Académique Documents

Professionnel Documents

Culture Documents

Ccs 125m Funding

Transféré par

kirandas_mullasseryCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Ccs 125m Funding

Transféré par

kirandas_mullasseryDroits d'auteur :

Formats disponibles

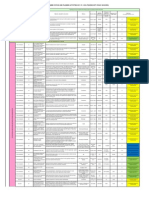

LCICG PROGRAMME STATUS AND PLANNED ACTIVITIES 2011-15 - CCS (TSB/DECC/ETI/ RCUK/ UKCCSRC)

Running or announced (with results known) projects /programmes Apr 2011-Mar 2015 Total project investment (public sector, private, other (eg EU)) M

Technology Area

id Programme (project) title Objective, rationale for intervention Partners Duration (dates)

Funders (HMG, ETI & International)

Assumed 11/15 public spend

TRL Focus (Technology Readiness Level)

Full chain

Computational modelling and Tackling current barriers of reactor scale-up in carbon capture of gas power optimisation of carbon capture plants using advanced CFD research

Cranfield

Oct12 - Sep16

EPSRC

0.58

0.580

Fundamental Research & Understanding

Full chain

FULL CHAIN

Computational Chemistry of Hybrid Frameworks

To allow the evaluation of new hybrid frameworks in a number of key fields, such as CO2 adsorption and storage

UCL

Sept 07-Aug 12

EPSRC

0.50

0.100

Fundamental Research & Understanding

Full chain

Carbon Capture and Storage: Techno-economic studies of CCS (3 projects) Realising the Potential Multiscale whole systems modelling and analysis for CO2 capture, transport and storage CCS System Modelling Toolkit Methodologies to design and analyse future CCS systems- generating insights into the most important interactions involved in system design and operationquantifying (economics, environmental impact, safety & operability) the performance of UK CCS systems Provide tool to assit in design and assessment of future CCS systems (whole chain, power generation to storage)

TOTAL PUBLIC INVESTMENT FULL CHAIN (M)

Uni Sussex +

Apr 10-Mar12

NERC/EPSR C/ESRC (UKERC via NERC)

0.41

0.220

Fundamental Research & Understanding

Full chain

Consortium

Jun 10 -May13

EPSRC

1.42

1.000

Fundamental Research & Understanding

Full chain

PSE, E4tech, EDF, E.ON, Petrofac, Rolls-Royce

September 2011 - April 2014

ETI

3.6

3.000

n/a

Component Development & Applied Research

6.513

4.900

Pre-combustion

Novel Catalytic Membrane Micro-reactors for CO2 Capture via Pre-combustion Decarbonisation Route Joint UK/China hydrogen production network

Advance membrane micro reactor for precombustion

Imperial

Jan11-Dec 13

EPSRC

0.458

0.430

Fundamental Research & Understanding

Pre-combustion

Advanced chemical cycles which allow clean hydrogen to be produced without a large energy penalty for capturing the CO2.

Consortium

Oct 09 - Sept 12

EPSRC

0.500

Fundamental Research & Understanding

Pre-combustion

The Next Generation of Activated Carbon Adsorbents Develop activated carbon adsorbents and system models to improve the for the Pre-Combustion efficiency, flexibility and operability of IGCC processes Capture of CO2 e-WaGS: Efficient Water Gas Development of Water Gas Shift technology for IGCC in which carbon Shift Technology for Lowmonoxide produced by gasification is reacted with steam to produce hydrogen Carbon Electric Power and CO2. Generation from Fossil Fuels Next Generation Capture Technology

Consortium

Nov11-Dec13

EPSRC

0.694

0.694

Fundamental Research & Understanding

Pre combustion

BP, Johnson Matthey

Feb 2010-Jan 2013

TSB/DECC

2 (total); 1 (public)

0.600

3 to 4

Fundamental Research & Understanding/ Component Development & Applied Research

Pre combustion

10

Advanced technology to reduce cost of CO2 capture in pre-combustion

Costain Millennium Generation; Calix (Europe) Limited; HEL East Limited; Imperial College

July 2011 June 2015 September 2012 - April 2014

ETI

23.5

1.500

5-6

Pilot Scale Demonstration

Pre combustion

11

Development of calcium looping technology. This 3MWe demonstrator is the Carbon capture pilot using an basis for scale up to 50MWt units for (i) industrial applications (ii) in multiple Endex Reactor units to decarbonise the fuel gas of NGCC or IGCC power stations. CO2 separation by adsorption onto nanoporous materials, materials by "filtration" of CO2 from power plant flue gases by newly created semipermeable membranes, and by membrane separation of oxygen from air, to enable oxy-fuel combustion and efficient CO2 separation (2 projects) High temperature ceramic membranes for energy applications and CO2 capture

DECC

5.8 (public)

5.800

Pilot Scale Demonstration

Post combustion

12

Carbon Capture from power plant and atmosphere Ceramic membranes for energy applications and CO2 capture Fundamentals of Optimised Capture Using Solids (FOCUS)

Heriot Watt +

Nov 08-Nov 13

EPSRC

4.45

2.000

Fundamental Research & Understanding

Post combustion

13

2 Projects, Newcastle +

Apr 09-Apr 14

EPSRC

1.1

0.700

Fundamental Research & Understanding Fundamental Research & Understanding

Post combustion

14

Solid adsorption of CO2 and UK-China collaboration

Consortium

Jan 11-Dec13

EPSRC

0.568

0.500

Post combustion

15

Innovative Adsorbent Materials and Processes for Simultaneous removal of SOx, NOx, HCl, HF, and toxic metals, particularly Integrated Carbon Capture mercury- China Collaboration and Multi-pollutant Control for Fossil Fuel Power Generation Methodologies for the rapid synthesis and screening of novel materials and solvents for carbon capture from power stations. Focus on absorption, adsorption and membrane processes combining molecular modelling and advanced process modelling A systematic, multiscale approach, which considers the detailed behaviour of the solid oxygen carriers, through to the systems level integration into a power station and energy grid

Nottingham

Oct 09-Sept 13

EPSRC

0.952

0.500

Fundamental Research & Understanding

Post combustion

16

Innovative Gas Separations for Carbon Capture

Consortium

Oct 09-Mar 13

EPSRC

1.89

1.000

Fundamental Research & Understanding

Post combustion

17

Multi-scale evaluation of advanced technologies for capturing the CO2: chemical looping applied to solid fuels.

Consortium

Jan11-Dec 13

EPSRC

0.578

0.510

Fundamental Research & Understanding

Post-combustion

18

Accelerate the pace of development of adsorbent technology as a viable Step Change Adsorbents and alternative to chemical absorption in post-combustion capture...The ultimate Processes for CO2 Capture. goal of the project is to demonstrate the adsorbent materials in real power plant environments Adsoprtion materials and processes for carbon capture from gas-fired power plants (AMPGas) Effective adsorbents for establishing solids looping as a next generation CCGT technology Advanced GasCCS (GasFACTS)

Consortium

Nov 09- Oct 13 EPSRC/E.ON

0.158

0.800

Fundamental Research & Understanding

Post-combustion

19

Capture technology for retrofit to existing CCGT plants. Addressing both materuals and process development for carbon capture.

