Académique Documents

Professionnel Documents

Culture Documents

ATT2578

Transféré par

Saptarshi SenguptaCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

ATT2578

Transféré par

Saptarshi SenguptaDroits d'auteur :

Formats disponibles

CERAM Alert Profile Update, Jan 2014

Refractories

AN: 237365 UP: 1401 TI: NEW ADDITIVE PACKAGE FOR SELF-FLOWING MICROSILICA GEL-BONDED MgO CASTABLES AU: Peng H; Nyhre B CS: Elkem Silicon Materials NA: 56th Int.Colloquium on Refractories. Refractories for Industrials SO: Aachen,25-26 September 2013,p.94-97 LA: English AB: Gel-bonded MgO castable, containing 4 wt% microsilica, was prepared using 2 wt% of a proprietary dispersant. For comparison, MgO castables were also prepared containing 6 wt% microsilica and 0.25 wt% conventional dispersants. The castables were characterised by measurements of flow and working time, and of cold crushing strength and cold modulus of rupture after firing to temperatures in the range 600-1500 C. Permanent linear change was measured as a function of pre-firing temperature, for temperatures in the range 600-1500 C. Hot modulus of rupture was measured at 1000-1500 C. Explosion resistance was determined by placing wet and dried specimens in a furnace at temperatures of 300-1000 C. It is concluded that the use of the proprietary dispersant enhanced the self-flow, hot strength and explosion resistance, whilst providing controllable setting characteristics. The bond system required less water than conventional castables, such that high firing rates could be used once free water was removed. 12 refs. AN: 237364 UP: 1401 TI: HIGH PERFORMANCE GUNNING MIX WITH ALUMINA PLASTICISER AU: Schmidtmeier D; Buhr A; Long B; Wang Z CS: Almatis GmbH; Qingdao Almatis Co.Ltd.; Wuhan,University of Science & Technology NA: 56th Int.Colloquium on Refractories. Refractories for Industrials SO: Aachen,25-26 September 2013,p.90-93 LA: English AB: Gunning mixes were prepared using different mixtures of tabular alumina, brown fused alumina, bauxite and plasticisers, with 10 wt% calcium aluminate cement. The plasticisers were either 5 wt% of a calcined alumina with high water retention, or a mixture of 3 wt% clay and 2 wt% silica fume. The firing shrinkage of the compositions prepared using the alumina plasticiser was reduced and the slag resistance increased compared with the compositions containing clay/silica fume. The tabular alumina-based mix with the calcined alumina plasticiser gave the best results for permanent linear change, hot modulus of rupture and slag corrosion resistance. This was attributed to the high chemical purity of the aggregate and matrix, which prevented the formation of low melting point silica-containing phases. Industrial gunning trials, subsequently fired to 1100 or 1550 C, confirmed the suitability of the calcined alumina plasticiser. 2 refs. AN: 237363 UP: 1401 TI: TEST METHODS FOR REFRACTORIES IN CONTACT TO GLASS MELTS RECOMMENDED BY TC11 OF THE ICG AU: Fleischmann B CS: Huttentechnische Verein.Deutschen Glasind. NA: 56th Int.Colloquium on Refractories. Refractories for Industrials SO: Aachen,25-26 September 2013,p.84-87 LA: English AB: The tests developed by Technical Committee 11 of the International Commission on Glass for determining the corrosion of refractories by molten glass are described.The corrosion due to laminar forced convection flow can be determined by rotating a cylindrical refractory specimen in the molten glass and measuring the loss in length. Corrosion associated with density induced convection as well as convection resulting from a difference in interfacial energy can be measured by immersing static plate specimens in molten glass. The advantages and disadvantages of the two tests are discussed. The dynamic blister test uses a refractory crucible containing molten glass as the specimen, and monitors the blistering rate of the refractory as a function of time. Observations are done in situ, over test periods in excess of 600 h, which realistically simulates glass tank conditions. The loss of glassy phase into the glass melt from fusion cast AZS can be determined using cuboid refractory specimens, the dimensions and mass of which are measured following immersion in the molten glass, such that the volume and mass loss is determined. 8 refs. AN: 237362 UP: 1401 TI: RESISTANCE TO CARBON MONOXIDE OF REFRACTORY MATERIALS: TOWARDS A RELIABLE TEST AU: Hocquet S; Mastroianni I; Tirlocq J; Lardot V; Cambier F CS: Centre Recherches Industrie Belge Ceramique NA: 56th Int.Colloquium on Refractories. Refractories for Industrials SO: Aachen,25-26 September 2013,p.80-83 LA: English

2014 CERAM Research Ltd

CERAM Alert Profile Update, Jan 2014

AB: Specimens were prepared using a refractory castable containing <0.025 wt% iron, to which was added 0.05-0.2 wt% Fe and Fe3O4. The specimens were dried and then heat treated in air at 540 C for 5 h. Resistance to carbon monoxide was measured by heating the samples at 540 C for 200 h in a carbon monoxide atmosphere. Carbon dioxide evolution was monitored, and the resistance was assessed visually and by SEM. The expansion of a specimen containing 0.05 wt% Fe in a carbon monoxide atmosphere at 540 C was also measured. The specimen containing 0.1 wt% Fe was severely cracked, whilst that containing 0.2 wt% totally disintegrated. CO2 evolution was detected before expansion was observed. It is proposed that carbon forms in the pores, which are filled before degradation commences. 7 refs. AN: 237361 UP: 1401 TI: REFRACTORY INDUSTRY SUFFERS FINANCIAL DAMAGES THROUGH IMPRECISE TEST PROCEDURES FOR THE DETERMINATION OF THE CO-RESISTANCE OF REFRACTORY MATERIALS - TIME TO REVISE ESTABLISHED TESTING METHODS: A PROPOSAL AU: Krause O; Urbanek G; Korber H CS: Koblenz,Fachhochschule; RHI AG; DIFK Deutsches Institut fur Feuerfest und Keramik GmbH NA: 56th Int.Colloquium on Refractories. Refractories for Industrials SO: Aachen,25-26 September 2013,p.76-79 LA: English AB: A round robin test involving 10 laboratories and six different monolithic refractories was used to evaluate ASTM C 704 and ISO 16282 standards for the measurement of the abrasion resistance of refractories. Ultrasonic testing was used to confirm the homogeneity of the specimens. Testing was done using a fixed air pressure of 450 kPa, and the abrasion resistance of a standard ASTM float glass specimen was measured prior to testing the refractories. Further testing was then done by adjusting the air pressure to achieve a float glass abrasion value of 9.3 cm3, and the refractories then re-tested using that air pressure. It is concluded that the test precision is significantly enhanced if the air pressure is adjusted to compensate for wear in the venturi system, by adjusting the air pressure to give a specified wear rate for a standard float glass specimen. 1 ref. AN: 237360 UP: 1401 TI: INVESTIGATION AND VERIFICATION OF THE ULTRASONIC AND RESONANT FREQUENCY MEASUREMENT METHODS FOR BURNED REFRACTORY PRODUCTS WITH ORIGINAL GEOMETRY AND AN APPLICATION EXAMPLE AU: Manhart C; Urbanek G; Stieblaichinger M CS: RHi AG; Leoben,Montan-Universitat NA: 56th Int.Colloquium on Refractories. Refractories for Industrials SO: Aachen,25-26 September 2013,p.72-75 LA: English AB: Resonant frequency measurement equipment was calibrated using precision acoustic calibrators, whilst ultrasonic pulse velocity measurement equipment was calibrated using an ultrasonic calibration block and reference fired refractory bricks with elastic moduli in the range 30-90 GPa. To study the influence of specimen dimensions on the measured values of elastic modulus, the width of these bricks was then progressively reduced and elastic moduli measured using both methods. The resonant frequency method was used to measure the change in elastic modulus of kiln batts as a function of the number of firing cycles. The elastic modulus and damping factor decreased with increasing number of cycles, attributed to alkali infiltration and to an increase in the size of the bridges between particles. 8 refs. AN: 237359 UP: 1401 TI: IMPORTANCE, ORGANISATION AND EVALUATION OF INTERLABORATORY TESTS AU: Urbanek G; Uhlig S CS: RHI AG; QuoData GmbH NA: 56th Int.Colloquium on Refractories. Refractories for Industrials SO: Aachen,25-26 September 2013,p.68-71 LA: English AB: The importance of inter-laboratory studies to compare and optimise test methods, to evaluate laboratory performance and to establish reference materials is discussed. Because the evaluation of inter-laboratory studies requires experience and detailed mathematical skills, it is proposed that such exercises are best done by specialist external companies using specialised software. Statistical models for the evaluation of laboratory results are discussed with reference to ISO 5725 for the estimation of measurement accuracy, and are illustrated with reference to results obtained for abrasion resistance, cold crushing strength, open porosity and bulk density of refractories. 6 refs. AN: 237358 UP: 1401 TI: DEVELOPMENT OF AIR-SETTING MORTARS HAVING GOOD BONDING STRENGTH AU: Goswami J; Satpathy S; Ganguli S; Samanta A K; Adak S; Chattopadhyay A K CS: TRL Krosaki Refractories Ltd. NA: 56th Int.Colloquium on Refractories. Refractories for Industrials

