Académique Documents

Professionnel Documents

Culture Documents

Loay MunicipalSlaughterhouse

Transféré par

Alexis SalamanderTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Loay MunicipalSlaughterhouse

Transféré par

Alexis SalamanderDroits d'auteur :

Formats disponibles

Republic of the Philippines Province of Bohol

Municipality of Loay OFFICE OF THE MUNICIPAL AGRICULTURE

PROJECT PROPOSAL

I. II. III. IV. V. VI. PROJECT TITLE PROPONENT PROJECT LOCATION BENEFICIARIES FUNDING SOURCE RATIONALE : : : : : : MUNICIPAL SLAUGHTERHOUSE Municipal Agriculture Office Site that meets NMIS Guidelines

A slaughterhouse or abattoir refers to the premises approved and registered by the controlling authority used in the slaughter of animals for human consumption. It is a basic commodity to be provided by the Local Government Unit (LGU) as stipulated under Rule 1, letter H, Article 25 of R. A. 7160 otherwise known as The Local Government Code of 1991. Being a key element in the production and distribution chain for meat it is essential that slaughterhouses be as hygienic as possible in order to prevent the spread of both human and animal diseases as well as to reduce economic losses due to premature spoilage of meat caused by contamination. The majority of abattoirs are public utilities provided by local government units but in LGU where there are no such established facilities slaughtering usually takes place in private facilities which are usually on a small scale and may or may not be under the supervision of a meat inspector. Others are not recognized abattoirs and may just be a part of a dwelling or other premises. Slaughtering at such places is generally considered to be illegal where the meat is to be sold but is mot illegal where it is consumed in the owners household, or the slaughter and consumption forms part of a festival or celebration. The obvious hygiene problem and inadequate meat inspection existing in the locality as in many other places do not always cause illness and disease because of practices which have evolved to reduce their effects. Although meat from unhygienic slaughterhouses may be heavily contaminated by microorganisms and other products which may cause food poisoning, the multiplication of these microorganisms is reduced by natural processes such as drying of the meat surface. Generally, meat is cooked thoroughly before consumption thereby destroying most of these harmful substances. It is in circumstances where these practices are not carries out that the most serious problems occur (e.g. keeping the meat unrefrigerated for too long; insufficient cooking, etc.). In order to prevent problems arising from inadequate standards of hygiene, there is an urgent and extensive need for the establishment of a duly recognized slaughterhouse to supply the needs of the local populace and that of the neighboring town. Hence, this proposal.

VII.

OBJECTIVES:

An accredited municipal slaughterhouse shall be established with the following objectives: 1. To provide every consumer a disease-free and quality meat and its by-products; 2. To protect its people against meat-borne diseases; 3. To eradicate the sale of Hot Meat

4. To reduce economic losses due to premature spoilage o meat caused by microbial contamination usually prevalent in unhygienic facilities.

VIII. PROJECT DESCRIPTION: A municipal slaughterhouse will be established in one of the barangays o the Municipality of Loay at a site that will meet the Guidelines on Slaughterhouse Design and Construction set by the National Meat Inspection System (see attached Guidelines). This is dome to ensure that the established slaughterhouse will pass NMIS Accreditation Standards, apply and enforce uniform national standards for hygiene and inspection, and reduce operating cost as the best utilization of facilities and expertise can be obtained. Furthermore, centralization of design expertise would result in a continuing improvement in designs.

GUIDELINES ON SLAUGHTERHOUSE DESIGN AND CONSTRUCTION

A. LOCATION : 1. Site is not subject to flooding 2. Not in the low lying area 3. Area is sufficient in size 4. With adequate distance from residential, and any other establishment (200 m.) 5. Not subject to undue pollution and contamination 6. With adequate distance from any inland water 7. With available and sufficient supply of potable water and electricity 8. Accessible to transportation 9. Suitable for adequate disposal of solid and liquid waste 10.Approved by the controlling authority

B. SLAUGHTERHOUSE DESIGN A complete project involves the construction of different infrastructures / buildings which is necessary for an efficient and economic handling of meat and by product, namely: 1. Lairage / Holding pen 2. Slaughterhouse 3. Perimeter Fencing 4. Guard House 5. Office of the Meat Inspector 6. Personnel amenities 7. Water supply system 8. Drainage system