Consortium / Edinburgh

Sept12 - Aug15

EPSRC

1.1

1.100

Fundamental Research & Understanding

CAPTURE TECHNOLOGIES INCLUDING COMPONENTS, SYSTEMS OR DEMONSTRATORS

Post-combustion

20

To overcome the perofmrance barriers for implmenting adsorbent systems i the solid looping technology specifically for CCGT power plants

Consortium

Aug12 - Jan16

EPSRC

0.78

0.600

Fundamental Research & Understanding

Post-combustion

21

Underpinning research for development and deployment on natural gas power plants, particularly for gas turbine modifications and advanced post combustion capture technologies for gas power plants

Consortium

Apr12 - Mar15

EPSRC

2.46

2.460

Fundamental Research & Understanding Fundamental Research & Understanding

Post-combustion

22

Carbon capture in the refining To develop a vacuum swing adsoprtion process to capture CO2 from a H2 process plants in the refining process New approach to extend durability of sorbent powders for multicycle high temperature CO2 capture in hydrogen Feasibility of a wetting layer absoprtion carbon capture process based on chemical solvents

Edinburgh

June12 - May 13

EPSRC

0.1

0.100

Post combustion

23

Materials engineering proposal addressing the major problem facing utlisiation of powder sorbents such as CaO for high temperature applications

Leeds

May12 - Oct13

EPSRC

0.168

0.168

Fundamental Research & Understanding

Post combustion

24

To investiogate a novel process based on the wetting layer absorption concept in which a porous material is used to support liquid-like regions of absorbing solvent, which in turn absorb carbon dioxide

Strathclyde/Edinburgh

Oct12-Sep15

EPSRC

1.2

1.200

Fundamental Research & Understanding

Post combustion

25

Chemical looping for low-cost Chemical looping (combustion, CLC) using fluidised beds at industrial scale oxygen production and other within the UK - experimental work and theoretical analysis tfor first large-scale applications demonstration of CLC within the UK. Membrane processes as an alternative to post-combustion capture technologies due to the reduced maintenance of the process, the absence of dangerous solvents and their smaller footprint. This project aims - support development of new mixed matrix membranes for post-combustion applications. fundamental knowledge is crucial in order to design the reliable materials needed for real-world-applications.

Imperial College London, Cranfield University & University of Cambridge

12 months

UKCCSRC

0.299

0.239

1 -3

Fundamental Research & Understanding

Post combustion

26

Mixed matrix membranes preparation for postcombustion capture

University of Edinburgh

36 months

UKCCSRC

0.072

0.058

1-3

Fundamental Research & Understanding

Post combustion

27

demonstrate 2nd generation carbon capture technology on an industrial Project Coral Integrated chemicals site: Carbon Water Exchange (CWX), an innovative, electroCHP, carbon water exchange chemical based sequestration technology that remediates principally CO2, Pilot Demonstration SOx&NOx from fossil fuel combustion emissions.

Future Environmental Technologies Group, Solutia UK; Hoare Lea & Partners; DB Core Ltd; Malvern Executives

November 2012 April 2015

DECC

2 (public)

2.000

Pilot Scale Demonstration

Post combustion

28

Ferrybridge CC Pilot 100+

Largest Pilot plant demonstration in UK,5MWe, 100t CO2 capture/day. System integration, solvent evaluation, skills & training

SSE, Doosan, Vattenfall

Jan 2011-2013

TSB/DECC

21 (total); 6.75 (public)

5.000

5-6

Pilot Scale Demonstration

Post combustion

29

Next Generaton capture for gas fired (CCGT) power stations

Advanced technology to reduce cost and capture penalty for retrofit and newbuild gas-fired power stations

tbn

July 2012 - Dec 2015

ETI

25

22.000

5-6

Pilot Scale Demonstration

Post combustion

30

Industrial CO2 as a precursor to sustainable biomass: Develop an innovative, algae based solution for the significant reduction of reducing energy consumption large scale industrial CO2 emissions. and CO2 footprint RECAP - Reduced Elevation CO2 Absorber Programme New Solvents for CO2 Capture develop innovative absorber configurations to lower the cost of CCS electricity generation from fossil fuel (or biomass) combustion

CPI, Sembcorp, Cemex, Steetley

April 2010-Feb 2013

TSB/DECC

2.6 (total); 1.2 (public)

0.775

Component Development & Applied Research

Post combustion

31

Costain, University of Edinburgh

Jan2013 - Dec 2013

DECC

0.157 (public)

0.157

Component Development & Applied Research Component Development & Applied Research

Post combustion

32

New solvent testing

C-Capture, PACT Carbon Clean Solutions; Imperial College; UK CCS Research Centre PACT facilities CMCL Innovations, Doosan, Drax, EDF, E4tech, Imperial College, University of Cambridge, University of Leeds Consortium

DECC

0.750

Post combustion

33

Process Design and Process standardization, intensification and industrial scale up for novel Optimization of New Solvents solvents that will reduce solvent regeneration energy footprint. for CO2 Capture Techno-economic assessment Identify opportunities and issues around use of biomass with CCS (co-firing of Biomass with CCS and 100% biomass) to achieve net negative CO2 emissions

October 2012 April 2014

DECC

3.621 (public)

3.621

Component Development & Applied Research

Post combustion

34

April 2011 July 2012 July09 - June 13

ETI

0.7

0.700

4-6

Component Development & Applied Research Fundamental Research & Understanding

Oxy-fuel

36

Oxyfuel combustion Experimental investigation and CFD modelling of oxycoal combustion on PACT facility with real flue gas and vent gas recycling

Academic programme to develop a better understanding investigating impacts of real flue gas and vent gas recycling on the combustion performance, emissions, ignition and flame stability of oxy-coal combustion by means of 250kW PACT facility testing and comprehensively validated CFD modelling, and to assess various flue gas recycling scenarios and the benefits of vent gas recycling by process simulation.

EPSRC/E.ON

1.8

0.800

Oxy-fuel

37

University of Nottingham & University of Leeds

24 months

UKCCSRC

0.254

0.203

1-.3

Fundamental Research & Understanding

Oxy-fuel

38

Oxyfuel and exhaust gas recirculation processes in gas turbine combustion for improved carbon capture performance In-depth Studies of OxyCoal Combustion Processes through Numerical Modelling and 3D Flame Imaging OxyPROP Oxyfuel Penalty Reduction Option Project

Oxyfuel based generating plant for CCGT-CCS processes. enhancement of oxygen in the combustion process and enhancement of CO2 concentration in plant exhaust via Exhaust Gas Recycling (EGR) to increase the net efficiency of CO2 scrubbers. Oxyfuel and EGR are potentially promising technologies for integration with CCGT-CCS processes, there is lack of fundamental data on design and reliable operation of industrial burner systems with this technology. Understanding of the impact of oxycoal on flame characteristics, critical reaction kinetics, and devolatilsation and char reaction in the combustion processes - China collaboration

