Académique Documents

Professionnel Documents

Culture Documents

1 s2.0 S0925400508004310 Main

Transféré par

NEMI CHAND SOODTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

1 s2.0 S0925400508004310 Main

Transféré par

NEMI CHAND SOODDroits d'auteur :

Formats disponibles

Sensors and Actuators B 135 (2008) 712

Contents lists available at ScienceDirect

Sensors and Actuators B: Chemical

journal homepage: www.elsevier.com/locate/snb

Methane gas-sensing and catalytic oxidation activity of SnO2 In2 O3 nanocomposites incorporating TiO2

Chen Aifan a, , Bai Shouli a , Shi Bingjie a , Liu Zhiyong a , Li Dianqing a , Chung Chiun Liu b

a b

State Key Laboratory of Chemical Resource Engineering, Beijing University of Chemical Technology, Beijing 100029, China Department of Chemical Engineering, Case Western Reserve University, Cleveland, OH 44106, USA

a r t i c l e

i n f o

a b s t r a c t

The InO1.5 SnO2 nanocomposites incorporating TiO2 were synthesized by a controlled co-precipitation method as sensing materials of a novel semiconductor CH4 sensor. Through manipulating the total salt concentration, cation ratio, precipitation pH, aging time and calcination temperature, the nanocrystalline composites were successfully derived with chemical homogeneity and superior thermal stability compared to tin oxide. The gas-sensing and catalytic activity for methane oxidation were examined in a micro xed bed reaction system. The experimental results showed that the nanocomposites exhibited high gas-sensing and catalytic activity, and these performances depended on composition of composites, calcination temperature of precursors and sensor operating temperature. It was found that the sensing behavior was straightforwardly related to the catalytic activity. The sensing and catalytic activity was greatly enhanced by the introduction of metal elements or oxide surface coatings. To guide for the search of better sensor materials or suitable additives, it is necessary to understand the sensing mechanism of the semiconductor oxide gas sensors by temperature-programmed desorption (TPD) study and X-ray photoelectron spectroscopic (XPS) analysis. 2008 Elsevier B.V. All rights reserved.

Article history: Received 21 January 2008 Received in revised form 18 June 2008 Accepted 18 June 2008 Available online 9 July 2008 Keywords: Nanocomposites Sn/In/Ti oxides Gas-sensing Catalytic activity Methane

1. Introduction The most recent research has been devoted towards nanostructured oxides, since reactions at grain boundaries and complete depletion of carriers in the grains can strongly modify the material transport properties. Yamazeo and Miura [1] studied the effect of grain size on the response of SnO2 gas sensors and concluded that the response to CO and H2 increased considerably as the grain size was reduced. Tin oxide is a wide-bandgap semiconductor, and the intrinsic carrier concentration is primarily determined by deviations from stoichiometry in the form of equilibrium oxygen vacancies, which are predominantly atomic defects. Tin oxide is the most common sensing material in semiconductor gas sensors because of its good chemical and mechanical stability and high response at lower operating temperature compared to other metal oxides for detection of reducing and oxidizing gases [2]. Unfortunately the high temperature required for the surface reactions to take place induces a grain growth by coalescence and prevents the achievement of stable materials. The gas-sensing performance of the material can be improved by incorporating an oxide of secondary component and a few additives into the base material.

Huang et al. [3] studied a novel ZnOSnO2 nanocomposite as a semiconductor gas sensor for NO2 and CO detection; especially, the introduction of 10 wt% Al2 O3 as a surface coating scored the highest response at an operating temperature of 200 C, which was about 84 times higher than that achieved by the uncoated 40% InO1.5 nanocomposite. Zhang and Liu [4] reported that the substitution of Sn ions by copper ions created more oxygen vacancies in the material, leading to an increase in response of the material. The approach used in this work was to incorporate InO1.5 and TiO2 into SnO2 to obtain binary and ternary nanocomposites and test their sensing and catalytic properties for CH4 oxidation. A correlation between the catalytic activity and the sensor response was presented. Although the structure of CH4 is the simplest among all kinds of hydrocarbon gases, the structure symmetry and high nature ring temperature determine its low reacting ability and low response. This is the key problem for the CH4 sensor. The CH4 sensor possessing good response and selectivity is very important for both environmental protection and domestic security. 2. Experimental 2.1. Preparation of nanocomposites

Corresponding author. E-mail address: chenaf@mail.buct.edu.cn (A. Chen). 0925-4005/$ see front matter 2008 Elsevier B.V. All rights reserved. doi:10.1016/j.snb.2008.06.050

The precursors of InO1.5 SnO2 nanocomposites were prepared by a controlled co-precipitation method. The metal salts of

