Académique Documents

Professionnel Documents

Culture Documents

CI Boom 2000 To 2006

Transféré par

Alister William MacintyreTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

CI Boom 2000 To 2006

Transféré par

Alister William MacintyreDroits d'auteur :

Formats disponibles

1 Critical Infrastructure disasters 2000 to 2006

1/31/2014 10:59:06 AM

Critical Infrastructure Disasters 2000 to 2006

News etc. digested by Alister William Macintyre This time line (CI Boom 2000 to 2006) describes critical infrastructure disasters, formerly included with larger research notes. Im splitting disaster time line into smaller, digestible chunks, by date ranges, keeping my notes on what more could be done to mitigate such disasters in the main related analysis document.1 Last updated 2014 Jan 30

Version 1.42

Table of Contents, thru level 3 Glossary of key acronyms........................................................................................... 1 Notable CI disasters 2000 to 2006 ...................................................................................... 2 2001 Jan 17 Hutchinson Kansas Two Gas Explosions............................................ 4 2001 Sep 21 Toulouse France.................................................................................. 4 2002 Aug 30 PHMSA Safety Bulletin........................................................................ 5 2003 Jan Cartagena Murcia Spain ........................................................................... 6 2003 Sep-Oct PHMSA audits Kingman KS Pipeline ................................................. 6 2004................................................................................................................................. 6 2004 March 16 Arkhangelsk Russia Deliberate Gas Explosion.............................. 6 2004 Mar 9 Barracas Spain......................................................................................... 6 2004 Apr 22 North Korea ........................................................................................... 7 2004 Apr 22 PHMSA notifies Enterprise re: Kingman KS ........................................ 7 2004 May 24 Romania................................................................................................ 7 2004 May-July Enterprise responds to PHMSA......................................................... 7 2004 July 23 GAO report on Pipeline safety .............................................................. 8 2004 Oct 27 Kingman KS Pipeline Ruptures ................................................................. 8 Kingman Dimensions................................................................................................ 10 2004 Oct 27 Kingman Time Line ............................................................................. 11 2004 Oct 28 Kingman Time Line ............................................................................. 15 2005 Oct 6 Formosa Plastics in Texas................................................................... 15 2005 Dec 11 Buncefield UK Gas Explosions and Fire.......................................... 15 2005 Dec 13 Bergenfield NJ PSE&G........................................................................... 16 Events leading to Bergenfield crisis. ........................................................................ 17 2006 Sep 15 RC = Rancho Cordova CA ................................................................... 21 2006 Nov 28 NJBPU citations on Bergenfield NJ incident...................................... 22 2006 Dec 6 Milwaukee WI Falk Co Explosion ..................................................... 22 Continued in more documents .......................................................................................... 22

Glossary of key acronyms

Some institutions are mentioned below, which may be worth defining.

http://www.scribd.com/doc/114094060/Indy-Boom

Critical Infrastructure disasters 2000 to 2006

Here is the main document: http://www.scribd.com/doc/114094060/Indy-Boom

2 Critical Infrastructure disasters 2000 to 2006

1/31/2014 10:59:06 AM

EPA = US Environmental Protection Agency. They have regulations to try to protect the environment. They also investigate incidents which are reported as being serious. GAO = US Government Accountability Office. They investigate various topics, mainly to satisfy US Congress. NTSB = National Transportation Safety Board. They investigate some types of disasters, involving transportation and pipelines. PHMSA = US pipeline and Hazardous Materials Safety Administration. They have regulations for the safe handling of dangerous chemicals in storage and transportation. They inspect various company facilities to identify safety lapses, then tell those companies what they need to do to fix the problems.

Notable CI disasters 2000 to 2006

Here is a section of my notes on Critical Infrastructure (CI) disasters. I collect info about many disasters, see what they have in common, then consider what improvements could be made in efforts to mitigate risk of high damage in the next similar incident, or even reduce the frequency in which they occur. My mitigation evaluation is in a separate parent document, from these incident time-line chunks.2 Scribd loses statistics when we change document name, so I kept the original name Indy Boom because I first started looking into this topic on the occasion of a gas explosion which demolished a housing sub-division of Indianapolis. That incident turned out to be deliberate sabotage for insurance fraud, which is not the typical cause of these disasters. There seem to be many causes, such as unintentional criminal negligence,, a lack of public education to get witnesses to promptly report leak odors and a lack of enforcement of national safety standards for the companies mis-managing these dangerous chemicals. The events, in this time line segment, occurred in: Britain; France; North Korea; Romania; Russia; Spain; USA. Incidents listed here include: Bergenfield NJ had a gas line break, leading to an apartment building exploding, killing several residents. The state of NJ had a safety process for making sure that construction work did not damage gas lines. As we walk thru the time line for this incident, we find there were problems implementing that process. o There were errors in relevant records. o Because it was winter time, PSE&G could not shut off the gas which apartment residents used for heat, cooking, and hot water. Instead, the construction work should have been rescheduled in a season when the gas could be shut off. o The construction work exposed the gas line to potential trouble, but at the end of day the construction crew, and PDE&G inspector left the situation at risk of getting worse, when they knocked off work at end of day. o 2005 Dec was when the disaster occurred. o 2006 Nov the authorities issued citations for safety violations. o 2007 May is when the NTSB report got published.

2

http://www.scribd.com/doc/114094060/Indy-Boom

Critical Infrastructure disasters 2000 to 2006

Here is the main document: http://www.scribd.com/doc/114094060/Indy-Boom

3 Critical Infrastructure disasters 2000 to 2006

1/31/2014 10:59:06 AM

Construction work can damage pipelines unless the lines are carefully marked, the construction crews trained in recognizing those markings, and inspection to identify any damage, or risk of damage, and get it resolved before that leads to a disaster. There are many lapses in this safety standard. Critical Infrastructure personnel have awesome duties, whether they work air traffic control, operate nuclear power plants, or control pipelines. They can be overwhelmed with data. They need systems to manage the data wisely, and they need good training in interpreting what the data is telling them. Many disasters occur for lack of that support. GAO info: o GAO = US Government Accountability Office. o GAO came out with a 2004 July report on US pipeline safety. I included links to the report, and summarized its content. Industrial storage, of dangerous chemicals, can have leaks. Those leaks can lead to fires and explosions. It sounds like there should be standards for inspecting storage to detect leaks, and fix them, before disasters strike. Kingman KS experienced a pipeline rupture 2004 Oct 27. No one was killed or injured but 204 thousand gallons of anhydrous ammonia leaked into the environment. This accident cost $680,715 including $459,415 for environmental remediation. o Because of the scale of this disaster, I have a lot of info in my time line about what we have learned about the circumstances. o See PHMSA in this time line summary. o I include time line of this particular incident, and lots of other related info. Labor Management disputes can occur, where the authorities sometimes blame the Union, or former disgruntled workers, as a convenient scapegoat. Evidence not important. Leaks can lead to smell, fire, explosion, witnessed by people near where the leaks are occurring, before the company is aware that they have a serious problem. These witnesses call 911, which calls the company, and only then it knows it has a problem, and acts to deal with it. Until the company acts on the info, it may continue to be pumping more fuel into the leak site. There can be some time between witness, 911 notified, company notified, relevant people figure out situation and implement remedial action. PHMSA Info. o PHMSA = US pipeline and Hazardous Materials Safety Administration. I include links to various PHMSA info, and summarize what was in them. o PHMSA safety advisory Aug 2002 to US industry in general. o PHMSA audit 2003 Sep-Oct on the Kingman KS Pipeline which has a 2004 Oct incident, then 2007 June NTSB report on that incident. o PHMSA notice 2004 Apr to the Kingman KS Pipeline, which has a 2004 Oct incident. The 2003 Sep-Oct audit had found many safety deficiencies at the company, and this notice identified what the company needed to fix, to avoid disaster. o Kingman responded to the latest PHMSA notice in 2004 May-July, in which they said they had fixed some, but not all of what PHMSA had Critical Infrastructure disasters 2000 to 2006

Here is the main document: http://www.scribd.com/doc/114094060/Indy-Boom

4 Critical Infrastructure disasters 2000 to 2006

1/31/2014 10:59:06 AM

asked for. This led to PHMSA closing the notice 2004 Oct 18, a week and a half before the Kingman 2004 Oct disaster.