2014 CERAM Research Ltd

CERAM Alert Profile Update, Jan 2014

SO: Aachen,25-26 September 2013,p.61-64 LA: English AB: Refractory mortars (alumina content of approximately 60%) were prepared using bauxite, sillimanite sand, synthetic mullite, clay and bentonite. Sodium silicate (10-25% of the dry mortar weight) was added to make the mortar air setting. The joint stability, tap flow and tap flow index were measured according to ISO 13765. Dried specimens were fired at 1200-1600 C and characterised by measurements of bulk density, cold crushing strength, and drying and firing shrinkage. Crystalline phases in the fired specimens were determined by XRD, and pyrometric cone equivalents were also measured. Bond strength between brick and mortar, tap flow and tap flow index increased with increasing sodium silicate content. The cold crushing strength increased with increasing sodium silicate content, but decreased at higher concentrations and temperatures, attributed to the formation of a more glassy phase. The joint stability time decreased with increasing sodium silicate content. The drying shrinkage and the firing shrinkage up to 1500 C increased with increasing sodium silicate content. The reduced shrinkage at higher temperatures was attributed to the formation of more secondary mullite. 4 refs. AN: 237357 UP: 1401 TI: FORMATION OF CALCIUM SILICATES IN THE STIRRING AUTOCLAVE AS A FUNCTION OF DIFFERENT PROCESS CONDITIONS AU: Schickle B; Telle R; Tonnesen T; Opsommer A; Abdul-Kader O CS: Aachen,RWTH University; Promat Research & Technology Centre NV NA: 56th Int.Colloquium on Refractories. Refractories for Industrials SO: Aachen,25-26 September 2013,p.58-60 LA: English AB: Calcium silicate was prepared by adding slaked calcium oxide to silica in a stirred autoclave. The processing conditions were varied: time to maximum pressure 1 or 4 h; pressure, 1.9 or 2.3 MPa; time at maximum pressure, 2 or 4 h; and stirring speed 150 or 250 rpm. The prepared materials were characterised by XRD, microscopy, and measurements of specific surface area and grain size distribution. The product was mainly xonotlite with small amounts of tobermorite and residual quartz. 10 refs. AN: 237356 UP: 1401 TI: THERMAL-MECHANICAL REINFORCEMENT OF CHAMOTTE AND BAUXITE CASTABLES BY USING ANDALUSITE AU: Xiong X-Y; Shi G CS: Imerys Refractory Materials; Luoyang,Institute of Refractories Research NA: 56th Int.Colloquium on Refractories. Refractories for Industrials SO: Aachen,25-26 September 2013,p.55-57 LA: English AB: Four low-cement castables were prepared, based on: andalusite, andalusite-bauxite, andalusite-chamotte and bauxite. The open porosity, bulk density, cold crushing strength and modulus of rupture were measured using samples fired at 1500 C. Permanent linear change was measured at 1300 and 1500 C. Hot modulus of rupture was measured at 1000 and 1300 C, whilst creep was measured at 1300 C and thermal conductivity at 1000 C. Specimens were water quenched from 1100 C to determine thermal shock resistance. It is concluded that the addition of andalusite enhanced the thermomechanical properties of chamotte and bauxite castables. 2 refs. AN: 237340 UP: 1401 TI: RAW MATERIAL STRATEGY FOR SELF-SUFFICIENCY OF INDIA AU: Banerjee G; Tripathi H S CS: IFGL Refractories Ltd.; Central Glass & Ceramic Research Institute JN: Ceram.Forum Int./Ber.DKG SO: 90,No.11/12,2013,p.E32-E38 LA: English AB: Most of the refractory raw materials available in India are of low purity, and the Indian refractory industry is largely dependent on raw material imports. The status of refractory raw materials in India is described, highlighting some of the strategies required for self-sufficiency. The available raw materials include bauxite containing iron oxide and other impurities, aluminosilicates of varying quality but no high-alumina grades (sillimanite beach sand; zircon beach sand), and significant amounts of low quality magnesite. China is the major source of the most important refractory raw materials such as bauxite, fused magnesia, graphite and brown fused alumina. India's sillimanite beach sand can be used as a partial substitute for other high-alumina materials. 18 refs. AN: 237301 UP: 1401 TI: BOUNDARY CONDITIONS FOR CALCULATING THE REGENERATOR AND CHECKER BRICKWORK IN A GLASSMAKING FURNACE AU: Dzyuzer V Ya CS: Ekaterinburg,Ural Federal University

2014 CERAM Research Ltd

CERAM Alert Profile Update, Jan 2014

JN: Glass Ceram. SO: 70,No.7/8,2013,p.241-244 LA: English AB: An engineering method to calculate the temperature of the regenerator brickwork in a glassmaking furnace is proposed. Recommendations are made concerning the structure of the checkerwork of a single-turn regenerator in a furnace with a horseshoe flame. 2 refs. AN: 237258 UP: 1401 TI: INFLUENCE OF FUSED ZIRCONIUM CORUNDUM ADDITION ON PROPERTIES OF CHROME-FREE CASTABLES FOR RH REFINING FURNACE AU: Zhu X; Liang Y; Qiu W; Zhao W; Yue P; Nie J; Cui R CS: Wuhan,University of Science & Technology; Shanghai Baosteel Institute JN: Ceram.Int. SO: 40,No.1,Pt.A,2014,p.849-852 LA: English AB: Based on the operational conditions of a RH refining furnace, the influence of fused zirconium corundum (ZA or FZA) additive on the performance of corundum-spinel castables, including the cold modulus of rupture (CMOR), cold crushing strength (CCS), permanent linear change, thermal shock resistance and slag resistance was investigated. Corundum and spinel were the main raw materials of the samples with the addition of different amounts of micro-powders and a highly effective dispersant. The samples, after drying at 110 C for 24 h, were fired at 1000, 1400 and 1550 C for 3 h, respectively. The results showed that ZA addition improved the CMOR, CCS, thermal shock resistance and slag resistance of the castables. 3 refs. AN: 237235 UP: 1401 TI: HIGH-TEMPERATURE SHEAR STRENGTH AND BONDING MECHANISM OF THE MULLITE CERAMIC/FIBRE BRICK COMPONENT JOINED BY PHOSPHATE ADHESIVE AU: Hao R; Liu J; Dong X; Guo A; Hou Z; Wang M CS: Tianjin,University JN: Int.J.Appl.Ceram.Technol. SO: 10,No.6,2013,p.978-985 LA: English AB: A mullite ceramic/fibre brick system was bonded using two kinds of phosphate adhesives. The specimens were treated from 200 to 1400 C. The mechanical properties were tested at room and high temperature, and the relevant bonding mechanism is discussed. The results show that silicon addition can greatly improve the adhesive's mechanical properties. The room-temperature shear strength of the component bonded by silica fume-added adhesive and calcined at 800 C was 6.58 MPa. The high-temperature shear strength (800 C) of the silica fume-added adhesive was 0.42 MPa. 20 refs. AN: 237223 UP: 1401 TI: CHINESE STANDARDS ON REFRACTORIES. REFRACTORY PRODUCTS - DETERMINATION OF ABRASION RESISTANCE AT AMBIENT TEMPERATURE JN: China's Refract. SO: 22,No.3,2013,p.37-40 LA: English AB: Chinese standard GB/T 18301-2012 specifies the terms and definitions, theory, apparatus, specimens, experimental procedure, calculation of results, calibration of the apparatus and test reports of abrasion resistance at ambient temperature of refractory products. It is applicable to determine the abrasion resistance at ambient temperature of dense refractory products exposed to erosion and corrosion conditions. AN: 237222 UP: 1401 TI: CORROSION OF MAGNESIA-CHROME BRICK BY SMELTING REDUCTION SLAG WITH IRON BATH AU: Li J; Wang W; Gan F; Wu J CS: Sinosteel Luoyang Institute of Refractories Research Co.Ltd.; Baoshan Iron & Steel Co.Ltd. JN: China's Refract. SO: 22,No.3,2013,p.32-37 LA: English AB: The effects of FeO content (0, 5, 10 or 15 wt%) in lab-synthesised smelting reduction slag with iron bath and test temperature (1450, 1500, 1550 and 1600 C) on the corrosion resistance and microstructure of fused rebonded magnesia-chrome brick containing 26.02 wt% of Cr2O3 were analysed using the rotary cylinder method. The results show that: the corrosion of magnesia-chrome brick by slag without FeO is higher than that by slag with 5% FeO, increasing when the FeO content increases from 5% to 15%; the test temperature is one of the most important factors affecting the slag resistance of