A. Chen et al. / Sensors and Actuators B 135 (2008) 712

SnCl4 5H2 O and InCl3 were dissolved in distilled water at a total salt concentration of 0.05 M. Ammonium hydroxide was added dropwise to the solution up to the nal solution pH value of about 8.0. Following precipitation the slurry was aged for 24 h at room temperature, and then draw ltrated, washed with distilled water to remove the chloride ions, dried at 100 C and grounded into powder. For ternary nanocomposites incorporating TiO2 , an appropriate amount of TiCl4 solution (2.262 M) was added dropwise to the above precipitated solution; the subsequent processes were the same as those above described. The precursors were calcined at different temperatures from 400 C to 1000 C to vary the particle size and crystallinity. The preparation parameters were critical in controlling the grain size and crystallinity of the composites derived since they governed the nucleation and crystal growth rates. 2.2. Characterization of nanocomposites To determine the particle morphology and composition of the nanocomposites, the calcined powders were analyzed by scanning electron microscopy (SEM) equipped with an X-ray microprobe of a 0.14 nm optimum resolution for energy dispersive X-ray analysis (EDX). Transmission electron microscopy (TEM) was used to determine the particle size of the nanocomposites by a JEM 200CX microscope (200 kV). The specic surface area of the nanocrystalline powders was measured from nitrogen adsorption analysis by a BET (BrunauerEmmettTeller) method on a Micromeritic ASAP 2010 gas adsorption analyzer. Phase structure was characterized by powder X-ray diffraction (XRD) analysis at room temperature with a Shimadzu HR 6000 diffractometer (Cu K line at 0.15406 nm). The mean size of crystallite was estimated from the width of XRD peaks by Scherrer formula, D = k /cos , where is the full width at half maximum of the peak, is the X-ray wavelength, is the Bragg angle, and k = 0.89. The lattice parameters of the nanocomposites were also obtained from XRD analysis. Temperature-programmed desorption (TPD) experiment was carried out on a TPD/R/O 110 series analyzer (Thermo Electron SPA, Italy). Samples of 0.15 g (4060 mesh) were pretreated at 500 C for 4 h to remove surface adsorbates, followed by cooling to room temperature in air. The samples were then exposed to CH4 or O2 for 3 h, desorption of adsorbed species was performed during heating (50700 C, ramp: 5 min1 ) in owing helium at a ow rate of 20 ml min1 , and the desorption amounts from the surface of nanocomposites were analyzed. X-Ray photoelectron spectroscopy (XPS) measurement was conducted on a PHI-5400 spectrometer (PerkinElmer, USA). 2.3. Measurement of response to CH4 The responses of the binary InO1.5 SnO2 and ternary InO1.5 SnO2 TiO2 nanocomposites to CH4 and CO were examined in a temperature range of 100350 C. The sensing element was fabricated [5] and was placed in a quartz tube, which was heated to 300500 C for several hours in a tube furnace to remove the adsorbates from the element surface. The sample gases and air were then introduced through gas ow meters to control the ow rates of sample gases and air. In a typical sensor response measurement, a constant current of 10 A was applied to each element. When air and ppm-level CH4 were own through the test tube, the corresponding steady-state resistance of the sensing elements were recorded using an EG&G potentiostat/galvanostat. The CH4 response (S) was dened as the ratio of the sensor resistance in air (Ra ) to that in an air-CH4 mixture (Rg ), S = Ra /Rg . 2.4. Measurement of catalytic activity for CH4 oxidation Catalytic activity tests of the nanocomposites for CH4 combustion were carried out in a temperature-controlled micro xed-bed

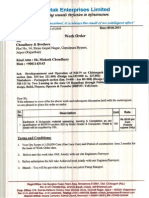

Fig. 1. The schematic diagram of catalytic activity evaluation to methane oxidation. 1: ow meters, 2: mixer, 3: a micro xed-bed reactor, 4: a temperature programming controller, 5: a thermal-couple, 6: a cool trap, 7: a six-way valve, 8: a gas chromatograph and 9: a data acquisition system.

reaction system under atmospheric pressure and in a temperature range of 300900 C. The 300 mg sample powders were sieved at 2040 mesh and mixed with 300 mg quartz particles. The mixture was loaded into a quartz microreactor with quartz ber packed at both ends of the catalytic bed. The reaction temperature was monitored by a thermal couple placed at the top of the packed catalytic bed. A gas mixture consisting of 4% CH4 and 17% O2 balanced by N2 was fed to the reactor system, the ow rate was adjusted to achieve a gas hourly space velocity (GHSV) of 5.0 104 h1 . The analysis of products and reactants were performed by on-line a GC-900 gas chromatograph equipped with a packed column and a ame ionization detector (FID). Methane conversions were measured at 20 C intervals as the temperature was increased from 300 to 900 C. The catalytic activity was expressed as the temperature for a given methane conversion, e.g. T10% , T50% and T90% , at which CH4 conversion was 10%, 50% and 90%, respectively. The schematic diagram of the catalytic evaluation system is shown in Fig. 1. 3. Results and discussion 3.1. Effect of incorporation TiO2 into nanocomposites on CH4 response The response of the nanocomposites prepared by controlled coprecipitation under the optimum condition were measured and correlated with their preparation parameters and composition. The response data of SnO2 , binary and ternary nanocomposites to 850 ppm CH4 were presented in Fig. 2. The binary nanocomposite of 25%InO1.5 75%SnO2 had a higher response of 7.2 than that of pure SnO2 at an operating temperature of 300 C. Incorporation of InO1.5 as a secondary component notably enhances the response of SnO2 up to InO1.5 content = 40 mol%. Since the ionic radius of In3+ (0.8 ) is considerably different from that of Sn4+ (0.69 ), substitutional dissolution of In3+ ions into the SnO2 lattice is difcult, and thus the InO1.5 diffraction peaks were not observed in XRD patterns. So, the InO1.5 (<40% mol) might exist as an amorphous oxide coating on the SnO2 nanocrystallites, and is considered to act as a barrier against the development of grain boundaries of SnO2 and effectively prevent the grain growth and a loss in surface area in the calcination process. For the higher InO1.5 loading composite, both SnO2 and InO1.5 crystalline phase were observed in the XRD patterns. The crystallization of InO1.5 was accompanied by a loss of specic surface area and the response decreased. An appropriate amount of a TiCl4 solution was added dropwise to the precipitated solution of In3+ and Sn4+ while vigorously stirring, and then the precipitation was aged for 24 h at room temperature, then ltrated, washed, dried and ground to precursor powders. The precursors were calcined at 600 C for 6 h to form the ternary nanocomposites of TiO2 , InO1.5 and SnO2 . The effect of the amount of TiO2 added on the response to