RC = Rancho Cordova CA PG&E

o 2006 Sep there was an odor report, leading to repair to a pipe, which was not conducted properly. o 2007 Oct there was other incorrect repair of a pipe. o 2008 Dec incident investigation found events, prior to the disaster, which had contributed to it. o 2010 May is when the NTSB report came out. Systemic failures at companies mis-managing fuels. o Example: o Companies dispatching people, to deal with some crisis, who lacked the training and tools to do anything constructive about it. A source of fuel, to an unfolding crisis, needs to be shut off. Company personnel dispatched to the scene, do not have the tools to get that job done. Vehicles carrying stuff, which might explode at any moment, going thru populated areas without police escort, or evacuation of people in harms way. Witnesses smell the distinct odor of a leak. They fail to notify authorities. The leak ultimately leads to a disaster.

2001 Jan 17 Hutchinson Kansas Two Gas Explosions

o Wikipedia reports3 that natural gas stored underground in Hutchinson, Kansas leaked into empty brine caverns. Two explosions resulted from the leak. One destroyed two businesses and damaged 26 others. Another destroyed a trailer park killing two people. Sinkholes and gas leaks formed all around the city and the gas had to be slowly burned off.4

2001 Sep 21 Toulouse France

At 10:15 am, in the AZF (Azote de France) fertilizer factory in Toulouse, France, an explosion occurred in a warehouse where the off-specification granular AN was stored flat, separated by partitions. About 200300 tons was involved in the explosion, resulting in 31 people dead and 2,442 injured, 34 of them seriously. 5 The blast wave shattered windows up to 3 kilometers away, and the resulting crater was 10 meters deep and 50 meters wide. The exact cause remains unknown. The material damage was estimated at 2.3 billion euros. France's Environment Minister concluded the explosion "may have been a terrorist attack" as it was soon after the September 11 attacks and linked to worker with militant views.6

3 4

https://en.wikipedia.org/wiki/Category:Gas_explosions https://en.wikipedia.org/wiki/Gas_explosions 5 https://en.wikipedia.org/wiki/Ammonium_nitrate_disasters 6 https://en.wikipedia.org/wiki/Ammonium_nitrate_disasters

Critical Infrastructure disasters 2000 to 2006

Here is the main document: http://www.scribd.com/doc/114094060/Indy-Boom

5 Critical Infrastructure disasters 2000 to 2006

2002 Aug 30 PHMSA Safety Bulletin

References in this write-up:

1/31/2014 10:59:06 AM

DOT = US Department of Transportation NTSB = US National Transportation Safety Board. PHMSA = US Pipeline and Hazardous Materials Safety Administration. RSPA = US Research and Special Programs Administration

August 30, 2002, PHMSA7 published a Federal Register notice issuing a safety advisory bulletin8 to operators of gas and hazardous liquid pipelines and liquefied natural gas facilities about telephonic reporting. In the notice, PHMSA stated that it is critical for an operator to provide accurate information on the extent of the incident and that PHMSA expects an operator to provide significant updated information during the emergency response phase. The bulletin stated that if additional information leads to a significant change in the estimated quantity of product released, the estimated number of fatalities and injuries, the extent of environmental damage, or the extent of property damage, the operator should make an additional telephonic report to the National Response Center. PHMSA considered significant change to include an increase or decrease of previously reported fatalities or injuries and a revised estimate of product released or property damage at least 10 times greater than previous estimates. Regarding release estimates, the bulletin also stated that if the operator does not provide an estimate, the National Response Center will record a default estimate of 1,000 barrels (42,000 gallons). February 2005, PHMSA informed the NTSB that rather than the National Response Center entering the 1,000-barrel default estimate, PHMSA will consider telephonic reports made without a spill estimate to have the same priority as reports with spill estimates of 1,000 barrels. The National Response Center confirmed in March 2005 that it will not enter the 1,000barrel default value, if the operator does not provide a spill estimate.

In a DOT reorganization, the RSPA ceased operations on February 20, 2005. RSPAs Office of Pipeline Safety programs moved to the new PHMSA. All references to predecessor agencies are designated as PHMSA in NTSB reports.

8

The August 30, 2002, advisory bulletin was issued in response to NTSB Safety Recommendation P-02-02 (See Rupture of Piney Point Oil Pipeline and Release of Fuel Oil Near Chalk Point, Maryland, April 7, 2000, Pipeline Accident Report, NTSB/PAR-02/01 [Washington, DC: NTSB, 2002.]). NTSB issued Safety Recommendation P-02-02 to PHMSA to require pipeline owners and operators to provide follow-up telephone updates to the National Response Center when they discover that the info they initially reported contains significant errors, or when they identify significant new info directly related to the reporting criteria.

Critical Infrastructure disasters 2000 to 2006

Here is the main document: http://www.scribd.com/doc/114094060/Indy-Boom

6 Critical Infrastructure disasters 2000 to 2006

1/31/2014 10:59:06 AM

Federal pipeline safety regulation for telephonic reporting of hazardous liquid pipeline accidents (49 CFR 195.52) requires telephonic notification to the National Response Center when the pipeline accident has caused a death or injury requiring hospitalization; has resulted in either an unintentional fire or explosion; has caused estimated property damage (including cleanup and recovery costs and the value of the lost product) exceeding $50,000; has resulted in pollution of streams, rivers, reservoirs, or other similar bodies of water; or, in the judgment of the operator, is significant even though the accident does not meet the other specified criteria. The regulation further requires an operator to include in the telephonic notification not only the basic details, such as the identity of the operator, the location and time of the accident, and the number of fatalities and injuries, but also all other significant facts known by the operator that are relevant to the cause of the failure or extent of the damages.

2003 Jan Cartagena Murcia Spain

The fertilizer storage facility of Fertiberia held a self-sustained decomposition (SSD) fire in January 2003. The fire was controlled after most of the material was removed by mechanical means.9

2003 Sep-Oct PHMSA audits Kingman KS Pipeline

In September and October 2003, PHMSA10 inspected the Enterprise integrity management program for the anhydrous ammonia pipeline, including the Enid Lateral pipeline segment.11 The inspection revealed some deficiencies, were noted on PHMSAs Integrity Management Inspection Form and Inspection Summary Report.

2004

Table of Contents navigation aid.

2004 March 16 Arkhangelsk Russia Deliberate Gas Explosion

o Arkhangelsk explosion of 2004: In Arkhangelsk, Russia, on March 16, 2004, a gas explosion in a 9 story apartment building killed 58 people. Reportedly, a former gas technician caused the explosion due to a dispute with his former employers.12

2004 Mar 9 Barracas Spain

A truck carrying 25 tons of ammonium nitrate fertilizer exploded half an hour after a traffic accident, killing two people and injuring five others. The explosion, which could be heard at a distance of several kilometers, caused a crater five meters deep.13 See 1959 Aug 7 Roseburg OR very similar incident.

9

10

https://en.wikipedia.org/wiki/Ammonium_nitrate_disasters PHMSA = US Pipeline and Hazardous Materials Safety Administration.

