Académique Documents

Professionnel Documents

Culture Documents

CAD

Transféré par

synayakCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

CAD

Transféré par

synayakDroits d'auteur :

Formats disponibles

Dept of Mech. Engg. IV Sem Mech.

Chapter 9

Computer Aided Design

CAD Definition: Computer aided design (CAD) can be defined as the use of computer

systems to assist in the creation, modification, analysis or optimization of a design. The

computer system consists of hardware and software to perform the specialized design

functions required by the particular user firm. The CAD hardware typically includes the

computer, one or more graphics display terminals, keyboards and other peripheral

equipment. The CAD software consists of the computer programs to implement computer

graphics on the system (system software) and application programs to facilitate the

engineering functions of the user company. The application programs include stress-strain

analysis of components, heat transfer calculations, lubrication, combustion, kinematics

and dynamics of machinery, etc. The collection of application programs will vary from

one user firm to the next depending upon product lines manufacturing process and

customer markets.

Scope of CAD System:

1. to increase the productivity of the designer

2. to improve the quality of design

3. to improve communications

4. to create database for manufacturing

Benefits of CAD:

1. Improved engineering productivity

2. Shorter lead times

3. Reduced engineering personnel requirements

4. Customer modifications are easier to make

5. Improved accuracy and design

6. Reduced errors in programming

7. Easy inspection of complicated parts

8. Saves materials and machine time and also contributes in reduced wastage

9. Better communication interfaces

10. Leads to standardization of design

Compiled by NSY Page 1of 7 MDD- Chapter 9

Dept of Mech. Engg. IV Sem Mech.

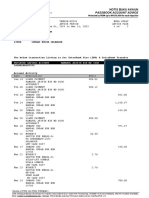

Hardware in CAD

Secondary

Storage

Design Workstation

Graphics Input

CPU Terminal Devices

Output

Devices and

Peripherals

The configuration of a CAD system is as shown above

The input devices can be keyboard, mouse, lightpen, digitizer, scanners, etc., while output

devices may be printer, plotter, etc. Secondary storage devices such as tapes, discs,

floppies, pen drives, portable hard disks, etc. helps in taking the backup of drawing. The

CPU is the main controlling part of the entire CAD system. For a CAD system the

processor should be fast enough to handle huge amount of data to carry out complex

mathematical calculations.

Design Workstation:

The CAD workstation is the system interface with the outside world. It provides a mode

to communicate with the computer. The workstation must accomplish five functions:

1. it must interface with the central processing unit

2. it must generate a steady graphic image for the user

3. it must provide digital descriptions of the graphic image

4. it must translate computer commands in to operating functions

it must facilitate communication between the user and the system

The Graphics Terminal:

The graphic terminals available today generally use the cathode ray tube (CRT) as the

display device. The graphic terminals are available in different sizes.

Compiled by NSY Page 2of 7 MDD- Chapter 9

Dept of Mech. Engg. IV Sem Mech.

A CRT is shown in the sketch below

A heated cathode emits a high speed electron beam onto a phosphor coated glass screen.

The electron energize the phosphor coating, causing it to glow at points where the beam

makes contact. By focussing the electron beam, changing its intensity, and controlling its

point of contact against the phosphor coating through the use of a deflector system, the

beam can be made to generate a picture on the screen.

Operator Input Devices

Input devices are needed for graphics workstation to facilitate convenient communication

between the user and the system. A number of input devices can be grouped into three

categories. They are:

1. Cursor control devices

2. Digitizers

3. Keyboard terminals

The first two are used for graphical interaction with system and the third one is used for

input of alphanumeric commands and text.

Compiled by NSY Page 3of 7 MDD- Chapter 9

Dept of Mech. Engg. IV Sem Mech.

