en trade; <<<<=es

Contr.

<<<<No

END OF CHECKLIST

CITYWIDE PUBLIC SAFETY BOND PROGRAM PREFUNCTIONAL CHECKLISTS RAMPART REPLACEMENT STATION

01813-35

"refunctional Checklist 2uct(ork Associated Checklists% 0ooftop "acka ed Gnit 1. ,ubmittals / Appro1als ,ubmittal. The abo1e equipment is complete and ready for functional testin . The checklist items are complete and ha1e been checked off only by parties ha1in direct kno(led e of the e1ent$ as marked belo($ respecti1e to each responsible contractor. This prefunctional checklist is submitted for appro1al$ sub7ect to an attached list of outstandin items yet to be completed. None of the outstandin items preclude safe and reliable functional tests bein performed. <<< Aist attached. <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< +echanical Contractor 2ate <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< !eneral Contractor 2ate <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< ,heet +etal Contractor 2ate <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< Electrical Contractor 2ate

"refunctional checklist items are to be completed as part of startup * initial checkout$ preparatory to functional testin . IContr.J column or abbre1iations in brackets to the ri ht of an item refer to the contractor responsible to 1erify completion of this item. A/E @ architect/en ineer$ All @ all contractors$ CA @ commissionin a ent$ CC @ controls contractor$ EC @ electrical contractor$ !C @ eneral contractor$ +C @ mechanical contractor$ ,C @ sheet metal contractor$ TA' @ test and balance contractor.

Appro1als. This filled&out checklist has been re1ie(ed. Its completion is appro1ed (ith the e#ceptions noted belo(. <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< Commissionin A ent 2ate <<<<<<<<<<<<<<<<<<<<<<<< <<<<<<<<< O(ner8s 0epresentati1e 2ate

CITYWIDE PUBLIC SAFETY BOND PROGRAM PREFUNCTIONAL CHECKLISTS RAMPART REPLACEMENT STATION

01813-36

:. Installation Checks Check if Okay. Enter N/A if not applicable. Enter Note number if deficient. Check 0un to/from 2ucts ,ound attenuators installed 2uct 7oints properly installed and sealed No apparent se1ere duct restrictions Turnin 1anes in square elbo(s as per dra(in s O,A intakes located a(ay from pollutant sources * e#haust outlets "ressure leaka e tests completed 'ranch duct control dampers operable 2ucts clean 'alancin dampers installed as per dra(in s "roper roof penetration curbs and flashin /ire&rated penetrations$ fire/smoke dampers properly located 2ucts insulated or lined per dra(in s 2uct(ork and plenums are clean and free of construction debris TA' -Test$ ad7ust$ air balance. Terminal units/2iffusers$ re isters$ rilles are ad7usted for air flo( quantity and direction Checklist items of "art : are all successfully completed for i1en trade; <<<<=es END OF CHECKLIST

Contr.

<<<<No

END OF SECTION

CITYWIDE PUBLIC SAFETY BOND PROGRAM PREFUNCTIONAL CHECKLISTS RAMPART REPLACEMENT STATION

01813-3

Vous aimerez peut-être aussi

- Air Cooled Chiller ChecklistDocument3 pagesAir Cooled Chiller ChecklistDevendra DhumalPas encore d'évaluation

- PC - Packaged DX Air Conditioning or Heat Pump, IdDocument7 pagesPC - Packaged DX Air Conditioning or Heat Pump, Idsushilalway4uPas encore d'évaluation

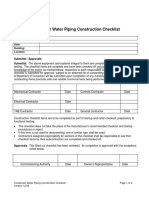

- Chilled Water Piping Construction Checklist: Project: Date: Building: LocationDocument4 pagesChilled Water Piping Construction Checklist: Project: Date: Building: LocationGopinath Gopi100% (1)

- Condenser Water Piping Construction Checklist: Project: Date: Building: LocationDocument4 pagesCondenser Water Piping Construction Checklist: Project: Date: Building: LocationGopinath GopiPas encore d'évaluation

- Cooling Tower Construction ChecklistDocument6 pagesCooling Tower Construction ChecklistGopinath GopiPas encore d'évaluation

- Testing and Commissioning Split ACDocument2 pagesTesting and Commissioning Split ACNuratiqah SharifahPas encore d'évaluation