11 12

See 2004 Oct 27 incident, and 2007 Jun 14 NTSB report. https://en.wikipedia.org/wiki/Arkhangelsk_explosion_of_2004 13 https://en.wikipedia.org/wiki/Ammonium_nitrate_disasters

Critical Infrastructure disasters 2000 to 2006

Here is the main document: http://www.scribd.com/doc/114094060/Indy-Boom

7 Critical Infrastructure disasters 2000 to 2006

2004 Apr 22 North Korea

1/31/2014 10:59:06 AM

Ryongchn A freight train carrying ammonium nitrate exploded in this important railway town near the Chinese border, killing 162 people and injuring over 3,000 others. The train station was destroyed, as were most buildings within 500 meters, and nearly 8,000 homes were destroyed or damaged. Two craters of about ten meters in depth were seen at the site of the explosion. The authorities blamed "human error" for the explosion, although rumors persist that it was in fact an attempt to assassinate the North Korean leader Kim Jong-Il, who was due to be passing through the station at the time.14

2004 Apr 22 PHMSA notifies Enterprise re: Kingman KS

2004 April 22, PHMSA15 identified several compliance issues, in the 2003 Sep-Oct audit, and issued a Notice of Amendment to Enterprise, to correct deficiencies in its integrity management program. One of the compliance issues pertained to risk factors used in prioritizing the baseline assessment schedule. PHMSA noted that the following risk factors required by regulation were not addressed by Enterprise: seam type, results of previous assessments, defect type and size that the assessment method can detect, and defect growth rate. PHMSA also asked that more detail be included in documentation describing how these risk factors will be integrated into the decision-making process for prioritizing the baseline assessment schedule. However, PHMSA did not identify that pipeline leak history also was not used in Enterprises calculation of relative risk scores.

2004 May 24 Romania

Mihileti, Buzu 4:57 am: A truck carrying 20 tones of ammonium nitrate tipped over on the European road E85 near Mihileti. Shortly afterwards, a fire started in the cabin. Two reporters got to the site of the accident and started filming while firemen were trying to stop the fire. Around 5:50 am the truck exploded, killing 18 and wounding 13 people. A crater 6.5 meters deep and 42 meters in diameter was formed by the explosion.16 See similar incidents with trucks carrying ammonium nitrate, which I think should have a police escort: 1959 Aug 7 Roseburg OR. 2004 Mar 9 Barracas Spain.

2004 May-July Enterprise responds to PHMSA

In letters dated May 21 and July 28, 2004, Enterprise responded to the PHMSA Notice of Amendment with revised procedures to integrate the risk factors that had been identified in the notice as deficient. However, Enterprise did not update its baseline assessment for

14 15

https://en.wikipedia.org/wiki/Ammonium_nitrate_disasters PHMSA = US Pipeline and Hazardous Materials Safety Administration. 16 https://en.wikipedia.org/wiki/Ammonium_nitrate_disasters

Critical Infrastructure disasters 2000 to 2006

Here is the main document: http://www.scribd.com/doc/114094060/Indy-Boom

8 Critical Infrastructure disasters 2000 to 2006

1/31/2014 10:59:06 AM

prioritizing the scheduling of pipeline segments using the revised procedures. Enterprise also did not modify or update the procedures for leak history in its revised procedures. After reviewing Enterprises May 21 and July 28 responses, PHMSA closed the Notice of Amendment on October 18, 2004. PHMSA did not require Enterprise to update the baseline assessment using the revised risk factor procedures.

2004 July 23 GAO report on Pipeline safety

Here is summary of GAO report17 on need to do a better job managing pipeline safety. Here is 77 page detail GAO report.18 While pipelines are inherently safer to the public than other modes of freight transportation, pipeline accidents involving natural gas and hazardous liquids (such as gasoline) can have serious consequences. For example, a natural gas pipeline ruptured near Carlsbad, New Mexico, in 2000, killed 12 people, and resulted in $1 million in damages or losses. The Office of Pipeline Safety (OPS) administers the national regulatory program to ensure safe pipeline transportation. OPS uses its enforcement program, when safety problems are found, as one means to do so. This study reports on (1) effectiveness of OPS's enforcement strategy and (2) OPS's actions for assessing monetary sanctions (civil penalties), among other things

2004 Oct 27 Kingman KS Pipeline Ruptures

2004 Oct 27 Kingman Kansas incident was an Anhydrous Ammonia Pipeline Rupture. Break for illustration.

17

http://www.gao.gov/products/GAO-04-801 http://www.gao.gov/assets/250/243542.pdf 18 http://www.gao.gov/assets/250/243540.pdf

Critical Infrastructure disasters 2000 to 2006

Here is the main document: http://www.scribd.com/doc/114094060/Indy-Boom

9 Critical Infrastructure disasters 2000 to 2006

1/31/2014 10:59:06 AM

References in this write-up: 3E Company = Enterprises accident reporting contractor. Abilene KS = pipeline pump station, between Linn to NNE, and Conway to SSW. Anhydrous ammonia19 = a highly corrosive and toxic hazardous liquid. Apex = Apex Environmental, Inc., Magellans environmental contracto r. Borger TX = SSW the end of the main pipeline, where Wellsford KS is next pumping station to NNE. CDT20 Conway KS = pipeline pump station, and delivery point terminal, between Abilene to NNE and Partridge to SSW.

19

Anhydrous ammonia is classified in 49 Code of Federal Regulations (CFR) Part 195 as a highly volatile liquid. Anhydrous ammonia is transported as a liquefied gas in a pipeline and, when released, will immediately return to a gaseous state and rapidly expand. It is a hazardous liquid that is highly corrosive and toxic, and its vapors also are extremely irritating and corrosive. Anhydrous ammonia may be fatal if inhaled, ingested, or absorbed through the skin.

20

All times in NTSB report are Central Daylight Time.

Critical Infrastructure disasters 2000 to 2006

Here is the main document: http://www.scribd.com/doc/114094060/Indy-Boom

10 Critical Infrastructure disasters 2000 to 2006

1/31/2014 10:59:06 AM

Enid OK = plant on lateral from main pipeline. To NNW is Harper KS. To East is Verdigris. Enterprise = Enterprise Products Operating L.P. Harper KS = pipeline pump station, on Enid lateral from main pipeline. To NNW is the rupture point, then Partridge KS, where the lateral splits from main pipeline. To SSE is Enid OK. KC = Kingman County KCFD = Kingman County Fire Department. KCS = Kingman County Sheriff. KDHE = Kansas Department of Health and Environment. KS = Kansas Linn KS = pipeline pump station, between Mankato MN to NNE, and Abilene KS to SSW. Magellan = Magellan Midstream Partners, L.P. MN = Minnesota NTSB = National Transportation Safety Board OK = Oklahoma Partridge KS = pipeline pump station, where Enid lateral splits off from main pipeline. To SSW on main line is Wellsford. To NNE on main line is Conway. To SSE on lateral, is the point of rupture, then Harper. SCADA = supervisory control and data acquisition. TX = Texas. Wellsford KS = pipeline pump station between Partridge to NNE and Borger TX to SSW on main line.

Kingman Dimensions

About 11:15 a.m. CDT October 27, 2004, an 8-inch-diameter pipeline owned by Magellan and operated by Enterprise ruptured near Kingman, Kansas, and released approximately 4,858 barrels (204,000 gallons) of anhydrous ammonia. Nobody was killed or injured due to the release. The anhydrous ammonia leaked into a creek and killed more than 25,000 fish, including some from threatened species. The cost of the accident was $680,715, including $459,415 for environmental remediation. See: 2007 Jun 14 for NTSB report. I have read the report, and include what I learned from it in my notes. My preliminary conclusions include: Pipeline controllers have awesome duties, similar to that of nuclear power plant operators, and air traffic control personnel. The quality of the instruments and alarms are such that pipeline controllers are easily overwhelmed with data. These systems are long overdue for improvements. Enterprise did take action after this incident, to address this challenge. There is a huge risk that pipelines will be damaged by construction work, so proper marking at ground level is critical, along with training any personnel likely to do construction work. This continues to be an area of major risk. 10 Critical Infrastructure disasters 2000 to 2006

Here is the main document: http://www.scribd.com/doc/114094060/Indy-Boom

11 Critical Infrastructure disasters 2000 to 2006

1/31/2014 10:59:06 AM

There are many dimensions of problems which contributed to this disaster. My mind boggles at all which is needed to mitigate against the risks of re-occurrence.