2014 CERAM Research Ltd

CERAM Alert Profile Update, Jan 2014

magnesia-chrome brick, with corrosion increasing with rising temperature. 8 refs. AN: 237221 UP: 1401 TI: INFLUENCE OF ALPHA-Al2O3 MICROPOWDER ADDITION ON PROPERTIES OF CORUNDUM DRY RAMMING MIX AU: Zhang P; Li X; Zhu B CS: Wuhan,University of Science & Technology JN: China's Refract. SO: 22,No.3,2013,p.28-31 LA: English AB: In order to improve the service life of corundum linings for induction furnaces, a corundum dry ramming mix was prepared using brown corundum, fused magnesia, and alpha-Al2O3 micropowder as the main starting materials, and the influence of alpha-Al2O3 micropowder additions (0, 1, 2 or 3 wt%) on the properties of the ramming mix was investigated. The results show that, after heat treating at 1600 C, with increasing alpha-Al2O3 addition, the permanent change in dimensions on heating of the specimens first decreases and then increases, the bulk density increases, the apparent porosity decreases and the crushing strength first declines and then increases; when the addition of alpha-Al2O3 is 2 wt%, the permanent change in dimensions on heating of the specimens is relatively small and the strength decreases to 22.8 MPa. XRD and SEM results show that, after firing at 1600 C for 3 h, small granular magnesium aluminate spinel forms and is well distributed, which enhances the density. 10 refs. AN: 237220 UP: 1401 TI: EFFECT OF ALUMINA MICROPOWDERS ON PROPERTIES OF CALCIUM HEXALUMINATE AU: Liu X; Liu K; Xie X; Liu Y; Luo Z CS: Beijing,China Iron & Steel Research Institute Group JN: China's Refract. SO: 22,No.3,2013,p.23-27 LA: English AB: Calcium hexaluminate (CA6) was synthesised by mixing lightweight CaCO3 and Al2O3 micropowder (calcined alpha-Al2O3, activated alpha-Al2O3 or rho-Al2O3) according to the stoichiometric ratio of CA6, and reaction sintering at 1200, 1300, 1400 and 1500 C for 3 h, respectively. The effect of the three alumina micropowders on the phase composition, microstructure and properties of CA6 were investigated. The results show that: for the three Al2O3 micropowders, the reaction to generate CA6 in specimens is completed at about 1500 C; CA6 generated in all specimens is planar, but the array modes are slightly different; the specimens prepared from calcined alpha-Al2O3 or rho-Al2O3 shrink, while those prepared from activated alpha-Al2O3 expand; the cold crushing strength of the specimen prepared from activated alpha-Al2O3 is the highest, reaching 42.5 MPa when only CA6 exists (after firing at 1500 C); the specimen prepared from rho-Al2O3 has the lowest generation temperature of CA6 and the highest apparent porosity, reaching 70.1% when only CA6 exists (after firing at 1500 C); the specimen prepared from calcined alpha-Al2O3 has the highest bulk density. 8 refs. AN: 237219 UP: 1401 TI: EFFECT OF Al SOURCE AND STARTING MATERIALS ADDITIONS ON SYNTHESIS OF Al8B4C7 AU: Cui P; Deng C; Zhu H; Yuan W CS: Wuhan,University of Science & Technology JN: China's Refract. SO: 22,No.3,2013,p.18-22 LA: English AB: Al8B4C7 is a promising antioxidant for carbon-containing refractories. Hexagon plate-like Al8B4C7 powders were successfully synthesised using a mixture of B2O3, activated carbon and aluminium or alumina by a carbothermal reduction process. The effect of Al source and starting material additions on Al8B4C7 synthesis was investigated. The phase composition and microstructure of Al8B4C7 powder were characterised by XRD, SEM and EDS. The main phase compositions of the products synthesised from Al, B2O3 and activated carbon are Al8B4C7 and Al2OC. Al2O3 can replace Al to synthesise Al8B4C7. Al8B4C7 grains synthesised from Al2O3, B2O3 and activated carbon are hexagon plate-like, and have a thickness of 10 micron and a size of about 100 micron. 17 refs. AN: 237218 UP: 1401 TI: TECHNICAL QUESTIONS IN CASTABLES INNOVATION FOR MAIN IRON TROUGH IN LARGE-SCALED BLAST FURNACES OF WISCO AU: Xyu G; Wang Y; Zhou W CS: Wuhan Iron & Steel Co. JN: China's Refract. SO: 22,No.3,2013,p.12-17 LA: English

2014 CERAM Research Ltd

CERAM Alert Profile Update, Jan 2014

AB: Technological developments in the castable refractories used to line the main iron troughs of large blast furnaces at WISCO over the past 10 years are outlined. Low-cement, sol-bonded and SiAlON-bonded products have been mainly used. In 2001, dense corundum was used as the main aggregate raw material, while sub-white fused corundum was partly used. Brown fused corundum or bauxite are now mainly used as aggregates, together with an increasingly finer matrix and higher SiC content. The strength, wear resistance, erosion resistance and hot MOR of these new castables are much higher than those of the former ones (although these meet YB/T 4126-2005 requirements). The morphologies of the old and new materials before and after use are shown and discussed. The service life of the castables has increased from 90000 tons to 140000-180000 tons thanks to improvements made to the matrix. The use of prefabricated castable blocks for the iron trough is outlined. The factors affecting castable performance and service life are considered. 5 refs. AN: 237217 UP: 1401 TI: REFRACTORIES WITH IMPROVED THERMAL SHOCK PERFORMANCE SERVING LOW CARBON ECONOMY AU: Aneziris C G; Roungos V; Dudczig S; Emmel M CS: Freiberg,TU Bergakademie JN: China's Refract. SO: 22,No.3,2013,p.7-11 LA: English AB: Nanoengineered carbon-bonded refractories as well as fine-grained carbon-free refractories with improved thermal shock resistance, suitable for steelmaking applications, are described. They include carbon-bonded bulk refractories and carbon-bonded nanoengineered filter materials with nanoscaled additions of commercial spinel, Chinese carbon nanotubes and alumina nanosheets, as well as a thermal shock resistant carbon-free fine-grained low porous alumina ceramic with TiO2 and ZrO2 additions. Brief details are given of the raw materials, formulations, preparation and properties. 5 refs. AN: 237216 UP: 1401 TI: CURRENT SITUATION AND DEVELOPMENT OF REFRACTORIES FOR CLEAN STEEL PRODUCTION AU: Li H; Liu G CS: Sinosteel Luoyang Institute of Refractories Research Co.Ltd. JN: China's Refract. SO: 22,No.3,2013,p.1-6 LA: English AB: Much attention has focused on low-cost, highly efficient, clean steelmaking in China. The refractories used are a key factor affecting the cleanliness and consequent quality of steel products. Increasing resource, energy and environmental restrictions makes it more important to improve refractory products. The principles involved in selecting suitable refractories for clean steelmaking according to their thermodynamic aspects are explained. Refractories for tundish and flow control in continuous casting, which play an important role in preventing secondary contamination of molten steel, are introduced. The development of low-carbon and carbon-free refractories is also described. 10 refs. AN: 237211 UP: 1401 TI: REFRACTORY RAW MATERIALS SUPPLY - IS THERE CAUSE FOR CONCERN? AU: Roberts J; Saxby A; Shaw S CS: Roskill Information Services Ltd. NA: 56th Int.Colloquium on Refractories. Refractories for Industrials SO: Aachen,25-26 September 2013,p.52-54 LA: English AB: The world consumption of alumina, bauxite, graphite and magnesia is tabulated, along with the proportion used by the refractories industry. This report discusses the production and consumption of these minerals in China. The Chinese refractories industry consumed 28.2 million tonnes (Mt) of raw materials in 2012, whilst exporting just over 2 Mt of product. China is the leading producer of refractory grade alumina, bauxite, graphite and magnesia, and the government policy has been to restrict raw materials exports and to favour the export of finished product. The consolidation of mineral resources, increasing environmental concern and emphasis on health and safety has reduced the number of Chinese producers of bauxite, magnesia and graphite. Possible supply difficulties and increasing prices have resulted in the development of material deposits elsewhere in the world, particularly for calcined bauxite, for which 85% of production is controlled by China. It is estimated that by 2017 refractories production will consume 1.78 Mt calcined alumina, 3.25 Mt bauxite, 575000 t natural graphite and 10.7 Mt magnesia. Considering the projected increase in refractory materials demand and the development of new raw material sources, it is concluded that refractory producers need not be concerned about raw materials supply. 3 refs. AN: 237210 UP: 1401 TI: DEVELOPMENT OF NEW, LIGHTWEIGHT STRUCTURES AS KILN FURNITURE AU: Scheithauer U; Haderk K; Moritz T; Zins M; Michaelis A CS: Fraunhofer-Institut fur Keram.Technol.und Systeme

2014 CERAM Research Ltd

CERAM Alert Profile Update, Jan 2014

NA: 56th Int.Colloquium on Refractories. Refractories for Industrials SO: Aachen,25-26 September 2013,p.45-48 LA: English AB: The development of kiln furniture with high stiffness and good thermal shock resistance, combined with low density and low heat, is described. The furniture consists of two sheets of refractory separated by a distance of approximately 10 mm and connected to each other by a series of struts. The furniture is fabricated using cast tape - alumina for dense systems, and a mixture of calcium aluminate and alumina for porous systems. The required shapes are obtained by wrapping the tape round formers, and they are joined using a lamination process developed in the paper industry. Finite element modelling was used to predict the deformation under load. Laboratory kiln firing trials show that the energy required to fire a kiln using this kiln furniture is significantly lower than that required when using conventional, solid kiln furniture. 12 refs. AN: 237209 UP: 1401 TI: NEW KILN ROOF DESIGN FOR FASTER TEMPERATURE CHANGES AND REDUCED THERMAL ROOF LOSSES AU: Hunlich A; Appel F CS: Lingl H.,Anlagenbau und Verfahrenstechnik GmbH & Co.KG NA: 56th Int.Colloquium on Refractories. Refractories for Industrials SO: Aachen,25-26 September 2013,p.42-44 LA: English AB: The arched roof in the high temperature zone of current tunnel kilns firing refractories creates a space which cannot be readily filled by product, leads to increased exhaust gas losses and poor temperature distribution. Expansion and contraction when the kiln temperature changes can result in damage and premature failure. Flat roofs can also have problems, including leaking expansion joints, temperature limitations due to the use of metallic anchors, heat loss due to thermal bridging, and the need for some designs to be actively cooled. An alternative design is proposed, with a low rise arch, the intrados of which is almost flat. This accommodates rapid temperature change and the absence of thermal bridging points reduces thermal loss. Horizontal loading on the arch is maintained by springs at the abutment. 3 refs. AN: 237208 UP: 1401 TI: PULSATING COLD-ISOSTATIC PRESSING - NEW EXTENDED POSSIBILITIES AU: Ludwig S; Roungos V; Aneziris C G CS: Freiberg,TU Bergakademie NA: 56th Int.Colloquium on Refractories. Refractories for Industrials SO: Aachen,25-26 September 2013,p.39-41 LA: English AB: Alumina-graphite refractories were prepared by mixing fused alumina, tabular alumina, fine graphite, coarse graphite, silicon, silica and novolak resin. The moisture contents were varied, and compositions were produced with and without an addition of borax. Specimens were prepared by isostatic pressing using three pressing cycles: linearly increasing pressure up to 100 MPa, followed by a short holding time and slow decompression; linearly increasing pressure up to 100 MPa, then modulating the pressure between 55 and 100 MPa for several cycles followed by decompression; and continually modulating the pressure as it was increased to a maximum of 100 MPa with a short holding time prior to decompression. The specimens were cured at 180 C and coked at 1400 C for 5 h. The different pressing cycles generated different pore size distributions in the green bodies. However, the pore size distributions after coking were similar. 5 refs. AN: 237207 UP: 1401 TI: SIMPLE AND COST-EFFECTIVE PROCESS FOR PRODUCING COMPRESSIBLE GRANULES AU: Lobe R CS: Maschinenfabrik Gustav Eirich GmbH & Co.KG NA: 56th Int.Colloquium on Refractories. Refractories for Industrials SO: Aachen,25-26 September 2013,p.36-38 LA: English AB: Processing equipment for the preparation of granular material from powder is described. Granules of 0.4-5 mm can be produced using a high intensity mixer consisting of an inclined rotating pan which contains a high speed rotor. Oversized granules can be eliminated by feeding them into a sizing machine, where the material passes through an adjustable cone-shaped gap and is reduced in size. It is possible to produce product which matches the grain size and flow characteristics of spray dried material, whilst requiring less energy, water and additives. AN: 237206 UP: 1401 TI: STUDIES ON FLOW BEHAVIOUR OF LOW CEMENT CASTABLES IN PRESENCE OF DIFFERENT REACTIVE ALUMINA AND MICROSILICA AU: Samanta A K; Satpathy S; Adak S; Chattopadhyay A K CS: TRL Krosaki Refractories Ltd.

