Académique Documents

Professionnel Documents

Culture Documents

Theory Cross Section Characteristics Enu

Transféré par

popaciprian27Description originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Theory Cross Section Characteristics Enu

Transféré par

popaciprian27Droits d'auteur :

Formats disponibles

Theoretical Background

Cross-Section Characteristics

Theoretical Background Cross-Section Characteristics

ii

All information in this document is subject to modification without prior notice. No part or this manual

may be reproduced, stored in a database or retrieval system or published, in any form or in any way,

electronically, mechanically, by print, photo print, microfilm or any other means without prior written

permission from the publisher. Scia is not responsible for any direct or indirect damage because of

imperfections in the documentation and/or the software.

Copyright 2012 Nemetschek Scia All rights reserved.

Table of contents

iii

Table of contents

Table of contents .............................................................................................................................. iii

Version Information................................................................................................................................. 1

Introduction .............................................................................................................................................. 2

Overview of Cross-section Characteristics .......................................................................................... 3

Axis Systems ..................................................................................................................................... 3

Cross-Section Characteristics ......................................................................................................... 4

Determination of Section Characteristics ............................................................................................. 5

Standardized Cross-section properties .......................................................................................... 5

Overall Procedure ............................................................................................................................. 6

Calculation of Standardized Cross-section properties Part I ....................................................... 7

Basic characteristics ...................................................................................................................... 7

Circumference and Drying surface............................................................................................... 11

Shear Area and Unit Shear Stress ............................................................................................... 12

Radii of Gyration .......................................................................................................................... 13

Elastic Section Moduli .................................................................................................................. 14

Plastic Moments and Section Moduli ........................................................................................... 15

Mono-Symmetry Constants .......................................................................................................... 18

Simplified Torsional Constant ...................................................................................................... 18

Calculation of Standardized Cross-section properties Part II .................................................... 19

Introduction ................................................................................................................................... 19

1D FE Method for Thin-Walled Sections ...................................................................................... 20

2D FE Method for Thick-Walled Sections .................................................................................... 23

Application of Closed-Form Formulae .......................................................................................... 27

Doubly-Symmetric I-section ......................................................................................................... 27

Asymmetric I-section .................................................................................................................... 27

Full Circular section ...................................................................................................................... 28

Full Rectangular Section .............................................................................................................. 29

Polygon with hole ......................................................................................................................... 29

Rectangular Hollow Section ......................................................................................................... 30

Asymmetric Rectangular Hollow Section ..................................................................................... 30

Circular Hollow Section ................................................................................................................ 32

Corrugated Web SIN1 .................................................................................................................. 33

Corrugated Web SIN2 .................................................................................................................. 34

Profile Library Properties ............................................................................................................... 35

References ............................................................................................................................................. 36

Theoretical Background Cross-Section Characteristics

1

Version Information

Welcome to the Theoretical Background for Cross-Section Characteristics.

This document provides background information regarding the calculation of Cross-section properties

according to different methods.

Version info

Document Title Theoretical Background Cross-Section Characteristics

Release 2013.0

Revision 12/2012

Theoretical Background Cross-Section Characteristics

2

Introduction

In this Theoretical Background in depth information is given regarding the calculation of cross-section

properties.

The first chapter gives an overview of the different axis systems as well as a list of all cross-section

properties calculated by Scia Engineer.

The second chapter details the actual methods for determining cross-section properties. After

introducing the standardization of cross-section properties the overall procedure followed by Scia

Engineer is explained.

The chapter then explains the different numerical methods, both using 1D Finite Elements and 2D

Finite Elements, for calculating section characteristics.

The chapter concludes with a listing of all closed-form formulae used for standard section shapes.

Theoretical Background Cross-Section Characteristics

3

Overview of Cross-section Characteristics

In this chapter the different Axis systems used within Scia Engineer are outlined.

The second part of this chapter gives an overview of the properties related to these Axis systems.

