Académique Documents

Professionnel Documents

Culture Documents

Bakery FLour

Transféré par

kmsalim0070 évaluation0% ont trouvé ce document utile (0 vote)

94 vues32 pagesBakery FLour

Copyright

© Attribution Non-Commercial (BY-NC)

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentBakery FLour

Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

94 vues32 pagesBakery FLour

Transféré par

kmsalim007Bakery FLour

Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 32

DTKFCPL Feb 03 1

We start with Wheat flour.

Wheat flour is the major ingredient used in manufacturing products . It directly affects

Profitability & performance of the product and the units. The performance of the raw

material is related to the various constituents in the wheat flour which play a major role

and go under various chemical, physical and microbiological changes during

processing. Good quality wheat flour helps to manufacture standard and consistent

quality product constantly and is directly responsible to the product yield and cost. It is

because all the constituents of wheat flour are responsible to achieve excellent quality

product, hence it becomes important for all of us to understand the contribution of

wheat and wheat flour in general so as be able to implement the same to control the

product manufacture and production process.

Wheat grain consists of :

Bran

Endosperm

Germ

DTKFCPL Feb 03 2

Varieties of Wheat

Triticum Vulgare

Triticum Durum

Triticum Compactum

Bulk of wheat is of the Vulgare variety and is used for manufacture of bread and

biscuits. The Drum variety of wheat is used to manufacture pasta goods. Very soft

wheat is suitable for manufacture of biscuits (compactum)

Wheat mainly consist of three major components

1) Germs

2) Endosperm

3) Bran/Husk.

These constituents exists in wheat in the falling ratios :

1) Germ embryo that produce new plant growth 2%

2) Starchy endosperm -- food for new plant growth 85%

3) Various Coverings Bran/Husk 13%

The chemical composition of these constituents will demonstrate the chemical role of

these constituents during manufacturing as well helps the flour mills to manufacture the

quality of the flour required by bakery product manufacture.

DTKFCPL Feb 03 3

Chemical Composition of Three Major Constituents of WHEAT

1. Bran

Protein 15-18 %

Fat 4-5%

Carbohydrate 61-73%

Fibre 2-13%

Ash 3-6.3%

2. Germ

Moisture 9.2%

Protein 28.9%

Crude Fiber 2.1%

Fat 9.7%

Mineral Water 4.1%

Carbohydrate 46.0%

3. Endosperm

Moisture 14.0%

Proteins 9.6%

Fat 1.4%

Ash 0.7%

Carbohydrate 74.3%

( Starch - 71.2

Hemicellulose - 1.8

Sugar - 1.1

Cellulose - 0.2

Total Carbon hydrate - 74.3)

DTKFCPL Feb 03 4

The Wheat composition consists of average composition of all these constituents.

Approximate composition of wheat : Moisture 9-18%

Starch 60-68%

Proteins 815%

Cellulose 2-2.5%

Fat 1.52%

Sugar 2-3%

Ash 1.52%

The wheat flour which is used for manufacture of various bakery products mainly

constitute of the endosperm.

To understand bakery operation in relation to the constitution of the wheat flour, there

are too major elements viz starch and Gluten (Protein) which affect the quality and yield

in bakery operation. It is important to understand the chemical composition and their all

level effects in the processing.

The profitability of flour mills is dependant upon the extraction rate. High extraction

provides better contribution and thereby increases overall profitability. Higher extraction

produces wheat flour of poor quality and also varies in the composition. It effects the

gluten quality. Higher extraction rates always damage the starch molecules. The

variation in composition due to extraction rate is shown below :

DTKFCPL Feb 03 5

Wheat Flour

72% Extraction 80% Extraction

Moisture 13-15.5 13-15

Starch 65-70 64-69

Protein 8-13 914

Cellulose 0-0.2 0.20.35

Fat 1.5-2.0 1.5-2.0

Miral Ash 0.3-0.6 0.6-0.8

Carbohydrate

Starch consists of Amylose and amylopectin. Amylose constitutes 23% and consists of

straight unbranched chain of glucose 1 : 4 gulcosidic linkage. White amylopectin

consists of highly branched short glucose chains.