A. Chen et al. / Sensors and Actuators B 135 (2008) 712

Fig. 2. Response of nanocomposites incorporating TiO2 to 850 ppm CH4 . (a) SnO2 , (b) 25%InO1.5 75%SnO2 , (c) 25%InO1.5 75%SnO2 10%TiO2 , (d) 25%InO1.5 75%SnO2 20%TiO2 , (e) 25%InO1.5 75%SnO2 30%TiO2 .

Fig. 4. XRD patterns of (a) SnO2 , (b) (25%InO1.5 75%SnO2 20%TiO2 , (c) (25%InO1.5 75%SnO2 )30%TiO2 .

CH4 was studied (Fig. 2). The response of the ternary nanocomposite towards 850 ppm CH4 was raised from 7.2 to 8.3 by introducing 10% TiO2 at an operating temperature of 300 C. When introducing 20 mol% TiO2 , the CH4 response was signicantly enhanced from 7.2 to 13.6 at the same temperature. This ternary composite was termed the optimum composite for the detection of CH4 . It was conrmed that the specic surface of the ternary nanocomposite containing 20 mol% TiO2 had a dramatic increase from 60.9 to 101.9 m2 g1 by the BET specic surface measurement, and the crystallite size of SnO2 in this composite decreased to 4 nm, which was estimated from Scherres formula by the diffraction peak (1 1 0) of SnO2 in XRD analysis. The crystallite phase of TiO2 was not observed for the optimum composite as shown in Fig. 4, and the TiO2 was not substituted into the SnO2 lattice because the unit cell parameters, a (4.776 ) and c (3.169 ), did not exhibit observable changes compared with a (4.738 ) and c (3.187 ) of SnO2 though the ionic radius of Ti4+ (0.62 ) is near to that of Sn4+ (0.69 ). The TiO2 dispersed as amorphous phase on the surface of SnO2 also enhanced the thermal stability of the SnO2 in the composite. A TEM photograph of the ternary composite containing 20% TiO2 was shown in Fig. 3. As can be seen, the particle shape was spherical and the powders were uniform in size (about 16 nm) for the composite calcined

at 600 C. But, when the amount of TiO2 was further increased to 30 mol%, the CH4 response in Fig. 2 was lower than that of the binary composite even that of SnO2 under various operating temperatures. These results were in good agreement with those observed by XRD analysis. Fig. 4 shows the XRD patterns of SnO2 and nanocomposites incorporating 20 and 30 % TiO2 . The diffraction peaks became wider than SnO2 after introducing TiO2 , indicating that the SnO2 crystallite size changed smaller. When the amount of TiO2 added reached 30 mol%, diffraction peaks of TiO2 were detected in Fig. 4. Thus, crystallization of TiO2 was also accompanied together with a loss of surface area and grain growth. The addition of excess TiO2 would decrease the response of the ternary nanocomposite to CH4 . Selectivity (e.g. cross response) is one of important gas-sensing properties for gas sensors. The selectivity between CH4 and CO is still one of the major problems for application of CH4 sensors due to the same reducing character of both gases. The effect of introducing TiO2 on the response of CO was also studied. The experimental data were presented in Fig. 5. It was obvious that the CO responses were decreased by introducing TiO2 into the

Fig. 3. A TEM photograph of the optimum ternary nanocomposite calcined at 600 C for 6 h.

Fig. 5. Response of nanocomposites incorporating TiO2 to 850 ppm CO. (a) 25%InO1.5 75%SnO2 , (b) (25% InO1.5 75%SnO2 )10%TiO2 , (c) (25% InO1.5 75%SnO2 )20%TiO2 , (d) (25% InO1.5 75% SnO2 )30% TiO2 .