9. Wastewater treatment facility

C. SITE LAYOUT The following aspects should be considered in designing the layout of buildings and facilities on the site: 1. Adequate access, traffic circle, washing and parking should be provided for vehicles bringing animals to the slaughterhouse and for meat transport vehicles. 2. Animal unloading facility and lairage should be located as far as practicable from the meat dispatching area 3. The direction of the prevailing wind should be considered together with natural slope of the land, to position the lairage downwind and downhill of the slaughter hall 4. Slaughterhouse building and facilities should be located to facilitate the natural run-off of storm water D. SLAUGHTERHOUSE CONSTRUCTION 1. BUILDING DESIGN Building should be constructed of durable and impervious materials, resistant to wear and corrosion. 2. SIZE AND GENERAL ARRANGEMENT a) Allow separate slaughter by species. b) One way operational flow c) Clean and dirty operation are physically separated. d) Separate the entrance of animals and exit of meat and by-products 3. VENTILATION a) Facilitate entry of fresh air and removal of obnoxious odor, heat and moisture b) Its opening provided with mesh wire / screen c) Movement of airs is from clean to dirty area 4. LIGHTING With adequate light both of natural and artificial for all work rooms All inspection area 3-40 watts (Fluorescent lamp) / 6.00 sq. m. Working area - 2-40 watts (Fluorescent lamp) / 6.00 sq. m. Chilling room - 1-20 watts (Fluorescent lamp) / 6.00 sq. m.

Other areas of the establishment: 1-40 watts (Fluorescent lamp) / 6.00 sq. m. 5. ROOF Properly design, durable and resistant to wear, with provision of skylight and Skylight and ventilator 6. FLOOR a) Construction of durable and impervious materials b) Easy to clean and non slip c) Slope towards drain d) All angles between the floors and walls curved of at least 7.62 cm. (3) from the floor 7. WALL a) Exterior walls should be constructed of durable and non permeable materials b) Interior walls should be smooth, flat and constructed in impervious materials. It should be of white or light color, or materials that do not require painting should be used. 8. DOOR / DOORWAY a) Wide enough to ensure no contact between the door jambs and means of conveyances / product (at least 1.5 m. wide). b) Opening from parts of the slaughterhouse where meat is handled should be fitted w/ plastic curtain or self closing door. c) Non permeable door. 9. WHEEL BATH a) Located at the main entrance of the premises / compound b) Sufficient length, width and depth to completely disinfect the whole tires. 10. FOOT BATH a) Located at all workers entrance of the slaughterhouse b) Sufficient width, length and depth to completely disinfect the lower half of the boots 11. WATER SUPPLY SYSTEM a) Adequate water reservoir b) Adequate supply of potable water for drinking, carcass washing and cleaning purposes. c) Supplies thru overhead pipes 12. DRAINAGE SYSTEM a) Sufficient to carry peak loads

b) Drainage at the interior of the building should be open canal with iron gratings c) Adequate slope to facilitate smooth flow of waste water 13. OFFOCE OF THE MEAT INSPECTOR Properly located with enough office equipment and facilities.

E. HOLDING FACILITIES AND SPACES FOR SPECIAL PURPOSES 1. HOLDING PEN / LAIRAGE a) Physically separated from the slaughter hall (10 m.) b) Provided with adequate unloading facility with squeeze chute for large animals. c) Enough space to accommodate holding capacity of slaughter (2.23 sq. m. / cattle and .60 sq. m. /hog) d) Minimum width of aisle (1.20 m. or 4 ft.) e) Floor constructed of durable and water resistant materials, and non slip f) Swing gates for individual pens will close the aisles or corridors. g) Good traffic flow (separate facilities for entry and exit of animals). h) Sufficient slope of floor towards open canal with iron gratings - Large animal 5% or 5 cm. in every 1 meter - Small animal 4% or 4 cm. in every 1 meter 1.) Adequate potable drinking water supply shall be provided for the animals j.) With built-in shower for cleaning of animals prior to slaughter. k.) Provided with artificial lighting when slaughtering is conducted after sunset before sunrise. l.) Provided with durable and properly design roof 2. ISOLATION PEN Physically separated from other holding pen, reserve for the isolated stock and suspected animals. 3. CHUTE a) Properly designed so as to facilitate movement of animals to stunning area b) Width of the chute should only accommodate one animal at a given time (0.50 m. width for swine and 0.80 m. width of r large animals)

4. TRIPERY AND GUTTERY SECTION a) Physically separated from the slaughtering area b) With facilities, equipments for efficient cleaning of tripes and guts 5. AMENITIES a) Dressing room with adequate and suitable lockers for each worker. With separate room for each gender b) Comfort room with hand washing lavatory and with separate room for each gender, toilet opening not directly to the area where meat and other edible products are being handled and equipments and facilities are being used 6. CANTEEN / DINING ROOM Provided w/ tables and chairs, eating utensils, and water jug / dispenser