Axis Systems

Within Scia Engineer the Cross-section Characteristics are referenced to three distinct Axis systems.

a) The UCS or 'Input' Axis system is defined using an arbitrary origin and uses a horizontal Y-axis

and a vertical Z-axis. This system serves as a reference from which the center of gravity is calculated.

b) The LCS Axis system has its origin in the center of gravity and YLCS and ZLCS axis parallel to the

axis of the UCS system. This system serves as a reference from which the rotation of the principal axis

is calculated.

c) The Principal Axis system has its origin in the center of gravity and principal y- and z-axis rotated

according to the angle of rotation between the principal and LCS systems.

The following picture illustrates these different Axis Systems:

In case the rotation angle of the Principal Axis system is zero, this system is equal to the LCS Axis

system. In this case, only the Principal Axis system is displayed.

Theoretical Background Cross-Section Characteristics

4

Cross-Section Characteristics

The following table provides an overview of all Cross-section Characteristics calculated by Scia

Engineer:

Property Description

A Area

Ay Shear Area in principal y-direction

Az Shear Area in principal z-direction

AL Circumference per unit length

AD Drying Surface per unit length

cYUCS Centroid coordinate in Y-direction of Input axis system

cZUCS Centroid coordinate in Z-direction of Input axis system

IYLCS Second moment of area about the YLCS axis

IZLCS Second moment of area about the ZLCS axis

IYZLCS Product moment of area in the LCS system

Rotation Angle of the principal axis system

Iy Second moment of area about the principal y-axis

Iz Second moment of area about the principal z-axis

iy Radius of gyration about the principal y-axis

iz Radius of gyration about the principal z-axis

Wely Elastic section modulus about the principal y-axis

Welz Elastic section modulus about the principal z-axis

Wply Plastic section modulus about the principal y-axis

Wplz Plastic section modulus about the principal z-axis

Mply+ Plastic moment about the principal y-axis for a positive My moment

Mply- Plastic moment about the principal y-axis for a negative My moment

Mplz+ Plastic moment about the principal z-axis for a positive Mz moment

Mplz- Plastic moment about the principal z-axis for a negative Mz moment

dy Shear center coordinate in principal y-axis measured from the centroid

dz Shear center coordinate in principal z-axis measured from the centroid

It Torsional constant

Iw Warping constant

y Mono-symmetry constant about the principal y-axis

z Mono-symmetry constant about the principal z-axis

In addition to these properties in each fibre of the cross-section for following unit stress values are

calculated:

Fibre stress Description

Shear y Shear stress in principal y-direction caused by a unit shear force Vy

Shear z Shear stress in principal z-direction caused by a unit shear force Vz

Torsion Primary Torsion stress caused by a unit torsion moment Mx

In the following chapters the calculation of these different characteristics is detailed.

Theoretical Background Cross-Section Characteristics

5

Determination of Section Characteristics

The first part of this chapter details the general procedure for calculating standardized cross-section

properties as well as the procedure used in Scia Engineer.

Subsequent subchapters deal with the actual calculation of properties, as well as the applied closed

form formulae.

Standardized Cross-section properties

In general the calculation of cross-section properties is divided into 2 parts as shown on the following

diagram:

For a detailed background into the calculation of properties according to the above diagram reference

is made to Ref.[1]. Applied to Scia Engineer this gives the following differentiation:

As indicated on the above diagram, each part is extended with multiple 'derived' properties i.e.

properties which are determined using the base properties calculated in that part.

Cross-section property calculation

Standardized Cross-section properties Part I: Biaxial bending and axial force

Standardized Cross-section properties Part II: Torsion

A, cYUCS, cZUCS, IYLCS, IZLCS, IYZLCS, , Iy, Iz

Extended with:

- Ay, Az, AL, AD, iy, iz, Wely, Welz

- Wply, Wplz, Mply+, Mply-, Mplz+, Mplz-

- Unit stress Shear y, Unit stress Shear z

- Initial values for y, z

- General solid It

dy, dz, It, Iw, Unit warping

Extended with:

- Unit Torsion stress

- Final values for y, z

Cross-section property calculation

Standardized Cross-section properties Part I: Biaxial bending and axial force

Standardized Cross-section properties Part II: Torsion

- Area

- Center of Gravity

- Angle of the principal axis system

- Principal moments of Inertia

- Shear Center

- Torsion Constant

- Warping Constant

- Standardized Warping Ordinate

Theoretical Background Cross-Section Characteristics

6

Overall Procedure

The previous paragraph showed the general principle of calculating cross-section properties using two

distinct parts. In addition to these parts, Scia Engineer also takes into account specific overrulings of

properties, for example in case the 2D FE Method is used, or in case a cross-section is taken from the

Profile Library etc.