10

A. Chen et al. / Sensors and Actuators B 135 (2008) 712

25% InO1.5 75%SnO2 composite at an operating temperature of 100350 C. The responses of CO at various temperatures were lower than those of the binary composite containing 25% InO1.5 . Thus, incorporation of TiO2 enhanced the CH4 selectivity against CO at the same operating temperature and gas concentration. For example, the CH4 selectivity of the binary composite without TiO2 was 1.1 at an operating temperature of 200 C, while the CH4 selectivity of the optimum ternary composite against CO was enhanced to 7.4, which was 6.5 times higher than that achieved by the binary nanocomposite of 25%InO1.5 75% SnO2 . What is more, the CH4 selectivity was enhanced from 0.54 and 0.79 to 6.3 and 6.7 at operating temperatures of 250 and 300 C, respectively, which were 12.0 times and 8.5 times higher than that achieved by the binary composite without TiO2 . The experimental data have demonstrated that the response and selectivity of the semiconducting sensors were greatly affected by introducing other oxides. 3.2. Effect of calcination and operating temperature on the CH4 response The heat treatment provides useful information on the thermal and phase stability as well as the sensing properties. The sensing materials have to be calcined at appropriate temperature to achieve a sufcient degree of crystallization, which is required to attain the desired sensing and catalytic performance for the application as a sensor and a catalyst. When calcination temperature was lower than 600 C, for example 400 C, the optimum composite had the highest specic surface area over 101.9 m2 g1 , but the sensor response was lower. This was because the optimum composite calcined at 400 C did not satisfy the requirement of sufcient crystallinity for a sensor. However, when the calcination temperature was above 600 C, the SnO2 crystallite in the nanocomposites underwent substantial growth or agglomeration, causing decrease in the surface area and the response. An appropriate calcination temperature of 600 C ensured sufcient SnO2 crystallinity in the optimum nanocomposite and without signicant grain growth to achieve a maximum response and catalytic activity. The calcination temperature was thus an important parameter for gas-sensing and catalytic activity in sensors and catalysts. The response test results were in good agreement with the characterization of BET specic surface and XRD analysis. The response of the nanocomposites was related not only with the calcination temperature but also with the operating temperature. As we can see from Figs. 2, 5 and 6, the gas response increased with an increase in operating temperature and reached a maximum value at a certain temperature. If the operating temperature increased again, the response decreased. The behavior was explained by taking into account that the chemisorption of O2 and CH4 needs activation energy; that is, the adsorption amounts would gradually increase with temperature until the rate of desorption became equal to the rate of adsorption, which would facilitate the sensor to oxidize CH4 molecules, immediately giving larger gas response. If the temperature was further increased, the amount of gases adsorbed would decrease with temperature, leading to the decrease of the gas response. 3.3. Effect of additives on CH4 response Many reports have demonstrated that the gas-sensing properties of semiconducting sensors are greatly improved by introducing other metal oxides or noble metals. In this study, the method of additive introduction as well as the nature and loading of additives were examined for the optimum nanocomposite. Nitrate or chloride salts of desired metal cations introduced to the precursor solution prior to precipitation were considered as dopants, while

Fig. 6. Effect of additives to CH4 response. (a) (25% InO1.5 75% SnO2 )20% TiO2 , (b) (25% InO1.5 75%SnO2 )20%TiO2 0.5 wt% MgO, (c) (25%InO1.5 MgO, (d) (25%InO1.5 75%SnO2 )20%TiO2 3 wt% 75%SnO2 )20%TiO2 1 wt% MgO, (e) (25%InO1.5 75%SnO2 )20%TiO2 3 wt% Pt.

those nitrate salts added through impregnating the dried precursor of nanocomposite were regarded as surface modiers or coatings. The experimental data showed that the CH4 response was enhanced from 7.2 to 13.6 at an operating temperature of 250 C by introducing 20% TiO2 into the 25% InO1.5 75% SnO2 composite (Fig. 2). TPD studies showed that the optimum nanocomposite had enhanced CH4 adsorption capability in comparison with that of pure SnO2 (Fig. 7), which was consistent with the larger CH4 response of optimum composite than that of pure SnO2 . The nature and loading of additives were further examined for optimum composite. A Pt dopant of a chloride form was introduced into the tin chloride precursor solution, and the amount of Pt ranged from 13 wt% (Pt/Sn), all the subsequent processes being the same as those described in the experimental section. Surface modication by impregnation was also employed in this paper. The dried precursor of the optimum nanocomposite was mixed with some amount of Mg(NO3 )2 solution in a range between 0.5 and 3 wt% (Mg/Sn),

Fig. 7. TPD of CH4 from (a) SnO2 and (b) (25%InO1.5 75%SnO2 )20%TiO2 .