The significant point here is that these compounds react differently to enzymic

(diastatic) attacks.

The analysis converts straight chain to maltose but is unable to attack amylopectin

beyond the branch point.

DTKFCPL Feb 03 6

The analyses however can attack linkage at branch point and once this is done

amylose can act on amylose and produce maltose with residue from amylopectin

position as dextrin

When amylose attack starch , dextrin (gummy) are formed from amylopectin and

these are compounds which are harmful during bread manufacture the formation of

dextrin makes the product clammy and sticky. During this reaction process , maltose is

produced. There has always been correlation between the amount of dextrin and

maltose. If one is able to estimate the percentage of maltose it would be possible to

derive the extent of starch damage that has taken place and in due course the quantity

of dextrin produced.

There are several methods for the estimation of maltose (which is one of the by

products of anylase reaction. This subjects has always been a very interesting aspect

of cereal chemistry . Rumsey develop a method of estimation and value was

represented as maltose figure. The autolysed flour at fixed time at 62

0

C after which a

separate meter reading was obtained.

Better physical methods were developed to understand the reaction of amylose

on wheat starch. Various equipment were developed and one of the most

important techniques presently used is Amylograph.

The process is described below:

The mixture is mixed at 75 rpm. The material is heated through bath by increasing

temperature at the rate of 1.5

0

C per minute. The shaft operate at the upper end of pen

that records the changes in viscosity .

To 50- 80gm flour add 450ml water in smooth suspension.

DTKFCPL Feb 03 7

The temperature is allowed to increase to 95

0

C and is held constant and apparatus is

allowed for an hour. The graph is recorded as a line at which it runs parallel to

horizontal axis but at 70

0

C starts to rise reaching as peak between 88

0

C to 95

0

C usually

after 45 to 50 mt. Lower peak shows addition of amylase or excess.

Baking Viscosity Diastatic activity of maltose Maltose

Per 10 gm

Very Poor 150 540 3.5

Fair 315 395

Good 442 -547 365 352

Very Good 763 1000

+

275 85 5.5

The other method adopted nowadays is Falling No. in milling industry

The sample of wheat is grounded is allowed to pass through 0.8mm screen. The 7 gm

of flour is mixed with 25 ml. of water in a tube provided with 20 to 30 shakes. The test

tube with a stirrer in position is immediately immersed in a lively boiling water bath. The

contents remain in bath for 60 sec. The stirrer is then raised on top and allowed to drop

by its own weight to a fixed depth. The time taken for the stirrer to drop is called falling

No.

Sprouted wheat would have : Falling No. 150 -300

This provides indication of amylose activity with liquefaction No.

DTKFCPL Feb 03 8

Liquefaction No. 6000

Falling No. -50 ( Although starch is insoluble in water the granules

swell in hot water and eventually burst. The effect is known a gelatinization of starch.

During the milling process the starch gets damaged due heat produced from rollers

during grinding as it is sheared and crushed between roller. A large amount of water

added which is around 50% or more in the mix is largely consumed by gluten and small

quantity is utilized by starch, which starts swelling. The top of the bread shows

preponderances of starch granules that are swollen. This represents first order

gelatinization. The inside of the loaf has temperature never more that 95 deg Celsius

and water is limited and the gelatinization is not complete.

High viscosity of starch is associated with low volume of baked loaf.

Protein

An Organic Compound where in amino acids are linked together.

Amino acetic acid CH2 (NH2)COOH

Amino group COOH (Carbonlic group).