The following diagram shows the complete calculation procedure as used in Scia Engineer.

By default, for Thick-walled sections the 2D FE Method is activated for Torsional analysis, however

this can be de-activated by the user leading to the Simplified Torsion analysis.

In the subsequent paragraphs of this chapter each item of the above diagram is described in detail.

Theoretical Background Cross-Section Characteristics

7

Calculation of Standardized Cross-section properties Part I

The first part of the standardised cross-section properties concerns those related to bending and axial

force.

Basic characteristics

The basic cross-section characteristics are calculated using the standard formulas from solid

mechanics. For detailed information, reference is made to Ref.[3] and Ref.[4].

The cross-section is discretized into n elemental areas dA.

First, using the arbitrary origin of the UCS or 'Input' Axis system the following properties are

calculated using a horizontal Y-axis and a vertical Z-axis:

Area:

First Moment of Area:

Theoretical Background Cross-Section Characteristics

8

Using these magnitudes the coordinates of the centroid are determined:

Centroid:

The centroid defines the origin of the LCS Axis system with YLCS and ZLCS axis parallel to the axis

of the UCS system. According to these axis the second moments of area can be determined:

Second Moment of Area:

Product Moment of Area:

Finally, using these magnitudes the Principal Axis system and corresponding characteristics can be

determined:

Second Moment of Area:

Theoretical Background Cross-Section Characteristics

9

Angle of Rotation: in case

in case

and

otherwise

The above determination of the angle of rotation accounts for minor numerical discrepancies. For

background information, reference is made to Ref.[1].

In addition, in case the angle of rotation is calculated according to the above formula and exceeds

a tolerance of 3, the angle is increased by

in case Iz > Iy.

Extension: Multi-Material (Composite) sections

In case of multi-material cross-sections the basic characteristics are determined using the principles

given in this paragraph. For background information see Ref.[5]

Centroid

First the area A

i

and centroid position of each cross-section part/polygon i are calculated.

To determine the location of the centroid (Neutral Axis 'NA') of the whole cross-section the following

general equation is used:

Where n represents the number of polygons and E

i

the E-modulus of the material of the respective

polygon.

Theoretical Background Cross-Section Characteristics

10

The distances z

1

, z

2

, z

n

are the distances from the NA to the centroid of each polygon (measured

in the UCS Axis system). These distances can be written in function of the centroid distance

cZUCS so the above equation can be solved this centroid distance.

The above equation illustrates the principle used for cZUCS, in the same way the equation can be

written out for cYUCS.

Area

The Area of the multi-material section is calculated using the following general formula:

Where n represents the number of polygons, E

i

the E-modulus of the material of the respective

polygon and A

i

the area of the respective polygon.

As indicated by the equation, each polygon of the multi-material cross-section is in fact referenced to

the material of the 'first' polygon.

Within Scia Engineer this literally means the 'first' inputted polygon. So the material of this 'first'

inputted polygon serves as reference material for the multi-material cross-section. This 'first'

material is shown with a cyan background color for easy reference.

Second Moment of Area

The Second Moment of Area of the multi-material section is calculated using the following general

formula:

Where n represents the number of polygons, E

i

the E-modulus of the material of the respective

polygon and A

i

the area of the respective polygon.

As indicated by the equation, each polygon of the multi-material cross-section is in fact referenced to

the material of the 'first' polygon.

The above equation is used to determine IYLCS, IZLCS and IYZLCS.

Theoretical Background Cross-Section Characteristics

11

Circumference and Drying surface

The Circumference per unit length or 'Exterior Surface' AL is calculated as the outer circumference of

the cross-section. This calculation accounts for the fact that parts are connected/touching.

For those parts which are not connected the circumference AL is calculated as the summation of the

outer circumference of the different unconnected parts:

The drying surface per unit length AD is calculated as the outer circumference AL increased by the

circumference of any openings within the cross-section. In case there are no openings AD will thus be

equal to AL.