The ammonia pipeline runs from Borger, Texas, to Mankato, Minnesota. 21

Type of System: Accident Type: Location: Date: Time: Owner: Facility: Operator: Fatalities/Injuries: Damage/Clean-up Cost: Material Released: Quantity Released: Pipeline Pressure: Component Affected:

Hazardous liquid Pipeline rupture and leak with vapor cloud 6 miles west of Kingman, Kansas October 27, 2004 11:15 a.m. central daylight time Magellan Midstream Partners, L.P. Magellan Ammonia Pipeline/Enid Lateral Enterprise Products Operating L.P. None $680,715 Anhydrous ammonia 4,858 barrels (204,000 gallons) 981 psig Pipe

2004 Oct 27 Kingman Time Line

11.15 and 11.16 am., when a pipeline controller returned to his console after getting his lunch, he noticed two rate-of-change alarms22 which had been displayed on the alarm screen for the ammonia pipeline less than a minute earlier. The SCADA event log23 indicated negative rate-of-change alarms for suction

21

See map in the NTSB report. A rate-of-change alarm is displayed when a change in pressure or flow exceeds an identified value.

22

23

The controller later explained to NTSB investigators that: The SCADA system can display a trend screen that shows pressure and flow trend data graphically, and looking at a trend screen would have been helpful in the analytical stage. However, he did not use trend screens in evaluating the incoming data. He said that his training did not specify which screens to use to analyze and evaluate SCADA data. From 11:15 a.m. to 11:48 a.m. an unusually high number of alarms and status events were displayed for the pipeline. The pipeline systems, that this controller operated, experienced an increase from an average of 137 alarms in an hour to 286 alarms between 11:00 a.m. and noon. During this 33-minute period, the SCADA system displayed 119 alarms and status events. The controller said that he felt that he had full authority to shut down the pipeline and that he did not believe there would be consequences from Enterprise if he shut down a pipeline, and it was subsequently determined that there was no leak.

11

Critical Infrastructure disasters 2000 to 2006

Here is the main document: http://www.scribd.com/doc/114094060/Indy-Boom

12 Critical Infrastructure disasters 2000 to 2006

1/31/2014 10:59:06 AM

pressure at both Harper Station (at 11:15:43 a.m.)24 and Conway Station (at 11:16:27 a.m.).25 About 11:18 a.m., an off-duty volunteer firefighter traveling on Highway 54 called 911 to report a huge vapor cloud on the north side of the highway that he believed was a pipeline release.26 The 911 center in Kingman County, Kansas, is in the county sheriffs office. On the basis of the 911 call at 11:18 a.m., the Kingman County sheriffs office responded to the site, and started telephoning residents in 35 houses; four families were evacuated; no residents were home at 28 houses. Between 11:19:34 a.m. and 11:19:55 a.m., four more alarms from Conway Station were displayed at the controllers console, including o low suction pressure,27 o low-low suction pressure,28 o an uncommanded pump shutdown, and o a rate-of-change alarm that was followed by a low suction pressure alarm from Partridge Station. About 11.20 a.m., KCFD was dispatched to the rupture site. Since rupture site was in an agricultural area, home to several threatened and endangered species of fish and wildlife, it was later designated by Enterprise as a high-consequence area.29 The vapor cloud moved northwest from rupture and affected vegetation in an area approximately 1/2 mile wide and 1 1/2 miles long. The release entered an unnamed tributary stream approx 36 feet from pipeline failure. The tributary stream enters Smoots Creek approx 1 1/2 miles downstream of rupture. Two additional rate-of-change alarms were displayed, at 11:20:31 a.m. from Conway, and at 11:21:26 a.m. from Partridge.30 In the 13 seconds between 11:27:33 a.m. and 11:27:46 a.m., five additional alarms were displayed, including low flow, and the uncommanded shutdown of Abilene Station.31 11:27:50 a.m., the controller increased flow rate set point on the flow control valve at Enid Station32 from approximately 450 barrels per hour to 550 barrels per hour.33

24 25

We now know that Harper station was the closest to the rupture, to its SSE. We now know that the rupture was between Partridge station and Harper station, with Conway being the next station on the main line, NNE of Partridge. 26 See photo in NTSB report. 27 A low suction pressure alarm for a pump at a pump station along a pipeline can be set at a value selected by the pipeline controller (higher than low-low) as a warning of an abnormal condition or a possible pipeline leak. 28 A low-low suction pressure alarm is a high level (red) alarm in the SCADA system that is considered an immediate response alarm. 29 A high-consequence area is defined in the Federal pipeline safety regulations as a commercially navigable waterway, high- or concentrated-population area, or unusually sensitive area that might be affected by an accident involving the pipeline. Title 49 CFR 195.450 contains the criteria for designating an area a high-consequence area for hazardous liquid pipelines. 30 Partridge was closest to the rupture, to the NNW. 31 We now know that Abilene station was further away from the rupture, than Conway station. 32 We now know that the rupture was on the line through Enid, on the other side of Harper station, from Enid.

12

Critical Infrastructure disasters 2000 to 2006

Here is the main document: http://www.scribd.com/doc/114094060/Indy-Boom

13 Critical Infrastructure disasters 2000 to 2006

1/31/2014 10:59:06 AM

11:27:51 a.m., a second low-low suction pressure alarm from Conway Station34 was displayed. The controller knew that Enterprise maintenance personnel were working at Conway Station. In a telephone call to Conway Station at 11:28 a.m., he asked why the pump had shut down. By 11:30 a.m., Conway Station personnel had told the controller that they had not caused the pump to shut down. 11:34:05 a.m., SCADA system displayed a low suction pressure rate-of-change alarm downstream at Linn Station,35 followed by a low-low suction pressure alarm at 11:34:30 a.m. By about 11:40 a.m., the sheriffs office and fire d epartment had blocked roads which could be affected by the vapor cloud. About 11:48 a.m., the 911 dispatcher called Enterprises control room to report the release that had been reported to 911. Another controller, who was sitting at the console adjacent to the ammonia pipeline controllers console, answered the phone and handled the call. The ammonia pipeline controller told investigators that when he heard the telephone ring he immediately realized that there was a leak on the ammonia pipeline. o He started to shut down the pipeline at 11:48:20 a.m. by remotely stopping the pumps at Enid, Verdigris, Wellsford, and Borger Stations,36 in that order. The last one, Borger, was shut down at 11:52:57 a.m. o From his console, he remotely closed the block valve at Harper Station, and at 11:54:24 a.m., he closed the block valve at Partridge Station. These

33

This is the direct opposite of what ought to be done, when there is a rupture, but it is type of activity common to other disasters, when the quality of the instrumentation, and training of the personnel, is such that they do not yet know there is a disaster in progress. The controller told investigators after the rupture that he had been viewing the tabular screen and knew the alarms indicated a potential problem with the pipeline. To evaluate the alarms from the pipeline, he used the tabular data screen in the SCADA system. This screen listed the pipeline facilities, and displayed current data for the entire pipeline system, including pump station suction and discharge pressures, pump status, tank levels, flow rates, valve status, and set points. Alarm information that was displayed on the alarm screen also flashed and changed color on the tabular screen. The controllers assessment was that he was d elivering more ammonia from the pipeline than was being added to the pipeline, and that this condition had decreased the pressure. This assessment led him to increase the flow rate at 11:27:50. He later said that he thought that within 10 or 15 minutes the pressure readings would increase. Therefore, he planned to wait for a few minutes, and, if the pressure readings for the pipeline did not increase, he would reevaluate and delve deeper into the situation. The operations control supervisor stated in an interview that he expects pipeline controllers to use the tabular screen as the main screen, or front page. He said that controllers are taught to access and display a trend screen, or second page, to further investigate an alarm and the condition that ca used it. The supervisor said that pressure and flow changes are the primary parameters used to detect leaks. He stated that at the time of the accident, rate-of-change alarms were displayed in blue and immediate response alarms were displayed in red. He indicated that he believes the controller had enough information between 11:20 a.m. and 11:25 a.m. to lead him to shut down the ammonia pipeline. 34 Conway station is on the main line, north of the rupture, between Partridge and Harper. 35 Linn station is on the main line, more north of the rupture, than all other stations mentioned so far. 36 The controller stopped pumps at these stations because at the time he did not know whether the leak was on the mainline from Borger, on the Enid Lateral, or on the mainline downstream of Partridge Station.