1. Cursor Control Devices

The cursor normally takes the form of a bright spot on the CRT screen. The computer is

capable of reading the current position of the cursor. Hence the user’s capability to

control the cursor position allows location data to be entered into the CAD system

database. A typical example would be for the user to locate the cursor to identify the

starting point of a line. Another, more sophisticated case would be for the user to position

the cursor to select an item from a menu of functions displayed on the screen. For

instance, the screen might be divided into two sections, one of which is an array of blocks

which correspond to operator input function. The user simply moves the cursor to the

desired block to execute the particular function.

There are variety of cursor control devices which have been employed in CAD systems.

These include:

a. The mouse

b. The thumbwheel

c. Joystick

d. Track ball

e. Light pen

f. Touch screen

Mouse

Mouse is the most popular input device. Mouse is a small hand held puck like instrument

which is attached to the computer. Mouse can be moved around by the operator on any

flat surface to provide graphic input. Its ability to rapidly position the cursor on the screen

is its most important advantage. Mouse is available as a mechanical or optical graphic

input device. In the case of a mechanical mouse, the rolling ball at the bottom of the

mouse causes two encoders to rotate. The movement of the mouse is thus converted into

pulses which move the cursor in the X and Y direction in proportion to the movement of

the mouse. An optical mouse works on the basis of signal generated by the reflecting light

from the plate on which the mouse is moved. The source of light is an LED located

underneath the mouse. There are no moving parts in an optical mouse and that is an

Compiled by NSY Page 4of 7 MDD- Chapter 9

Dept of Mech. Engg. IV Sem Mech.

advantage over the mechanical mouse. Slippage at the contact surfaces is a disadvantage

of mouse.

Thumbwheel

Two wheels are used to control the cursor position along the horizontal and vertical

direction. The position is indicated by a cross-hair on the screen. Thumbwheels are

mounted on the keyboard by the side. Thumbwheels are used in animation packages. Two

of them are provided for X and Y movements of the cursor.

Joystick

Joystick is a potentiometric device that contains sets of variable resistors which feed

signals that indicate the device position to the computer. These devices rely on the

operator’s sense of touch and hand-eye co-ordination to control the position of the cursor

on the screen.

Joystick devices are normally set so that side-to-side movement produces change in X co-

ordinate and front to back movements produce change in Y co-ordinates. Thus they are

best suited for pointing in tasks such as menu selection or creating simple schematics.

Three dimensional capability is possible by moving the handle up and down by twisting it

to provide data entry in the Z-axis.

Track ball

Track ball has a ball and socket construction but the ball must be rolled with fingers or

the palm of the hand. The cursor moves in the direction of the roll at a rate corresponding

to rotational speed. Its function is similar to joystick and allows closer control over the

cursor movement. These are ideal for flight simulation control through CAD software

packages.

Light Pen

The light pen is a pointing device in which the computer seeks to identify the position

where the light pen is in contact with the screen. Light pen is nothing but a detector of

Compiled by NSY Page 5of 7 MDD- Chapter 9

Dept of Mech. Engg. IV Sem Mech.

light on the CRT screen and uses a photodiode, phototransistor, or some other form of

light sensor. Selection is done by pressing a push button in the pen.

Touch Screen

Touch screens are direct devices. They are used by simply touching CRT display with

one’s finger or a pointing device. Two types of touch screens namely, mechanical and

optical are used in CAD applications.

Mechanical type is a transparent screen overlay which detects the location of the touch.

Optical touch screen systems use rows of light emitters and receptors mounted just in

front of the screen with the touched location determined by broken beams.

2. Digitizer

Digitizer boards or tablets are electro-mechanical vector graphic input devices that

resemble a drafting board. These are used together with a movable stylus called puck.

The puck can be moved over the surface to following existing lines. It is a common

technique in CAD systems for taking x and y co-ordinates from a paper drawing. The

tracking device (puck) contains a switch for the user to record the desired x and y co-

ordinates. The co-ordinates are either directly sent to the computer or stored in secondary

storage devices like magnetic tapes. Digitizers with a large board provide high resolution

and accuracy. Digitizers are more frequently used to create drawing using an interactive

drafting package to enter a sketch or a drawing which can be redrawn or edited as the

display appears on the CRT screen.

