Académique Documents

Professionnel Documents

Culture Documents

Argus Automatic Pigging Brochure

Transféré par

Kehinde AdebayoCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Argus Automatic Pigging Brochure

Transféré par

Kehinde AdebayoDroits d'auteur :

Formats disponibles

PIGGING

2 inch through 12 inch

AUTOM ATIC

For safe and efficient pigging

ARGUS MACHINE CO. LTD.

www.argusmachine.com

The Argus Automatic Pig Launcher allows for remote pigging operation for up to eleven launches. This system is ideally suited for remote well locations, limited access, offshore production platforms and environmentally sensitive areas.

CONSIDER THESE BENEFITS

1. 2. 3. 4. 5. 6. 7. 8. 9. Optimized production through effective liquids sweeping and debris removal Reduced travel time and operator intervention resulting in lower operational costs Remote pigging from the control room Enhanced operator safety through reduced intervention Reduced emissions by more than 85% Reduce and prevent the formation of hydrates by effectively keeping moisture content in the pipeline at lower levels Mitigate corrosion through frequent pigging Maintain pipeline integrity Small footprint and minimized weight for offshore applications

10 Pneumatic, electric eld power supply, manual or self contained solar actuation options

INVEST IN INCREASED PRODUCTIVITY

Gas ow rates - and ultimately, your bottom line - are inuenced by pipeline constrictions. Debris and extraneous uid within the pipeline causes reduced ow and results in decreased production. Installation of an Argus Automatic Pig Launcher, coupled with an appropriate pigging program, consistently maintains lower pressure within the pipeline. This equates to more efcient ow rates and increased production. While the payback period may vary, the purchase of an Argus Automatic Pig Launcher is an investment which pays for itself in a relatively short period of time, then continues to generate prots.

REDUCE EMISSIONS BY MORE THAN EIGHTY-FIVE PERCENT

Compared to conventional barrel-style launching and receiving, the Argus Automatic Pig Launcher is clearly more efcient, saving you time and money.

GAS EMISSIONS COMPARISON

Argus Automatic Pig Launcher vs. Fabricated Barrel-Style Launching & Receiving Traps

12" 4+1 Pigs 10" 4+1 Pigs 8" 6+1 Pigs 6" 10+1 Pigs 4" 10+1 Pigs 3" 10+1 Pigs 2" 10+1 Pigs

90% 92% 93% 92% 87%

86 %

Argus Automatic Pig Launcher Fabricated, Barrel-Style Launching & Receiving Traps

92%

1,000

2,000

3,000

4,000

5,000

6,000

7,000

8,000

Emission Volume (ft 3)

*Comparison criteria based on one cycle of the Automatic Pig Launcher compared to equivalent number of cycles required by the Barrel Launcher as dictated by total number pigs. (Approximation uses the "ideal gas law", constant temperatures, and gas pressure @ 1480 psi).

OPERATION AND LOADING OF AUTOMATIC PIG LAUNCHER

PRESSURE ALERT VALVE

STEPS 1-6

1 2 3 4 5 6

Close pig valve (gain of signal) Shut-off valve on pressure energizing line must be closed Relieve pressure in pig launcher by opening the blow-down valve

SHUT-OFF VALVE (SPRING RETURN) PRESSURE EQUALIZING LINE

BLOW-DOWN VALVE

STEP 7

7

PIG WEIGHT

Open closure & remove pig weight using the supplied pig weight retriever

Open drain valve on bottom of pig valve (if equipped) Install safety pin through actuator adapter, preventing accidental operation of valve (pin should freely engage to ring) Open pressure alert valve (verify system has been effectively bled-down)

STEPS 9-14 STEP 8

8

Install Argus pigs nose down & re-install pig weight

9 10 11 12 13 14

Re-install cap on closure & pressure alert valve Close blow-down & drain valves Remove safety pin from actuator adapter Hold-open the shut-off valve on the pressure equalizing line until pig launcher chamber is fully energized Check closure, pressure alert valve, & blow-down valve for leakage Open pig valve and launch 1st pig (loss of signal)

* The above operational procedure pertains to a pneumatically operated Argus Automatic Pig Launcher. This procedure will vary according to operational and actuation methods.

