Académique Documents

Professionnel Documents

Culture Documents

Unit II Corrosion

Transféré par

avishekpatelTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Unit II Corrosion

Transféré par

avishekpatelDroits d'auteur :

Formats disponibles

www.jntuworld.

com

UNIT-II CORROSION SCIENCE & ITS CONTROL METHODS 1. an inhibitor which when added in small quantities to aqueous corrosive environment a effectively decreases the corrosion of the metal b. increases the corrosion of a metal c. no effect on the corrosion of metal d. increases the corrosion nature of the environment. 2. in the electrochemical corrosion a. anode undergoes oxidation b. cathode undergoes oxidation c. anode undergoes reduction d. both cathode and anode under goes oxidation 3. The deciding factor in atmospheric corrosion is a presence of oxygen in air b. presence of gases like SO2

c. humidity of air d. frequency of rainfall

4. during corrosion of iron in aqueous solution a corrosion occurs at cathode b. corrosion product is deposited at anode c. corrosion occurs at anode d. corrosion occurs at cathode with deposition of rust at cathode. 5. The metal at the top of the electrochemical series is a. most stable b. most noble

6. The following metal is used for the cladding of aluminum a. 99.5% pure Al c. 98.5 % pure Al b. 100% pure Al d. 99% pure Al 7. Opacity and desired colour to paint is provided by a. pigments b. extenders c. dries d. thinners 8. The oxygen carriers of the paint is provided by a. drier b. pigments c. thinner d. drying oil

9. Cathodic coatings if punctured a. have affect on the base metal b. causes less corrosion of the base metal c. causes accelerated corrosion of the base metal d. Cathodic coating corrodes first followed by the corrosion of base metal. 10. The rusting of iron is catalyzed by one of the following a. Fe b. O2 c. Zn d. H+ 11. Corrosion is an example of a. oxidation b. reduction c. electrolysis d. erosion

T N

W U

R O

c. least active

D L

d. more active

12. For the corrosion of iron one of the following factors is essential a. presence of moisture c. presence3 of hydrogen b. presence of both moisture and oxygen d. presence of strong acid 13. The buried pipeline is protected from corrosion by connecting to Mg block it is called a. impressed voltage protection b. sacrificial cathodic protection

www.jntuworld.com

www.jntuworld.com

c. sacrificial anodic protection 14. during wet corrosion a. the anodic part undergoes oxidation b. the cathodic part undergoes oxidation c. the anodic part undergoes reduction

d. any of these

d. Neither cathodic nor anodic part undergoes any change.

15. The rate of corrosion of iron in atmosphere depends on a. Humidity of atmosphere b. degree of pollution in atmosphere c. frequency of rain fall d. all the above. 16. In water line corrosion the maximum amount of corrosion takes place a. Along the line just above the level of water meniscus b. along the line at the level of water meniscus c. along the line just below the level of water meniscus d. at the bottom of the vessel. 17. Addition of hydrazine hydrate to corrosive environment a. Retards anodic reaction b. prevents diffusion of proton to cathode c. retards cathodic reaction by consuming dissolved oxygen. D. increases hydrogen over voltage. 18. Anodic coating protects the underlined metal a. Due to its nobel character b. sacrificially c. due to its higher electrode potential d. none. 19. Drying oils supply to paint film a. main film forming constituents b. medium or vehicle c. water proof-ness d. all the above 20. The function of ammonium chloride used as flux in galvanization is to a. Prevent oxide formation. B. prevent deposition of impurities c. reduce the content of base metal and coating metal. D. none. 21. The process of covering steel with tin to prevent it from corrosion is called a. galvanizing b. tinning c. metal cladding d. electro plating 22. Sand blasting is used for removing the following from the metal surfaces a. oxide scale b. oils c. greases d. old paints 23. Acid pickling of steel is carried out by dipping in a. dil HCl b. warm Dil HCl. C. warm Dil H2SO4 d. dil H2SO4 24. The following reagents are used for solvent cleaning of metal surface a. Naphtha b. acid c. alkali d. sodium carbonate. 25. Electroplating is process of depositing a thin layer of a. Superior metal over inferior base metal. B. inferior metal over superior base metal c. superior metal over superior base metal d. inferior metal over inferior base metal 26. Anodic coating protects underlined metal a. due to noble character b. higher oxidation potential c. due to its lower oxidation potential d. due to its higher reduction potential 1. A 2. A 3.A 4.C 5.D 6.A 7.A 8. A 9. C 10.D 11. A 12.B 13.C 14.A 15. D 16. C 17. C 18. B 19. D 20. A 21. B 22. A 23. B 24. A 25. B 26.B