2014 CERAM Research Ltd

CERAM Alert Profile Update, Jan 2014

NA: 56th Int.Colloquium on Refractories. Refractories for Industrials SO: Aachen,25-26 September 2013,p.29-33 LA: English AB: Low cement alumina castables were prepared using bauxite, chamotte, ground fused alumina, sillimanite, microsilica, calcium aluminate cement and four different grades of reactive alumina. Flow was measured as a function of time. Specimens were fired to temperatures of 800-1500 C and characterised by measurements of cold crushing strength, cold modulus of rupture, bulk density, apparent porosity and permanent linear change. Specimens fired to 1100-1500 C were characterised by XRD. Differences in flow characteristics were attributed to differences in the specific surface area and particle size distribution of the different reactive aluminas. It is concluded that high specific area and bimodal or multimodal particle size distributions give castables of enhanced flow characteristics and that the use of calcined or reactive alumina results in mullite and other phase formation at relatively low temperatures. 4 refs. AN: 237205 UP: 1401 TI: NEW DESIGN CONCEPTS FOR HYDRAULICALLY BONDED CASTABLES USED IN THE ALUMINIUM INDUSTRY AU: Pawlig O; Parr C; Wohrmeyer C; Szepizdyn M; Zetterstrom C; Amghar I; Wuthnow H CS: Kerneos SA; DIFK Deutsches Institut fur Feuerfest und Keramik GmbH NA: 56th Int.Colloquium on Refractories. Refractories for Industrials SO: Aachen,25-26 September 2013,p.25-28 LA: English AB: Microstructural changes of a bauxite-based castable, achieved by replacing the calcium aluminate cement with calcium magnesium aluminate cement, were studied as a means of reducing aluminium penetration. Castables were prepared using bauxite, reactive alumina and spinel, with either 6% calcium aluminate cement or 18% calcium magnesium aluminate cement. Some compositions also contained 5% barium sulphate. Crucible testing at 950 C showed that the presence of barium sulphate reduced corrosion and infiltration by aluminium alloy, and further slight improvements were achieved when the calcium aluminate cement was substituted by calcium magnesium aluminate cement in barium sulphate-containing castable. Similar behaviour was observed when the testing was performed with an aluminium alloy-cryolite mixture containing 20 wt% cryolite. 13 refs. AN: 237204 UP: 1401 TI: DEVELOPMENT OF REFRACTORY CASTABLES FORMULATIONS THROUGH THE MODELLING OF SLURRIES BEHAVIOUR: A MULTI-SCALE APPROACH AU: Traianidis M; Vandeneede V; Tirlocq J; Lardot V; Cambier F CS: Centre Recherches Industrie Belge Ceramique NA: 56th Int.Colloquium on Refractories. Refractories for Industrials SO: Aachen,25-26 September 2013,p.21-24 LA: English AB: Alumina castables were developed by considering the influence of the particle sizes of the constituent materials on the rheology. Calcium aluminate cement binder was used in conjunction with four grades of fine material, including reactive alumina, calcined alumina and tabular alumina as fillers, along with three grades of tabular alumina as aggregate. Citric acid deflocculant and a superplasticiser were also added. The shear viscosity of aqueous suspensions of different grain size distributions was determined as a function of solids concentration and the results compared with model predictions. It is concluded that multiscale models are applicable to alumina suspensions and castables. When studying suspension rheology, the cement can be substituted by an equivalent alumina powder, and so avoid the complications introduced by hydration reactions. 7 refs. AN: 237203 UP: 1401 TI: MIXING OPTIMISATION OF AN ALUMINA-BASED LC-CASTABLE BY APPLYING VARIABLE POWER INPUTS AU: Kasper J; Krause O CS: Hohr-Grenzhausen,Coblenz University of Applied Sciences NA: 56th Int.Colloquium on Refractories. Refractories for Industrials SO: Aachen,25-26 September 2013,p.18-20 LA: English AB: Alumina self-flowing castables containing 5 wt% calcium aluminate cement, tabular alumina and reactive alumina and with polycarboxylate ether as the dispersing agent were prepared using an intensive mixer. Three mixing speeds were used and the power input to the mixer was measured during mixing. The rheological properties of the prepared castables were measured using a rotational rheometer with a spherical paddle, the setting and hardening characteristics were determined by sonic velocity measurements, and the dry cold crushing strength was measured. It is concluded that the end of the mixing process coincides with a levelling of the power consumption. The viscosity can be halved by increasing the mixing time or the mixing speed. The castables were shear thinning at low shear rates and shear thickening at higher shear rates. The setting kinetics were dependent upon the mixing temperature, whilst the cold crushing strength increased with increasing mixing speed, but was not influenced by the mixing time. 8 refs.

2014 CERAM Research Ltd

CERAM Alert Profile Update, Jan 2014

AN: 237202 UP: 1401 TI: CASTABLES FOR INDUSTRIAL APPLICATIONS - STILL ROOM FOR IMPROVEMENT! AU: Schnabel M; Buhr A; Kockegey-Lorenz R; Schmidtmeier D; Dutton J CS: Almatis GmbH NA: 56th Int.Colloquium on Refractories. Refractories for Industrials SO: Aachen,25-26 September 2013,p.13-17 LA: English AB: The role of matrix alumina in castables used at intermediate temperatures is reviewed, and methods of improving the performance of low cement castables are described. The strength and abrasion resistance, at both room temperature and at intermediate temperatures, can be significantly increased by increasing the particle packing density and the adhesion of the ultrafine particles. The cold crushing strength after pre-firing at 800 C is shown to increase by 55% when calcined alumina is replaced by reactive alumina. The replacement of calcined alumina by reactive alumina in a low cement castable containing silica fume also reduces the water demand, the fast wetting minimises the risk of adding too much water at the mixing stage, and permits the use of low energy mixers. The use of dispersing aluminas instead of conventional dispersing agents can reduce the water demand, enhance dispersion and control of the working time and increase the shelf life. 7 refs. AN: 237183 UP: 1401 TI: HOW TO FUTURE-PROOF MAGNESIA-CARBON REFRACTORY PRODUCTION AU: Hughes E JN: Ind.Miner. SO: No.553,2013,p.23 LA: English AB: A slump in end-user markets and continued strong competition from China has caused many western refractory producers to initiate a series of strategic measures in a bid to make "future-proof" refractory products. RHI's production of magnesia-carbon bricks has focused on backward integration of raw material supply, environmental impact, performance, and providing special product solutions. Examples of this include the takeover of Premier Periclase in Ireland, the construction of a new magnesia fusion plant in Norway and increased capacity in Turkey for natural, high-grade, sintered magnesia. RHI is also processing recycled material in order to maximise the proportion of secondary magnesia available. Major steps have been taken towards achieving strong carbon bonding without the need for metallic additives. AN: 237137 UP: 1401 TI: SLAG RESISTANCE OF Al2O3-MgO REFRACTORY CASTABLES IN DIFFERENT ENVIRONMENTAL CONDITIONS AU: Sako E Y; Braulio M A L; Luz A P; Zinngrebe E; Pandolfelli V C CS: Sao Carlos,Federal University; Tata Steel Europe JN: J.Am.Ceram.Soc. SO: 96,No.10,2013,p.3252-3257 LA: English AB: Although the corrosion performance of spinel-containing castables has been extensively investigated in recent years, no previous studies assessed the different conditions present in the ladle bottom, where strong variations in the atmospheric environment are often detected, which could drastically change the interactions between refractory and molten slag. Therefore, the main corrosion mechanisms of an alumina-magnesia castable in two environmental conditions (oxidising - pO2 = 0.21 atm or reducing - pO2 = 10-15 atm atmosphere) were evaluated using SEM and EDS analyses of the corroded samples and thermodynamic simulations. The results showed that the slag penetration was suppressed in the presence of oxygen due to the precipitation of a great amount of calcium monoaluminate (CA) crystals as the refractory interacted with the slag. Conversely, the CA phase was not stable under reducing conditions and as a result many more refractory components (Al2O3, MgO, and MgAl2O4) had to be dissolved to precipitate calcium dialuminate (CA2) by reacting with the infiltrating slag. Besides providing a suitable and more realistic understanding of the castable performance in service conditions, the results also indicated that the prediction of the environmental conditions is of utmost importance for the design of high performance refractories. 24 refs. AN: 237110 UP: 1401 TI: MICROSTRUCTURE AND STRENGTH OF NEEDLE COKE MODIFIED CERAMIC CASTING MOULDS AU: Wang F; Li F; He B; Sun B CS: Shanghai,Jiao Tong University JN: Ceram.Int. SO: 40,No.1,Pt.A,2014,p.479-486 LA: English AB: The properties of investment casting moulds containing needle coke additions were investigated. The use of needle coke increased the mould thickness by a factor of 30% on the flat section and 60% at the sharp edges over that of a comparable fully fused silica system. The extra mould thickness of the needle coke modified system, especially at the edges, gave a higher load bearing capacity. Ceramic moulds modified with needle coke had a higher green dry strength, and show less reduction in the