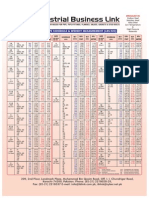

WEIGHTS AND DIMENSIONS

MODEL P 10+1 AUTOMATIC PIG LAUNCHERS

SIZE AND PRESSURE RATING 2" 2" 2" 3" 3" 3" 4" 4" 4" 6" 6" 6" 150 ANSI 300 ANSI 600 ANSI 150 ANSI 300 ANSI 600 ANSI 150 ANSI 300 ANSI 600 ANSI 150 ANSI 300 ANSI 600 ANSI A (Overall Length) RF inches 11.50 14.25 14.25 12.75 14.00 14.00 15.50 16.00 17.00 18.00 18.88 22.00 mm 292 362 362 324 356 356 394 406 432 457 480 559 inches 11.88 14.62 14.62 13.12 14.12 14.12 16.00 16.62 17.12 18.38 19.38 22.12 RTJ mm 302 371 371 333 359 359 406 422 435 467 492 562 inches B mm inches C mm inches D mm inches E mm APPROX. WEIGHT lbs 205 215 215 290 310 310 530 540 560 1080 1120 1200 kg 93 98 98 132 141 141 240 245 254 490 508 544

59.25

1505

4.00

102

7.62

194

6.25

159

72.72

1847

4.75

121

8.38

213

6.50

165

94.56

2402

5.62

143

10.75

273

8.50

216

126.56

3215

7.12

181

12.12

308

9.88

251

MODEL D 6+1 AUTOMATIC PIG LAUNCHERS

SIZE AND PRESSURE RATING 8" 300 ANSI 8" 600 ANSI 28.50 31.20 A (Overall Length) RF 724 792 29.00 31.32 RTJ 737 109.25 796 2775 10.67 271 32.70 831 12.00 305 2755 1250 inches B mm inches C mm inches D mm inches E mm APPROX. WEIGHT lbs 2605 kg 1182

MODEL D 4+1 AUTOMATIC PIG LAUNCHERS

10" 300 ANSI 10" 600 ANSI 12" 300 ANSI 12" 600 ANSI 35.36 37.12 40.75 42.06 898 943 1035 1068 35.86 37.25 41.25 42.19 911 98.50 946 1048 111.50 1071 2832 14.17 360 38.88 988 15.66 398 6130 2781 2502 12.00 305 34.56 878 13.62 346 3975 5950 1803 2699 3800 1724

E D

MODEL P

MODEL D

C A A

Argus Machine Co. Ltd. has provided design expertise, quality manufacturing and reliable service to the oil and gas industry since 1958. Argus holds five API licenses and has a quality assurance program that is certified to API Q1 and ISO 9001:2008; ensuring audited quality in all our products.

ARGUS MACHINE CO. LTD.

HOUSTON 12623 Duncan Rd, Suite I Houston, Texas 77066 Phone: (281) 781-8581 5820 97th Street Edmonton, AB Canada T6E 3J1 Phone: (780) 434-9451 Toll Free: 1-888-434-9451 CALGARY 1450, 540 - 5th Avenue SW Calgary, AB T2P 0M2 Phone: (403) 263-3517

www.argusmachine.com

Copyright 2010 Argus Machine Co. Ltd. All rights reserved AMCL00 *Design & specifications subject to change without prior notice

Vous aimerez peut-être aussi

- Hydrogen Transfer Eng Hyd 1Document4 pagesHydrogen Transfer Eng Hyd 1minsseok hhaPas encore d'évaluation

- Ful Vane Gas Compressors 2011Document8 pagesFul Vane Gas Compressors 2011nricquartPas encore d'évaluation

- HFD Catalog CN PDFDocument13 pagesHFD Catalog CN PDFPartsGopher.comPas encore d'évaluation

- Pump SpecificationsDocument2 pagesPump Specificationsstranger252LavaPas encore d'évaluation

- Pneumatic Metering PumpsDocument7 pagesPneumatic Metering PumpsDayo IdowuPas encore d'évaluation