T N

W U

R O

D L

www.jntuworld.com

www.jntuworld.com

FILL IN THE BLANKS: 1. Galvanization means coating of _________on the iron and steel objects. 2. In chromium plating the electrolytic solution contains _____ as electrolyte. 3. ____ Sheeting consists of plate of duraluminium sandwitched between two layers of aluminium of 99.5% pure. 4. An example of cathodic coating ________. 5. corrosion is a gradual decay of metal by the attack of ___________. 6. soil corrosion is pure _________ in character. 7. the phenomenon of a metal or an alloy exhibiting a much higher corrosion resistance than expected is called as ______. 8. the corrosion that results in the formation of pin holes, pits and cavities in the metal is _____________--. 9. the type of corrosion which occurs along grain boundarys is called___. 10. the rate of corrosion increases with ___ in pH. 11. impurities in metal causes____. 12. the mechanical dispersion of mixture of one or more pigments in a vehicle is called __. 13. ____ oils are used as vehicle in paints. 14. the oxygen carriers in paints are called ________. 15. __ coating are produced from coating metals which are anodic to the base metal. 16. Cathodic coatings are obtained by coating a __________ metal than the base metal. 17. The process by which coating metal is deposited on the base metal by passing a direct current through an electrolytic solution containing soluble salt of the metal is ____________. 18. ______________ is used to remove oils , greases, buffing compounds and fatty substances from the base metal surfaces. 19. sand blasting is used for removing __ scales. 20. ________ method is more widely used for common metal spraying. 21. During colorizing the composition of the protecting layer formed is ___. 22. _____ is produced by the interaction of a mixture of volatile chromos chloride and hydrogen with steel parts at 10500C. 23. __________ are inorganic surface barrier, produced by chemical or electrochemical reaction, brought at the surface of the base metal. 24. An example of anodic corrosion inhibitor_______________. 25. when the ratio of anodic to cathodic area decreases the rate of corrosion___________. 26. the chemical composition of the corrosion prodect of iron is _______. 27. in acidic environment lower the value of hydrogen over voltage ___ is the rate of corrosion. 28. in galvanic corrosion the metal having relatively __________ Eo value will undergo corrosion. 29. formation of _____ type of metal oxide causes rapid and continous corrosion. 30. pickling method is used for the removal of __________ deposits on the metal surface

T N

W U

R O

D L

Answers:1. Zinc 2. H2CrO4 + H2SO4 3. Alclad 4. Tinning 5.Environment 6.Electrochemical 7.Passivity 8.Pitting

corrosion 9.Intergranular 10. increases 11.Heterogenisity 12. Paint 13.Drying oils 14. Driers 15. Anodic 16. Noble 17. Electroplating 18.Solvent Cleaning 19.Oxide 20.Wire Gun method 21. Al3F2 22. Chromising 23. Chemical conversion coating 24.Chromate or Phosphate 25.Increase 26.Fe2O3.3H2O 27.Higher 28.Lower 29.Volatile and porous 30.Scale or rust

www.jntuworld.com

Vous aimerez peut-être aussi

- Workshop Viva QuestionsDocument10 pagesWorkshop Viva QuestionskrishnaPas encore d'évaluation

- Experiment-1 Name of Student: Batch: Branch: Roll No Problem StatementDocument5 pagesExperiment-1 Name of Student: Batch: Branch: Roll No Problem StatementdhirajPas encore d'évaluation

- Nucleation and Growth of Metals: From Thin Films to NanoparticlesD'EverandNucleation and Growth of Metals: From Thin Films to NanoparticlesPas encore d'évaluation

- ITI QuestionDocument204 pagesITI QuestionBlue Eye'sPas encore d'évaluation

- Micromachining Techniques for Micro ComponentsDocument33 pagesMicromachining Techniques for Micro Componentskshitij shahPas encore d'évaluation