2014 CERAM Research Ltd

CERAM Alert Profile Update, Jan 2014

green wet strength. The extra cavities left after needle coke combustion did not act as defects which would have reduced the hot strength of the moulds. 21 refs. AN: 237610 UP: 1402 TI: IMPULSE EXCITATION MEASUREMENT UP TO 1600 C - AN ADVANCED ANALYSIS TECHNIQUE FOR REFRACTORIES AU: Werner J; Aneziris C G; Schaffoner S; Fruhstorfer J; Oppelt M; Dudczig S CS: Freiberg,TU Bergakademie NA: 56th Int.Colloquium on Refractories. Refractories for Industrials SO: Aachen,25-26 September 2013,p.138-140 LA: English AB: Three refractory materials were studied: resin-bonded alumina containing 20% graphite; cement-free alumina castable; and reaction-bonded fused calcium zirconate. Specimens were subjected to impulse excitation and the resulting vibrations analysed by fast Fourier transformation. Measurements were made at room temperature and during heating to temperatures in the range 1450-1600 C. The resin-bonded alumina exhibited a large increase in Young's modulus during heating, whilst the Young's modulus of the alumina castable decreased with increasing temperature up to 1000 C, attributed to dehydration of the hydraulic alumina phase. It also showed a large increase in Young's modulus during cooling to 700 C. Studies of the calcium zirconate refractory detected binder decomposition at temperatures up to 400 C, a reduction in Young's modulus at temperatures above 700 C, attributed to reaction between CaO and ZrO2, and also the onset of sintering at 1050 C. 20 refs. AN: 237609 UP: 1402 TI: POTENTIAL OF ULTRASOUND BASED METHODS FOR MONITORING THE SETTING OF REFRACTORY CASTABLES AU: Flament P; Abdelouhab S; Lardot V; Cambier F; Pierre C; Vanhamme G CS: Centre Recherches Industrie Belge Ceramique; Centre de Recherche de l'Industrie Cimentiere NA: 56th Int.Colloquium on Refractories. Refractories for Industrials SO: Aachen,25-26 September 2013,p.134-137 LA: English AB: The curing of calcium aluminate cement-bonded castable, as well as low-cement, ultra-low and zero cement castables was monitored by measurements of ultrasonic compression and shear wave velocities, from which were calculated the Poisson's ratio, elastic modulus and shear modulus. Exothermic reactions were monitored during curing by an embedded thermocouple. Flow and cold crushing strength were also measured. There was good correlation between the sonic velocity measurements and the development of mechanical properties. It is concluded that this technique can be used to monitor the curing of all castable types, including those containing no cement. 6 refs. AN: 237608 UP: 1402 TI: RECENT LINING CONCEPTS FOR THERMAL TREATMENT OF HAZARDOUS WASTES AU: Schweez D; Sperber J; Burgard R CS: Steuler-KCH GmbH NA: 56th Int.Colloquium on Refractories. Refractories for Industrials SO: Aachen,25-26 September 2013,p.127-130 LA: English AB: The refractories used in the different zones of rotary furnaces used for the thermal treatment of hazardous wastes are described. The inlet zone is required to withstand the thermal stresses created by feedstock loading, as well as impact and abrasion. Phosphate-bonded andalusite brick has been successfully used in this zone. Fused corundum bricks containing Cr2O3 and ZrO2 are used in the combustion zone where highly reactive slags are formed. Refractory brick with a lower Cr2O3 content may be used in the outlet zone where the slag is less reactive. Typical brick compositions and properties are tabulated. 4 refs. AN: 237607 UP: 1402 TI: INTERACTION OF NEW ALUMINA-TITANIA-REFRACTORIES WITH COAL AND GASIFIER SLAGS AU: Gehre P; Aneziris C G; Klinger M; Schreiner M; Neuroth M CS: Freiberg,TU Bergakademie; RWE Power AG NA: 56th Int.Colloquium on Refractories. Refractories for Industrials SO: Aachen,25-26 September 2013,p.122-126 LA: English AB: Self-flowing alumina castables containing 0.0-5.0% titania were prepared using tabular alumina, reactive alumina and hydratable alumina, and specimens fired at 1650 C. The castables were characterised by measurements of open porosity, modulus of rupture at room temperature and 1400 C, and thermal shock resistance. Slag resistance was measured by cup testing with acidic coal slag and evaluated by hot stage microscopy in an argon atmosphere containing 5 vol% hydrogen. The castables containing 2.5 wt% TiO2 exhibited high strength and outstanding thermal shock resistance, attributed to the reinforcement of the microstructure by needle-shaped NaTi2Al5O12, formed by the reaction with Na2O impurities. The strength

2014 CERAM Research Ltd

10

CERAM Alert Profile Update, Jan 2014

of the castable containing 5.0% TiO2 was very low, attributed to needles growing between the alumina grains and expanding the microstructure. The addition of a low concentration of titania to the alumina refractory prevented slag penetration and crack formation. 11 refs. AN: 237606 UP: 1402 TI: MULTI-STEP MODELLING OF SLAG INDUCED CORROSION OF REFRACTORIES AU: Reinmoller M; Klinger M; Schreiner M; Meyer B CS: Freiberg,TU Bergakademie NA: 56th Int.Colloquium on Refractories. Refractories for Industrials SO: Aachen,25-26 September 2013,p.117-121 LA: English AB: The corrosion of refractories by the liquid slag formed in solid fuel gasifiers was studied using thermochemical modelling software and experimentally. Three ashes were used: acidic, intermediate and basic. The refractories tested were two spinel-based materials, a calcium aluminate, and a commercial Cr2O3-ZrO2-Al2O3. Reaction between the refractories and the ash was measured at 1450 C in an argon atmosphere containing 5 vol% hydrogen. Three-step and multi-step thermochemical models were used to calculate the liquid slag phases and to study the chemical reactions taking place between the slag and the refractory. 9 refs. AN: 237605 UP: 1402 TI: REFRACTORY CORROSION MECHANISMS IN BIOMASS GASIFICATION AND INCINERATION PROCESSES AU: Tonnesen T; Simon R; Telle R CS: Aachen,RWTH University NA: 56th Int.Colloquium on Refractories. Refractories for Industrials SO: Aachen,25-26 September 2013,p.112-116 LA: English AB: The corrosion of calcium aluminate cement in low-cement refractory castables lining biomass gasification plant and incinerators was studied using crucible specimens which had been prefired at 1500 C. Two refractory compositions were studied: alumina-rich, and andalusite-containing material with enhanced silica content. The test were performed at 1300 C using different corrosive mixtures: potassium carbonate; a mixture of potassium carbonate, potassium phosphate and potassium metaphosphate (melt and vapour); and potassium sulphate (melt and vapour). It is concluded that slag reactions were controlled by calcium aluminosilicate melt formation. Beta-alumina was formed in high alumina castables in alkali-rich environments. Melt formation and precipitation of alkali- and phosphate-rich calcium aluminates were also studied. 3 refs. AN: 237604 UP: 1402 TI: REFRACTORY MATERIALS IN GLASS MELTING FURNACES FIRED WITH BIOGAS AU: Wuthnow H; Dannert C CS: Forschungsgemeinschaft Feuerfest eV NA: 56th Int.Colloquium on Refractories. Refractories for Industrials SO: Aachen,25-26 September 2013,p.108-111 LA: English AB: A mobile furnace was constructed using silica, mullite, magnesia-zircon and AZS refractories, with silica and magnesia mortars. It was fired using biogas (50-52% methane, 48% CO2) obtained by the fermentation of maize, reaching temperatures of 1500-1530 C in the firing zone and 300 C in the exhaust gas channel. Attack of the refractories was studied, and the materials compared with the unused refractory, and with specimens taken from a natural gas-fired glass melting tank. The surfaces of the refractories containing a glassy silicate phase were the most affected. It is concluded that glass melting tanks could be converted from natural gas to crude biogas firing without adversely affecting the lifetime of the refractories. 5 refs. AN: 237603 UP: 1402 TI: HIGH PERFORMANCE REFRACTORY LININGS FOR TiO2 CHLORINATORS AU: Mevec G; Fuchs S; Owens R CS: Rath AG; Rath Refractories Inc. NA: 56th Int.Colloquium on Refractories. Refractories for Industrials SO: Aachen,25-26 September 2013,p.103-104 LA: English AB: The development of a refractory fireclay brick for the fluidised bed reactors used to produce titania pigment is described. The process involves the reaction of a rutile/carbon mixture with chlorine at 700-1200 C. Two mullite raw materials were identified, one of which gives a brick with a porosity of 0.5% and requires a firing temperature of < 1600 C. This product was developed for large, continuously operated reactors. Bricks produced using the other material are fired at temperatures <1550 C and are of higher porosity. They are suitable for smaller reactors with more process flexibility. The bricks are classified as grade A for carbon monoxide resistance, and they exhibit only a slight weight loss of 1.5-2.5% after 24 months' service. The high