- TD Pmo 6000 en 080108Document16 pagesTD Pmo 6000 en 080108Ricardo DávilaPas encore d'évaluation

- Engineered Nitrogen Generator Systems - E4Document8 pagesEngineered Nitrogen Generator Systems - E4herdin56Pas encore d'évaluation

- V Series Pneumatic Metering PumpDocument6 pagesV Series Pneumatic Metering PumpDayo IdowuPas encore d'évaluation

- 41 Sullair Openframe COMPRESORES SIMMADocument2 pages41 Sullair Openframe COMPRESORES SIMMAWalter Andrés OrqueraPas encore d'évaluation

- A12370 PerformanceDocument2 pagesA12370 PerformanceClef GonadanPas encore d'évaluation

- Zest Iris Duct DamperDocument6 pagesZest Iris Duct Damperfaisal58650Pas encore d'évaluation

- All Diafragms Meters Sb3500Document17 pagesAll Diafragms Meters Sb3500Ruben Romero SotoPas encore d'évaluation

- Tappan Furnace FG6RK 096N 16BDocument4 pagesTappan Furnace FG6RK 096N 16BAnubis RahlPas encore d'évaluation

- Actionair Iris DamperDocument12 pagesActionair Iris DamperPeterOLearyPas encore d'évaluation

- Catálogo de Flujometros Industriales Spirax SarcoDocument152 pagesCatálogo de Flujometros Industriales Spirax SarcosaconaconacaPas encore d'évaluation

- Automax Valve Automation Systems - Pneumatic Actuators and Accessories - FlowserveDocument24 pagesAutomax Valve Automation Systems - Pneumatic Actuators and Accessories - FlowserveKakoDaPas encore d'évaluation

- CGS PDFDocument13 pagesCGS PDFRotceh SeyerPas encore d'évaluation

- GasTec As Series PSA Oxygen PlantDocument2 pagesGasTec As Series PSA Oxygen PlantyoanPas encore d'évaluation

- 8100 Series Brochure PDFDocument12 pages8100 Series Brochure PDFHeny MarthaPas encore d'évaluation

- Ammann Apollo IndiaDocument8 pagesAmmann Apollo IndiaFelix SandersPas encore d'évaluation

- Almig Belt GB WebDocument8 pagesAlmig Belt GB WebIPV_UAPas encore d'évaluation

- Quincy Qrds Series Single-Stage, Oil-Less Reciprocating Air Compressors 2-30 HPDocument8 pagesQuincy Qrds Series Single-Stage, Oil-Less Reciprocating Air Compressors 2-30 HPCoral IcmPas encore d'évaluation

- Leader PPV Positive Pressure Ventilation FanDocument6 pagesLeader PPV Positive Pressure Ventilation Fandonald_wilson4741Pas encore d'évaluation

- Chemical Injection Pumps and Products: Api 675 PerformanceDocument6 pagesChemical Injection Pumps and Products: Api 675 PerformancerudrakrPas encore d'évaluation

- DS Q Q75 en - InstrometDocument4 pagesDS Q Q75 en - InstrometHannifinPas encore d'évaluation

- Erc Series BrochureDocument4 pagesErc Series Brochurelepoulet0% (1)

- 24abs3 4pdDocument66 pages24abs3 4pdleonardo_suarez_82Pas encore d'évaluation

- QAF (GD-300Q) Continuous Duty Pump Brochure & Data SheetDocument2 pagesQAF (GD-300Q) Continuous Duty Pump Brochure & Data SheetmawannnPas encore d'évaluation

- Catalogohce090 150Document18 pagesCatalogohce090 150Xol DiaMa GarciaPas encore d'évaluation

- Ac Predator Brochure LoresDocument4 pagesAc Predator Brochure LoresAnonymous kjJfuvMMPas encore d'évaluation

- Cd60 Low Leakage Control DamperDocument3 pagesCd60 Low Leakage Control Dampermorucha_chiclePas encore d'évaluation

- Api 23 02Document4 pagesApi 23 02montsegranPas encore d'évaluation

- Rad Torque CatalogDocument16 pagesRad Torque CatalogJesus CcoylloPas encore d'évaluation