Cardiff University

12 months

UKCCSRC

0.99

0.792

1-3

Fundamental Research & Understanding

Oxy-fuel

39

3 Projects

To mid 2013

EPSRC

0.800

Fundamental Research & Understanding

Oxy-fuel

40

Address key penalties for oxyfuel combustion of coal and biomass in boiler January 2013 Costain; University of plant through novel application of innovative CO2 separation and compression December Edinburgh; University of Leeds technology. 2013 PUBLIC INVESTMENT CAPTURE (M) Consortium led by Loughborough with Cardiff, Cranfield, Imperial, Nottingham, Warwick. Industrial Partners: Alstom; EDF; Emerson Process Mgmt; R-MC Power Recovery Ltd; SSE; TWI; Doosan; Goodwins Steel Castings; Rolls Royce; Siemans plc; E.on; Eggborough Power Ltd; NPL; RWE npower; TSB Consortium

DECC

0.192 (public)

0.192

Component Development & Applied Research

91.991

59.249

35

Flexible and Efficient Power Plant: Flex-E-Plant

key issues of Plant Efficiency, Plant Flexibility, Fuel Flexibility and Sustainability and how impact upon plant operation and design, combustion processes and structural integrity of conventional and advanced materials utilised in conventional power plants. Outcomes: understanding of economic viability; Novel & improved monitoring; new models for optimising operating conditions.

March 2013 Sept 2017

EPSRC

1.000

Fundamental Research & Understanding

41

SUPERGEN - Conventional Development of novel tools and technologies to extend the life of existing power plant lifetime extension conventional steam and combined cycle power plants SUPERGEN - Bioenergy hub Advanced surface protection for CCS plant Carbon Abatement Using Surface Engineering Technologies (CASET) Whole systems approach to bionergy, including increasing understanding of biomass combustion and bio-CCS Coating development to improve steam plant reliability

July08-Dec12

EPSRC

4.2

1.500

Fundamental Research & Understanding

42

Consortium EON, Alstom, RWE, Loughborough Uni

Aug12-Jul17

EPSRC

3.55 1.4 (total); 0.65 (public)

3.000

Fundamental Research & Understanding Component Development & Applied Research

CONVERSION AND GENERATION

43

TBA

TSB

0.400

Component development (including efficiency improvements eg gas, steam turbine, boiler) & co-firing

44

Coating development to improve gas turbine component reliability in co-firing, oxy-fuel firing

Siemens, Praxair, Cranfield, Uni Birmingham Rolls Royce, SERCO, Cranfield Uni, Swansea University EON, RWE, Doosan, Alstom, NPL, Loughborough Uni, Goodwin Steel Castings

April 2010-Jan 2013 May 2010-April 2013

TSB/DECC

1.7 (total); 0.85 (public) 1.7 (total); 0.85 (public)

0.540

Component Development & Applied Research Component Development & Applied Research

45

46

47

Gas turbine operation in aggressive environments.Develop and verify life Corrosion LIfing Methods And prediction methods for corrosion assisted fatigue that will allow plant to be TEsting (CLIMATE) operated safely under more arduous conditions. IMPACT - Innovative Materials, Design and To improve the efficiency of future coal-fired power plant, through Monitoring of Power Plant to development and application of high T materials Accommodate Carbon Capture Verified Approaches to Life Management & Improved Improved reliability of future coal-fired power plant, through improved weld Design of High Temperature integrity of high T materials Steels for Advanced Steam Plants VALID Fast REsponse Temperature Sensors for GAs Turbine Efficiency (FRETSGATE Advanced sensors and control systems for flexible fueled GTs,including IGCC

TSB/DECC

0.582

April 2010-Feb 2013

TSB/DECC

1.8 (total); 0.9 (public)

0.582

Component Development & Applied Research

TWI, Air Liquide, Polysoude, SSE, Doosan, Centrica, Metrode

Jan 2012-Dec 2014

TSB/DECC

1.1 (total); 0.46 (public)

0.460

Component Development & Applied Research

48

Oxensis, Rolls-Royce, Siemens

March 2010Feb 2013

TSB/DECC

1.2 (total); 0.6 (public)

0.381

Component Development & Applied Research

49

High Hydrogen

To assess the issues of burning high levels of hydrogen in gas turbines and engines

Health & Safety Laboratories, Imperial College

July 2011 June 2014

ETI

2.2

2.200

5-6

Component Development & Applied Research / Pilot Scale Demonstration

50

Materials for NetPower oxy combustion process

Development of high performance materials to enable higher pressure turbine operation and in turn higher pressure temperature and pressure supercritical CO2 power generation cycle to capture emissions at low cost

Net Power Plc; Toshiba; Shaw Power Group Ltd; Goodwin Steel Castings

September 2012 - March 2015

DECC

4.98 (public)

4.980

5-6

Component Development & Applied Research / Pilot Scale Demonstration

TOTAL PUBLIC INVESTMENT CONVERSION/GENERATION (M) "The aims of this PhD research are to develop workflows and methodologies of using 3D seismic data to track potential leakage routes of CO2 through likely Quantifying the risk of leakage sealing lithologies.The main thrust of this research will be to quantify the of CO2 from subsurface leakage flux of methane via contrasting leakage routes to yield a relative riskstorage sites based ranking of bypass systems and other leakage mechanisms for a range of potential storage sites"

21.24

15.625

51

Cardiff

Oct10-Sept14

NERC

0.066

0.050

Fundamental Research & Understanding

52

QICS2 Scoping Project: Exploring the viability and scientific opportunities of a follow-on marine impact project

A key element of risk assessment for the geological storage of CO2 offshore is the monitoring of transport of leaks from the subsurface via shallow sediments in the marine environment, including its effect on the ecosystem. In 2012, the NERC-funded QICS project constructed the first marine in situ controlled subseabed release facility for CO2 in the world in Ardmucknish Bay, Oban when 4.2 tonnes of CO2 was injected. There is significant international interest in this University of Edinburgh, PML unique facility and the project provides an opportunity for the UK to consolidate & SAMS its leadership in environmental monitoring and impact studies for CCS. This scoping project will explore with the local community, stakeholders and the broader scientific community the viability and potential scientific goals for a follow on project, with the capability of delivering useful knowledge at the start of the UK CCS commercialisation program.