An 'opening' in this case concerns any closed in empty area within the cross-section. This calculation

method thus accounts for 'constructed' openings for example when creating an RHS from four separate

rectangles.

Theoretical Background Cross-Section Characteristics

12

Shear Area and Unit Shear Stress

The Shear Area Ay and Az in principal directions are determined as follows:

With: b(z) The width of the cross-section at position z from the principal y-axis

b(y) The width of the cross-section at position y from the principal z-axis

S

y

(z) The First moment or Area of the 'cut-off' area A', determined

according to the principal y-axis

S

z

(y) The First moment or Area of the 'cut-off' area A', determined

according to the principal z-axis

Iy Second moment of area about the principal y-axis

Iz Second moment of area about the principal z-axis

On the following picture the 'cut-off' area A' is illustrated for the Shear Area Az.

Theoretical Background Cross-Section Characteristics

13

The Unit Shear stresses in the fibres are calculated as follows:

Unit stress Shear y in fibre i:

Unit stress Shear z in fibre i:

With Vy and Vz taken as unity and y

i

and z

i

the coordinates of fibre i in the principal axis system.

In case the width b at a given fibre position is zero the Unit Shear stress is taken as zero for that

fibre.

For multi-material (Composite) sections reference is made to the 2D FE Method.

Radii of Gyration

The Radii of Gyration iy and iz about the principal axis are determined as follows:

Theoretical Background Cross-Section Characteristics

14

Elastic Section Moduli

The Elastic Section Moduli Wely and Welz about the principal axis are determined as follows:

The distances z and y according to the principal axis are determined for each fibre of the cross-section.

In essence each fibre thus has a different Elastic Section Modulus. The Moduli shown in the cross-

section properties are the minimal values taken over all fibres. These minimal values are thus obtained

by using the maximal fibre distances as shown in the above formulas.

The following picture illustrates the maximal distances for an arbitrary cross-section:

During stress calculations in the fibres (for example in the Steel checks), the stresses are

calculated in each fibre separately. These stress calculations thus use the actual Elastic Section

Moduli in each fibre and not the minima over the entire cross-section.

Theoretical Background Cross-Section Characteristics

15

Plastic Moments and Section Moduli

Basic principle

In this paragraph the basic principle of the plastic property calculation is explained.

The principle is illustrated for a general cross-section made out of one material which has equal

characteristics in both tension and compression (like for example Steel).

As shown on the following picture, this cross-section is loaded by a bending moment M which causes

part of the cross-section to be in compression (C) and part of the cross-section to be in tension (T).

All the fibres in this cross-section have yielded as shown by the stress blocks.

The Plastic Neutral Axis (PNA) is defined by the axis located between the fibres yielding in

compression and those yielding in tension. This axis is off course parallel to the principal axis about

which the moment was applied.

For a single material cross-section with homogeneous material characteristics the PNA is easily

determined as the axis which splits the cross section into two equal areas: the area A

C

in compression

and A

T

in tension.

The Plastic Section Modulus Wpl is calculated as the sum of the First Moments of Area of the part in

tension (S

T

) and the part in compression (S

C

):

With: A

C

and A

T

The areas of the section in compression and tension respectively for a bending

moment about the given principal axis.

d

C

and d

T

The distances from the centroid of the areas of the section in compression and

tension respectively to the Plastic Neutral Axis, measured perpendicular to the

given principal axis.

Using the material strength f of the homogeneous material the Plastic Moment Mpl is calculated as

follows:

Theoretical Background Cross-Section Characteristics

16

General formulation

The basic principle explained in the previous paragraph holds true for a homogeneous uni-strength

material. In general however there are several complexities which need to be accounted for:

- The material of the cross-section can have different characteristics in compression and in tension.

- The cross-section can be composed out of multiple materials.

- The material characteristics depend on the sign of the moment.

Consider the following composite section as an example:

For a positive My bending moment about the principal axis, the concrete will be in compression while

the steel will be in tension.

In case of a negative My bending moment about the principal axis, the concrete will be in tension while

the steel will be in compression.