- Emission Characteristics and Performance of Catalytic Converter A ReviewDocument8 pagesEmission Characteristics and Performance of Catalytic Converter A ReviewEditor IJTSRDPas encore d'évaluation

- Instrument Mechanic.146180122Document32 pagesInstrument Mechanic.146180122swami061009Pas encore d'évaluation

- Micro Project: Title of The ProjectDocument11 pagesMicro Project: Title of The Projectomkar digamabar sononePas encore d'évaluation

- HHP.fflo~.f..tpoo/'W S'06: 1 FN:AN201lAD301(1401Document14 pagesHHP.fflo~.f..tpoo/'W S'06: 1 FN:AN201lAD301(1401Bipin BabuPas encore d'évaluation

- Structural steel I: Killed, semi-killed & rimming steelDocument20 pagesStructural steel I: Killed, semi-killed & rimming steelabhi arotePas encore d'évaluation

- 1 6 A Discoverengineering 1Document6 pages1 6 A Discoverengineering 1api-264758535Pas encore d'évaluation

- Lab Manual 2 PrintDocument17 pagesLab Manual 2 Printmonikandakumar ramachandranPas encore d'évaluation

- Electrodeposition Andreas Tolz PPGDocument14 pagesElectrodeposition Andreas Tolz PPGAndi MusdalifahPas encore d'évaluation

- Production Lab Viva Question & AnswersDocument13 pagesProduction Lab Viva Question & AnswersPradeep GsPas encore d'évaluation

- Me2401 Mechatronics - 2 Marks With AnswerDocument29 pagesMe2401 Mechatronics - 2 Marks With AnswerAravind Selva50% (2)

- Viva Questions ChemistryDocument7 pagesViva Questions ChemistryAbaan KoulPas encore d'évaluation

- Unconventional Machining Processes C. Devanathan-137-200Document64 pagesUnconventional Machining Processes C. Devanathan-137-200LokitoPaTlpvRomeroHernandezPas encore d'évaluation

- SASTRA Metallurgy Lab Test AnswersDocument3 pagesSASTRA Metallurgy Lab Test AnswersHARIMETLYPas encore d'évaluation

- Extrusions DefectDocument2 pagesExtrusions DefectDanish Yacoob BandarkarPas encore d'évaluation

- LESSON PLAN FOR ENGINEERING MATERIALSDocument6 pagesLESSON PLAN FOR ENGINEERING MATERIALSDinesh Kumar RPas encore d'évaluation

- 2017HT30004 - Mechanical System Design - Assignment 2Document15 pages2017HT30004 - Mechanical System Design - Assignment 2Partha Pratim SarkarPas encore d'évaluation

- MPR MCQ 1Document10 pagesMPR MCQ 1Naveen Prabhu100% (1)

- Plastic MouldingDocument22 pagesPlastic Moulding4064 Harshitha RampellyPas encore d'évaluation

- IJSRD journal explores fabrication of stir casting setupDocument2 pagesIJSRD journal explores fabrication of stir casting setupChandresh Motka100% (1)

- Aircraft Engineering and Aerospace Technology: Article InformationDocument13 pagesAircraft Engineering and Aerospace Technology: Article InformationjeffinPas encore d'évaluation

- MODULE - 3 - Corrosion Science and E-Waste ManagementDocument16 pagesMODULE - 3 - Corrosion Science and E-Waste ManagementGangadhara CPas encore d'évaluation

- Lab ManualDocument14 pagesLab ManualBlair RogersPas encore d'évaluation

- Satyabhama MechDocument97 pagesSatyabhama MechRahul Kumar KPas encore d'évaluation

- Mechatronics - Unit 5 - NotesDocument13 pagesMechatronics - Unit 5 - NotesDulce DePas encore d'évaluation

- Smoke Meters: Guided by Prof. V.R. Patil Presented by Parikshit LadkeDocument5 pagesSmoke Meters: Guided by Prof. V.R. Patil Presented by Parikshit Ladkesyedthahir6609Pas encore d'évaluation