6 months

UKCCSRC

0.058

0.046

1-3

Fundamental Research & Understanding

53

CO2 MONITORING

MMV AND M&R including remote or in situ, for deep water and along transport network

The project will three-dimensionally image hydraulically conductive features in the reservoir, caprock and overburden of an active CO2 injection site: the Aquistore site, Canada. Our research will provide important information on potential migration pathways within the storage complex to inform future 3D mapping of large-scale monitoring strategies at the Aquistore site and at future storage sites. We will subsurface flow pathways monitor micro-seismic events prior to, and during, CO2 injection using a threeusing nanoseismic monitoring component nanoseismic surface monitoring array which will complement data collected by the existing geophone network at the site. This analysis can be used to provide deep focussed monitoring information on permeability enhancement near the injection point. As injection continues it will also enable imaging of any flowing features within the caprock. Nanoscale Gravity Sensors for Monitoring CO2 Storage Development of an innovative gravity imaging system based upon a e high sensitivity accelerometer capable of making quantitative measurements of CO2 volume which can be deployed down reservoir borehole

University of Strathclyde & University of Edinburgh

24 months

UKCCSRC

0.073

0.058

1-3

Fundamental Research & Understanding

54

BP, Cambridge University

March 2010Feb-2013 April 2010-Feb 2013 TBA

TSB/DECC

1.2 (total); 0.56 (public) 0.7 (total); 0.35 (public) 2 (total); 0.9 (public) 5

0.352

Component Development & Applied Research Component Development & Applied Research Component Development & Applied Research Component Development & Applied Research / Pilot Scale Demonstration Component Development & Applied Research

55

Carbon Storage: assessment Develop a suite of advanced CO2 sensing technologies that combine to and validation of emissions (Cprovide validated monitoring of each stage of the CCS process SAVE) Project AMADEUS Marine and shallow monitoring MMV system Project COMET (Coriolis Metering Technology in CO2 Transportation for CCS) CO2 Monitoring for downhole applications and field trial Develop techniques and overall system for monitoring for CO2 in marine and shallow-subsurface environment Assess suitability of available metering technologies for use in CO2 transportation by pipeline

Signal Group, NPL, BP Guardian Global Technologies, Strathclyde Uni, National Grid tbn - project in commissioning

TSB/DECC

0.226

56

TSB

0.900

57

2013 - 2015 December 2012 December 2013

ETI

5.000

5-6

58

Interconnector; Heriot-Watt University

DECC

0.085 (public)

0.085

59

Carbon Storage Monitoring Using Muon Tomography

Premier Oil Plc; Durham University; University of Sheffield; University of Bath; Newcastle University; National Grid Carbon Limited; Development and testing of novel technique (cosmic ray muon tomography) to Cleveland Potash Limited; monitor CO2 movement. Applications for geological storage of CO2. Rutherford Appleton Laboratory; NASA Jet Propulsion Laboratory, California Institute of Technology (Caltech)

University of Edinburgh

December 2012 April 2015

DECC

0.647 (public)

0.647

Component Development & Applied Research

65

Fingerprinting captured CO2 using Funded through EPSRC 2012 Call Challenges in Geological Storage for CCS - project looking at natural tracers: Determining CO2 fate monitoring CO2 using natural tracers and proving ownership TOTAL PUBLIC INVESTMENT CO2 MONITORING (M)

June13-June15

EPSRC

0.236

0.157

Fundamental Research & Understanding

7.975

7.522

60

61

Multiphase flow modelling for Accurate prediction the transient outflow following the accidental failure of hazard assessment of dense dense-phase CO2 pipelines transporting various stream impurities. -public phase CO2 pipelines acceptability of CO2 pipelines containing impurities first design and operating guidelines for the flexible operation of CCS pipeline networks. The research will explore how CCS pipeline networks can react Flexible CCS Network effectively to short, medium and long term variations in the availability and Development flow of CO2 from capture plants, as well as responding to the constraints imposed on the system by the ability (or otherwise) of CO2 storage facilities to accept variable flow. This project will determine the dew point of water, or "water solubility", in impure CO2 mixtures (e.g. containing N2 and H2). At present, key data for defining water levels have not been determined. The data are important because liquid water is highly acidic in the presence of excess CO2; this acidity can be increased by trace amounts of SO2 and H2S and acidity will greatly accelerate corrosion. This research will provide the first accurate data for CO2 transportation systems, which can be used to develop accurate equations of state and define more robust pipeline specifications. These in turn can be applied to inform cost benefit analyses on the additional costs on the pipeline material and construction balanced against the cost of purification and the needs of safety. The research will provide critical physical property data to enable the safe and cost effective transportation of CO2. modelling the phase behaviour of impure carbon dioxide, under the conditions typically found in carbon capture from power stations, and in high-pressure (liquid phase) and low-pressure (gas phase) pipelines. This project will use cutting-edge computer algorithms to automatically reparameteriseEoS for CCS modelling.

University College London

14 months

UKCCSRC

0.115

0.092

1-3

Fundamental Research & Understanding

Newcastle University & University of Edinburgh

15 months

UKCCSRC

0.221

0.177

1-3

Fundamental Research & Understanding

CO2 TRANSPORT

Onshore & offshore transport; including optimisation of network, pipe issues

62

Determination of water solubility limits in CO2 mixtures to deliver water specification levels for CO2 transportation

University of Nottingham

12 months

UKCCSRC

0.1

0.080

1-3

Fundamental Research & Understanding

63

Tractable equations of state for CO2 mixtures in CCS: algorithms for automated generation and optimisation, tailored to end-users

University of Nottingham

12 months

UKCCSRC

0.093

0.074

1-3

Fundamental Research & Understanding

64

Materials for Next Generation CO2 Pipeline Transport Systems (MATTRAN) Materials for Next Generation will take that lead and provide the tools and information necessary for pipeline CO2 Transport Systems engineers to select appropriate materials and operating conditions to control (MATTRAN) corrosion, stress corrosion cracking and fracture propagation in pipelines and associated equipment carrying supercritical CO2 from the capture processes TOTAL PUBLIC INVESTMENT CO2 TRANSPORT developing our understanding of the geometry and properties of the CO2 storage in Palaeogene overburden above the potential reservoirs (including their seals), and by and Neogene hydrogeological developing an understanding of the likely hydraulic connectivity in the systems of the North Sea: reservoirs, surrounding strata and overburden and hence the likely flow paths preparation of an IODP for CO2 and formation brine within and between them. These reservoirs scientific drilling bid promise to be of great significance if CCS

Newcastle

Oct 09-Jan13

EPSRC/E.ON

1.54

0.900

Fundamental Research & Understanding

2.069

1.323

66

BGS & University of Edinburgh

24 months

UKCCSRC

0.289

0.231

1-3

Fundamental Research & Understanding

67

68

Predicting the fate of CO2 in geological reservoirs for Determining the nature and kinetics of fluid-rock interactions between CO2-rich modelling geological carbon brines and rocks, in field settings as well as in laboratory experiments, storage Determining the nature and kinetics of fluid-rock interactions between CO2-rich Quantifying and Monitoring brines and rocks, in field settings as well as in laboratory experiments, in order Potential Ecosystem Impacts to formulate and test models of the behaviour and fate of CO2 injected in g of Geological Carbon Storage eological strata. -Create a database and methodology that enables the results (QICS) of this study to be used in risk a ssessments and performance modelling of geological carbon storage sites. Derive physically correct dispersion models for multicomponent multiphase Dispersive Mixing in flow and to implement them in a three-dimensional streamline-based reservoir Multicomponent Multiphase simulator. When this project is completed, the simulator will be used to design Flow: Numerical and Physical efficient CO2 storage and enhanced oil recovery projects with a higher-degree Effects of certainty that stored CO2 will remain in oil reservoirs for geologic time Geological characterisation of deep saline aquifers for CO2 Use of borehole data and seismic reflection surveys to provide improved storage on the UK Continental geological characterisations of 3 deep saline aquifers systems, located in the Shelf using borehole and 3D Inner Moray Firth, Southern North Sea and East Irish Sea basins seismic data Fundamental study of migration of supercritical carbon dioxide in porous media under conditions of saline aquifers