- Water Flushing Witnessing and TestDocument3 pagesWater Flushing Witnessing and TestNeguib FarahPas encore d'évaluation

- LAWA Basic Commissioning Forms - CompleteDocument53 pagesLAWA Basic Commissioning Forms - Completemohammed_hatem0% (1)

- Testing & Commissioning Procedure for Ventilation and General Exhaust FansDocument3 pagesTesting & Commissioning Procedure for Ventilation and General Exhaust FansDong VanraPas encore d'évaluation

- Plumbing CommissioningDocument5 pagesPlumbing CommissioningZineddine ALICHEPas encore d'évaluation

- PPM Checklist RegisterDocument9 pagesPPM Checklist Registermarmarzamani10% (1)

- VRF & DX Split Type ACU Testing MethodologyDocument1 pageVRF & DX Split Type ACU Testing MethodologydamianPas encore d'évaluation

- Installation of AHUDocument4 pagesInstallation of AHUamg007Pas encore d'évaluation

- Procedure For Testing and Commissioning of Water Booster Jockey Pumps PDFDocument2 pagesProcedure For Testing and Commissioning of Water Booster Jockey Pumps PDFHumaid ShaikhPas encore d'évaluation

- Procedure For Testing & Commissioning of Water Booster Jockey PumpsDocument3 pagesProcedure For Testing & Commissioning of Water Booster Jockey Pumpsvin ssPas encore d'évaluation

- T&C Method StatementDocument16 pagesT&C Method StatementMohd Salleh Zainal79% (24)

- Hvac Testing Adjusting BalancingDocument7 pagesHvac Testing Adjusting Balancingarour.mokranePas encore d'évaluation

- Air handling unit startup log templateDocument4 pagesAir handling unit startup log templateAhmed SofaPas encore d'évaluation

- Testing and Commissioning Check ListDocument1 pageTesting and Commissioning Check ListarifzakirPas encore d'évaluation

- Method Statement For Testing & Commissioning of AHUDocument4 pagesMethod Statement For Testing & Commissioning of AHUsamsul maarif100% (1)

- Method of Statement For Precommissioning & Commissioning of Chiller Plant ManagerDocument3 pagesMethod of Statement For Precommissioning & Commissioning of Chiller Plant Managervin ssPas encore d'évaluation

- AHU ManualDocument17 pagesAHU ManualwolfzemunPas encore d'évaluation

- Commissioning Request and Check List (Form 9180)Document5 pagesCommissioning Request and Check List (Form 9180)Sraz MidnitePas encore d'évaluation

- Heating Plant Functional TestDocument81 pagesHeating Plant Functional TestFederico BrigatoPas encore d'évaluation

- MEEZA CRAC and Downflow SpecificationDocument57 pagesMEEZA CRAC and Downflow SpecificationSwamy Dhas DhasPas encore d'évaluation

- Fcu Method StatementDocument3 pagesFcu Method StatementBalajiPas encore d'évaluation

- Testing & Commissioning ExampleDocument12 pagesTesting & Commissioning Examplemikeo2Pas encore d'évaluation

- Air Handler Check ListDocument3 pagesAir Handler Check Listmnt6176100% (1)

- Refrigerant Piping Work1Document13 pagesRefrigerant Piping Work1Le Manh HieuPas encore d'évaluation

- AHU - Pre-Commissioning Checklist FormDocument5 pagesAHU - Pre-Commissioning Checklist FormMarvin ArinueloPas encore d'évaluation

- Preventative Maintenance Task Sheet: Plant/Equipment: Job IDDocument29 pagesPreventative Maintenance Task Sheet: Plant/Equipment: Job IDJaveria KhanPas encore d'évaluation

- Install Electric Water HeaterDocument5 pagesInstall Electric Water HeaterGwenn AsprerPas encore d'évaluation

- NFMT 11 Specifying Networked Controls With BACnetDocument44 pagesNFMT 11 Specifying Networked Controls With BACnetAkira ToyamaPas encore d'évaluation

- The Central Business District: New Administrative CapitalDocument18 pagesThe Central Business District: New Administrative CapitalAbanoub HakeemPas encore d'évaluation

- HVAC System: Exhaust FanDocument4 pagesHVAC System: Exhaust FanAnsari1918Pas encore d'évaluation