- JNTUK - B Tech - 2018 - 4 1 - Mar - R16 R13 R10 - MECH - RT41037022018 MATERIAL CHARACTERIZATION TECHNIQUESDocument1 pageJNTUK - B Tech - 2018 - 4 1 - Mar - R16 R13 R10 - MECH - RT41037022018 MATERIAL CHARACTERIZATION TECHNIQUESConor StevensonPas encore d'évaluation

- MD MCQDocument15 pagesMD MCQshweta_770587100% (1)

- Ashok LeylandDocument8 pagesAshok LeylandNaveen KumarPas encore d'évaluation

- Chapter 3 SQCDocument22 pagesChapter 3 SQCShishir GyawaliPas encore d'évaluation

- FT Lab Manual27-12-17 PDFDocument48 pagesFT Lab Manual27-12-17 PDFJay JoshiPas encore d'évaluation

- Me2204 Fluid Mechanics and Machinery SyllabusDocument1 pageMe2204 Fluid Mechanics and Machinery SyllabusrajapratyPas encore d'évaluation

- ProjectDocument14 pagesProjectoladipo GracePas encore d'évaluation

- Mems Descriptive Question and Answers Jntu AnantapurDocument10 pagesMems Descriptive Question and Answers Jntu AnantapurSai kiran0% (1)

- 53207-mt - Industrial TribologyDocument2 pages53207-mt - Industrial TribologySRINIVASA RAO GANTAPas encore d'évaluation

- Cipet ReportDocument36 pagesCipet Reportsfthayyil100% (1)

- Department of Mechanical Engineering: Seminar Synopsis OnDocument18 pagesDepartment of Mechanical Engineering: Seminar Synopsis OnAdithya KovuriPas encore d'évaluation

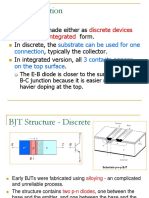

- BJT Fabrication: Discrete Devices Planar IntegratedDocument73 pagesBJT Fabrication: Discrete Devices Planar Integratedjayalaxmi HPas encore d'évaluation

- Unconventional Machining MCQsDocument72 pagesUnconventional Machining MCQsVig NeshPas encore d'évaluation

- Copper & Its Alloys - Engineering Materials & Metallurgy Questions and Answers - SanfoundryDocument4 pagesCopper & Its Alloys - Engineering Materials & Metallurgy Questions and Answers - SanfoundrySample UsePas encore d'évaluation

- Final - PPT On Aqua SilncerDocument35 pagesFinal - PPT On Aqua SilncerPravin PatilPas encore d'évaluation

- Laboratory Corrosion Testing PDFDocument7 pagesLaboratory Corrosion Testing PDFeid elsayedPas encore d'évaluation

- Summer Training ReportDocument16 pagesSummer Training ReportmohitPas encore d'évaluation

- AutoCAD VIVADocument6 pagesAutoCAD VIVADeva RajPas encore d'évaluation

- Automation of Ac System Employing PLC and ScadaDocument10 pagesAutomation of Ac System Employing PLC and Scadaeyob feshaPas encore d'évaluation

- Module 3 PDFDocument55 pagesModule 3 PDFSandeep VermaPas encore d'évaluation

- PLC Mid SyllabusDocument2 pagesPLC Mid SyllabusHardik PatelPas encore d'évaluation

- NUS ME5309 Aircraft Engines and Rocket Propulsion ExamDocument8 pagesNUS ME5309 Aircraft Engines and Rocket Propulsion ExamBenedict ChinPas encore d'évaluation

- C PROGRAM of Machine DesignDocument12 pagesC PROGRAM of Machine DesignPiyush Baid100% (1)

- Answers To Materials and Heat Treatment Board Exam Review QuestionsDocument3 pagesAnswers To Materials and Heat Treatment Board Exam Review Questionsrex tanongPas encore d'évaluation

- Cyaniding: M.Venkatesh Prabhu SPG 16 1431Document11 pagesCyaniding: M.Venkatesh Prabhu SPG 16 1431Sathu satishPas encore d'évaluation

- Corrosion Failures: Theory, Case Studies, and SolutionsD'EverandCorrosion Failures: Theory, Case Studies, and SolutionsPas encore d'évaluation