A. Chen et al. / Sensors and Actuators B 135 (2008) 712 Table 1 Catalytic activity of nanocomposites incorporating TiO2 and coated with MgO. Samples 25%InO1.5 75%SnO2 (25%InO1.5 75%SnO2 )10%TiO2 (25%InO1.5 75%SnO2 )20%TiO2 (25%InO1.5 75%SnO2 )30%TiO2 (25%InO1.5 75%SnO2 )20%TiO2 1%MgO T10% ( C) 527 509 491 543 462 T50% ( C) 598 573 557 604 558 T90% ( C) 649 621 601 658 597

11

4. Gas-sensing mechanism of nanocomposites The fundamental sensing mechanism of metal oxide based gas sensors relies on a change in electrical conductivity due to the interaction process between the surface reactive chemical species and the gas molecules to be detected. The interaction includes chemical and electronic processes, and the chemical interaction involves the adsorption and the reaction between the adsorbed gas and oxygen on the surface of the semiconductor oxides. At elevated temperature, oxygen molecules in air are chemisorbed on the semiconductor surface and react with the excess electrons in the semiconductor, to give chemisorbed oxygen anions (Oads ), O2 + 2e 2Oads This would create an electron-depleted region, known as the space charge layer, on the surface of these sensor materials. When test gases are adsorbed, electrons are added to or removed from the space charge layer, leading to a change in electrical conductivity of the sensor. The adsorbed reducing gas G (CH4 ) reacts with the chemisorbed oxygen anions to be oxidized G + Oads GOdes + e and the removed chemisorbed oxygen anions cause a change in the thickness of the space charge layer and an increase of free electron concentration, leading to an increase in conductivity (or a decrease in resistance) of the semiconductor oxide. In contrast, the n-type semiconductors change their resistance from low to high in the presence of oxidizing gases (NO2 ) because the gases capture electrons and are reduced. TPD studies showed that the 25% InO1.5 75% SnO2 nanocomposite incorporating TiO2 enhanced CH4 and O2 adsorption in comparison with pure SnO2 and 25% InO1.5 75% SnO2 nanocomposite (Fig. 7), which was consistent with the higher CH4 response of the same nanocomposite. The second type electronic interaction involves direct electron exchange between components in the composites, which may be evidenced by XPS analysis. XPS analysis was performed on the 20% TiO2 added 25% InO1.5 75% SnO2 nanocomposite. The measured binding energies (Table 2) of Sn3d5/2, In3d5/2, Ti2p3/2 and O1s were 488.7 eV, 446.7 eV, 454.7eV and 532.7eV, respectively, while their binding energies for pure SnO2 , InO1.5 and TiO2 were 486.4 eV, 445.6 eV, and 453.8 eV, respectively, with the same of O1s value of 531.0 eV. Signicant positive chemical shifts of 2.3 eV, 1.1 eV, 0.9 eV and 1.7 eV in the Sn3d5/2, In3d5/2, Ti2p3/2 and O1s peaks relative to those for pure SnO2 , InO1.5 and TiO2 were observed for the optimum nanocomposite. This suggested that electronic interactions existed between SnO2 , InO1.5 and TiO2 in the nanocomposite. The shifts in binding energies reected the shifts in the Fermi energy of SnO2 due to the electronic interaction with InO1.5 and TiO2 , which was responsible for the enhanced gas response of the nanocomposite. It also suggested that the electronic interactions of metal oxide semiconductors played an important role in enhancing the CH4 response. Thus, the gas-sensing performance of the nanocomposites may be attributed to the synergistic effects of chemical and electronic [10].

Table 2 Binding energies of pure oxides and composites. Samples SnO2 In2 O3 TiO2 25%InO1.5 75%SnO2 (25%InO1.5 75%SnO2 )20%TiO2 Sn3d5/2 486.4 487.0 488.7 Binding energy (eV) In3d5/2 445.6 445.5 446.7 Ti 2p3/2 453.8 454.7 O1s 531.0 531.0 531.0 531.5 532.7

then calcined at 600 C for 6 h to form the nanocomposite with an oxide surface layer. It was found that the effect of the surface modication through the impregnation method was more effective than the above-described method. The sensing test results showed that the CH4 response increased from 12.0 to 24.3, 28.5 and 17.5 at an operating temperature of 250 C, when impregnated with 0.5 wt%, 1 wt% and 3 wt% Mg(NO3 )2 , respectively. Particularly, the doping of 3 wt% Pt enhanced the CH4 response from 13.6 to 47.2 at an operating temperature of 300 C. It is well known that the CH4 response arises from the adsorption of the test gas and the surface reactions of the adsorbed gases on the active sites of the material. Doping a noble metal of Pt as a catalyst decreased the activation energy of chemisorption and enhanced the rate of surface reaction of the test gas, leading to an increase in response or a decrease in optimum operating temperature of the ternary composite. The MgO coating supplied a larger surface area and a large amount of surface active sites for both gas adsorption and surface reaction, resulting in an increase in CH4 response. Sberveglieri et al. [9] reported a large increase in NO2 response of SnO2 using a mechanical mixture of 10 wt% Al2 O3 and 90 wt% SnO2 , and the effect was attributed to enhanced NO2 adsorption on the SnO2 surface. 3.4. Effect of introducing TiO2 and MgO on catalytic activity of CH4 oxidation Sensing properties of semiconductor CH4 sensors have a signicant inuence on their activities for catalytic oxidation. The catalytic activities of sensing materials for methane oxidation have been examined by a micro xed-bed reactor system. The experimental results were presented in Table 1. It showed that the ternary nanocomposites containing 10% and 20% TiO2 had higher catalytic activities than the 25% InO1.5 75%SnO2 nanocomposite; especially, the nanocomposite incorporating 20% TiO2 had the highest catalytic activity, whose T10% (light-off temperature) and T90% (dened full combustion temperature) values were 491 C and 601 C, respectively, the difference of both being only 110 C, while the catalytic activity of the composite containing 30 % TiO2 was far lower than other samples. It illustrated that the catalytic activity was straightforwardly related to the sensing response. The rate of variation of the methane conversion with the temperature increase reached a maximum value, which corresponded to half of the maximum catalytic conversion. At higher temperature, there was a decrease in the variation rate, corresponding to the decrease of the amount of CH4 molecules remaining on the sites available for their catalytic conversion. In a parallel way, the sensor response increased with the operating temperature reaching a maximum, then decreasing as the temperature further increased. However, the sensing characteristics of the sensor corroborated that the response decreases before the catalytic conversion achieves its maximum saturation value [10]. The catalytic activities for CH4 oxidation were also further enhanced by the surface modication with 1% MgO for the 25 % InO1.5 75 % SnO2 nanocomposite containing 20%TiO2 ; the T10% and T90% values decreased from 527 C and 649 C to 462 C and 597 C, respectively, as shown in Table 1.