MAIN FEATURES OF THE SLAUGHTERHOUSE

1. Facilities for proper care of animals prior to slaughter 2. Separate dressing floor between hogs and large animals 3. Separate handling of meat and offals 4. Equipments and implements for proper handling of meat and by-products 5. Provisions for hanging room and if possible refrigeration 6. Provision for adequate meat inspection and disposal of condemned 7. Adequate water and light facilities 8. Drainage 9. Separate room or portion of a room under lock and key for storing suspected meat. This shall be designed as to prevent contamination of other meat 10.Separated room or any other appropriate device under lock and key for storing condemned meat and by-product 11.Separate room for deboning and cutting in cases where meat is boned-out and cut-up 12.Supply of hot water 13.Amenities for meat inspectors, butchers and other workers

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Catalog Celule Siemens 8DJHDocument80 pagesCatalog Celule Siemens 8DJHAlexandru HalauPas encore d'évaluation

- Capital Expenditure DecisionDocument10 pagesCapital Expenditure DecisionRakesh GuptaPas encore d'évaluation

- Lending OperationsDocument54 pagesLending OperationsFaraz Ahmed FarooqiPas encore d'évaluation

- Tanzania Finance Act 2008Document25 pagesTanzania Finance Act 2008Andrey PavlovskiyPas encore d'évaluation

- Shahroz Khan CVDocument5 pagesShahroz Khan CVsid202pkPas encore d'évaluation

- Action Plan Lis 2021-2022Document3 pagesAction Plan Lis 2021-2022Vervie BingalogPas encore d'évaluation

- CANELA Learning Activity - NSPE Code of EthicsDocument4 pagesCANELA Learning Activity - NSPE Code of EthicsChristian CanelaPas encore d'évaluation

- A320 TakeoffDocument17 pagesA320 Takeoffpp100% (1)

- Selvan CVDocument4 pagesSelvan CVsuman_civilPas encore d'évaluation

- Chapter 5Document3 pagesChapter 5Showki WaniPas encore d'évaluation

- Audit Certificate: (On Chartered Accountant Firm's Letter Head)Document3 pagesAudit Certificate: (On Chartered Accountant Firm's Letter Head)manjeet mishraPas encore d'évaluation

- ST JohnDocument20 pagesST JohnNa PeacePas encore d'évaluation

- 4th Sem Electrical AliiedDocument1 page4th Sem Electrical AliiedSam ChavanPas encore d'évaluation

- Bajaj Allianz InsuranceDocument93 pagesBajaj Allianz InsuranceswatiPas encore d'évaluation

- ADS 460 Management Principles and Practices: Topic 1: Introduction To ManagementDocument33 pagesADS 460 Management Principles and Practices: Topic 1: Introduction To ManagementNURATIKAH BINTI ZAINOL100% (1)

- Star Link SafetyDocument2 pagesStar Link SafetyJeronimo FernandezPas encore d'évaluation

- SND Kod Dt2Document12 pagesSND Kod Dt2arturshenikPas encore d'évaluation

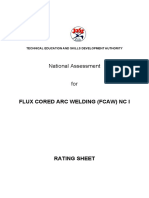

- Rating SheetDocument3 pagesRating SheetShirwin OliverioPas encore d'évaluation

- Aircraftdesigngroup PDFDocument1 pageAircraftdesigngroup PDFsugiPas encore d'évaluation

- An RambTel Monopole Presentation 280111Document29 pagesAn RambTel Monopole Presentation 280111Timmy SurarsoPas encore d'évaluation

- Oem Functional Specifications For DVAS-2810 (810MB) 2.5-Inch Hard Disk Drive With SCSI Interface Rev. (1.0)Document43 pagesOem Functional Specifications For DVAS-2810 (810MB) 2.5-Inch Hard Disk Drive With SCSI Interface Rev. (1.0)Farhad FarajyanPas encore d'évaluation

- JAZEL Resume-2-1-2-1-3-1Document2 pagesJAZEL Resume-2-1-2-1-3-1GirlieJoyGayoPas encore d'évaluation

- Material Safety Data Sheet (According To 91/155 EC)Document4 pagesMaterial Safety Data Sheet (According To 91/155 EC)Jaymit PatelPas encore d'évaluation

- NOP PortalDocument87 pagesNOP PortalCarlos RicoPas encore d'évaluation

- Executive Summary - Pseudomonas AeruginosaDocument6 pagesExecutive Summary - Pseudomonas Aeruginosaapi-537754056Pas encore d'évaluation

- Address MappingDocument26 pagesAddress MappingLokesh KumarPas encore d'évaluation

- CodebreakerDocument3 pagesCodebreakerwarrenPas encore d'évaluation

- Doterra Enrollment Kits 2016 NewDocument3 pagesDoterra Enrollment Kits 2016 Newapi-261515449Pas encore d'évaluation

- (X-09485) XYLENE RECTIFIED Extra Pure (Mix Isomers)Document9 pages(X-09485) XYLENE RECTIFIED Extra Pure (Mix Isomers)Bharath KumarPas encore d'évaluation

- Brochure Ref 670Document4 pagesBrochure Ref 670veerabossPas encore d'évaluation