- Method of Statement Testing Commissioning With Sprinkler HeadsDocument5 pagesMethod of Statement Testing Commissioning With Sprinkler HeadskushiPas encore d'évaluation

- MTC-COMMISSIONING PLAN-v0Document12 pagesMTC-COMMISSIONING PLAN-v0Murat Sezgin100% (1)

- Learning Guid For Elecrical CommisioningDocument9 pagesLearning Guid For Elecrical CommisioningAbela DrrsPas encore d'évaluation

- LVFR Sprinkler System RequirementsDocument4 pagesLVFR Sprinkler System RequirementsridwanPas encore d'évaluation

- Duct Work Method StatementDocument3 pagesDuct Work Method StatementADsupermanPas encore d'évaluation

- Hvac Sys Verification Checklist v2 5 PDFDocument4 pagesHvac Sys Verification Checklist v2 5 PDFtsraj10100% (1)

- MVAC Testing & Commissioning Procedure - 2007Document245 pagesMVAC Testing & Commissioning Procedure - 2007spencersiu100% (6)

- Water System Test ReportDocument2 pagesWater System Test ReportNorman MuñizPas encore d'évaluation

- Installation Check ListDocument4 pagesInstallation Check ListAbdul Hakkim0% (1)

- DCC T&C Ms-PlumbingDocument11 pagesDCC T&C Ms-Plumbing721917114 47100% (1)

- "Fan Coil Unit": Testing and Commissioning Method Statement ForDocument16 pages"Fan Coil Unit": Testing and Commissioning Method Statement Forselcuk pekenPas encore d'évaluation

- Fire Sprinkler Installation MethodDocument3 pagesFire Sprinkler Installation MethodAnkit KumarPas encore d'évaluation

- Method Statement For Precommissioning & Commissioning of Close Control Units CCU'sDocument3 pagesMethod Statement For Precommissioning & Commissioning of Close Control Units CCU'svin ssPas encore d'évaluation

- Technical Submittal 03656Document37 pagesTechnical Submittal 03656Abdel HamidPas encore d'évaluation

- Functional Checklist For HVACDocument34 pagesFunctional Checklist For HVACAdhyartha KerafPas encore d'évaluation

- MSN 057 Solas II 2 Maintenance and Inspection of Fire Protection Systems and AppliancesDocument14 pagesMSN 057 Solas II 2 Maintenance and Inspection of Fire Protection Systems and AppliancesJothimanikkam SomasundaramPas encore d'évaluation

- Method Statement For Testing Precommissioning & Commissioning of Fuel Oil PumpsDocument3 pagesMethod Statement For Testing Precommissioning & Commissioning of Fuel Oil Pumpsvin ssPas encore d'évaluation

- Itp Mum10 - FcuDocument3 pagesItp Mum10 - FcuSaid Massinissa Elhadj AliPas encore d'évaluation

- CHECKLSITDocument2 pagesCHECKLSITaboobacker siddiquePas encore d'évaluation

- AHU Commissioning Report DF016eDocument8 pagesAHU Commissioning Report DF016evishwas salunkhePas encore d'évaluation

- Rmprtbiddoc PREFUNCTIONALCHECKLISTSDocument37 pagesRmprtbiddoc PREFUNCTIONALCHECKLISTSDani HambalinaPas encore d'évaluation

- SECTION 01813 Prefunctional ChecklistsDocument36 pagesSECTION 01813 Prefunctional ChecklistsBalasuperamaniam RamanPas encore d'évaluation

- Check ListDocument6 pagesCheck Listiman2222Pas encore d'évaluation

- Testing, Adjusting and Balancing: SECTION 15-1-9Document6 pagesTesting, Adjusting and Balancing: SECTION 15-1-9Ahmed Yousri AhmedPas encore d'évaluation

- D002 (I&C) Instrument and Calibration Procedure For Turbine & Boiler AreaDocument38 pagesD002 (I&C) Instrument and Calibration Procedure For Turbine & Boiler AreaSurya Darma100% (1)

- Section 16900 Systems Integration: Summary - This Section IncludesDocument6 pagesSection 16900 Systems Integration: Summary - This Section Includesrenjithv_4Pas encore d'évaluation