Protein Composition of wheat flour

Carbon 50-55%

DTKFCPL Feb 03 9

Hydrogen 6.5-7.5%

Nitrogen 15- 9%

Oxygen 22-27%

Sulphur 0-3.5%

Protein in wheat flour is a combination of the following:

Albumin

Globulin

Protease

Prolamin ( Glidnin)

Glutelin (glutenin)

The first three are insignificant because of their quantities in wheat flour are

approximately 1.7 %. The other two protein are commonly known as gluten and Glidnin

. Glutenin gives solidity and gliadnin imparts softness. The estimation of

extensity/strechability and strength is estimated by various techniques as below:

1) Alveograph

2.5 % salt solution for making dough at 25

0

C - weigh 250 gm start mixer carefully add

calculated qty of salt water taking approximately 15 sec. Allow mixing to proceed for 7

minutes. Stop mixer, raise the shutter A. Extrude the dough cut into four piece . Place

the dough in tempering compartment . Relax for 20 min. If a bubble is created, the

recording monometer should watch the bubble as it punctures.

DTKFCPL Feb 03 10

Area is measured by Planimeter provides strength of the dough

P = Height of peak is measured in mm stability

L = MM gives stretching ability

Stability 45 90

Strength 20 75

Condition Wheat stability 90

Strength 70 -75

Sticky body is responsible for binding. The bran and germane richer in protein contact. It

is quality of gluten rather than quantity that influences baking quality. The quality of

gluten depends upon chiefly the collidal state of protein.

2) Farino Graph

P

L

DTKFCPL Feb 03 11

0

A= Dough Consistency B = Dough Development

D= Elasticity C = Dough Stability

C

B

A

E D

DTKFCPL Feb 03 12

E= Weakening of dough

Quality Of flour

a) There must be sufficient sugar and enough diastatic activity to produce reserve

sugar during fermentation to ensure continuous sufficiency of gas to distant the

dough

b) Protein must be sufficient in quality to hold sufficient gas

c) The dough must be ripe at the time of baking.

B

A

C

Tension D Proportional No

D = B/C

Time Seconds

Visco elastic behavior of the dough.

DTKFCPL Feb 03 13

Fat and lipids

The whole grain contain 2% rather under 4% fat

The oil is present in germ contain : Oleic = 30.0

Linoleic = 44 %

Linolenic = 10%

Other saturated = 13 14%

Germ oil acidity is very important it is responsible for the oxidation of the product. It is

always necessary to check the germoil acidity on a regular basis. It has been observed

that more than 20 units is not an acceptable quality for manufacture of biscuits and

baked varieties.

The lipids in flour affect both formation of dough as it is influenced by the gluten and

also a method to understand the gluten quality and water absorption.

Sugar and Dextrin

Dextrin are responsible to glaze the side / Top of the bread. Excessive dextrin causes

heaviness, stickiness in curb which is noticeable with amylose process.

DTKFCPL Feb 03 14

Standards of white flour

Moisture Ash Protein PH fat maltose Gluten %

min.

14 0.65 10.5 6.0 -6.8 1.5 250 8

Other ingredients

Other important ingredients used in baking operation is yeast which help in proofing the

to the required size and volume . It is important to understand the quality of yeast used

in manufacturing process. The yeast which is commonly used in bakery operation is

called SACCHAROMYCES CEREVISIAE (YEAST).

Saccharomyces Cerevisiae

Dry matter basis - 52% Protein

2% Fat

8 9 %mineral matter

30% glycogen

Yeast is also used a leavening. Yeast converts fermentable sugars such as maltose,

glucose, fructose and sucrose into CO

2

and alcohol. Yeast is a living organism and its

activity can be influenced by storage practices, dough temperature and PH, availability

of water and food supply. Out of these control points, the most important is temperature.

Yeast is available in two forms: Compressed yeast

Dried yeast

DTKFCPL Feb 03 15

The compressed yeast needs to be stored at refrigerated conditions. Active dry yeast

must be pre hydrated 5-to 15 mins before adding to dough at 95 110

o

F water. Instant

Dry yeast can be added directly without pre-hydrating.