13

Critical Infrastructure disasters 2000 to 2006

Here is the main document: http://www.scribd.com/doc/114094060/Indy-Boom

14 Critical Infrastructure disasters 2000 to 2006

1/31/2014 10:59:06 AM

closures isolated a 50.85-mile-long segment of pipeline in which the rupture had occurred. o At 12:08 p.m., he dispatched Enterprise personnel to close manual block valves at milepost markers 21 and 32 to further isolate the leaking pipeline segment. At 12:56 p.m. and 1:09 p.m., respectively, those valves were closed. These valve closures reduced the isolated segment of pipeline in which the rupture had occurred to 11 miles. About 12:15 p.m., the controller notified Enterprises central region operations manager of the release. Because field personnel were too busy to make the call, the manager called the controller back to tell him to report the accident to Enterprises accident reporting contractor.37 o 12.23 p.m., in the controllers phone conversation with the accident reporting contractor, the controller reported that a large quantity of anhydrous ammonia had been released and had formed an ammonia vapor cloud, but he stated that he did not know the amount of anhydrous ammonia that had been released. o When the contractor responded that without an estimate of a specific quantity the National Response Center would enter a 1,000-barrel estimate in its incident report, the controller told the contractor that a 1,000-barrel estimate would be fine. The contractor asked whether the amount released was at least 20 gallons.38 The controller confirmed that it was. o Later, when the contractor asked for a damage estimate, the controller said that he had no idea. When the contractor asked him to choose one of several ranges of dollar values from less than $5,000 to exceeding $50,000 as an estimate of the damage caused by the release, the controller chose the less-than-$5,000 range. 1:08 p.m., Enterprises reporting contractor reported the release to the National Response Center. The National Response Center report of the incident stated that the release was a vapor cloud over the pipeline due to unknown causes. The contractor reported estimated quantity of release as 20 gallons and told the National Response Center that Enterprise would calculate the amount released when it got a chance. An updated release amount was never reported to the National Response Center.39 About 2:42 p.m., EPA received initial report of a 20-gallon release from the National Response Center. EPA representatives indicated that the EPA had not responded to the accident site because the reported release volume was so small.

37

3E Company was Enterprises accident reporting contractor.

38

When reporting an anhydrous ammonia release of unknown volume, Enterprise reported small releases as at least 20 gallons to indicate that a reportable quantity had been released.

39

See 2002 Aug 30 Federal Regulations, which require updated reporting, if when later info reveals extent of problem at least 10 times initial estimates. We now know that the release was: not 20 barrels but 4,858

14

Critical Infrastructure disasters 2000 to 2006

Here is the main document: http://www.scribd.com/doc/114094060/Indy-Boom

15 Critical Infrastructure disasters 2000 to 2006

2004 Oct 28 Kingman Time Line

1/31/2014 10:59:06 AM

7:00 a.m., a PHMSA inspector arrived on site. About 8:00 a.m., the PHMSA inspector learned from Enterprise operations employees that at that time, the estimated amount of anhydrous ammonia released was at least 3,000 barrels (126,000 gallons). 40 This estimate of the release volume was based on an approximation of the amount of product normally contained in the pipeline between the two valves that had been manually closed. The final estimate of the release volume was later calculated by Enterprise to be 4,858 barrels (204,000 gallons). 9.30 a.m., The EPA duty officer called Enterprise to ask why a vapor cloud was associated with a 20-gallon release.41 The Enterprise representative told the duty officer that the amount of ammonia released was much greater than the reported quantity, and he estimated the release to be at least 2,000 barrels (84,000 gallons). Following the phone call, two EPA on-scene coordinators were dispatched to the site to investigate. 5.00 p.m., EPA on-scene coordinators arrived at the site. and discussed with Apex, the need for sparging42 at Smoots Creek to lower pH levels in the creek. 9.00 p.m., Apex began sparging, and this continued for several weeks following the rupture. o Later, KDHE authorized spreading of 3,500 cubic yards of nitrogen-rich soil, which had been excavated from rupture location, over a cultivated area to fertilize the ground.

2005 Oct 6 Formosa Plastics in Texas

o There were explosions, and a fire which took 5 days to put out. A problem is that petroleum products, such as plastics, contain fuel for a fire, which you cannot put out with water.43

2005 Dec 11 Buncefield UK Gas Explosions and Fire

o The Hertfordshire Oil Storage Terminal, was the fifth largest oil-products storage depot in the United Kingdom, with a capacity of about 60,000,000 imperial gallons (270 ML) of fuel.44 The British Geological Survey monitored the first and

40

The 3,000-barrel estimate was a rough field estimate. With post accident implementation of new reporting procedures, Enterprise would have been able to provide a more refined estimate of 3,600 barrels. See Enterprises Post accident Actions Telephonic Report Procedure in the NTSB report.

41

EPA requires that an anhydrous ammonia release equal to or greater than 100 pounds of ammonia (equivalent to approximately 20 gallons) be reported within 15 minutes of discovery.

42

Sparging is the process of injecting compressed air into a waterway causing volatile pollutants such as ammonia to vaporize into the air.

43 44

https://en.wikipedia.org/wiki/Formosa_Plastics_propylene_explosion https://en.wikipedia.org/wiki/2005_Hertfordshire_Oil_Storage_Terminal_fire

15

Critical Infrastructure disasters 2000 to 2006

Here is the main document: http://www.scribd.com/doc/114094060/Indy-Boom

16 Critical Infrastructure disasters 2000 to 2006

1/31/2014 10:59:06 AM

largest explosion, which measured 2.4 on the Richter scale. There were a series of explosions which eventually overwhelmed 20 large storage tanks, and the fire was the largest in Europe since WW II.45 It lasted several days. The explosions were heard up to 125 miles (200 km) away, in nations on the other side of the North Sea. However, the explosions were not as large as the 1974 Flixborough disaster also in the UK. o The area was surrounded by office buildings, packed with people during the day, so they were fortunate this happened outside regular business hours, as this happened early in the morning, before the start of the business day. Hundreds of homes in the area were evacuated, about 227 schools, libraries, and other public buildings across Hertfordshire and Buckinghamshire closed, also nearby motorway, until it was safe again. Some early news reports mis-reported missing persons as fatalities, but eventually everyone was accounted for, no fatalities, but maybe 43 injured. o As with many other similar disasters, government investigations led to new safety regulations.

2005 Dec 13 Bergenfield NJ PSE&G

2005 Dec 13 Bergenfield NJ Natural Gas Line Break, Explosion and Fire References in this write-up: American Tank = American Tank Service Company, hired by JP Mgmt, to do construction work on apartment property. BFD = Bergenfield Fire Department. BPD = Bergenfield Police Department dispatches police dept and fire dept. EST = Eastern Standard Time. JP Mgmt = JP Management = a real estate company which owned apartment building, destroyed in the incident. NJ = New Jersey NJBPU = NJ Board of Public Utilities NTSB = National Transportation Safety Board. PSE&G = Public Service Electric and Gas Company Type of System: Accident Type: Location: Date: Time: Owner/Operator: Fatalities: Injuries:

45

Natural gas distribution Pipeline break, explosion, and fire Bergenfield, NJ December 13, 2005 9:26 a.m. EST46 Public Service Electric and Gas Company 3 5

Thanks to John Parkinson on Scribd, for calling this to my attention: http://www.scribd.com/john_parkinson_18 46 All times, in NTSB report on this incident, are eastern standard time.