Modern day digitizers can pick 3-dimensional information from a model, moving the tip

of a wand along the model. These systems generate signals that are analysed to produce

co-ordinates. This type of digitizer is very useful for reverse engineering.

3. Keyboard Terminals

It is an alphanumeric terminal used to enter commands, co-ordinates, functions and

process data to the CAD system. The information typed is displayed on the CRT screen.

The typed information displayed on the CRT screen can be changed. CAD systems make

use of special function keyboards. These function keys are provided to eliminate

extensive typing of commands. The number of function keys varies from about 8 to 80.

Compiled by NSY Page 6of 7 MDD- Chapter 9

Dept of Mech. Engg. IV Sem Mech.

Soft and Hard Prototyping

Prototyping is the process of building a model of a system. A prototype is often used as

part of the product design process to allow engineers and designers the ability to explore

design alternatives, test theories and confirm performance prior to starting production of

a new product.

A solid model of a part, or an assembly of solid parts, provides a more complete product

definition. Boeing Commercial Airplane Group uses the CATIA solid modelling product.

The solid models let Boeing spot interference problems before expensive mock-ups are

built. This results in significant savings. One of the biggest paybacks Boeing is

experiencing is the visualization benefits of solid modelling. It gives their engineers a

realistic view of the part. They can print colour images of the parts and share them with

other groups inside and outside the organisation. The process of building a prototype and

analysing it using the computer is known as soft prototyping. When a hard copy output is

taken of the prototype it is known as hard prototyping.

Compiled by NSY Page 7of 7 MDD- Chapter 9

Vous aimerez peut-être aussi

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Merchant Banking Is A Combination of Banking and Consultancy ServicesDocument3 pagesMerchant Banking Is A Combination of Banking and Consultancy ServicessynayakPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Orthographic ProjectionsDocument26 pagesOrthographic ProjectionssynayakPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- MarschDocument5 pagesMarschsynayakPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Meta MarketingDocument11 pagesMeta Marketingwaseemkhan406Pas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Atmospheric CorrosionDocument40 pagesAtmospheric Corrosionsynayak100% (1)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- AutoCAD Lab ManualDocument14 pagesAutoCAD Lab ManualsynayakPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- List of National CapitalsDocument11 pagesList of National CapitalssynayakPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- 3 & 4 Sem Scheme of StudiesDocument2 pages3 & 4 Sem Scheme of StudiessynayakPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Labview TutorialDocument349 pagesLabview TutorialArsla KhanPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Experiment No 01 VenturimeterDocument4 pagesExperiment No 01 Venturimetersynayak50% (2)

- M&M First IA - Aug 2008Document1 pageM&M First IA - Aug 2008synayakPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- TE I - Auto - Assgn 1Document1 pageTE I - Auto - Assgn 1synayakPas encore d'évaluation

- Personal Time TableDocument2 pagesPersonal Time TablesynayakPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Jet Propulsion System: Dept of Mech. Engg. III Sem AutoDocument4 pagesJet Propulsion System: Dept of Mech. Engg. III Sem AutosynayakPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Applications of Vacuum TechniqueDocument1 pageApplications of Vacuum Techniquesynayak100% (2)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Jet Propulsion System: Dept of Mech. Engg. III Sem AutoDocument4 pagesJet Propulsion System: Dept of Mech. Engg. III Sem AutosynayakPas encore d'évaluation

- Throttling ProcessDocument2 pagesThrottling Processsynayak100% (4)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Experion Legacy IO Link Module Parameter Reference Dictionary LIOM-300Document404 pagesExperion Legacy IO Link Module Parameter Reference Dictionary LIOM-300BouazzaPas encore d'évaluation

- GoodElearning TOGAF Poster 46 - Adapting The ADMDocument1 pageGoodElearning TOGAF Poster 46 - Adapting The ADMFabian HidalgoPas encore d'évaluation

- Swanand 2009Document3 pagesSwanand 2009maverick2929Pas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- BC 672772 RBRS Service TraningDocument385 pagesBC 672772 RBRS Service TraningTeknik Makina100% (2)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Bearing TypesDocument5 pagesBearing TypesWayuPas encore d'évaluation