Cambridge + 3 projects

2008-2013

NERC

2.96

1.500

Fundamental Research & Understanding

PML lead +7 projects

2010-2013

NERC

1.32

1.000

Fundamental Research & Understanding

69

Oct 08-Sept11

NERC

0.33

0.100

Fundamental Research & Understanding

70

Durham

Oct 09-Sept 13

NERC

0.065

0.030

Fundamental Research & Understanding

71

Development of computational solvers to predict CO2-brine multiphase flows in porous media China collaboration

Jan11- Dec13

NERC

0.485

0.400

Fundamental Research & Understanding

72

The Propagation of Wetting Novel modelling techniques for the movement of CO2 and HCs through Fronts Through Porous Media reservoirs An integrated geophysical, geodetic, geomechanical and By detecting microseismic emissions, it is possible to determine how the geochemical study of CO2 subsurface is responding to CO2 injection. storage in subsurface reservoirs Investigating the role of Develop workflows and methodologies of using 3D seismic data to track natural tracers in subsurface potential leakage routes of CO2 through likely sealing lithologies CO2 storage and monitoring

CO2 injection and storage - Short Funded through EPSRC 2012 Call Challenges in Geological Storage for CCS - project optimising and long-term behaviour at different the injection of CO2 into reservoirs and saline aquifers spatial scales Imperial (+Progressive Energy Limited)

Nov09-Oct 12

NERC

0.215

0.100

Fundamental Research & Understanding

CO2 STORAGE

73

Bristol

Sept11 - Aug14

NERC

0.249

0.249

Fundamental Research & Understanding

74

July09- June12

NERC

0.284

0.100

Fundamental Research & Understanding

75

June13-Sept16

EPSRC

1.212

0.606

Fundamental Research & Understanding

95

DiSECCS: Diagnostic Seismic toolbox for the Efficient Control of CO2 Storage The impaCt of hydrOcarbon depletioN on the Treatment of cAprocks within performance assessment for CO2 InjectioN schemes - CONTAIN

Funded through EPSRC 2012 Call Challenges in Geological Storage for CCS - project will identify storage reservoir types suitable for large-scale CO2 storage, develop monitoring tools for safe storage as well some work to explore public attitudes to CO2 storage.

BGS-NERC (+ BP Exploration Operating Company Ltd; DECC; Statoil Petroleum ASA)

April13-March16

EPSRC

0.894

0.596

Fundamental Research & Understanding

96

Funded through EPSRC 2012 Call Challenges in Geological Storage for CCS - project assessing BGS-NERC (+ Shell Global Solutions the impacts of CO2 injection on reservoirs and caprock and International BV)

May13 - 30Apr17

EPSRC

0.925

0.370

Fundamental Research & Understanding

76

UK Storage Appraisal Project (UKSAP)

Realistic, defensible & fully auditable assessment of potential CO2 storage capacity in the UK

Senergy Alternative Energy, BGS, Durham University, Element Energy, Geopresure Technology, Geospatial Research, Heriot Watt University, Imperial College, RPS Energy, University of Edinburgh

October 2009 October 2011

ETI

1.000

Fundamental Research & Understanding

77

Long term performance of geological seals to carbon storage

Assessment of risks of leakage from geological storage due to long-term exposure of caprocks and faults to CO2 and CO2-rich fluids. Project will sample caprocks to natural carbon dioxide reservoirs in Utah, USA UKs first drilling assessment of a saline formation site for the storage of CO2, at a site 70km off Flamborough Head in Yorkshire (saline formation; a layer of porous sandstone rock over 1km below the seabed). The operation, using standard oil and gas drilling activities, will involve drilling up to two wells in the seabed to gather data to confirm: CO2 can be safely and permanently stored at the site and; the scale and economics of the store.

TOTAL PUBLIC INVESTMENT CO2 STORAGE (M)

Shell Global Solutions; University of Cambridge; Manchester University; October 2012 Natural Environment Research April 2015 Council through British Geological Survey

DECC

0.735

0.735

Component Development & Applied Research

78

Aquifer Appraisal Project

National Grid

October 2012 December 2013

ETI

2.000

Pilot Scale Demonstration

15.963

9.017

79

Design and development of a new class of sulphide catalysts, tailored Bioinspired nano-catalysts for specifically to the reductopn and conversion of CO2 into chemical feedstock CO2 conversion molecules Nano-structured catalysts for CO2 reduction to fuels Nano-integration of metalorganic frameworks and catalysis for the uptake and utlisation of CO2 A Coordinated, Comprehensive approach to Carbon Capture and Utilisation Mineralisation Project Production of polymers using CO2 Novel fibre technology to generate soil fertiliser using CO2 Development of new, highly active metal/metal oxide nano-structured catalysts toenable use of carbon dioxide as the fuel and feedstock material One step CO2 capture and utilisation by linking catalysts directly with a novel CO2 absorber

Consortium

May10-Apr13

EPSRC

1.14

1.000

Fundamental Research & Understanding Fundamental Research & Understanding Fundamental Research & Understanding

80

Consortium

May10-Ap13

EPSRC

1.7

1.100

81

Consortium

May10-Ap13

EPSRC

1.19

0.800

82

This project is looking at ways in which a portion of the methane can be used to convert the CO2 into fuel To assess the techno-economic feasibility of Mineralisation to abate at least 2% of UK CO2 emissions Characterisation of the polymers produced using CO2 from a power station. The polymers produced, could replace polymers derived from petroleum feedstocks. Validate benefits of novel process to produce fertliser from plant derived material combined with CO2. Use of marine transport will be assessed for economic distribution of agricultural product produced

Consortium

Sep12 - Mar17

EPSRC

4.6

4.000

Fundamental Research & Understanding Component Development & Applied Research Component Development & Applied Research Component Development & Applied Research

CO2 UTILISATION

Alternative uses for CO2 eg mineralisation, commercial products

83

Caterpillar, BGS,University of Nottingham Econic Technologies Ltd, Imperial College London

May 2010 August 2012 January 2013 December 2013 January 2013 August 2013 December 2012 December 2013 December 2012 November 2013

ETI

1.3

0.770

84

DECC

0.103 (public)

0.103

85

CCm Research

DECC

0.079 (public)

0.079

86

Engineering feasibility study to establish technological/ financial/ operational Methanation: CO2 as a issues of using hydrogen from renewable energy sources to turn CO2 (from feedstock for synthetic natural industrial sources) into synthetic methane; its role as a demand side gas and energy storage management technology and potential as scalable energy storage. Mineralisation: using novel algae and high-efficiency bioreactor technology to create high value chemicals from captured CO2 feasibility project to determine novel & cost effective method to convert captured CO2 into commodity product via a mineralisation process using a new genetically engineered microalgae. and a patented microbubble technology within a bioreactor-based process

TOTAL PUBLIC INVESTMENT CO2 UTILISATION (M)

ITM Power Trading Ltd; Scotia Gas Networks (SGN); Logan Energy Ltd (LEL); Kiwa GASTEC at CRE (KGC) Carbon Sequestation; Perlemax Ltd; Viridor Waste Management Ltd; University of Sheffield

DECC

0.1 (public)