16

Critical Infrastructure disasters 2000 to 2006

Here is the main document: http://www.scribd.com/doc/114094060/Indy-Boom

17 Critical Infrastructure disasters 2000 to 2006

Property Damage and Losses47: Material Released: Pipeline Pressure: Component Affected:

1/31/2014 10:59:06 AM

$863,300 Natural gas 11 1/2 pounds per square inch, gauge 1 1/4-inch steel service line

See: 2007 May 01 NTSB report48 on Bergenfield NJ Gas disaster December 13, 2005, at 9:26 a.m., an apartment building exploded in Bergenfield, NJ, after natural gas migrated into the building from a damaged pipeline. Investigators found a break in an underground 1 1/4-inch steel natural gas distribution service line, operating at 11 1/2 pounds per square inch, gauge. The break occurred at an underground threaded tee connection downstream from where excavators were removing an oil tank, which was buried under asphalt parking lot adjacent to the building. The break occurred, under the parking lot, about 7 feet 4 inches from the buildings wall. Three residents of the apartment building were killed. Four residents and a tank removal worker were injured and transported to hospitals.

Events leading to Bergenfield crisis.

JP Mgmt had hired American Tank to remove and replace the buried oil tank. On Dec 5, 2005, American Tank requested markouts49 of utilities at 30 Elm Street through the New Jersey One Call System.50 On Dec 7, 2005, a PSE&G51 street inspector went to the site and marked the location of the buried gas service line to the building. The marked location showed that the service line ran under the parking lot and about parallel to the buildings wall. At a point downstream o f the excavation area, the pipeline turned 90o toward the building. (See diagram in NTSB report. The gas line ran parallel alongside the underground tank, to be removed.

47 48

The apartment building, which was totally lost, thanks to the disaster. http://www.ntsb.gov/investigations/reports_pipeline.html http://www.ntsb.gov/investigations/fulltext/PAB0701.htm

49

A markout is a ground marking that is typically color coded and that indicates the location of underground utilities.

50

New Jersey One Call is a one-call operation for anyone planning to dig (excavation, demolition, blasting), regardless of the size of the project. This operation is for both commercial construction and homeowners. Under NJ Board of Public Utilities regulations (see NTSB report), excavators must inform NJ One-Call 3 to 10 days before excavating, and to immediately report any damage to the operator of the facility. 51 PSE&G is one of the largest combined electric and gas companies in the United States, and is New Jerseys oldest and largest publicly owned utility.

17

Critical Infrastructure disasters 2000 to 2006

Here is the main document: http://www.scribd.com/doc/114094060/Indy-Boom

18 Critical Infrastructure disasters 2000 to 2006

1/31/2014 10:59:06 AM

Mon Dec 12, about 8:30 a.m., the American Tank crew arrived at the site, saw the gas and water utility markouts, and began excavating the asphalt parking lot which was adjacent to the building. The work contract indicated that the tank capacity was 2,000 gallons.52 o According to the American Tank foreman, when the excavation was about 30 inches deep, the top of the tank was exposed. At this time, the crew realized that the tank was a 5,000-gallon tank rather than a 2,000-gallon tank.53 Because the larger tank was wider, longer, and heavier than expected, and thus closer to the natural gas service line, the excavation crew had concerns about its safe removal. o In a later interview, one of the crewmembers stated, [At the time] I said our concern is once we move the tank or roll it over, to roll it and take it out, it may undermine the gas line. o An American Tank vice president went to the site to verify that it was a larger tank and to reassess its removal. He arranged for his office staff to call New Jersey One Call for a second markout of the utilities. o The PSE&G inspector arrived at the apartment building about 11:14 a.m. and re-marked the gas service line. He made a slight change to the original marking where the gas line entered the building. The American Tank foreman told investigators that Dec 12 he asked the PSE&G inspector whether the gas line could be shut off while they excavated. This request was a precaution to prevent the release of gas if the line was damaged during the tank removal. o The PSE&G inspector told investigators he told the American Tank foreman that because it was wintertime54 the gas could not be shut off. However, the PSE&G inspector said that he would ask his supervisor. When the supervisor told the inspector that turning off the natural gas to the building would not be possible, the inspector informed the American Tank foreman. o According to PSE&G, shutting off the gas to the building without making prior arrangements with PSE&G and the buildings owner, would have created a health risk to the residents by leaving them without gas for heat, hot water, and cooking. The American Tank foreman and assistant manager said during post accident interviews that, based on their examination of the worksite after the initial excavation, they thought the excavation was stable and secure, and the excavation

52

Will we learn how the 2k 5k error was made?

53

Based on the length and depth of the tank, an American Tank vacuum truck operator referred to the tank capacity reference books that he carried in his truck, and correctly determined the capacity of the tank to be 5,000 gallons.

54

Will we learn how come JP asked for this job to be done in the wintertime?

18

Critical Infrastructure disasters 2000 to 2006

Here is the main document: http://www.scribd.com/doc/114094060/Indy-Boom

19 Critical Infrastructure disasters 2000 to 2006

1/31/2014 10:59:06 AM

wall was far enough from the pipe to be safe. However, the American Tank crew did not evaluate the soil at the walls of the ditch for stability. 55 The excavation crew exposed a portion of the gas pipeline by excavating with hand shovels to confirm the service lines location. The e xcavation was done by digging into the eastern trench wall, near the gas pipeline and the building, while standing in the trench. o The PSE&G street inspector, who had marked the pipeline, told Safety Board investigators that he was on site when the service line was first uncovered. The service line was partially exposed in two locations that were each about 1 foot long. The service line was buried about 30 to 36 inches and was about 2 feet from the extended eastern edge of the trench. To excavate the 5,000-gallon tank, the crew had to open a trench that was about 24 feet long, which was considerably larger than originally planned. The PSE&G inspector determined that the pipeline was a PSE&G gas pipeline and that it was accurately marked. o The inspector said he reminded the American Tank crew members of their obligation to protect the gas pipe from damage, by supporting the pipe against an immovable object, such as the building, or shoring the trench. 56 o The PSE&G inspector did not remain to ensure that the pipeline was adequately protected. In addition, he did not attempt to test the curb valve to ensure it could be rapidly closed if the pipeline was broken. The inspector gave the American Tank foreman his business card and asked him to call if he needed assistance, or had any questions. o 11.47 a.m., the inspector departed the site. o According to the American Tank foreman, the trench was not shored and was about 4 to 5 feet deep at the end of the first day. Tues Dec 13, about 8.30 a.m., American Tank crew (assistant manager, foreman, and two crew members) arrived, to continue work on the excavation. The American Tank crew members told NTSB investigators that they did not start any excavation equipment, or expand the excavation Dec 13, the day of the accident. o When they first arrived, they saw that the ground surrounding the pipeline had collapsed57 and fallen from underneath portions of the asphalt parking lot along the eastern wall of the trench. The crew members said that they tied one end of a rope to the gas pipeline and the other end to the oil tank vent pipe at the building wall in an effort to help support the pipeline. o American Tank had placed a pump into the trench to remove some accumulated water, when some crew members reported hearing a

55

Trench wall soils can be tested for stability by using a penetrometer, which is a mechanical device that measures the force needed for a probe to enter the soil. Another method is the thumb test, in which the thumb is pushed into the soil along the wall.

56 57

So what do the American Tank personnel remember from this conversation? It seems reasonable to Al, that the collapse of the pipe into the trench, could have pulled pipe connections loose, leading to the gas leak. At the same time as some crew addressing the problem, others should have called PSE&G immediately. Theres a problem, whose resolution ought to be checked.