- Quincy QR25 Compressor BrochureDocument12 pagesQuincy QR25 Compressor BrochureBelynda BrownPas encore d'évaluation

- KSWG BruchureDocument4 pagesKSWG BruchureJack AboutboulPas encore d'évaluation

- Brahma Specs ScrewCompressorsDocument12 pagesBrahma Specs ScrewCompressorsDavid AbbadoPas encore d'évaluation

- Vanzetti Cryogenic Pumps & Technology GuideDocument0 pageVanzetti Cryogenic Pumps & Technology GuidekanchanabalajiPas encore d'évaluation

- 'C' Series Control ValvesDocument12 pages'C' Series Control Valvesابزار دقیق100% (1)

- SBC 782 Slam Shut Valves GuideDocument8 pagesSBC 782 Slam Shut Valves Guideluis_d_mPas encore d'évaluation

- Sullair Screw Air Compressor As 04-110Document4 pagesSullair Screw Air Compressor As 04-110MuhammadChabibiPas encore d'évaluation

- Transair CatalogDocument108 pagesTransair CatalogAvinash Singh RawatPas encore d'évaluation

- RMS 30 To 55Document2 pagesRMS 30 To 55nuno paivaPas encore d'évaluation

- Elgi Screw CompressorDocument12 pagesElgi Screw CompressorRAVINDER DHINGRAPas encore d'évaluation

- York Furnace ManualDocument8 pagesYork Furnace ManualToky100Pas encore d'évaluation

- BogeDocument7 pagesBogeWage KarsanaPas encore d'évaluation

- CCI DRAG® Compressor RecycleAnti-surge ValveDocument8 pagesCCI DRAG® Compressor RecycleAnti-surge ValvescribdkhatnPas encore d'évaluation

- High Pressure Filters for Hydraulic ApplicationsDocument12 pagesHigh Pressure Filters for Hydraulic ApplicationsIgor Alberto MarkovPas encore d'évaluation

- Air RecieverDocument3 pagesAir Recieverjp220288Pas encore d'évaluation

- Q.Sonic 5 Path Ultrasonic Gas Meter: T 1 T 1 2 L V CosDocument4 pagesQ.Sonic 5 Path Ultrasonic Gas Meter: T 1 T 1 2 L V Cossaid250009250Pas encore d'évaluation

- 01 Portable Nitrogen UnitsDocument8 pages01 Portable Nitrogen UnitsbracioPas encore d'évaluation

- G61MPV - 09 01 2007Document104 pagesG61MPV - 09 01 2007Baryonyx Troodon100% (1)

- Mouvex Abaque Series Peristaltic Hose Pump Spec SheetDocument3 pagesMouvex Abaque Series Peristaltic Hose Pump Spec SheetAnkur BhargavaPas encore d'évaluation

- MANUAL DezumidificatorDocument98 pagesMANUAL DezumidificatorcivodulPas encore d'évaluation

- ROTARY SCREW COMPRESSORS ENCAPSULATED HP 7,5 - 10 - 15 20 - 25 - 30Document6 pagesROTARY SCREW COMPRESSORS ENCAPSULATED HP 7,5 - 10 - 15 20 - 25 - 30Daniel Arbeláez0% (1)

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesD'EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesPas encore d'évaluation

- Southern Marine Engineering Desk Reference: Second Edition Volume ID'EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IPas encore d'évaluation

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsD'EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsÉvaluation : 4.5 sur 5 étoiles4.5/5 (10)

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentD'EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- Automotive Air Conditioning and Climate Control SystemsD'EverandAutomotive Air Conditioning and Climate Control SystemsÉvaluation : 4 sur 5 étoiles4/5 (6)

- Fire Pump System ChecklistDocument4 pagesFire Pump System ChecklistAhmed Sayed Abdel Tawab100% (1)

- Cosasco Access FittingsDocument2 pagesCosasco Access FittingsE_Rodriguez20Pas encore d'évaluation

- 1 - Pipe Schedule & Weight MeasurementDocument1 page1 - Pipe Schedule & Weight MeasurementSutrisno KlsPas encore d'évaluation