- CompreDocument4 pagesCompreSiddhant KatariaPas encore d'évaluation

- Ronak Mehta ContentDocument12 pagesRonak Mehta ContentDevashish JoshiPas encore d'évaluation

- 05 Corrosion and Its Prevention What Is Meant by CorrosionDocument8 pages05 Corrosion and Its Prevention What Is Meant by CorrosionLucky BoatPas encore d'évaluation

- Print Release Report of Development Index of StatesDocument2 pagesPrint Release Report of Development Index of StatesavishekpatelPas encore d'évaluation

- Question Paper - 07-10-2007Document10 pagesQuestion Paper - 07-10-2007avishekpatelPas encore d'évaluation

- Shortlisted Candidates For 5th Mains (Result 5th CCS (PT) - 2013Document8 pagesShortlisted Candidates For 5th Mains (Result 5th CCS (PT) - 2013avishekpatelPas encore d'évaluation

- Advt. O6 - 2013 - On - 12.08.2013Document8 pagesAdvt. O6 - 2013 - On - 12.08.2013riju_rahmanPas encore d'évaluation

- Print Release5 Review of Population Control ProgrammeDocument2 pagesPrint Release5 Review of Population Control ProgrammeavishekpatelPas encore d'évaluation

- Representing MatrixDocument9 pagesRepresenting MatrixavishekpatelPas encore d'évaluation

- Forum General Approach Subjects PhysicsDocument3 pagesForum General Approach Subjects PhysicsavishekpatelPas encore d'évaluation

- AP-PCS Exam 2012Document6 pagesAP-PCS Exam 2012Anshul VarshneyPas encore d'évaluation

- EngDocument13 pagesEngRajesh DharamsothPas encore d'évaluation

- Pressure Vessel Design (Basic)Document10 pagesPressure Vessel Design (Basic)Jason Gibbs100% (1)

- English Grammar SecretsDocument66 pagesEnglish Grammar SecretsMbatutes94% (33)

- IFS - Chemical Engg I 1Document4 pagesIFS - Chemical Engg I 1avishekpatelPas encore d'évaluation

- Ifs Chemical Engg Ii PDFDocument7 pagesIfs Chemical Engg Ii PDFavishekpatelPas encore d'évaluation

- IFS - Chemical Engg IDocument7 pagesIFS - Chemical Engg IavishekpatelPas encore d'évaluation

- GSTest3 VajiramDocument5 pagesGSTest3 VajiramavishekpatelPas encore d'évaluation

- 11elasticity - 183-197Document7 pages11elasticity - 183-197avishekpatelPas encore d'évaluation

- India Rio 2012Document2 pagesIndia Rio 2012avishekpatelPas encore d'évaluation

- MBA Entrance Exam Verbal Ability and Critical Reasoning QuestionsDocument24 pagesMBA Entrance Exam Verbal Ability and Critical Reasoning QuestionskoyibabaPas encore d'évaluation

- Gis and Decision Making Literature Review 1201526288991804 3Document17 pagesGis and Decision Making Literature Review 1201526288991804 3avishekpatelPas encore d'évaluation

- Exam 1Document2 pagesExam 1avishekpatelPas encore d'évaluation

- DIY Knifemaker's Info Center - Heat Treatment Oven ProjectDocument34 pagesDIY Knifemaker's Info Center - Heat Treatment Oven ProjectRicardo VelozPas encore d'évaluation

- Shell and Tube Heat Exchanger: Wall ThicknessDocument10 pagesShell and Tube Heat Exchanger: Wall ThicknessZeke KazamiPas encore d'évaluation

- 08 - TDS - Emaco S66 TDocument4 pages08 - TDS - Emaco S66 TaahtagoPas encore d'évaluation

- Experiment of Reinforce Concrete Beams at Different Loading RatesDocument8 pagesExperiment of Reinforce Concrete Beams at Different Loading RateskapolaPas encore d'évaluation

- S# Isin CFI Code (As Per New ISO) Security Name Security Symbol Sector Name Security Type StatusDocument25 pagesS# Isin CFI Code (As Per New ISO) Security Name Security Symbol Sector Name Security Type StatusahmedalishPas encore d'évaluation