19

Critical Infrastructure disasters 2000 to 2006

Here is the main document: http://www.scribd.com/doc/114094060/Indy-Boom

20 Critical Infrastructure disasters 2000 to 2006

1/31/2014 10:59:06 AM

popping sound, and two crew members smelled natural gas. Shortly afterward, the other two crewmembers smelled natural gas.58 From across the street, a local business owner saw the American Tank crew working at 30 Elm Street. He said that he saw water flowing down the road and when he went across the street to where the American Tank crew was working, he smelled natural gas. o The business owner said that he would call the police for them. o 8.49 a.m., he called the Bergenfield Police Department (BPD)59 and reported a gas leak. His call was the only one that BPD received about the incident before the explosion. o An apartment resident later told NTSB investigators that she also had smelled natural gas, but had not called police dept, fire dept, nor PSE&G. o 8:52 a.m., BFDs chief,60 a fire official,61 and an engine company responded to the initial notification of a gas leak. Two BPD police officers were also dispatched. A Bergenfield police officer directed traffic away from the area. o 8.54 a.m., American Tank foreman called PSE&G to report: the ground had collapsed, and the service line was broken. o About 8:54 a.m., the fire chief asked police dispatchers to notify PSE&G. o 8:58 a.m., police dispatchers notified PSE&G of the incident. The fire chief told NTSB investigators that he had not observed any signs of a leak at the trench (i.e., smelling gas, hearing a hissing sound, or seeing bubbling of water in the trench). The fire official said that he did not smell gas at the scene. o No one from BFD checked the apartment building for the presence of natural gas. The fire dept did not attempt to evacuate the building before the explosion. The Bergenfield fire chief said that the American Tank crew warned him, before the explosion, about the soil giving way in the trench and to be careful while walking near the trench. The fire chief also said that he looked into the trench, and could see that the soil beneath the asphalt on the east side of the trench had fallen into the trench. About 9:22 a.m., a PSE&G service technician arrived on scene. o The technician attempted to close the curb valve to shut off the gas, but he was unable to apply enough force to close it.

58

This should be a trigger to have the building evacuated until PSE&G says it is safe to go back in. The Bergenfield Police Department dispatches the police department and the fire department.

59

60

Bergenfield Fire Department was composed mostly of volunteers. The fire chief, a volunteer, served for a 1-year term.

61

Bergenfield had five career fire officials who conducted site inspections and fire investigations. The fire officials also responded to fire incidents.

20

Critical Infrastructure disasters 2000 to 2006

Here is the main document: http://www.scribd.com/doc/114094060/Indy-Boom

21 Critical Infrastructure disasters 2000 to 2006

1/31/2014 10:59:06 AM

o In a post accident interview, the service technician said that as he approached the building to investigate the gas leak, an American Tank crew member told him to not get too close to the trench because it had already collapsed. The service technician said that he had seen a piece of asphalt which had fallen into the trench. o The service technician, using a portable gas detector, detected a positive gas reading just inside the boiler room doorway of the apartment building. He started moving away from the building as it exploded at 9:26 a.m. The police and fire departments, American Tank, and PSE&G started rescue actions. The fire departments started firefighting. About 10:00 a.m., a PSE&G street crew was able to shut off gas to the service line by closing the curb valve.

2006 Sep 15 RC = Rancho Cordova CA

See 2008 Dec 24 for info about Rancho Cordova Ca Pacific Gas & Electric (PG&E) Explosion, Leak Release, and Ignition of Natural Gas. See 2010 May 18 for info from NTSB full report on PG&Es 2008 -12-24 Rancho Cordova Ca Explosion and Fire.62 The NTSB report found that there had been events prior to the disaster, which contributed to the disaster.

Quoting from NTSB report:63 September 15, 2006, about 7:00 a.m., PG&E received a gas odor complaint from the owners of 10708 Paiute Way. So, about 4:00 p.m. the same day, PG&E dispatched a crew to the house to evaluate the complaint. The crew determined that the source of the odor was a leak in the 2-inch Aldyl-A plastic pipe gas main located in front of the house, off the south side of the street. PG&E, and the pipe manufacturer (US Poly), have approved ways to repair leaks, and to test64 that they have been done properly. PG&E believed that this had in fact been done properly, and they had no complaints from the neighborhood, about gas leak smells between the time of this repair, and the morning of the Dec 24, 2008 incident. After the Dec 24, 2008 incident, PG&E and California Public Utilities Commission (CPUC) investigated records of other similar piping repairs to determine whether same kind of coupling leakage or pullout had been encountered elsewhere in PG&E system. See 2007 Oct 7 Sacramento CA, for info about another incident.

62

http://www.ntsb.gov/investigations/reports_pipeline.html http://www.ntsb.gov/investigations/fulltext/PAB1001.htm 63 http://www.ntsb.gov/investigations/reports_pipeline.html http://www.ntsb.gov/investigations/fulltext/PAB1001.htm

64

In a soap test, a soap solution is applied to a gas pipe which may have a leak. If gas is leaking, soap bubbles will form.

21

Critical Infrastructure disasters 2000 to 2006

Here is the main document: http://www.scribd.com/doc/114094060/Indy-Boom

22 Critical Infrastructure disasters 2000 to 2006

1/31/2014 10:59:06 AM

2006 Nov 28 NJBPU citations on Bergenfield NJ incident

References in this write-up: American Tank = American Tank Service Company, hired by JP Mgmt, to do construction work on apartment property. JP Mgmt = JP Management = a real estate company which owned apartment building, destroyed in the 2005 December incident. NJ = New Jersey NJBPU = NJ Board of Public Utilities NTSB = National Transportation Safety Board, report came out 2007 May. PSE&G = Public Service Electric and Gas Company November 28, 2006, New Jersey Board of Public Utilities sent Notices of Probable Violation to American Tank and the PSE&G. American Tank was cited for a probable violation of the New Jersey Underground Facility Protection Act for not planning the excavation to avoid damage and minimize interference with an underground facility, and not using reasonable care in an excavation. PSE&G was cited for three probable violations of 49 CFR Part 192. PSE&G employee, after being notified of a potential hazard, left the site with the potential hazard remaining. PSE&Gs response did not facilitate most effective course of action under circumstances following notice of a reported gas leak and ruptured service on December 13, 2005. PSE&G did not have sufficient communication and exchange of info with Bergenfield fire officials regarding its gas emergency programs.

Outcome of citations to American Tank and PSE&G were still pending as of May 1, 2007, when NTSB report got published.

2006 Dec 6 Milwaukee WI Falk Co Explosion

o The same company has had multiple explosions over the years. This one was caused by multiple leaks in a pipe delivering propane to multiple locations within the facility. 3 people were killed, 47 injured.65

Continued in more documents

Time Line of these disasters to be continued in related documents to be named: CI Boom 0 thru 199966 CI Boom 2000 to 2006 CI Boom 2007 CI Boom 2008 to 2009

65 66

https://en.wikipedia.org/wiki/2006_Falk_Corporation_explosion http://www.scribd.com/doc/203317455/CI-Boom-0-thru-1999

22

Critical Infrastructure disasters 2000 to 2006

Here is the main document: http://www.scribd.com/doc/114094060/Indy-Boom

23 Critical Infrastructure disasters 2000 to 2006

CI Boom 2010 to 2011 CI Boom 2012 CI Boom 2013 Jan-Mar CI Boom 2013 Apr CI Boom 2013 May-Dec

1/31/2014 10:59:06 AM

These other time line history segments, shall be uploaded to the same SCRIBD Critical Infrastructure collection.67 Revision history will be maintained in the main parent document.

67

http://www.scribd.com/collections/4108500/Critical-Infrastructure

23

Critical Infrastructure disasters 2000 to 2006

Here is the main document: http://www.scribd.com/doc/114094060/Indy-Boom

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Production Chemicals CatalogDocument58 pagesProduction Chemicals CatalograchedPas encore d'évaluation

- East African Crude Oil Pipeline Environmental and Social Impact Assessment ReportDocument28 pagesEast African Crude Oil Pipeline Environmental and Social Impact Assessment ReportAfrican Centre for Media Excellence100% (1)

- Matrx D MDM Cabinet MT Flowmeter Users ManualDocument20 pagesMatrx D MDM Cabinet MT Flowmeter Users ManualNasr Eldin AlyPas encore d'évaluation

- Pipeline Abandonment AssumptionsDocument2 pagesPipeline Abandonment Assumptionsyiyita01Pas encore d'évaluation

- Rules and Regulation For Cross Country Pipeline in IndiaDocument14 pagesRules and Regulation For Cross Country Pipeline in IndiaUpendra Nath BhaskarPas encore d'évaluation

- XCMG TrenchlessDocument29 pagesXCMG TrenchlessFasri HatomiPas encore d'évaluation

- Inspection EngineerDocument8 pagesInspection Engineervishal bailurPas encore d'évaluation

- EY Oil and Gas Equipment Industry in IndiaDocument32 pagesEY Oil and Gas Equipment Industry in IndiaArjav Desai100% (1)