12

A. Chen et al. / Sensors and Actuators B 135 (2008) 712 [4] G. Zhang, M.L. Liu, Effect of particle size and dopant on properties of SnO2 -based gas sensor, Sens. Actuators B 69 (2000) 144152. [5] J.T. McCue, J.Y. Ying, SnO2 In2 O3 nanocomposites as semiconductor gas sensors for CO and NOx detection, Chem. Mater. 19 (2007) 10091015. [9] G. Sberveglieri, G. Faglia, S. Groppelli, P. Nelli, Methods for the preparation of NO, NO2 and H2 sensors based on tin oxide thin lms grown by means of the sputtering technique, Sens. Actuators B 8 (1992) 7988. [10] O. Safonova, I. Bezverkhy, P. Fabrichnyi, Mechanism of sensing CO in nitrogen by nanocrystalline SnO2 and SnO2 (Pd) studied by Mssbauer spectroscopy and conductance measurements, J. Mater. Chem. 12 (2002) 11741178.

5. Conclusions The sensing nanocomposites based on Sn, In and Ti oxides were successfully derived with high response and selectivity for CH4 through optimizing the preparation parameters. Their optimal conditions were a 0.05 M salt concentration, a precipitation pH of 8, an aging time of 24 h. The optimized composition, the most appropriate calcination temperature, operating temperature, and the amounts of a doping metal and a coating oxide were 20%Ti-(25%InO1.5 75%SnO2 ), 600 C, 300 C, 3% Pt and 1% MgO, respectively. Enhancement of gas-sensing properties of the semiconducting CH4 sensor could be attributed to the much smaller crystallite size of SnO2 , the adsorption behavior and chemical reaction of CH4 and O2 on the composite surface, and introduction of the additives. The sensing behavior was straightforwardly related to the catalytic activity for CH4 oxidation. The sensing mechanism was attributed to synergistic effects of chemical and electronic. Acknowledgements This research work was supported by the National Natural Science Foundation of China (Nos.: 50872007, 50702004 and 20706004) and Beijing Natural Science Foundation (Nos.: 8072018 and 8082018). References

[1] N. Yamazeo, N. Miura, Some basic aspects of semiconductor gas sensor, Chem. Sens. Tech. 4 (1992) 1923. [2] B.R. Eggins, Chemical Sensors and Biosensors, John Wiley & Sons Ltd., England, 2003 (Chinese translation by Chen Aifan, Chen Lianghuan and Luo Ruixian, Chemical Industry Press, Beijing, 2005). [3] X.D. Huang, S.L. Bai, D.Q. Li, R.X. Luo, A.F. Chen, C.C. Liu, Preparation, characterization and gas sensing properties of ZnOSnO2 nanocomposites, Chin. J. Inorg. Chem. 21 (2005) 11431148.

Biographies

Chen Aifan was a visiting professor at Purdue University and Case Western Reserve University in 19861988. His research interests are in catalysis and sensors. He is currently a professor at College of Science of Beijing University of Chemical Technology (BUCT). Bai Shouli received MS in physical chemistry from Chinese Academy of Science in 1990. His research interests are in the eld of catalysis and sensors, he is presently a research fellow and doctoral tutor in BUCT. Shi Bingjie received MS in chemical engineering from BUCT in 2003. Her research interests are in the separating eld of chemical engineering, she is currently a associate Professor and pursuing PhD degree in chemical engineering at BUCT. Liu Zhiyong studied Rare Earth perovskite-type semiconductor sensors at BUCT, he will receive MS degree in May 2009. Li Dianqing was awarded MS in 1989 from Beijing Institute of Chemical Technology and PhD degree in 2001 from Tianjin University. His main research interests are in the areas of novel functional inorganic materials. He is currently a professor and doctoral tutor in State key Laboratory of Chemical Resource Engineering at BUCT. Chung Chiun Liu is the Wallace R. Persons professor of Sensor Technology and Control. He is Director of the Electronic Design Center and professor in the Department of Chemical Engineering at Case Western Reserve University. His research interest is in the areas of electrochemical engineering, microelectronic material and fabrication processes. He works in the areas of electrochemical and biomedical sensors.