Average quantity requirements : 1.5 lb 280. lb per sack

4 lb per sack

Addition Salt

The fermentation by yeast depends on Quality flour and process parameters used in

manufacturing. It has been observed that good quality of flour shows an over jump of

approximately 1.7cm. This is achieved by ability to produce co

2

while entering the oven

and gluten able to extend to encompass the gas which qualified as over jump.

These are various method for manufacture of bread and commonly used are sponge

and dough and straight dough methods. Sponge and dough process is commonly used

in Europe, straight dough process has been adopted as common manufacturing

process. Both these processes have advantages and disadvantage and produce quality

bread . In American countries sliced bread and soft buns are mostly consumed hence

the adoption of soft spong process allows them to achieve better texture for soft bread.

In the European market French bread, Italian bread etc are available from straight

dough method. Bread obtained by such a method provides quality bread and shows

better performance.

The spong dough process is carried out by using half of the flour in formation process

and half the flour is later added to achieve complete dough. While as in straight dough

method all ingredients are mixed at one time and dough is straight taken for

manufacturing process

DTKFCPL Feb 03 16

In the spong dough process the flour quality has to be good otherwise during

fermentation process amylose activity is likely produce more dextrin. So if the quality

of starch is poor it is always recommended to use straight dough process for

manufacture of bread/ bun etc.

For soft flour some oxidsing and reducing agents have been recommended. Oxidsing

agents help to achieve good volume and provide strength to the flour while reducing

agents help gluten to achieve the ability to extend / stretch by breaking down the protein

structure.

Oxidizing agents - Ascorbic acid. KBro

3

Reducing agents - Lcystenien Hydrochloride

SSL Strength

Ethoxylated monoglyciride

SH

SH

SH Free oxygen by

O KBro3

SH

S

S

Di Sulphide

bands

O

H

H

SH

SH

SH

ADA

H

ADA

H

S

S

Di Sulphide

bands

OXIDIZING AGENTS

DehyoAscorbicacid

KBo

3

SH

DTKFCPL Feb 03 17

There are many theories on how oxidizing agents work. We know that oxiding agents

strengthen the dough. Oxidizing agents have the ability to form disulphide band which

like protein, chain together. It also allows the dough to recover from mixing faster. This

may be due to disulphidethiol interchange. Another theory suggests that oxidizing

agents promote protein aggregation through ionic and hydrogen bonding. When dough

is under oxidized the dough tends to be over sticky and with poor gas retention

properties. A dough that is over oxidized will be too tight and stiff and the resulting

product usually is low in volume( except for over usage of ascorbic acid and KBro

3

) and

grain is dense with holes.

Our strategy is to give longer fermentation time. As the fermentationt time increases, the

oxidation requirements are reduced. Another strategy is to reduce proofing temperature.

The only problem in reducing the proofing temperature is , it extends the proofing time.

This can be overcome by adding additional quantities of yeast.

The oxidizing agents: Strengthens dough structure by creating bond between

proteins

Improves dough handling

Increases product volume

Produces tigular grain

DTKFCPL Feb 03 18

S

S

HS-X

REDUCING AGENTS

Free L-cystine

S

S

SH

S-S-X

Disulphide

bands

Break band between protein chain

Reducing Agents :

Wakens dough structure by breaking

bonds between proteins

Allows shorter mixing time

Improves machine reliability

HS X

DTKFCPL Feb 03 19

Changes During Baking

Mai Lard reaction/ broconing 121/350

Alpha Amylose

Starch Gelitinization

Slow

Begins starch geletinization

Protien

Thermal death point of yeast

CO2 liberated expanding cell

Mixing Makeup Proofing baking Cooling

200

180

160

140

120

100

80

93

o

C

79-80

o

60

0

49

o

DTKFCPL Feb 03 20

Some of the reducing agents and emulsifiers performance in bakery operations

Strength Soft

SSL (0.5%) +++ +++ Sodium stearoyl Lactate

CSL(0.5) +++ ++ Calcium stearoyl lactate

DATEM ++ + Diacetlge Tartrate ESTER of

EMG (0.5) +++ - Ethoxylated Monoglycicle

SE +++ 0 Sucrose Ester

Poly60 (0.5) +++ 0 Prysorbate 60

SMG + ++ succinylated Mono glyoxide

Hardamono - +++ Hard monoglycode

Soft Mono - +++ Soft Monoglyonde.