- New LV Cable ScheduleDocument13 pagesNew LV Cable Schedulerenjithv_4Pas encore d'évaluation

- General Plant Cost EstimatingDocument27 pagesGeneral Plant Cost EstimatingAnand Gupta73% (11)

- Business Plan For The Small Construction FirmDocument31 pagesBusiness Plan For The Small Construction FirmAlvie Borromeo Valiente100% (1)

- Commissioning Test Procedure Overhead LinesDocument10 pagesCommissioning Test Procedure Overhead LineshusnikhalilPas encore d'évaluation

- Self-Assessment Guide: ELCICS306-0510 1 Instrumentation and Control Servicing NC IIIDocument2 pagesSelf-Assessment Guide: ELCICS306-0510 1 Instrumentation and Control Servicing NC IIIrenjithv_4Pas encore d'évaluation

- Supplier's Documentation of EquipmentDocument32 pagesSupplier's Documentation of Equipmentrenjithv_4Pas encore d'évaluation

- 9556 - CM-707 - Supplement 5.6 - InstrumentationDocument19 pages9556 - CM-707 - Supplement 5.6 - Instrumentationrenjithv_4Pas encore d'évaluation

- Commissioning Test Procedure Overhead LinesDocument10 pagesCommissioning Test Procedure Overhead LineshusnikhalilPas encore d'évaluation

- Process Industries Data Handover Procedure 1Document2 pagesProcess Industries Data Handover Procedure 1renjithv_4Pas encore d'évaluation

- Procurment Process Manual 1Document1 pageProcurment Process Manual 1renjithv_4Pas encore d'évaluation

- Ball Valves vs Gate Valves: Which is Best for Your ApplicationDocument4 pagesBall Valves vs Gate Valves: Which is Best for Your Applicationrenjithv_4Pas encore d'évaluation

- 2 Pneumatic Systems Part 1 of 3Document32 pages2 Pneumatic Systems Part 1 of 3ashunitkPas encore d'évaluation

- Understanding CalibrationDocument1 pageUnderstanding Calibrationrenjithv_4Pas encore d'évaluation

- QA&QC - Installation of Field InstrumentationDocument4 pagesQA&QC - Installation of Field InstrumentationMuhammadZahirKhan100% (1)

- Geothermal Pipe Line DesignDocument15 pagesGeothermal Pipe Line DesignjohnjuantamadPas encore d'évaluation

- How To Conquer MountainDocument11 pagesHow To Conquer Mountainrenjithv_4Pas encore d'évaluation

- MOS For InstrumentationDocument6 pagesMOS For Instrumentationrenjithv_4100% (1)

- Process Industries Data Handover Procedure 8Document2 pagesProcess Industries Data Handover Procedure 8renjithv_4Pas encore d'évaluation

- Process Industries Data Handover Procedure 9Document2 pagesProcess Industries Data Handover Procedure 9renjithv_4Pas encore d'évaluation

- Instrumentation and ControlDocument37 pagesInstrumentation and ControlMukesh Raghuvanshi100% (2)

- HZ WriteUpDocument20 pagesHZ WriteUprenjithv_4Pas encore d'évaluation

- QA Protocols for Equipment ConstructionDocument1 pageQA Protocols for Equipment Constructionrenjithv_4Pas encore d'évaluation

- QA&QC - Installation of Field InstrumentationDocument4 pagesQA&QC - Installation of Field InstrumentationMuhammadZahirKhan100% (1)

- Boiler AnnexDocument66 pagesBoiler Annexrenjithv_4Pas encore d'évaluation

- QapDocument9 pagesQaprenjithv_4Pas encore d'évaluation

- Final - CFR CqappDocument134 pagesFinal - CFR CqappPatricia JacksonPas encore d'évaluation

- Quality Assurance Protocol-4Document2 pagesQuality Assurance Protocol-4renjithv_4Pas encore d'évaluation

- Quality Assurance Protocol-2Document1 pageQuality Assurance Protocol-2renjithv_4Pas encore d'évaluation

- Quality Assurance Protocol-1Document1 pageQuality Assurance Protocol-1renjithv_4Pas encore d'évaluation

- Employee Management System Project ReportDocument30 pagesEmployee Management System Project ReportPawanPas encore d'évaluation