2014 CERAM Research Ltd

11

CERAM Alert Profile Update, Jan 2014

performance is attributed to a mullite:cristobalite:glassy phase ratio of 75:10:15, and to the high silica content of the glassy phase. 4 refs. AN: 237602 UP: 1402 TI: MODELLING THE FIRST HEAT-UP OF REFRACTORY CONCRETE AU: Fey K-G; Riehl I; Gross U; Wulf R CS: Freiberg,TU Bergakademie NA: 56th Int.Colloquium on Refractories. Refractories for Industrials SO: Aachen,25-26 September 2013,p.99-102 LA: English AB: A model was developed for the heat and mass transfer which occurs in a refractory concrete lining of a furnace during the first firing of the furnace. It is assumed that the concrete is homogeneous and that there is a thermal equilibrium between the gas, liquid and solid phases. Equations are given for the mass balances of liquid water, vapour, and air, for energy conservation, and for the transport of gases and liquid water. The model was used to predict the behaviour of a furnace wall consisting of three layers of different materials and subjected to two different heating cycles. The maximum pressure developed in the concrete and its location were determined as a function of time. 4 refs. AN: 237601 UP: 1402 TI: MODELLING FOR PORE PRESSURE PREDICTION DURING THE FIRST DRYING OF REFRACTORY CASTABLES - A SHORT REVIEW AU: Valentin O; Meunier P; Nazaret F; Lemaistre H; Cutard T CS: Aurock; Calderys France; Ecole des Mines d'Albi NA: 56th Int.Colloquium on Refractories. Refractories for Industrials SO: Aachen,25-26 September 2013,p.98 LA: English AB: References for thermohygromechanical models for the initial stages of drying of refractory castables are given. They relate heat transfer, mass transfer and temperature-dependent mechanical properties. They include considerations of spalling. Model complexity makes them difficult to relate to an industrial environment. 6 refs. AN: 237550 UP: 1402 TI: DEGRADATION MECHANISMS AND USE OF REFRACTORY LININGS IN COPPER PRODUCTION PROCESSES: A CRITICAL REVIEW AU: Malfliet A; Lotfian S; Scheunis L; Petkov V; Pandelaers L; Jones P T; Blanpain B CS: Leuven,Catholic University JN: J.Eur.Ceram.Soc. SO: 34,No.3,2014,p.849-876 LA: English AB: The use and degradation of refractory linings in copper furnaces are discussed, thereby describing the main steps taken at the research, development and industrial level to minimise refractory wear. Which combination of chemical, thermal and mechanical degradation mechanisms is dominant depends on many factors including the furnace type, the lining design, refractory type and the processing conditions. Magnesia-chrome bricks are widely used to line copper furnaces, despite the potential risk of forming hexavalent Cr under specific conditions, typically in the presence of alkali or alkaline earth oxides. To understand and predict refractory degradation, both post-mortem investigations and lab scale tests were considered to be helpful tools, supported by phase diagrams and thermodynamic and kinetic calculations. This review concludes with refractory selection and use on an industrial level, including the waste and recycling management of spent refractories. 80 refs. AN: 237531 UP: 1402 TI: EFFECT OF OXIDATION ON EROSION OF CASTABLE FOR BLAST FURNACE AU: Nakabo K; Yasuo K; Iida T; Kitamura M; Saito K CS: Shinagawa Refractories Co.Ltd. JN: Refractories (Tokyo) SO: 65,No.3,2013,p.139 LA: Japanese AB: The wear behaviour of SiC-Al2O3 castable samples used to line a blast furnace was studied. The composition of the sample mixtures, which contained varying amounts of carbon black, is shown. The wear rate is plotted against carbon black addition for samples prefired with arc, non-fired with arc or non-fired with oxygen-propane. The maximum wear rate of two of the castable samples after use in the slag zone of an actual furnace is shown. AN: 237530 UP: 1402

2014 CERAM Research Ltd

12

CERAM Alert Profile Update, Jan 2014

TI: INFLUENCE OF B4C ON THE HOT STRENGTH OF SiC CONTAINING CASTABLE AU: Morimoto Y; Kitamura M; Saito K CS: Shinagawa Refractories Co.Ltd. JN: Refractories (Tokyo) SO: 65,No.3,2013,p.138 LA: Japanese AB: The hot MOR of SiC-based castables with/without 9 wt% calcined alumina and varying amounts of B4C (0, 0.2, 0.6, 1.5 wt%) was studied. The hot MOR was measured at 1400 C. The results are tabulated and the relationship between B4C content and hot MOR is plotted. AN: 237529 UP: 1402 TI: WEAR PROPERTIES OF SiC BRICKS AT HIGH TEMPERATURE AU: Sawai S; Kasai A CS: Nippon Steel & Sumitomo Metal Corp. JN: Refractories (Tokyo) SO: 65,No.3,2013,p.137 LA: Japanese AB: The wear behaviour of four SiC brick samples bonded with different materials (SiAlON (two samples); SiC; Si3N4) was studied. The porosities and bending strengths are tabulated. The relationship between the wear volume (sand blast test method) and bending strength and the temperature dependence of mean wear depth (pin-on-disc test method) are plotted. AN: 237528 UP: 1402 TI: ENERGY SAVING BY IMPROVING INSULATION REFRACTORIES FOR REHEATING FURNACES AU: Sato M; Takeuchi T; Kohno K; Shimpo A CS: Nippon Steel & Sumitomo Metal Corp. JN: Refractories (Tokyo) SO: 65,No.3,2013,p.136 LA: Japanese AB: An improved insulating refractory lining structure for use on the skid beams and support pipes of reheating furnaces was developed. The structure includes a high-spec insulation sheet together with an inner layer of ceramic fibre and outer layer of CA6-based castable. The cross-sections and heat transfer rates of conventional and improved lining structures are shown and compared. The energy savings achieved in different furnaces are also shown. 3 refs. AN: 237527 UP: 1402 TI: DISCUSSIONS ABOUT DRYING METHOD OF THE CASTABLE REFRACTORIES FOR LADLE USING MICROWAVE AU: Hoshizuki H; Chiba H; Maki Y CS: Mino Ceramic Co.Ltd. JN: Refractories (Tokyo) SO: 65,No.3,2013,p.135 LA: Japanese AB: The microwave drying of castable refractories used to line steel ladles was studied. The mean, minimum and maximum drying temperatures, weight loss and drying efficiency of samples dried for 2, 4 and 5.5 h are tabulated. AN: 237526 UP: 1402 TI: THERMODYNAMIC SIMULATION OF SLAG PENETRATION INTO ALUMINA-MAGNESIA CASTABLE AU: Goda K CS: Krosaki Harima Corp. JN: Refractories (Tokyo) SO: 65,No.3,2013,p.134 LA: Japanese AB: Thermodynamic predictions of slag penetration into Al2O3-MgO castables of varying composition were made using computer models. The compositions of the castables, which contained varying amounts of MgO and SiO2, are tabulated. Plots of MgO content against distance from the hot face are presented. 2 refs. AN: 237525 UP: 1402 TI: ANALYSIS OF SETTING RETARDER MECHANISM OF LOW CEMENT CASTABLES WITH BORIC ACID AU: Kaneko M; Oba Y; Oba J; Ishikawa M CS: Taiko Refractories Co.Ltd. JN: Refractories (Tokyo)

2014 CERAM Research Ltd

13

CERAM Alert Profile Update, Jan 2014

SO: 65,No.3,2013,p.133 LA: Japanese AB: The effect of boric acid on setting retardation in low-cement castables was studied. Calcium aluminate-based samples with/without 0.1% H3BO3 were prepared and tested. The Ca2+ ion concentrations in filtrates are shown and compared. 1 ref. AN: 237524 UP: 1402 TI: EFFECT OF RESIDUAL CASTABLE IN A MIXER ON THE HARDENING CHARACTERISTIC OF LOW CEMENT CASTABLE AU: Haraguchi K; Kusunoki A CS: Krosaki Harima Corp. JN: Refractories (Tokyo) SO: 65,No.3,2013,p.132 LA: Japanese AB: The hardening characteristics of low-cement castables were studied, looking at the effect of residual castable material in the mixer. The working and setting times and changes in pH value, and Ca and Al ion concentration changes in mixing water are shown. 1 ref. AN: 237523 UP: 1402 TI: INFLUENCE OF PORE SIZE DISTRIBUTION ON SLAG PENETRATION RESISTANCE IN ALUMINA-MAGNESIA CASTABLE AU: Nishida S; Nishimura M; Namba M; Saito K CS: Shinagawa Refractories Co.Ltd. JN: Refractories (Tokyo) SO: 65,No.3,2013,p.131 LA: Japanese AB: The slag resistance of alumina cement-bonded Al2O3-MgO castable samples with different water contents was studied. Chemical compositions and penetration depths after slag testing (1650 C for 4 h; C/S = 3) are tabulated. The effect of pore size distribution on slag penetration resistance is shown. AN: 237522 UP: 1402 TI: EFFECT OF SILICA FUME FOR HYDRATION OF ALUMINA CEMENT IN CASTABLE REFRACTORY AU: Nishigami Y; Nakamichi T; Goda K CS: Krosaki Harima Corp. JN: Refractories (Tokyo) SO: 65,No.3,2013,p.130 LA: Japanese AB: The hydration of alumina cement samples containing 0.5 wt% sodium phosphate and substituted with different amounts of silica fume (0, 10, 50 wt%) was studied. The water-cement ratio was 1.2 in each case. The samples were cured at 5, 20 and 40 C. DTG curves are plotted over the temperature range from RT to 500 C for each sample. The appearance of various phases at different temperatures is indicated. 3 refs. AN: 237521 UP: 1402 TI: IMPROVEMENT OF ALKALI RESISTANCE OF SPINEL BRICKS FOR LOWER TRANSITION ZONE IN CEMENT ROTARY KILNS AU: Nishida K; Miyagishi Y; Yamamoto T; Ukawa S CS: AGC Ceramics Co.Ltd. JN: Refractories (Tokyo) SO: 65,No.3,2013,p.129 LA: Japanese AB: Spinel bricks with improved alkali resistance were developed for lining the lower transition zone of rotary cement kilns. The chemical compositions and properties (porosity; density) of conventional, fine spinel and improved brick samples are tabulated. Cross-sections of these samples after corrosion tests in KCl solution (790 C for 10 h) are shown. AN: 237520 UP: 1402 TI: IMPROVED COATING ADHESION ABILITY FOR BURNING ZONE OF CEMENT ROTARY KILNS AU: Hayashi K; Tanaka K; Kawamori Y CS: Yotai Refractories Co.Ltd. JN: Refractories (Tokyo) SO: 65,No.3,2013,p.128 LA: Japanese AB: A chrome-free MgO-Al2O3 brick containing 0.5 wt% Fe2O3 and with improved coating adhesion ability was developed for lining the burning zone of rotary cement kilns. The compositions and properties of conventional and improved bricks are