The reducing agents reacts during the mixing cycle and has infinite and limited reaction.

It should always be balanced with oxidizing agents. It helps to achieve proper mixing

and flour time.

Usage in rays for same important Ascobric acid 100200 ppm

Cystaine 10-90 ppm

Sodium bisulphate (bakery) 20- 100 mm

(Pie, crackers)

DTKFCPL Feb 03 21

Dough strengtheners/ Crumb softeners are also called emulsifiers or surface active

agents or surfacetants. They help to change surface tension. These emulsifiers have

both strengthening and softening effect upon the product. The most common softeners

are mono and triglycerides. They also help to increase shelf life. For breads, we need

hard monoglycerides and for cakes we need soft monoglycerides are used. The

percentage of alpha alpha monoglycerides is important as it has better dispersibility.

Softeners flows down starch retrogradation thereby inhibiting the staling process. It also

slows moisture migration and improves moistures retention.

In manufacturing process several bread softness have been used. This help to develop

the linkage with starch molecules and also provide help in retaining better moisture

which in togetherness give rise to very soft brand.

The Common Softners - Monoglycerides, starch glycerids

During baking process the flour and other constituents go under various changes. It is

important to understand these changes so as to be able take appropriate steps to

achieve better quality products.

The flour will affect the handling qualities of dough and all the quality factors that will be

evaluated in the product.

Water : The second largest ingredient in bakery operation is water. The main function is

hyderation. Gluten must be hydrated and for gelatinization of starch water is essential .

It also serves as dispersing agent and a medium for fermentation. Water is used to

control dough temperature. The total level of water in a bread dough is normally in the

DTKFCPL Feb 03 22

range of 55 to 65%. Water is the best cereal softener. Higher quantity of water can

dilute an otherwise good product.

Salt : The main function of salt is to bring out the flavor of the baked product. Its usage

levels range from 1.75to2.25%. Bread made out of 1.75% of salt, tastes bland and

bread made out of 2.25% of salt tastes very brackish. Salt also inhibits fermentation due

to osmatic pressure effect and it also toughens gluten . Salt lengthens mixing time.

Therefore addition of salt should be delayed to have proper mixing.

Bacterial analyses (180)

0

F Temperature at which these enzymes get

destroyed in baking operation

Fungal at (150)

0

F

(Cereal amylose) 170

0

F

In baking operation other than mixing other parameters like proof time, weight loss, P,

are responsible for loaf volume. Tables are provided to explain the correlation o these

parameter which is self-explanatory.

Effect of proofing Temperature on proof time loaf volume

Temp OC Time (min) Volume Lb

Ml

21.1 120 2200

30.0 60 2280

35.0 50 2270

40.0 47 2290

46.1 41 2260

DTKFCPL Feb 03 23

Effect of proofing time on loaf volume PH of bread and loss of weight in baking.

Proof line Volume lb PH of Bread Loss in baking (g)

of bread

(ml)

0 1270 5.49 46

15 1610 5.46 52

30 1980 5.41 61

60 2640 5.34 72

75 2780 5.31 73

90 3030 5.26 80

120 3550 5.16 88

150 4090 5.13 89

Effect of humidity during proofing on proof time , loaf volume and yield.

RH Proof Loss in Volume / lb

% Time Proofing + of bread

(min) Baking

35 57 74 2230

50 52 72 2320

60 54 71 2230

80 49 64 2150

90 46 64 2270

DTKFCPL Feb 03 24

Average Proof condition

Straight dough dry bulbs wet bulb RH

F C

100 - 110 37.8-43.3 5-8 2.8-4.5 75 -80

Continuous Process 115 -120 46.1 48.9 3-5 1.7 -2.8 80 -90

Correlation between time and Temperature is shown to help bakers to achieve better

product quality.