- Dynamic Shear Modulus SoilDocument14 pagesDynamic Shear Modulus SoilMohamed A. El-BadawiPas encore d'évaluation

- 2SA1016Document4 pages2SA1016catalina maryPas encore d'évaluation

- WallthicknessDocument1 pageWallthicknessGabriela MotaPas encore d'évaluation

- Business Logic Module 1Document5 pagesBusiness Logic Module 1Cassandra VenecarioPas encore d'évaluation

- Electric PotentialDocument26 pagesElectric PotentialGlitchPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Power-Miser 12 Water Heater ManualDocument32 pagesPower-Miser 12 Water Heater ManualClaudeVanDammPas encore d'évaluation

- Formula Renault20 Mod00Document68 pagesFormula Renault20 Mod00Scuderia MalatestaPas encore d'évaluation

- Sai Deepa Rock Drills: Unless Otherwise Specified ToleranceDocument1 pageSai Deepa Rock Drills: Unless Otherwise Specified ToleranceRavi BabaladiPas encore d'évaluation

- Zilog Z80-SIO Technical Manual TextDocument58 pagesZilog Z80-SIO Technical Manual Textprada.rizzoplcPas encore d'évaluation

- AnimDessin2 User Guide 01Document2 pagesAnimDessin2 User Guide 01rendermanuser100% (1)

- 3.15.E.V25 Pneumatic Control Valves DN125-150-EnDocument3 pages3.15.E.V25 Pneumatic Control Valves DN125-150-EnlesonspkPas encore d'évaluation

- Bio 104 Lab Manual 2010Document236 pagesBio 104 Lab Manual 2010Querrynithen100% (1)

- Planetary Yogas in Astrology: O.P.Verma, IndiaDocument7 pagesPlanetary Yogas in Astrology: O.P.Verma, IndiaSaptarishisAstrology50% (2)

- DJF 41032 Manufacturing Workshop Practice 3 Plastic Lab: Mini Project (Transfer Moulding)Document7 pagesDJF 41032 Manufacturing Workshop Practice 3 Plastic Lab: Mini Project (Transfer Moulding)Lokhman HakimPas encore d'évaluation

- Logarithms Functions: Background Information Subject: Grade Band: DurationDocument16 pagesLogarithms Functions: Background Information Subject: Grade Band: DurationJamaica PondaraPas encore d'évaluation

- RHB Islamic Bank BerhadDocument2 pagesRHB Islamic Bank BerhadVape Hut KlangPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Native Instruments Sibelius Sound Sets - The Sound Set ProjectDocument3 pagesNative Instruments Sibelius Sound Sets - The Sound Set ProjectNicolas P.Pas encore d'évaluation

- 09-11-2016 University Exam PaperDocument34 pages09-11-2016 University Exam PaperSirisha AsadiPas encore d'évaluation

- Tutorial: MSBA7003 Quantitative Analysis MethodsDocument29 pagesTutorial: MSBA7003 Quantitative Analysis MethodsAmanda WangPas encore d'évaluation

- Bug Life Cycle in Software TestingDocument2 pagesBug Life Cycle in Software TestingDhirajPas encore d'évaluation

- Lifecycle of A Butterfly Unit Lesson PlanDocument11 pagesLifecycle of A Butterfly Unit Lesson Planapi-645067057Pas encore d'évaluation

- S010T1Document1 pageS010T1DUCPas encore d'évaluation

- Hayek - Planning, Science, and Freedom (1941)Document5 pagesHayek - Planning, Science, and Freedom (1941)Robert Wenzel100% (1)

- Jazz PrepaidDocument4 pagesJazz PrepaidHoney BunnyPas encore d'évaluation

- Input and Output Statements PDFDocument11 pagesInput and Output Statements PDFRajendra BuchadePas encore d'évaluation

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchD'EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchÉvaluation : 4 sur 5 étoiles4/5 (10)