0.100

Component Development & Applied Research

87

DECC

0.079 (public)

0.079

Component Development & Applied Research

10.291

8.031

88 89

Centre for Innovation in CCS CO2Chem network Efficient Power from Fossil Energy and Carbon Capture Technologies (EPFECCT) NERC Centres UK CCS Research Centre UK CCS Research Centre (UKCCSRC) PACT facilities

Skills Development Network to act as a focus for research in carbon dioxide cpature and utilisation with a remit to revolutionise the chemical industry Eng Doc Centre

Nottingham Sheffield

Oct 07- Sept 12 Jun12-Jun17

EPSRC EPSRC 0.446 0.300

2 2

Fundamental Research & Understanding Fundamental Research & Understanding Fundamental Research & Understanding Fundamental Research & Understanding Fundamental Research & Understanding Fundamental Research & Understanding/ Component Development & Applied Research Fundamental Research & Understanding

90

MISCELLANEOUS

Nottingham CCS research related to environmet incorporated work from NERC centres Research Facilities Consortium The UKCCSC network will be the main mechanism to enable intercommunication between Research Council-funded projects on CCS. It will alsocontributeto maximising the efficiency of UK intellectual leverage, including within the international community Collaborations

Oct09-Mar18

EPSRC

2.820

Other relevant oprogrammes not covered above. Eg skills, training, Centres of Excellence

91 92

BGS,NOC,PML Consortium

Annual Ap12-Mar17 Launched April 2012

NERC EPSRC

1 10

4.000 8.000

2 2

93

DECC

3.000

2 to 4

94

UK Carbon Capture and Storage Community Network (UKCCSC)

Edinburgh (2 projects)

EPSRC

1.02

0.816

21.466

18.936

Total

124.60

Breakdown of total spend through the UK CCS Innovation Programme 2011 - March 2015 Fundamental Research & Understanding Component Development & Applied Research Pilot Scale

April

54.150 27.153 43.300

TOTAL

124.603

Version 1.3, May 2013 URN: 13D/029

Vous aimerez peut-être aussi

- Costperf Ccs PowergenDocument51 pagesCostperf Ccs PowergenJose DenizPas encore d'évaluation

- Ageing Management and Long Term Operation of Nuclear Power Plants: Data Management, Scope Setting, Plant Programmes and DocumentationD'EverandAgeing Management and Long Term Operation of Nuclear Power Plants: Data Management, Scope Setting, Plant Programmes and DocumentationPas encore d'évaluation

- Ccs - ReportDocument25 pagesCcs - Reportammar sangePas encore d'évaluation

- Solar-Driven Green Hydrogen Generation and StorageD'EverandSolar-Driven Green Hydrogen Generation and StorageRohit SrivastavaPas encore d'évaluation

- Map of EU CCS Projects 1Document2 pagesMap of EU CCS Projects 1aurembiaixPas encore d'évaluation

- Waste and Biodiesel: Feedstocks and Precursors for CatalystsD'EverandWaste and Biodiesel: Feedstocks and Precursors for CatalystsPas encore d'évaluation

- Process Design and Economics For Conversion of Lignocellulosic Biomass To EthanolDocument187 pagesProcess Design and Economics For Conversion of Lignocellulosic Biomass To EthanolAlim Ur RahmanPas encore d'évaluation

- Global CCS Projects Map 1Document8 pagesGlobal CCS Projects Map 1aurembiaixPas encore d'évaluation

- The Shand CCS Feasibility Study Public ReportDocument124 pagesThe Shand CCS Feasibility Study Public ReportSai RuthvikPas encore d'évaluation

- Brunel OGJS Energy OutlookDocument74 pagesBrunel OGJS Energy OutlookSUDHEER NANDIPas encore d'évaluation

- Southern Company/MHI Ltd. Plant Barry CCS DemonstrationDocument23 pagesSouthern Company/MHI Ltd. Plant Barry CCS Demonstrationrecsco2100% (1)

- Upgrade Your Furnace For Clean FuelsDocument4 pagesUpgrade Your Furnace For Clean Fuelssagar1503Pas encore d'évaluation

- Life Cycle Assessment of The Process of Carbon Capture and StorageDocument8 pagesLife Cycle Assessment of The Process of Carbon Capture and Storagerajnish14feb8516Pas encore d'évaluation

- Biomass Gasification Smallwood04patelDocument37 pagesBiomass Gasification Smallwood04patelGiovani de MoraisPas encore d'évaluation

- MMSA Methanol World Supply and Demand Summary Jan 2020Document2 pagesMMSA Methanol World Supply and Demand Summary Jan 2020rifqi98Pas encore d'évaluation

- Biomass Gasification ProcessDocument27 pagesBiomass Gasification ProcessTony AppsPas encore d'évaluation

- Techno-Economic Performance of The Coal-To-olefins Process With CCSDocument10 pagesTechno-Economic Performance of The Coal-To-olefins Process With CCSAlbertus ArdikaPas encore d'évaluation

- 2021-01 Biorefineries With CCSDocument69 pages2021-01 Biorefineries With CCSPeace100% (1)

- Request For Quotation (RFQ) For The Provision of Vehicle Hire ServiceDocument6 pagesRequest For Quotation (RFQ) For The Provision of Vehicle Hire ServiceYonas LeulPas encore d'évaluation

- NGCC Plant Case - FClass With CCS - 051607Document4 pagesNGCC Plant Case - FClass With CCS - 051607DWWillsonPas encore d'évaluation

- Technical Bulletin 149Document3 pagesTechnical Bulletin 149osperPas encore d'évaluation

- Paper Failure Weld JointDocument6 pagesPaper Failure Weld JointWildan HamdaniPas encore d'évaluation

- Oil Refinery Information SourcesDocument5 pagesOil Refinery Information SourcesBien Molintapang BastianPas encore d'évaluation

- Key Performance Indicators CCSDocument11 pagesKey Performance Indicators CCSAnudeep ChittluriPas encore d'évaluation

- DOE Issue Brief - Carbon Capture Utilization and Storage - 2016!08!31Document12 pagesDOE Issue Brief - Carbon Capture Utilization and Storage - 2016!08!31vggupta2Pas encore d'évaluation

- Alloy 800 Steam Generator Tube Stress Corrosion CracksDocument9 pagesAlloy 800 Steam Generator Tube Stress Corrosion CracksETSPas encore d'évaluation

- Fossil Power Generation With Carbon Capture and Storage (CCS) : Policy Development For Technology DeploymentDocument24 pagesFossil Power Generation With Carbon Capture and Storage (CCS) : Policy Development For Technology Deploymentjubatus.libroPas encore d'évaluation

- Gasification Activities in Finland 2009Document18 pagesGasification Activities in Finland 2009Rodolfo Barbosa YoungPas encore d'évaluation

- Scaling The Ccus Industry To Achieve - FinalDocument9 pagesScaling The Ccus Industry To Achieve - FinalTac LeungPas encore d'évaluation

- Biomass GasificationDocument358 pagesBiomass GasificationSandor Maneses100% (1)

- CCS Directive Evaluation Interim Report PDFDocument89 pagesCCS Directive Evaluation Interim Report PDFmardiradPas encore d'évaluation