Effect Baking rolls

a) Rigid in 10 mts. But danger

In crest coloration

b) Rigid in 14min no coloration

Considered

c) Roll Rigid should have been

Removal at 17 min.

d) Barely rigid difficult to remove

From pan

e) No rigid rolls collapsed dough

or doughy

0 5 10 15 20

210

170

150

Rigid roll

225

o

F

200

o

F

275

o

F

280

o

F

250

o

F

1 2

3

4

5

Minutes of baking

DTKFCPL Feb 03 25

Some of the bread rolls characteristics are presented below to draw our attention to

their uniqueness..

Hard Rolls : American Hard

Jewish

Kaiser or crown rolls

Italian or French

All are made almost from same type of dough . the dough is left until is light enough to

be flattened by Shimmy Machine

Flour Water Yeast KBro

3

Diastatic moulten

60 33 36 2 -3 -0.0375 0-2

Italian Bread : Lean Formula

(Normal Composition Flour, Water, yeast, salt, V. less sugar)

Incorporate Old Dough. Proof bread is provided with smell certs. To appear shell like

bread different shapes, twist S, must have hard, thick crust with dry crumb. Sometimes

the bread is proofed in oven so that it will be crusted when it goes to oven thus

producing heavier crust on the baked loaf.

French Bread : Made from old fermented dough, it is thick, hard crust

and characteristic taste. Fermentation line 3/4 to 1

1/2

hrs. Molding should be tight with

tight skin without tearing. Gain character is open. Proofing should be just to the point

where it will receive cut and open slightly not over proofed should be baked with low

pressure steam. Steam should be left in the oven for sometime (5mt.) No definite temp

and time of baking is recommended. slow baking produces better results.

DTKFCPL Feb 03 26

Bread Faults

Deviations from the normal bread quality standards, whether perceived subjectively or

determined by objective measurements, are designed by the collective terms bread

faults. They arise from two principal sources : inferior ingredients and improper

processing. in many instances bread faults result from a combination of various factors

so that it is more convenient to classify them into broad categories and indicate the

possible causes that may be involved in each.

Pelshenke has made the very succinct observation that every bakery encounters as

many bread faults as it deserves. This implies that bread faults can be held to a

minimum by paying close attention to the quality of the ingredients and by accurate

control of the production process. It is often quite difficult to the correct diagnose the

immediate cause of a given bread fault and to apply the appropriate remedial action.

However , bread faults will manifest themselves less frequently and their effect will

generally be less serve if an adequate quality control program is adopted and effectively

implemented .Adequate

Quality assurance implies that proper steps are taken at all times to ensure that only

ingredients of satisfactory quality are used, that errors in formulation are avoided, that

proper environmental conditions are consistently maintained. That proper time

temperature and humidity requirements are satisfied without fail at all stages of dough

processing and baking , and that the equipment us maintained in optional operating

condition at all times.

DTKFCPL Feb 03 27

The table below is a list broad classes of common bread faults, together with their

probable causes.

Bread Faults

External Faults

Lack of Loaf Volume

Immature or green Flour

Wrong type of flour.

Insufficient absorption

Insufficient Yeast

Poor quality or mishandled yeast.

Excess salt

Excessive diastatic activity

Lack of shortening

Improper mixing over or under termented dough

Over mentioned or under fermented dough

Dough temperature too low.

Insufficient pan proof.

Insufficient dough weigh for size

Hot Oven

Excessive Loaf Volume

Overaged Dough

Insufficient salt

Over proofing

Overscaling for pan size

Cool oven

Pale crust colour

DTKFCPL Feb 03 28

Insufficient residual sugar

Deficiency in diastatics activity

Excessive mineral yeast food.