- Question Paper Code:: Reg. No.Document3 pagesQuestion Paper Code:: Reg. No.Vijaya LakshmiPas encore d'évaluation

- CyBOK v1.1.0-4Document200 pagesCyBOK v1.1.0-4Adrian NPas encore d'évaluation

- Software Testing Concepts: QualityDocument33 pagesSoftware Testing Concepts: QualitySankar NaiduPas encore d'évaluation

- Daslight5 installer log captures errorsDocument6 pagesDaslight5 installer log captures errorsCalin PopaPas encore d'évaluation

- Software Quality - PROG8440: Testing Levels, Types and Reasons for KNIMEDocument4 pagesSoftware Quality - PROG8440: Testing Levels, Types and Reasons for KNIMEHarshil JoshiPas encore d'évaluation

- BCS 051 Solved AssignmentsDocument11 pagesBCS 051 Solved AssignmentsAmit GuptaPas encore d'évaluation

- Repport Btech FinalDocument50 pagesRepport Btech FinalSuzelle NGOUNOU MAGAPas encore d'évaluation

- Unit test -2 Sample Paper appendixDocument13 pagesUnit test -2 Sample Paper appendixManoj KavediaPas encore d'évaluation

- ISTQB FL Definitions and ExamplesDocument28 pagesISTQB FL Definitions and ExamplesSimeon TodorovPas encore d'évaluation

- SCDHHS - Test StrategyDocument24 pagesSCDHHS - Test StrategyKomalPas encore d'évaluation

- Uat Test ProcessDocument9 pagesUat Test ProcessmadhukommiPas encore d'évaluation

- Logistics Management System Complete DocumentationDocument99 pagesLogistics Management System Complete DocumentationDrapeeto33% (9)

- The Agile Unified Process AUPDocument34 pagesThe Agile Unified Process AUPAlejandro SanchezPas encore d'évaluation

- Software Engineer ResumeDocument22 pagesSoftware Engineer ResumeAnindita DuttaPas encore d'évaluation

- Expert Banking QA Analyst with 18+ Years ExperienceDocument5 pagesExpert Banking QA Analyst with 18+ Years ExperienceEmiPas encore d'évaluation

- ITI Intensive Code Camp - Software Testing FoundationsDocument4 pagesITI Intensive Code Camp - Software Testing Foundationskarim abou elmakaremPas encore d'évaluation

- i-SIGMA Certification Specifications Reference Manual - 0420A PDFDocument37 pagesi-SIGMA Certification Specifications Reference Manual - 0420A PDFaakbaralPas encore d'évaluation

- A Project Report On Facial Recognition Based Attendance SystemDocument52 pagesA Project Report On Facial Recognition Based Attendance SystemJAY DESAIPas encore d'évaluation

- Testing OrangeHRMDocument8 pagesTesting OrangeHRMSHIVAM POOJARAPas encore d'évaluation

- GAWIS 0215 Reduced 4pagerDocument4 pagesGAWIS 0215 Reduced 4pagerCristian SahoneroPas encore d'évaluation

- Object Oriented Analysis and Design Using UMLDocument10 pagesObject Oriented Analysis and Design Using UMLukkinguPas encore d'évaluation

- ISO 12207 Lecture NotesDocument106 pagesISO 12207 Lecture Notesziktar0123Pas encore d'évaluation

- Manhattan Profile DescriptionDocument5 pagesManhattan Profile DescriptionArup KR MondalPas encore d'évaluation

- Synopsis of Event Management SystemDocument29 pagesSynopsis of Event Management Systemshayaan kashaanPas encore d'évaluation

- SRS&SDS Format WithDetailedPoints 083013Document20 pagesSRS&SDS Format WithDetailedPoints 083013Arusi KumariPas encore d'évaluation

- Risk Mitigation, Monitoring, and Management PlanDocument27 pagesRisk Mitigation, Monitoring, and Management PlanSamPas encore d'évaluation

- Software Testing MicroprojectDocument26 pagesSoftware Testing MicroprojectLalit BorsePas encore d'évaluation

- Unit 4Document7 pagesUnit 4Sonia AroraPas encore d'évaluation

- Ethics in Language TestingDocument32 pagesEthics in Language TestingPamela Villahermosa100% (1)