Vous aimerez peut-être aussi

- Abstract Template - ICSM 2014Document1 pageAbstract Template - ICSM 2014NEMI CHAND SOODPas encore d'évaluation

- Ar ConstructionDocument2 pagesAr ConstructionNEMI CHAND SOODPas encore d'évaluation

- 2451 Cel C&B EarthworkDocument2 pages2451 Cel C&B EarthworkNEMI CHAND SOODPas encore d'évaluation

- Ejigh Sensitivity and Selectivity Methane Gas Sensors Doped With RH A43 A CatalystDocument4 pagesEjigh Sensitivity and Selectivity Methane Gas Sensors Doped With RH A43 A CatalystNEMI CHAND SOODPas encore d'évaluation

- Excess (+) %: ValidateDocument22 pagesExcess (+) %: ValidateNEMI CHAND SOODPas encore d'évaluation

- LED Basics - How To Tell Which Lead Is Positive or Negative - West Florida ComponentsDocument3 pagesLED Basics - How To Tell Which Lead Is Positive or Negative - West Florida ComponentsNEMI CHAND SOODPas encore d'évaluation

- Rajasthan Knowledge Corporation LTDDocument2 pagesRajasthan Knowledge Corporation LTDNEMI CHAND SOODPas encore d'évaluation

- mobile services bill detailsDocument68 pagesmobile services bill detailsNEMI CHAND SOODPas encore d'évaluation

- Gas Leak Detector CircuitDocument12 pagesGas Leak Detector CircuitNEMI CHAND SOODPas encore d'évaluation

- Motar Gredar QuaitationDocument1 pageMotar Gredar QuaitationNEMI CHAND SOODPas encore d'évaluation

- 1 s2.0 S0925400508001287 MainDocument6 pages1 s2.0 S0925400508001287 MainNEMI CHAND SOODPas encore d'évaluation

- 6Document4 pages6NEMI CHAND SOODPas encore d'évaluation

- A Study On Thin ®LM Gas Sensor Based On Sno Prepared by Pulsed Laser Deposition MethodDocument5 pagesA Study On Thin ®LM Gas Sensor Based On Sno Prepared by Pulsed Laser Deposition MethodNEMI CHAND SOODPas encore d'évaluation

- Ejigh Sensitivity and Selectivity Methane Gas Sensors Doped With RH A43 A CatalystDocument4 pagesEjigh Sensitivity and Selectivity Methane Gas Sensors Doped With RH A43 A CatalystNEMI CHAND SOODPas encore d'évaluation

- Nemi Chand Sood C/O Badri Narayan Sood 47-Shivnath Vihar Sirsi Road Bhankrota Jaipur Jaipur Rajasthan Rajasthan 302026Document3 pagesNemi Chand Sood C/O Badri Narayan Sood 47-Shivnath Vihar Sirsi Road Bhankrota Jaipur Jaipur Rajasthan Rajasthan 302026NEMI CHAND SOODPas encore d'évaluation

- 16Document5 pages16NEMI CHAND SOODPas encore d'évaluation

- 15Document7 pages15NEMI CHAND SOODPas encore d'évaluation

- 5Document4 pages5NEMI CHAND SOODPas encore d'évaluation

- 9Document4 pages9NEMI CHAND SOODPas encore d'évaluation

- 17Document5 pages17NEMI CHAND SOODPas encore d'évaluation

- Norms For Engineering Non Eng Annex-G5Document14 pagesNorms For Engineering Non Eng Annex-G5NEMI CHAND SOODPas encore d'évaluation

- 8Document2 pages8NEMI CHAND SOODPas encore d'évaluation

- Efficient 3.3ym Light Emitting Diodes For Detecting Methane Gas at Room TemperatureDocument2 pagesEfficient 3.3ym Light Emitting Diodes For Detecting Methane Gas at Room TemperatureNEMI CHAND SOODPas encore d'évaluation

- Magnetocrystalline Anisotropy in L10 Fept and Exchange Coupling in Fept/Fe3Pt NanocompositesDocument15 pagesMagnetocrystalline Anisotropy in L10 Fept and Exchange Coupling in Fept/Fe3Pt NanocompositesNEMI CHAND SOODPas encore d'évaluation

- Efficient 3.3ym Light Emitting Diodes For Detecting Methane Gas at Room TemperatureDocument2 pagesEfficient 3.3ym Light Emitting Diodes For Detecting Methane Gas at Room TemperatureNEMI CHAND SOODPas encore d'évaluation

- Affidavit On Rs. 10/-Non Judicial Stamp PaperDocument1 pageAffidavit On Rs. 10/-Non Judicial Stamp PaperNEMI CHAND SOODPas encore d'évaluation

- Accreditation CriteriaDocument39 pagesAccreditation CriteriaNEMI CHAND SOODPas encore d'évaluation

- Dget Iti User ManualDocument82 pagesDget Iti User ManualNEMI CHAND SOODPas encore d'évaluation