Fermentation temperature too high

Old dough

Insufficient humidity in final proof

Cool oven

Low top heat in oven

Under baking

Dark Crush Colour

Excessive sugar in formula

Immature milk Products in formula

Excessive milk products in formula

Hot oven

High top heat in oven

Over baking

Blisters Under Crust

Undermixing

Young dough

Careless moulding

Excessive steam in final proof

Over proofing

Rough handling at oven

Excessive oven steam ( condensation)

Excessive vacuum at depanner (separation)

DTKFCPL Feb 03 29

Thick Crust

Insufficient sugar and shortening in formula

Insufficient milk in formula

Deficient diastatic activity

Old Dough

Insufficient humidity in final proof

Low oven temperature

Over baking

Shell Tops

Immature Flour

Deficient diastatics activity

Inadequate oxidation

Young dough

Insufficient humidity in final proof

Too tight moulding (low pressure board)

Excessive to heat in oven

Insufficient Oven

Wild Break and Shred

Slightly overaged dough

Overmixing

Inadequate oxidation

Insufficient STEAM IN OVEN

Improper moulding (low Pressure Board)

DTKFCPL Feb 03 30

Absences of break and Shred

Weak Flour

Undermixing

Excessively diastatic activity

Over oxidation

Excessive final proof

Excessively hot Oven

Internal Faults

Gray Dull Crumb Color

Excessive diastatics

Overmixing or undermixing

Young Dough (round , thick, cells)

Old dough (open Cell structure)

Improper sheeting and moulding

Underweight dough for pan size.

Excessive proof

Low oven temperature

Streaked Crumb

Improper dough mixing

Excessive dusting flour.

Too much trough grease or divider oil.

Insufficient shortening

Dough crushing during termination and final proof

DTKFCPL Feb 03 31

Improper use of rework dough

Excessive pan grease

Poor Gain

Weak flour

Overly stiff dough

Overly slack dough

Overmixing

Young dough

Improper moulding

Insufficient dough weight for pan size

Low oven temperatures

Poor Texture :

Overly stiff dough

Improper mixing

Excessive diastatic activity

Insufficient Shortening

Old Dough

Crushing of sponge or dough fermentation

Crushing of sponge or dough during fermentation

Over Proofing

Insufficient dough weigh for pan size

Low over heat.

DTKFCPL Feb 03 32

Holes in breads

Immature or weak flour

Unbalanced formula

Improper mixing either over or under mixed

Old dough, young dough

Crusting of sponge or dough during fermentation

Excessive dusting four or divider oil.

Improper moulding

High final proof temperature

Insufficient Oven steam

Poor Flavor

Poor quality ingredients

Improper storage of ingredients

Unbalanced formula

Insufficient salt

Old dough , young dough

Insanitary plant conditions

Old trough and pan grease

Over or underbaking

Poor Keeping Quality

Unbalanced formula

Lean formula

Poor quality ingredients

Improper mixing

Overfermentation

Under proofing

Low oven temperature

Excessive cooling before wrapping.

Vous aimerez peut-être aussi

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Sample Study Material: CSIR-NET Life SciencesDocument74 pagesSample Study Material: CSIR-NET Life Sciencesshravani sahuPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- MODULE 2 IUPAC System NomenclatureDocument18 pagesMODULE 2 IUPAC System NomenclatureJude's TimePas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- WWW - Srmuniv.ac - in Downloads Chapter-Ix Microbiological AssayDocument28 pagesWWW - Srmuniv.ac - in Downloads Chapter-Ix Microbiological AssayAlexiel NguyenPas encore d'évaluation