- CCS Meeting The Challenge Web PDFDocument56 pagesCCS Meeting The Challenge Web PDFmasimaha1379Pas encore d'évaluation

- CCS For LNG LiquefactionDocument17 pagesCCS For LNG Liquefactionbkonly4uPas encore d'évaluation

- Advances in Carbon CaptureDocument3 pagesAdvances in Carbon Capturetassili17Pas encore d'évaluation

- Energy: Key Drivers of CCUS Project EconomicsDocument55 pagesEnergy: Key Drivers of CCUS Project EconomicsDanielPas encore d'évaluation

- 4 S2-5 Mr. Fuji 20150115 Rev3(ト書き入り) JCCP Chiyoda Presentation on Jan2015Document29 pages4 S2-5 Mr. Fuji 20150115 Rev3(ト書き入り) JCCP Chiyoda Presentation on Jan2015hutuguoPas encore d'évaluation

- 2018-03 5th CCS Cost Network 2017 Workshop Proceedings PDFDocument248 pages2018-03 5th CCS Cost Network 2017 Workshop Proceedings PDFvivekpatel1234Pas encore d'évaluation

- Methanol Market Services Asia, Xiaoshu WangDocument27 pagesMethanol Market Services Asia, Xiaoshu WangAnggit Saputra DwipramanaPas encore d'évaluation

- Global Ccs Cost Updatev4 PDFDocument16 pagesGlobal Ccs Cost Updatev4 PDFTint LwinPas encore d'évaluation

- Carbon CaptureDocument8 pagesCarbon CapturePRATYUSH PRAKASHPas encore d'évaluation

- Finn JoensenDocument30 pagesFinn JoensenYogga AdhityaPas encore d'évaluation

- Review IChemE PartA Full Paper V9 28may2010 PDFDocument22 pagesReview IChemE PartA Full Paper V9 28may2010 PDFaziziPas encore d'évaluation

- ImpactOfLoadFollowingOnPowerPlantCostAndPerformance FR Rev1 20121010Document49 pagesImpactOfLoadFollowingOnPowerPlantCostAndPerformance FR Rev1 20121010Anonymous knICaxPas encore d'évaluation

- DellDocument3 pagesDellAneesh VarghesePas encore d'évaluation

- Project Plan Greenway Plasma Energy ParkDocument40 pagesProject Plan Greenway Plasma Energy ParkqueenslandferalPas encore d'évaluation

- Carbon Capture TechnologiesDocument63 pagesCarbon Capture TechnologiesShamsMohdPas encore d'évaluation

- SCCS CO2 EOR JIP Tax Study Non Technical Report 2013Document23 pagesSCCS CO2 EOR JIP Tax Study Non Technical Report 2013Farzaneh SedighiPas encore d'évaluation

- GTLDocument11 pagesGTLSyahrinPas encore d'évaluation

- The 9f PlatformDocument8 pagesThe 9f Platformsevero97Pas encore d'évaluation

- Corrosion Failures of AISI Type 304 Stainless Steel in A Fertiliser PlantDocument11 pagesCorrosion Failures of AISI Type 304 Stainless Steel in A Fertiliser PlantAndrea CalderaPas encore d'évaluation

- Lurgi and Ammonia Casale Have Disclosed Their Jointly Developed Ammonia Process TechDocument2 pagesLurgi and Ammonia Casale Have Disclosed Their Jointly Developed Ammonia Process TechSisca AmeliaPas encore d'évaluation

- NREL Biomass Gasification MKT Assessment 46190Document32 pagesNREL Biomass Gasification MKT Assessment 46190Siringul Ay100% (1)

- EthyleneDocument2 pagesEthyleneEmOosh MohamedPas encore d'évaluation

- SR 510 39944Document51 pagesSR 510 39944anafeesPas encore d'évaluation

- HON UOP Overview 2023 - Ploiesti Oil & Gas UniversityDocument20 pagesHON UOP Overview 2023 - Ploiesti Oil & Gas UniversityVlad GăureanuPas encore d'évaluation

- Troubleshooting ST Path Damage MechanismsDocument40 pagesTroubleshooting ST Path Damage Mechanismsjerezg25100% (1)

- Operation and Maintenance Cost Model To Identify Cost of Energy Savings Low Wind Speed Turbines PDFDocument72 pagesOperation and Maintenance Cost Model To Identify Cost of Energy Savings Low Wind Speed Turbines PDFfacma00Pas encore d'évaluation

- 2-Jan Kollmus-Siemens Carbon Capture Technologies - Successful Technology Development From Pilot Scale To Application in Mega Plant ScaleDocument39 pages2-Jan Kollmus-Siemens Carbon Capture Technologies - Successful Technology Development From Pilot Scale To Application in Mega Plant ScaleIsmar AdrianPas encore d'évaluation

- Overview of The Cost of Desalinated Wate PDFDocument14 pagesOverview of The Cost of Desalinated Wate PDFAhmed AnsariPas encore d'évaluation

- HazMat Math The Rest of The StoryDocument4 pagesHazMat Math The Rest of The Storykirandas_mullasseryPas encore d'évaluation

- CP S HW CH 9 DetailedDocument6 pagesCP S HW CH 9 Detailedkirandas_mullasseryPas encore d'évaluation

- HazMat Math The Rest of The StoryDocument4 pagesHazMat Math The Rest of The Storykirandas_mullasseryPas encore d'évaluation

- Performance of One Unit Shell Side Tube SideDocument1 pagePerformance of One Unit Shell Side Tube Sidekirandas_mullasseryPas encore d'évaluation

- 2010 Rockwell Collins Shuttle Badminton LeagueDocument2 pages2010 Rockwell Collins Shuttle Badminton Leaguekirandas_mullasseryPas encore d'évaluation

- Heat Exchangersdasd DasdfsdfaffsdDocument15 pagesHeat Exchangersdasd Dasdfsdfaffsdkirandas_mullasseryPas encore d'évaluation

- Design of AgitatorDocument23 pagesDesign of Agitatorkirandas_mullassery100% (3)

- Heat TransferDocument1 pageHeat TransferhuangjlPas encore d'évaluation

- ACS ProcessDocument24 pagesACS Processkirandas_mullasseryPas encore d'évaluation

- Eplc Meeting Minutes TemplateDocument4 pagesEplc Meeting Minutes TemplateAbdelRhman ElfkyPas encore d'évaluation

- Shell & Dish ThicknessDocument3 pagesShell & Dish Thicknesskirandas_mullasseryPas encore d'évaluation

- Limpet Coil CalculationDocument1 pageLimpet Coil Calculationkirandas_mullassery100% (1)

- Ballbal DirectDocument13 pagesBallbal DirectDavid RojasPas encore d'évaluation

- Demister PadDocument4 pagesDemister PadPatel Mehulkumar0% (1)

- Hermes-2012-Thermodynamic Design of Condensers and Evaporators-2100Document9 pagesHermes-2012-Thermodynamic Design of Condensers and Evaporators-2100kirandas_mullasseryPas encore d'évaluation