- Termpaper Ee618Document3 pagesTermpaper Ee618NEMI CHAND SOODPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (120)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- FLOW 3D General BrochureDocument12 pagesFLOW 3D General BrochurehhadPas encore d'évaluation

- Textile Testing and Quality Control: End-Term JuryDocument20 pagesTextile Testing and Quality Control: End-Term Jurytripti keshanPas encore d'évaluation

- ENG-TIPS de Vessel Circular Section Single Diametral Staying Member Rev 000c-3Document1 pageENG-TIPS de Vessel Circular Section Single Diametral Staying Member Rev 000c-3RomeoMendozaPas encore d'évaluation

- Junction Diode Characteristics ReviewDocument55 pagesJunction Diode Characteristics ReviewSanthosh DheerajPas encore d'évaluation

- Ibtm5660 2223-08Document84 pagesIbtm5660 2223-08Yuki ChanPas encore d'évaluation

- Chem 121-1Document45 pagesChem 121-1Zechariah NggitaPas encore d'évaluation

- Glyphosate MSDS SummaryDocument5 pagesGlyphosate MSDS SummaryAhfi Rizqi FajrinPas encore d'évaluation

- Electrocoagulation of Wastewater Using Aluminum, Iron, and MagnesiumDocument7 pagesElectrocoagulation of Wastewater Using Aluminum, Iron, and MagnesiumPraveen KumarPas encore d'évaluation

- Single Effect Evaporation Final (Compatibility Mode)Document19 pagesSingle Effect Evaporation Final (Compatibility Mode)AlfiNurfauziahPas encore d'évaluation

- Polycarbonate (PC) : PropertiesDocument3 pagesPolycarbonate (PC) : PropertiesnaninoPas encore d'évaluation

- Thermal analysis of inoculation effects on ductile iron solidificationDocument13 pagesThermal analysis of inoculation effects on ductile iron solidificationXantos YulianPas encore d'évaluation

- 1Document8 pages1surajchutiyaPas encore d'évaluation

- Gymnast's Balance BeamDocument3 pagesGymnast's Balance BeamPakito XtradaPas encore d'évaluation

- CBN/Diamond Coated Carbide Insert GuideDocument10 pagesCBN/Diamond Coated Carbide Insert GuideChellamuthu MechPas encore d'évaluation

- Experiences with 2.25Cr-1Mo-Steel Equipment after 30 Years: Cracking InsightsDocument10 pagesExperiences with 2.25Cr-1Mo-Steel Equipment after 30 Years: Cracking InsightsGrootPas encore d'évaluation

- Science: Quarter 1 - Module 2: Elements Are Like Spices, When Mixed Together, They Become BetterDocument33 pagesScience: Quarter 1 - Module 2: Elements Are Like Spices, When Mixed Together, They Become BetterGINA OTARAPas encore d'évaluation

- PIPES FITTINGS, VALVES AND PUMPS (SCHMIDTDocument16 pagesPIPES FITTINGS, VALVES AND PUMPS (SCHMIDTMoca PhoenixPas encore d'évaluation

- 1.1 LOKRING Brass Technical-Submittal enDocument32 pages1.1 LOKRING Brass Technical-Submittal enByron RubyPas encore d'évaluation

- Natural Muscovite Block Mica and Thins Based On Visual QualityDocument6 pagesNatural Muscovite Block Mica and Thins Based On Visual QualityMaxPas encore d'évaluation

- Fire-Safe Triple Offset Butterfly ValveDocument22 pagesFire-Safe Triple Offset Butterfly ValveDevendra BangarPas encore d'évaluation

- A Review On Minimum Quantity Lubrication For Machining ProcessesDocument20 pagesA Review On Minimum Quantity Lubrication For Machining ProcessesYanuar Hennry ChristianPas encore d'évaluation

- ChemicalDocument232 pagesChemicalhendra93Pas encore d'évaluation

- Lec 7-8 Module 1 Lec 9 Module 3Document39 pagesLec 7-8 Module 1 Lec 9 Module 3vedant chavanPas encore d'évaluation

- Astm A255Document26 pagesAstm A255Yherson Cerin Chavarria100% (1)

- Paints & CoatsDocument29 pagesPaints & CoatsMaitreyi YellapragadaPas encore d'évaluation

- 02 States of Matter + ExpansionDocument5 pages02 States of Matter + ExpansionmelissaPas encore d'évaluation

- APHA 3125 (Logam) Air PDFDocument11 pagesAPHA 3125 (Logam) Air PDFdini100% (1)

- V Shape Block Drain (JKR) - Enrich Multitrade Sdn. Bhd.Document4 pagesV Shape Block Drain (JKR) - Enrich Multitrade Sdn. Bhd.AdrianPas encore d'évaluation

- Structure and Bonding Updated 2Document82 pagesStructure and Bonding Updated 2jadabrown542Pas encore d'évaluation

- Qingdao Headway Technology Co LTD - Amy Qu PDFDocument27 pagesQingdao Headway Technology Co LTD - Amy Qu PDFvangeliskyriakos8998Pas encore d'évaluation