2014 CERAM Research Ltd

14

CERAM Alert Profile Update, Jan 2014

tabulated. The adhesion strength of samples in coating tests and the results of erosion and penetration tests are shown and compared. AN: 237519 UP: 1402 TI: REACTION MECHANISMS OF BASIC BRICKS WITH CEMENT CLINKER AU: Igabo K; Ogata M; Saito K CS: Shinagawa Refractories Co.Ltd. JN: Refractories (Tokyo) SO: 65,No.3,2013,p.127 LA: Japanese AB: The reactions between basic refractory bricks used to line rotary cement kilns with cement clinker were experimentally studied. MgO-spinel, MgO and MgO-Cr2O3 brick samples were tested and their compositions and porosities are tabulated. The composition of the cement clinker is also given. The apparatus used in the tests is diagrammatically shown. Cut sections of samples after testing are also shown. 2 refs. AN: 237518 UP: 1402 TI: INFLUENCE OF GRAIN SIZE DISTRIBUTION OF MgO-C BRICKS ON MgO + C REACTION AU: Yoshioka H; Kakihara M; Saito K; Tada H CS: Shinagawa Refractories Co.Ltd. JN: Refractories (Tokyo) SO: 65,No.3,2013,p.126 LA: Japanese AB: Nine MgO-C brick samples containing various amounts of coarse and fine grain magnesia together with graphite were prepared. The properties of samples after heating at 1800 C and the effect of MgO fine grain content (0, 10, 20 wt%) on the weight loss after heating at 1800 C are shown. AN: 237517 UP: 1402 TI: EFFECT OF ADDITIVES ON THE EXPANSION PROPERTIES OF MgO-C BRICK AU: Fujita M; Sakai T; Takeuchi K; Tanaka M; Yoshitomi J CS: Krosaki Harima Corp. JN: Refractories (Tokyo) SO: 65,No.3,2013,p.125 LA: Japanese AB: The thermal expansion behaviour of magnesia-carbon refractories containing 87 wt% MgO, 13 wt% graphite with/without 2 wt% additive combinations (Al; Al+Si; Al+B4C) was studied. Expansion curves are plotted over the temperature range 0-1400 C. AN: 237516 UP: 1402 TI: PROPERTIES AND ORGANISATION MODIFICATIONS OF MgO-C BRICK BY FIRING CONDITIONS AU: Tomita Y; Matsuo Y; Tanaka M; Yoshitomi J; Lippert N; Aneziris C G CS: Krosaki Harima Corp.; Freiberg,TU Bergakademie JN: Refractories (Tokyo) SO: 65,No.3,2013,p.124 LA: Japanese AB: Magnesia-carbon brick samples containing 92 wt% MgO and 8 wt% C as well as Al additive were fired at 1400 C for 10 or 30 h and their thermal shock resistance was determined. The samples were analysed by FESEM and EDS. The cut faces of thermally shocked specimens and the distribution of Al-Mg and Si-Ca in the matrix of the samples are shown. 1 ref. AN: 237515 UP: 1402 TI: DETERMINATION FOR MODULUS OF ELASTICITY OF MgO-C BRICK AU: Asakura H; Zhu H; Soga N; Takeuchi S; Yamaguchi A CS: Okayama Ceramics Research Foundation JN: Refractories (Tokyo) SO: 65,No.3,2013,p.123 LA: Japanese AB: The elastic modulus (MOE) of MgO-C refractory brick samples was determined on test specimens cut either in the forming surface direction (FD) or in a direction perpendicular to the forming surface direction (PD), as well as on different specimen faces. Test results for the MOE after drying are tabulated. Model diagrams for graphite orientation in two of the FD test faces and a schematic diagram of MOE distribution of PD test pieces in the brick after drying are shown.

2014 CERAM Research Ltd

15

CERAM Alert Profile Update, Jan 2014

AN: 237513 UP: 1402 TI: APPLICATION OF CARBURISED MAGNESIA FOR REFRACTORY AU: Shiotani T; Nishimura N; Yamamoto T CS: Yotai Refractories Co.Ltd. JN: Refractories (Tokyo) SO: 65,No.3,2013,p.121 LA: Japanese AB: Magnesia-carbon refractory brick samples containing different amounts of carburised MgO (0, 30, 70 wt%) substituting for fused MgO and flake graphite were prepared and tested. Their compositions and properties are tabulated and the results of oxidation and corrosion tests are given. AN: 237512 UP: 1402 TI: CRACK RESTRAINT OF CASTABLE OF RH SNORKEL AU: Terada S; Chihara K; Koide K; Soeda T CS: TYK Corp. JN: Refractories (Tokyo) SO: 65,No.3,2013,p.120 LA: Japanese AB: Cracking in 8 castable refractory samples used for RH snorkels was studied. The appearance of cracks in the samples under restraint is schematically shown, and the amount of deformation is shown and compared. 2 refs. AN: 237511 UP: 1402 TI: DEVELOPMENT OF CHROME-FREE REFRACTORY WITH HIGH RESIDUAL EXPANSION AU: Morita K; Shimizu K; Tanaka M; Yoshitomi J CS: Krosaki Harima Corp. JN: Refractories (Tokyo) SO: 65,No.3,2013,p.119 LA: Japanese AB: Three chrome-free magnesia-alumina refractory brick samples containing between 82.0 and 83.0 wt% MgO, 11.2 and 12.5% Al2O3, 2.6% TiO2 and 0 or 0.2% B2O3 were developed and tested. The chemical compositions and apparent porosities of the samples are tabulated and their residual expansion after heating at 1673 K for up to 3 h is plotted. The corrosion rate of the specimens is also shown and compared. The effect of B2O3 addition is considered. 2 refs. AN: 237510 UP: 1402 TI: EFFECT OF Cr2O3 ADDED TO UNBURNED ALUMINA-MAGNESIA BRICKS AU: Kamiyama K; Igabo K; Tomiya H; Saito K CS: Shinagawa Refractories Co.Ltd. JN: Refractories (Tokyo) SO: 65,No.3,2013,p.118 LA: Japanese AB: Unburnt alumina-magnesia bricks containing 90 wt% Al2O3 and 7 wt% MgO and various amounts of Cr2O3 (0, 3, 5, 10, 20 wt%) substituting for the Al2O3 were prepared and their slag corrosion resistance was determined. A magnesia-alumina brick sample containing 76 wt% MgO, 18 wt% Al2O3 and 3 wt% Cr2O3 was prepared for comparison. The chemical compositions of the samples are tabulated. The effect of Cr2O3 content on the slag corrosion index and the cross-sectional appearance of samples after testing are shown. 1 ref. AN: 237509 UP: 1402 TI: CHARACTERISTICS OF MAGNESIA POROUS REFRACTORY ADDED ZIRCONIA AND ALUMINA AU: Omichi R; Tsuchinari A CS: Rozai Kogyo Kaisha Ltd. JN: Refractories (Tokyo) SO: 65,No.3,2013,p.117 LA: Japanese AB: The spalling and corrosion resistance of porous MgO-ZrO2-Al2O3 refractories were studied. Test results are shown. 2 refs. AN: 237508 UP: 1402 TI: DEVELOPMENT OF THE ZrO2 RING INSERT MATERIAL FOR Ca TREATED STEEL AU: Makino T; Wakita T; Ohmaru Z; Akamine K; Yoshitomi J

2014 CERAM Research Ltd

16

CERAM Alert Profile Update, Jan 2014

CS: Krosaki Harima Corp. JN: Refractories (Tokyo) SO: 65,No.3,2013,p.116 LA: Japanese AB: An improved ZrO2 insert ring material for a sliding nozzle plate used in producing Ca-treated steel was developed. The properties of conventional and improved materials and their microstructure and rate of stroke damage after use are shown and compared. 1 ref. AN: 237507 UP: 1402 TI: INFLUENCE OF STEEL GRADE TO REACTIONS BETWEEN SLIDE PLATE REFRACTORY AND MOLTEN STEEL AU: Mizobuchi F; Hamamoto N; Morikawi K; Saito K CS: Shinagawa Refractories Co.Ltd. JN: Refractories (Tokyo) SO: 65,No.3,2013,p.115 LA: Japanese AB: The reactions between Al2O3-ZrO2-C slide gate plate refractory specimens and molten steel were studied using three different steel grades, viz. high-oxygen steel (122 ppm O; 0.1 wt% Si; 0.25 wt% Mn), calcium-treated steel (27 ppm Ca) and aluminium-killed steel (18 ppm C). The hot faces of specimens as seen under backscattered electron imaging are shown. 1 ref. AN: 237506 UP: 1402 TI: BASIC RESEARCH ON THE PENETRATION OF Cs AND PROPERTIES OF INCINERATION REFRACTORIES AU: Mizuhara S; Kawamoto K JN: Refractories (Tokyo) SO: 65,No.3,2013,p.113 LA: Japanese AB: The penetration of caesium nuclides released from waste incinerators into the incinerator lining materials was studied. SiO2-Al2O3, Cr2O3 and SiC refractories, commonly used for such linings, were tested. Results of Cs activity (Cs-134, Cs-137 and K-40 nuclides) in a SiC refractory are tabulated. 2 refs. AN: 237505 UP: 1402 TI: DISCUSSIONS ABOUT CHROME SOURCE OF MAGNESIA CHROME REFRACTORIES AU: Chiba H; Toda H; Tsuchiya Y CS: Mino Ceramic Co.Ltd. JN: Refractories (Tokyo) SO: 65,No.3,2013,p.112 LA: Japanese AB: Five different sources of chrome for MgO-Cr2O3 refractories were investigated. The apparent porosities of refractory specimens containing the different chrome sources, the chemical compositions and grain size of the chrome sources, and the results of corrosion tests are shown and discussed. AN: 237504 UP: 1402 TI: IMPROVEMENT OF ALUMINA-CHROME BRICKS FOR WASTE MELTING FURNACES AU: Tanida H; Hoshizuki H; Yoshimi Y; Ohta S CS: Mino Ceramic Co.Ltd. JN: Refractories (Tokyo) SO: 65,No.3,2013,p.111 LA: Japanese AB: Al2O3-Cr2O3 refractory brick samples containing various additives were prepared and tested. Their apparent porosity, bulk density and cold crushing strength are tabulated and compared. The results of slag penetration tests (C/S ratios of 0.6 and 1.2) are also presented. AN: 237502 UP: 1402 TI: EVALUATION OF ELASTIC MODULI OF MAGNESIA-SPINEL REFRACTORY AU: Sakaida Y; Yoshida H; Watanabe Y; Suzuki K JN: Refractories (Tokyo) SO: 65,No.3,2013,p.109 LA: Japanese AB: The elastic moduli of MgO-spinel refractory samples were evaluated by different static and dynamic methods. Stress-strain