- Johnson Et Al 2018 Safety Assessment of Tripeptide 1 Hexapeptide 12 Their Metal Salts and Fatty Acyl Derivatives andDocument13 pagesJohnson Et Al 2018 Safety Assessment of Tripeptide 1 Hexapeptide 12 Their Metal Salts and Fatty Acyl Derivatives andSoumi MondalPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- F334 SowDocument48 pagesF334 SowTom MoorePas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Chemistry of Digestion TransesDocument2 pagesChemistry of Digestion Transesbaekhyunee exoPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Physical Science Grade 12 Definitions Paper 2 Free StateDocument114 pagesPhysical Science Grade 12 Definitions Paper 2 Free StateKenneth100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Application of Vermicast and Fermented Plant Juice On The Growth and Yield Performance of RadishDocument16 pagesApplication of Vermicast and Fermented Plant Juice On The Growth and Yield Performance of RadishJevelyn Mendoza FarroPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Stainless Steel (Ss316L/En2348) Chemical Compatibility ChartDocument12 pagesStainless Steel (Ss316L/En2348) Chemical Compatibility ChartEntropay UserPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Effects of Minor Constituents On Cold Flow Properties and PerformanceDocument9 pagesEffects of Minor Constituents On Cold Flow Properties and PerformanceNestor Armando Marin SolanoPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Introduction To WaterproofingDocument44 pagesIntroduction To Waterproofingg7711637100% (2)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Degenerate PrimerDocument2 pagesDegenerate PrimerAmod KumarPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Gasohol ProductionDocument16 pagesGasohol ProductionPrashant Kumar82% (11)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Synthesis of Important DyesDocument80 pagesSynthesis of Important DyesVishal Dhapa100% (1)

- 2015 Authenticity of Essential Oils PDFDocument12 pages2015 Authenticity of Essential Oils PDFvaminosPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- 26 Biology 2 - 16 - 08 Cellular RespirationDocument48 pages26 Biology 2 - 16 - 08 Cellular RespirationNiranjan BhuvanaratnamPas encore d'évaluation

- Fixing AgentsDocument2 pagesFixing Agents10jackyPas encore d'évaluation

- Syllabus For Master of Science in Organic Chemistry Part-Ii (Semester III and IV)Document14 pagesSyllabus For Master of Science in Organic Chemistry Part-Ii (Semester III and IV)Bhushan ChaudhariPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- DFDVDVVCVCX XC VXC VX VXCVVCXDocument14 pagesDFDVDVVCVCX XC VXC VX VXCVVCXaadadadPas encore d'évaluation

- Cape Biology - Unit 1 - EnzymesDocument7 pagesCape Biology - Unit 1 - EnzymesSteven IStudy Smith67% (3)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

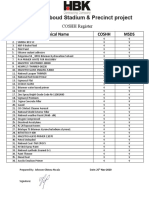

- Ras Abu Aboud Stadium & Precinct Project: Chemical Name Coshh MsdsDocument1 pageRas Abu Aboud Stadium & Precinct Project: Chemical Name Coshh Msdssharon Aisha malroy100% (1)

- Some of The Physical and Mechanical Properties of Composites Made From Tetra Pak™/LDPEDocument13 pagesSome of The Physical and Mechanical Properties of Composites Made From Tetra Pak™/LDPEhectoriturbePas encore d'évaluation

- Energy Flow and Material Cycling Through The EcosystemDocument5 pagesEnergy Flow and Material Cycling Through The EcosystemJaffy BustamantePas encore d'évaluation

- Minesite Water Management HandbookDocument128 pagesMinesite Water Management Handbookedatgka100% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- PRACTICE MCQ HYDROCARBONS - 11ScADocument7 pagesPRACTICE MCQ HYDROCARBONS - 11ScAArda RahmainiPas encore d'évaluation

- Yamada Ecuacion de Rackett PDFDocument3 pagesYamada Ecuacion de Rackett PDFNapoleon BerriosPas encore d'évaluation

- Validation of A Cleaning Process For Medical DevicesDocument7 pagesValidation of A Cleaning Process For Medical DevicesmanchorusPas encore d'évaluation

- Water Tightness EquipmentDocument9 pagesWater Tightness EquipmentZivadin LukicPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Mid-Term: ExaminationDocument2 pagesMid-Term: ExaminationrahulPas encore d'évaluation

- Tri Pure Isolation ReagentDocument8 pagesTri Pure Isolation ReagentMiftahuddin MadjidPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)