- SmartTrap Launcher ReceiverDocument4 pagesSmartTrap Launcher ReceiverKehinde AdebayoPas encore d'évaluation

- NPL-NG-P140001-BM-752 Pipe Material Class Summary - Rev 2.0Document38 pagesNPL-NG-P140001-BM-752 Pipe Material Class Summary - Rev 2.0Kehinde AdebayoPas encore d'évaluation

- Sweco CatDocument21 pagesSweco CatArmandoZacariasAcostaPas encore d'évaluation

- Astm d1785Document5 pagesAstm d1785Kehinde AdebayoPas encore d'évaluation

- Access Fittings (Non Tee)Document3 pagesAccess Fittings (Non Tee)anup_sahaniPas encore d'évaluation

- Overview of Piping Layout.Document4 pagesOverview of Piping Layout.Kehinde AdebayoPas encore d'évaluation

- 2010 Pipe Materials GuideDocument36 pages2010 Pipe Materials GuideAlmeghalawyPas encore d'évaluation

- METRIC_ENGLISHDocument14 pagesMETRIC_ENGLISHKehinde AdebayoPas encore d'évaluation

- FPSODocument143 pagesFPSORagunath KarthickPas encore d'évaluation

- Piping Design ProcedureDocument42 pagesPiping Design ProcedureKehinde Adebayo75% (4)

- Vista Complate Pressure Vessels CatalogeDocument11 pagesVista Complate Pressure Vessels CatalogeKehinde Adebayo100% (1)

- Stress Analysis Training - Caesar IIDocument2 pagesStress Analysis Training - Caesar IIKehinde Adebayo100% (2)

- The Two Most Common Methods of Measuring The Volume of Petroleum Liquids Are Tank Gauging and Liquid MeteringDocument4 pagesThe Two Most Common Methods of Measuring The Volume of Petroleum Liquids Are Tank Gauging and Liquid MeteringKehinde AdebayoPas encore d'évaluation

- Pump document title under 40 charactersDocument32 pagesPump document title under 40 charactersKehinde Adebayo100% (1)

- Stress Analysis of Piping1Document90 pagesStress Analysis of Piping1sateesh chand100% (2)

- Process Plant Layout and Piping DesignDocument460 pagesProcess Plant Layout and Piping Design~E~97% (32)

- Table of Contents and Piperack Design GuidelinesDocument20 pagesTable of Contents and Piperack Design GuidelinesKehinde AdebayoPas encore d'évaluation

- Wellheadcon NumenclatureDocument2 pagesWellheadcon NumenclatureKehinde AdebayoPas encore d'évaluation

- Cooling Water SystemDocument14 pagesCooling Water SystemKehinde AdebayoPas encore d'évaluation

- Variable Spring Hangers - Installation & Maintenance GuideDocument3 pagesVariable Spring Hangers - Installation & Maintenance GuideKehinde AdebayoPas encore d'évaluation

- Table of Contents and Piperack Design GuidelinesDocument20 pagesTable of Contents and Piperack Design GuidelinesKehinde AdebayoPas encore d'évaluation

- Class 1500 2500 3pc Flanged Ball Valve-Ningbo Valve FactoryDocument3 pagesClass 1500 2500 3pc Flanged Ball Valve-Ningbo Valve FactoryKehinde AdebayoPas encore d'évaluation

- PumpsDocument22 pagesPumpsKehinde AdebayoPas encore d'évaluation

- Table of Contents and Piperack Design GuidelinesDocument20 pagesTable of Contents and Piperack Design GuidelinesKehinde AdebayoPas encore d'évaluation

- Preliminary Piping Design - 45Document1 pagePreliminary Piping Design - 45Kehinde AdebayoPas encore d'évaluation

- Double Block and Bleed Valves - Instrumentation - Oliver ValvesDocument4 pagesDouble Block and Bleed Valves - Instrumentation - Oliver ValvesKehinde AdebayoPas encore d'évaluation

- CR 6Document672 pagesCR 6Francisco José Fontelles ObelenisPas encore d'évaluation

- ECSS E 20 01A - Rev.1 (1march2013)Document93 pagesECSS E 20 01A - Rev.1 (1march2013)jsadachiPas encore d'évaluation