- CI Boom 2010 To 2011Document23 pagesCI Boom 2010 To 2011Alister William MacintyrePas encore d'évaluation

- Boeing 777 Asia 2014 Mar 08Document53 pagesBoeing 777 Asia 2014 Mar 08Alister William MacintyrePas encore d'évaluation

- CI Boom 2014 FebDocument23 pagesCI Boom 2014 FebAlister William MacintyrePas encore d'évaluation

- CI Boom 2014 MarDocument26 pagesCI Boom 2014 MarAlister William MacintyrePas encore d'évaluation

- Currency Turmoil 2014 Feb DCDocument1 pageCurrency Turmoil 2014 Feb DCAlister William MacintyrePas encore d'évaluation

- CI Boom 2013 Jan To MarchDocument24 pagesCI Boom 2013 Jan To MarchAlister William MacintyrePas encore d'évaluation

- CI Boom 2013 Mar To DecDocument11 pagesCI Boom 2013 Mar To DecAlister William MacintyrePas encore d'évaluation

- CI Boom 2014 JanDocument30 pagesCI Boom 2014 JanAlister William MacintyrePas encore d'évaluation

- CI Boom 2008 To 2009Document19 pagesCI Boom 2008 To 2009Alister William MacintyrePas encore d'évaluation

- Bubble III 2013 Dec DCDocument1 pageBubble III 2013 Dec DCAlister William MacintyrePas encore d'évaluation

- CI Boom 2013 AprilDocument24 pagesCI Boom 2013 AprilAlister William MacintyrePas encore d'évaluation

- CI Boom 2007Document24 pagesCI Boom 2007Alister William MacintyrePas encore d'évaluation

- CI Boom 2012Document40 pagesCI Boom 2012Alister William MacintyrePas encore d'évaluation

- CI Boom 2014 Jan 9 W Va WaterDocument70 pagesCI Boom 2014 Jan 9 W Va WaterAlister William MacintyrePas encore d'évaluation

- War Cycle 2014 Jan DCDocument1 pageWar Cycle 2014 Jan DCAlister William Macintyre100% (1)

- CI Boom 0 Thru 1999Document22 pagesCI Boom 0 Thru 1999Alister William MacintyrePas encore d'évaluation

- Debt 2014 Jan 19 DCDocument1 pageDebt 2014 Jan 19 DCAlister William MacintyrePas encore d'évaluation

- Debt Limit 2013 Sep DCDocument2 pagesDebt Limit 2013 Sep DCAlister William MacintyrePas encore d'évaluation

- Hunger Games 2013 Dec DCDocument1 pageHunger Games 2013 Dec DCAlister William MacintyrePas encore d'évaluation

- Stock Market Bubble 2013 Nov DCDocument1 pageStock Market Bubble 2013 Nov DCAlister William MacintyrePas encore d'évaluation

- Doomers 2013 Nov DCDocument1 pageDoomers 2013 Nov DCAlister William MacintyrePas encore d'évaluation

- Debt $ 2013 Oct DCDocument1 pageDebt $ 2013 Oct DCAlister William MacintyrePas encore d'évaluation

- Leverage 2013 Nov DCDocument1 pageLeverage 2013 Nov DCAlister William MacintyrePas encore d'évaluation

- Money Multiplier 2013 Oct DCDocument1 pageMoney Multiplier 2013 Oct DCAlister William MacintyrePas encore d'évaluation

- House Oversight 2013 Aug 02 NTADocument22 pagesHouse Oversight 2013 Aug 02 NTAAlister William MacintyrePas encore d'évaluation

- Financial Bubbles Explained 2011 July DCDocument1 pageFinancial Bubbles Explained 2011 July DCAlister William MacintyrePas encore d'évaluation

- House Oversight 2013 Aug 02 IRSDocument10 pagesHouse Oversight 2013 Aug 02 IRSAlister William MacintyrePas encore d'évaluation

- House Oversight 2013 Aug 02 GA RevDocument5 pagesHouse Oversight 2013 Aug 02 GA RevAlister William MacintyrePas encore d'évaluation

- House Oversight 2013 Aug 02 TIGTADocument17 pagesHouse Oversight 2013 Aug 02 TIGTAAlister William MacintyrePas encore d'évaluation

- Corrosion in Oil and Gas Industry A Perspective On Corrosion InhibitorsDocument1 pageCorrosion in Oil and Gas Industry A Perspective On Corrosion InhibitorsAsma Sed100% (1)

- SeaFlex Riser TechnologiesDocument20 pagesSeaFlex Riser TechnologiesResandi SasmitaPas encore d'évaluation

- Asme Section I & Section Viii Fundamentals: Pdhonline Course M398 (3 PDH)Document59 pagesAsme Section I & Section Viii Fundamentals: Pdhonline Course M398 (3 PDH)vuchinhPas encore d'évaluation

- Client: Medco E & P Lematang Project Title: Singa Gas Development Project Location: Lematang Block, South SumateraDocument7 pagesClient: Medco E & P Lematang Project Title: Singa Gas Development Project Location: Lematang Block, South SumateraRohmat Benny IsmantoPas encore d'évaluation

- UniSim Design PIPESYS Getting StartedDocument26 pagesUniSim Design PIPESYS Getting Startedapi-3750488Pas encore d'évaluation

- Vol. II of IV-WebDocument1 329 pagesVol. II of IV-Webrahulchakri0369Pas encore d'évaluation

- Titan Flow Control, Inc.: Installation, Operation, and MaintenanceDocument5 pagesTitan Flow Control, Inc.: Installation, Operation, and MaintenanceArvnd VckyPas encore d'évaluation

- Ief Hydrogen Market Pathways Report - Scaling Up The Hydrogen MarketDocument33 pagesIef Hydrogen Market Pathways Report - Scaling Up The Hydrogen MarketVenkat PachaPas encore d'évaluation

- Asgard Development BDocument10 pagesAsgard Development BelifasmaiaPas encore d'évaluation

- Fundamentals of Gas Pipeline Metering StationDocument5 pagesFundamentals of Gas Pipeline Metering Stationsandeepsri9Pas encore d'évaluation

- SWOT Analysis On Power Generation IndustriesDocument43 pagesSWOT Analysis On Power Generation IndustriesPawan21100% (4)

- Tacite UgDocument129 pagesTacite Ugarmando0212-1Pas encore d'évaluation

- 3 - Development of An Inspection Robot ForDocument7 pages3 - Development of An Inspection Robot ForZaida AsyfaPas encore d'évaluation

- Pig AlertDocument2 pagesPig AlertHieu NguyenPas encore d'évaluation

- Maritime Globalpresentation en Jan2020 OptimizedDocument207 pagesMaritime Globalpresentation en Jan2020 OptimizeddlopezarPas encore d'évaluation

- Compressor - 101Document66 pagesCompressor - 101Juan Pablo Chavez IxtepanPas encore d'évaluation

- 49 CFR 192.completeDocument154 pages49 CFR 192.completeJames White100% (2)

- NOPSA DOIR Report On 2008 Varanus Pipe Explosion 07oct2008 Scanned Searchable ReducedDocument88 pagesNOPSA DOIR Report On 2008 Varanus Pipe Explosion 07oct2008 Scanned Searchable ReducedHawk HendryPas encore d'évaluation

- Servigistics User Guide v9 6 3 PricingDocument613 pagesServigistics User Guide v9 6 3 PricingcanthePas encore d'évaluation

- A081 ILFM AD 0049 RevDocument65 pagesA081 ILFM AD 0049 RevMarcus BarberPas encore d'évaluation

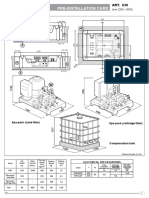

- Pre-Installation Card: Spa-Pack (Sand Filter) Spa-Pack (Cartridge Filter)Document4 pagesPre-Installation Card: Spa-Pack (Sand Filter) Spa-Pack (Cartridge Filter)ahoirebaPas encore d'évaluation