2014 CERAM Research Ltd

17

CERAM Alert Profile Update, Jan 2014

curves are plotted for two different materials and their Young's moduli are listed. 1 ref. AN: 237501 UP: 1402 TI: FABRICATION METHOD OF BIMODAL POROUS CERAMICS USING SEGREGATION REACTION AND GAS-SOLID EUTECTIC REACTION ON THE SOLIDIFICATION OF WATER AU: Ueno S; Woo L J JN: Refractories (Tokyo) SO: 65,No.3,2013,p.108 LA: Japanese AB: A chemical process for fabricating porous ceramics with a bimodal pore size distribution is described. 2 refs. AN: 237404 UP: 1402 TI: HIGH PERFORMANCE REFRACTORY LININGS FOR TiO2 CHLORINATORS AU: Mevec G; Fuchs S; Owens R CS: Rath AG; Rath Refractories Inc. JN: Keram.Z. SO: 65,No.5,2013,p.302-304 LA: German AB: The history of TiO2 pigment production goes back more than 100 years. Commercial production had already started in Germany in 1916. Today, TiO2 pigments production is mainly done by means of the chlorine route, which requires a very special refractory brick such as DURRATH HD45. The chlorine process and the specific technical requirements necessary to enable long and continuous operation of chlorinators are explained. In view of the results achieved so far from more than ten years of chlorinator operation, DURRATH HD45 is shown to offer the lowest life cycle cost in the industry. 4 refs.

2014 CERAM Research Ltd

18

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Science Act Practice Test 67cDocument12 pagesScience Act Practice Test 67capi-232033431100% (1)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Introduction and Bravais LatticesDocument17 pagesIntroduction and Bravais LatticesBilal BarutPas encore d'évaluation

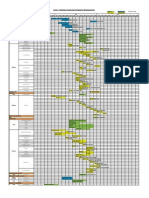

- 2.2.4 Construction Schedule For Mechanical WorkDocument2 pages2.2.4 Construction Schedule For Mechanical WorkĐình Nam100% (1)

- Organization of Genes and Chromosomes CompleteDocument13 pagesOrganization of Genes and Chromosomes Completebiotecnika_testPas encore d'évaluation

- Manual IrDocument292 pagesManual IrSISOYDANNYPas encore d'évaluation

- Almatis - Andus Buhr - TrendsRefractoriesCleanSteelTechnology - LitcorrectionDocument15 pagesAlmatis - Andus Buhr - TrendsRefractoriesCleanSteelTechnology - LitcorrectionSaptarshi SenguptaPas encore d'évaluation

- Interpreting Phase DiagramsDocument131 pagesInterpreting Phase Diagramsweltwind100% (2)

- Chapter 1 To 4Document121 pagesChapter 1 To 4Haiqal Aziz100% (1)

- High-Performance Liquid ChromatographyDocument5 pagesHigh-Performance Liquid ChromatographyYulia PrimasariPas encore d'évaluation

- 62 65 EngDocument34 pages62 65 EngSaptarshi SenguptaPas encore d'évaluation

- Value Enhancement For Refractory Castables by DeflocculantsDocument4 pagesValue Enhancement For Refractory Castables by DeflocculantsSaptarshi SenguptaPas encore d'évaluation

- Is 1528 1 2010Document9 pagesIs 1528 1 2010Saptarshi SenguptaPas encore d'évaluation

- Gantt Chart Template PlanioDocument10 pagesGantt Chart Template PlanioSaptarshi SenguptaPas encore d'évaluation

- Setting Time PDFDocument1 pageSetting Time PDFSaptarshi SenguptaPas encore d'évaluation

- Calcined Magnesite MSDS3Document3 pagesCalcined Magnesite MSDS3Saptarshi SenguptaPas encore d'évaluation

- Microsilica Grade 940 ConstructionDocument2 pagesMicrosilica Grade 940 ConstructionSaptarshi SenguptaPas encore d'évaluation

- Alkali PaperDocument3 pagesAlkali Papermahreza189Pas encore d'évaluation

- Us 8618006Document8 pagesUs 8618006Saptarshi SenguptaPas encore d'évaluation

- Shrinkage NBG 2011 FinalDocument11 pagesShrinkage NBG 2011 FinalSaptarshi SenguptaPas encore d'évaluation

- Insulation Refractory MSDSDocument7 pagesInsulation Refractory MSDSSaptarshi SenguptaPas encore d'évaluation

- Science & GlassDocument8 pagesScience & GlassSaptarshi SenguptaPas encore d'évaluation

- 1 s2.0 S218707641400027X MainDocument14 pages1 s2.0 S218707641400027X MainSaptarshi SenguptaPas encore d'évaluation

- Disclosure To Promote The Right To InformationDocument10 pagesDisclosure To Promote The Right To InformationSaptarshi SenguptaPas encore d'évaluation

- Durability of Concrete StructuresDocument8 pagesDurability of Concrete StructuresjineeshdathPas encore d'évaluation

- Sol Gel Mullite Coatings GCECT Kolkatta Feb 2014Document7 pagesSol Gel Mullite Coatings GCECT Kolkatta Feb 2014Saptarshi SenguptaPas encore d'évaluation

- Iron and Steel AdditivesDocument1 pageIron and Steel AdditivesSaptarshi SenguptaPas encore d'évaluation

- Carbon BlackDocument4 pagesCarbon BlackSaptarshi SenguptaPas encore d'évaluation

- CementDocument4 pagesCementSaptarshi SenguptaPas encore d'évaluation

- FT SpectrosDocument5 pagesFT SpectrosSaptarshi SenguptaPas encore d'évaluation

- Notes 8Document24 pagesNotes 8Kunal PatelPas encore d'évaluation

- PT-2 S. Alumina PaperDocument7 pagesPT-2 S. Alumina PaperSaptarshi SenguptaPas encore d'évaluation

- RedBus Ticket 33242579Document1 pageRedBus Ticket 33242579Saptarshi SenguptaPas encore d'évaluation

- How Does It WorkDocument1 pageHow Does It WorkSaptarshi SenguptaPas encore d'évaluation

- Influence of The Damage Level During Quenching On Thermal Shock Behavior of Low Cement CastableDocument9 pagesInfluence of The Damage Level During Quenching On Thermal Shock Behavior of Low Cement CastableSaptarshi SenguptaPas encore d'évaluation

- Clean Steel Production: Aspects for Controlling Oxygen and InclusionsDocument12 pagesClean Steel Production: Aspects for Controlling Oxygen and InclusionsSaptarshi SenguptaPas encore d'évaluation

- Overcoming Conflict between Long BOF Refractory Lifetime and Efficient Bottom StirringDocument12 pagesOvercoming Conflict between Long BOF Refractory Lifetime and Efficient Bottom StirringSaptarshi SenguptaPas encore d'évaluation

- Sheet 1 - Introduction To Heat Transfer MechanismsDocument2 pagesSheet 1 - Introduction To Heat Transfer MechanismsAhmed YousryPas encore d'évaluation

- Csec Chemistry - A5Document17 pagesCsec Chemistry - A5Mencarty DocentPas encore d'évaluation

- Organic ChemistryDocument122 pagesOrganic ChemistryromaliaPas encore d'évaluation

- Paper IATMIDocument18 pagesPaper IATMIpermanahendPas encore d'évaluation

- 2022 Puc I Chem Imp QuestionsDocument13 pages2022 Puc I Chem Imp QuestionsCHAKRI BABLUPas encore d'évaluation

- Lab Report Measuring MassDocument6 pagesLab Report Measuring Massapi-298868993100% (2)

- Bhagwad Gita in Hindi ISKON-IntroductionDocument30 pagesBhagwad Gita in Hindi ISKON-IntroductiontazinabhishekPas encore d'évaluation

- Experimental and Modeling of A Non-Isothermal CSTRDocument10 pagesExperimental and Modeling of A Non-Isothermal CSTRAlejandra SantosPas encore d'évaluation

- Modelling of A Fixed-Bed Water-Gas Shift Reactor: 1. Steady-State Model VerificationDocument10 pagesModelling of A Fixed-Bed Water-Gas Shift Reactor: 1. Steady-State Model VerificationFalcon WingPas encore d'évaluation

- Downhole Tool Dressing Brochure 2022Document7 pagesDownhole Tool Dressing Brochure 2022Ricky VelascoPas encore d'évaluation

- MiniProject Stage 3 - Process Dynamic & ControlDocument8 pagesMiniProject Stage 3 - Process Dynamic & ControlFarihah Eyfa100% (2)

- Intellipak Manual ProgrammingDocument157 pagesIntellipak Manual ProgrammingArt kPas encore d'évaluation

- The Novak Guide To Dana 20Document9 pagesThe Novak Guide To Dana 20Hunter HincksPas encore d'évaluation

- Dry Gas Seal BrochureDocument8 pagesDry Gas Seal BrochureJai-Hong ChungPas encore d'évaluation

- Lesson 11 Environmental Crisis and Sustainable DevelopmentDocument41 pagesLesson 11 Environmental Crisis and Sustainable DevelopmentJoyce GarciaPas encore d'évaluation