- Ebook 042 Tutorial Spss Hierarchical Cluster AnalysisDocument17 pagesEbook 042 Tutorial Spss Hierarchical Cluster AnalysissnehaPas encore d'évaluation

- 07 DiagnosticsDocument132 pages07 DiagnosticsJosué Soldera100% (2)

- VHDL Introduction by J BhaskerDocument4 pagesVHDL Introduction by J BhaskerVishi Agrawal0% (1)

- ATV Suspension Design Report SummaryDocument4 pagesATV Suspension Design Report SummaryMohit KumarPas encore d'évaluation

- Diaphragm Valves: A Class of Their OwnDocument9 pagesDiaphragm Valves: A Class of Their OwnROMNAPas encore d'évaluation

- Air Filter - WikipediaDocument5 pagesAir Filter - WikipediaSuprabho IslamPas encore d'évaluation

- M-1002 MSRP-C3 - 2014Document664 pagesM-1002 MSRP-C3 - 2014A Reed100% (1)

- TC SwitchDocument5 pagesTC SwitchGolgojan NicusorPas encore d'évaluation

- Takeoff Thrust SettingDocument29 pagesTakeoff Thrust SettingarmandosentraPas encore d'évaluation

- H. J. THIM TRUST’S THEEM COLLEGE PUC REPORTDocument13 pagesH. J. THIM TRUST’S THEEM COLLEGE PUC REPORTPriyanka BhidePas encore d'évaluation

- Crompton Greaves Leading Manufacturer of Power EquipmentDocument12 pagesCrompton Greaves Leading Manufacturer of Power Equipmentcarlos vidal100% (1)

- PCRFDocument9 pagesPCRFDebasish RautPas encore d'évaluation

- s71200 Motion Control Function Manual en-US en-US PDFDocument396 pagess71200 Motion Control Function Manual en-US en-US PDFjmarcelo_pitPas encore d'évaluation

- Ditch Witch PR100 ManualDocument107 pagesDitch Witch PR100 ManualPablo Cesar PanessoPas encore d'évaluation

- Chipanalog-CA-IF4820HS C2846827Document21 pagesChipanalog-CA-IF4820HS C2846827Mudassar RafiqPas encore d'évaluation

- Uclinux Course Day 1Document12 pagesUclinux Course Day 1sarathkumar3389Pas encore d'évaluation

- Z1 ManualDocument6 pagesZ1 ManualIvana JazidzijaPas encore d'évaluation

- EAST+NDT+CHINA Calibration BlocksDocument6 pagesEAST+NDT+CHINA Calibration BlocksmgmqroPas encore d'évaluation

- CTSDG 06513 XDMDocument5 pagesCTSDG 06513 XDMArchnotPas encore d'évaluation

- A511Document8 pagesA511Vishal SharmaPas encore d'évaluation

- lmp91000 PDFDocument36 pageslmp91000 PDFCleberNogueiraBorgesPas encore d'évaluation

- Tata Steel - SlimdekDocument36 pagesTata Steel - SlimdekdevgrpPas encore d'évaluation

- Ieee Standard Requirements For Ac Highvoltage Air Switches RatedDocument12 pagesIeee Standard Requirements For Ac Highvoltage Air Switches RatedalexPas encore d'évaluation

- ODU-MAC Blue-Line Open Modular Connector System PDFDocument77 pagesODU-MAC Blue-Line Open Modular Connector System PDFConstantin-Iulian TraiciuPas encore d'évaluation

- 1.-Partlow Serie MRC 5000Document4 pages1.-Partlow Serie MRC 5000Angel RamirezPas encore d'évaluation

- Lecture1 InstrumentationDocument46 pagesLecture1 InstrumentationNavinan SubramaniamPas encore d'évaluation

- Belden 9463 PDFDocument3 pagesBelden 9463 PDFtr0184Pas encore d'évaluation

- Kim Lighting AFL2 Series Architectural Floodlights Brochure 1995Document32 pagesKim Lighting AFL2 Series Architectural Floodlights Brochure 1995Alan MastersPas encore d'évaluation