- Guide To Inspecting The WorkplaceDocument29 pagesGuide To Inspecting The Workplacekirandas_mullasseryPas encore d'évaluation

- Design of AgitatorDocument23 pagesDesign of Agitatorkirandas_mullassery100% (3)

- DRC - SP - DRC 11-35 Ps Guide Important For Safety Items - EngDocument30 pagesDRC - SP - DRC 11-35 Ps Guide Important For Safety Items - Engkirandas_mullasseryPas encore d'évaluation

- 2010 Rockwell Collins Shuttle Badminton LeagueDocument2 pages2010 Rockwell Collins Shuttle Badminton Leaguekirandas_mullasseryPas encore d'évaluation

- Productflyer - 978 0 7923 1202 4Document1 pageProductflyer - 978 0 7923 1202 4kirandas_mullasseryPas encore d'évaluation

- Ccs 125m FundingDocument3 pagesCcs 125m Fundingkirandas_mullasseryPas encore d'évaluation

- ACS ProcessDocument24 pagesACS Processkirandas_mullasseryPas encore d'évaluation

- 2010 Rockwell Collins Shuttle Badminton LeagueDocument2 pages2010 Rockwell Collins Shuttle Badminton Leaguekirandas_mullasseryPas encore d'évaluation

- Binary Distillation McCabe ThieleDocument2 pagesBinary Distillation McCabe Thielelsastré_11Pas encore d'évaluation

- Material Safety Data Sheet: Product Name: Mobil Stern Tube LubricantDocument9 pagesMaterial Safety Data Sheet: Product Name: Mobil Stern Tube Lubricantkirandas_mullasseryPas encore d'évaluation

- Guide To Inspecting The WorkplaceDocument29 pagesGuide To Inspecting The Workplacekirandas_mullasseryPas encore d'évaluation

- Design of AgitatorDocument23 pagesDesign of Agitatorkirandas_mullassery100% (3)

- Design NewDocument9 pagesDesign Newkirandas_mullasseryPas encore d'évaluation

- Chapter 2: Heat Exchangers Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallDocument85 pagesChapter 2: Heat Exchangers Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallNadirah RahmanPas encore d'évaluation

- Response - Records - Phase 2Document31 pagesResponse - Records - Phase 2Bob MackinPas encore d'évaluation

- Utmost TFT Training Part1Document96 pagesUtmost TFT Training Part1gideontargrave7Pas encore d'évaluation

- JM at - 20040129Document11 pagesJM at - 20040129wreckedweaselPas encore d'évaluation

- D758-Et Minipurge ManualDocument39 pagesD758-Et Minipurge ManualNicholas marcolan (nmarcolan)Pas encore d'évaluation

- Rendering An Exterior Scene - V-Ray 2.0 For SketchUp - Chaos Group HelpDocument9 pagesRendering An Exterior Scene - V-Ray 2.0 For SketchUp - Chaos Group HelpRapha RachoPas encore d'évaluation

- Creating A Use Case Diagram in Rational RoseDocument2 pagesCreating A Use Case Diagram in Rational RoseRaguramrecPas encore d'évaluation

- Lecture 1-Gas Supply SystemDocument28 pagesLecture 1-Gas Supply SystemMuhammad FakhriPas encore d'évaluation

- Lecture-14 Sheet Metal Forming ProcessesDocument34 pagesLecture-14 Sheet Metal Forming ProcessesDida KhalingPas encore d'évaluation

- GREYWECKDocument260 pagesGREYWECKarslanpasaPas encore d'évaluation

- Chery A1 PartesDocument54 pagesChery A1 PartesAlexferminPas encore d'évaluation

- Nghi Son 2 BOT Thermal Power Plant Project Design Query SheetDocument4 pagesNghi Son 2 BOT Thermal Power Plant Project Design Query SheetDoan Ngoc DucPas encore d'évaluation

- HZS120F8Document2 pagesHZS120F8saimunPas encore d'évaluation

- Design of Beam by WSM For Reference FinalDocument22 pagesDesign of Beam by WSM For Reference Finaljeffmugacha6Pas encore d'évaluation

- Chapter 17 Product RecoveryDocument2 pagesChapter 17 Product RecoveryCarlos Miguel DacaimatPas encore d'évaluation

- Water Supply and Distribution SystemingDocument5 pagesWater Supply and Distribution SystemingMelissa GabayPas encore d'évaluation

- On Windows Syscall Mechanism and Syscall Numbers Extraction MethodsDocument26 pagesOn Windows Syscall Mechanism and Syscall Numbers Extraction MethodsqdwqdPas encore d'évaluation

- 7.3.2.3 Packet Tracer - Configuring RIPng InstructionsDocument3 pages7.3.2.3 Packet Tracer - Configuring RIPng InstructionsCristian GarciaPas encore d'évaluation

- C Library Math.h Functions - GeeksforGeeksDocument11 pagesC Library Math.h Functions - GeeksforGeeksSoumadip Banerjee100% (1)

- FortiGate Troubleshooting GuideDocument16 pagesFortiGate Troubleshooting Guidesreekumarpg100% (1)

- Kool Calc GuideDocument24 pagesKool Calc GuideAlonso MejíaPas encore d'évaluation

- Thomson Chasis ICC17Document52 pagesThomson Chasis ICC17videosonPas encore d'évaluation

- Ford Explorer CodigosDocument183 pagesFord Explorer Codigosjose gabriel0% (1)

- The CPL Exams: CHUF - CPL Human Factors ExaminationDocument5 pagesThe CPL Exams: CHUF - CPL Human Factors Examinationgreg mPas encore d'évaluation

- Principles of Communications: Systems, Modulation, and Noise, 7Document2 pagesPrinciples of Communications: Systems, Modulation, and Noise, 7Rahul MenonPas encore d'évaluation

- Design of Connecting Rod For Light Weight Using C70S6 MaterialDocument9 pagesDesign of Connecting Rod For Light Weight Using C70S6 MaterialKongala Vamsi KrishnaPas encore d'évaluation

- MEMB453 - Eddy Current (ET) Home Quiz 2018S1Document4 pagesMEMB453 - Eddy Current (ET) Home Quiz 2018S1Menny RossPas encore d'évaluation

- EMC For Functional Safety: Introductory Manager's Guide ToDocument2 pagesEMC For Functional Safety: Introductory Manager's Guide ToentindanPas encore d'évaluation

- HBN PVC Free Alternatives ChartDocument24 pagesHBN PVC Free Alternatives ChartaggibudimanPas encore d'évaluation

- Review Guide For The Qatar Electrical Engineers GradeDocument84 pagesReview Guide For The Qatar Electrical Engineers GradeHerman ArcalasPas encore d'évaluation

- SAP Basis Questions AnsDocument5 pagesSAP Basis Questions AnsSantanu Kar GuptaPas encore d'évaluation

- University of Chicago Press Fall 2009 Distributed TitlesD'EverandUniversity of Chicago Press Fall 2009 Distributed TitlesÉvaluation : 1 sur 5 étoiles1/5 (1)

- University of Chicago Press Fall 2009 CatalogueD'EverandUniversity of Chicago Press Fall 2009 CatalogueÉvaluation : 5 sur 5 étoiles5/5 (1)