- Geopolymer Paver Blocks: Aaron Darius Vaz, Donal Nixon D'Souza, Noothan Kaliveer, Satish K.T and Amar S.MDocument6 pagesGeopolymer Paver Blocks: Aaron Darius Vaz, Donal Nixon D'Souza, Noothan Kaliveer, Satish K.T and Amar S.MRodrigo RamosPas encore d'évaluation

- Astm D 6184Document3 pagesAstm D 6184김인식Pas encore d'évaluation

- APC Boosts Polypropylene OperationDocument6 pagesAPC Boosts Polypropylene OperationJuan AlejandroPas encore d'évaluation

- Dyeing of 100% Polyester Fabric With Disperse Dye by Exhaust Method.Document6 pagesDyeing of 100% Polyester Fabric With Disperse Dye by Exhaust Method.Naimul Hasan100% (1)

- LNG Ships: by F. R. ChowdhuryDocument6 pagesLNG Ships: by F. R. ChowdhuryThusitha DalpathaduPas encore d'évaluation

- Ieee STD C57 100-1995Document4 pagesIeee STD C57 100-1995José Enrique García VillarrealPas encore d'évaluation

- 39 Tractor EmulsionDocument4 pages39 Tractor EmulsionJaga NathPas encore d'évaluation

- Stress Corrosion Cracking of ASTM A517 Steel in Liquid Ammonia - Environmental FactorsDocument11 pagesStress Corrosion Cracking of ASTM A517 Steel in Liquid Ammonia - Environmental FactorsEzzah HanifPas encore d'évaluation

- GS Yuasa Battery Europe Ltd. Safety Data SheetDocument11 pagesGS Yuasa Battery Europe Ltd. Safety Data SheetVioleta MitićPas encore d'évaluation

- Science Exam NewDocument3 pagesScience Exam NewShahani BarredoPas encore d'évaluation

- Plasma arc cutting cost analysis and optimizationDocument5 pagesPlasma arc cutting cost analysis and optimizationLisandro GianottoPas encore d'évaluation

- A513A513M-15 Standard Specification For Electric-Resistance-Welded Carbon and Alloy Steel Mechanical TubingDocument13 pagesA513A513M-15 Standard Specification For Electric-Resistance-Welded Carbon and Alloy Steel Mechanical TubingChuthaPas encore d'évaluation

- ESP ButtonDocument17 pagesESP ButtonDamjan MilanovićPas encore d'évaluation

- 1.1. Usb Legal PDFDocument60 pages1.1. Usb Legal PDFnadzrin_akatsuki94100% (1)

- 32LC818 Lcd26v88amDocument53 pages32LC818 Lcd26v88amDaniel AvecillaPas encore d'évaluation

- Latching Assignment PLC Ladder LogicDocument4 pagesLatching Assignment PLC Ladder LogicsalonyPas encore d'évaluation

- Pressure-Temperature-Ratings of Flanges As Per ASME B16.5 PDFDocument1 pagePressure-Temperature-Ratings of Flanges As Per ASME B16.5 PDFPawan Patil100% (1)

- IFR 101 ManualDocument28 pagesIFR 101 ManualsunhuynhPas encore d'évaluation

- METAL ORGANIC FRAMEWORKS (MOFs)Document8 pagesMETAL ORGANIC FRAMEWORKS (MOFs)FabianCcahuanaAymaPas encore d'évaluation

- Conveyor installation diagramDocument2 pagesConveyor installation diagramLuis PurisPas encore d'évaluation

- Instructions for Houillon Viscometer TubesDocument2 pagesInstructions for Houillon Viscometer Tubescarlos trilloPas encore d'évaluation

- TDS MasterRheobuilld-623Document2 pagesTDS MasterRheobuilld-623Taposh PaulPas encore d'évaluation

- SUPPLY OF LABOR MATERIALS EQUIPMENT FOR STAINLESS STEEL TANKSDocument2 pagesSUPPLY OF LABOR MATERIALS EQUIPMENT FOR STAINLESS STEEL TANKSWilliam LimPas encore d'évaluation

- Transporte IntermodalDocument8 pagesTransporte IntermodalDavid LatorrePas encore d'évaluation

- Geberit Silent-PP Pipe With One SocketDocument2 pagesGeberit Silent-PP Pipe With One SocketeneajataganiPas encore d'évaluation