Depending on the position of the Plastic Neutral Axis one of the materials can even be partially in

compression and partially in tension.

The calculation of the Plastic Moment is therefore split according to axis and according to sign which

leads to Mply+, Mply-, Mplz+ and Mplz-. For each of these plastic magnitudes a separate calculation

is done.

The determination of the Plastic Neutral Axis needs to take into account the material characteristic of

each part. In general the following equation is solved which specifies an equilibrium of tensile and

compressive forces:

With: n The number of cross-section parts

A

C,i

The area in compression of part i

f

C,i

The compressive strength of part i

A

T,i

The area in tension of part i

f

T,i

The tensile strength of part i

Theoretical Background Cross-Section Characteristics

17

With the position of the PNA known, the Plastic Moment can be determined as follows:

In which d

i

signifies the distance from the centroid of the area of part i of the section to the plastic

neutral axis, measured perpendicular to the given principal axis.

The above Plastic Moment calculation assumes a 'full bond' between the different materials. The

actual Composite checks take into account the effects of partial bond and recalculate the Plastic

Moments accordingly.

Since for each part the material strength can be different there is no more straightforward way to obtain

the Plastic Section Modulus Wpl. Within Scia Engineer, this value is referenced to the material of the

'first' inputted polygon, see also the paragraph on Multi-Material sections.

In addition, since there is both a positive and a negative Plastic Moment for the given axis, the final

Plastic Section Modulus is determined using the minimum of both.

With f

1

the material strength of the 'first' polygon. This can either be the compressive or tensile strength

of this material depending on which stress dominates in this part.

These values for the Plastic Section Moduli are merely used for display in the Cross-Section

Manager. The actual Composite checks directly use the Plastic Moments which are thus not

referenced to the 'first' material but take into account all material characteristics.

Material Characteristics

As indicated in the above paragraphs the plastic calculation requires the compressive and tensile

strength of the respective material. These values are defined as follows for materials with code

dependent data:

Material Compressive strength f

C

Tensile strength f

T

Steel fy fy

Aluminium fy fy

Concrete fck Taken as zero

Masonry fck Taken as zero

Timber fc,0,k ft,0,k

Other 240 N/mm^2 240 N/mm^2

Any material which does not have code dependent data is taken as 'Other'.

Theoretical Background Cross-Section Characteristics

18

Mono-Symmetry Constants

The Mono-Symmetry Constants y and z about the principal axis are determined as follows:

With: Iy Second moment of area about the principal y-axis

Iz Second moment of area about the principal z-axis

y & z Coordinates in the principal axis system

y

0

Distance between centroid and shear centre, taken as dy

z

0

Distance between centroid and shear centre, taken as dz

When these parameters are initially calculated the shear centre coordinates dy and dz are not yet

determined. The Mono-Symmetry Constants y and z are thus initially calculated taking dy and dz

equal to zero. After the analysis of Part II the actual shear centre coordinates dy and dz are

determined after which the Mono-Symmetry Constants y and z are modified accordingly.

For more background information regarding these parameters reference is made to Ref.[2]

Simplified Torsional Constant

To finalize the calculation of Part I of the Standardised Cross-section properties the Torsional constant

It is calculated using the following simplified formula for a general solid Cross-section:

with

In normal cases this It value will be overwritten by the exact It calculation done in Part II. In case

however the Part II calculation is not done the above calculation ensures there is at least an

approximate value for It. This approach avoids numerical instabilities during the analysis.

Theoretical Background Cross-Section Characteristics

19

Calculation of Standardized Cross-section properties Part II

The second part of the standardised cross-section properties concerns those related to torsion.

Introduction

For calculating properties related to torsion the general theory makes a distinction between the

following types of cross-sections, see Ref.[1]:

a) Thin-walled, open cross-sections

b) Thin-walled, closed cross-sections

c) Arbitrary, thick-walled cross-sections

A cross-section is defined as thin-walled if, through a reduction to the profile centreline and the

application of simplified theories, sufficiently exact calculation results are obtained. Ref.[1].

Within Scia-Engineer a thin-walled section is thus a section for which a centreline is available. To

simplify the identification, the Shape Type (thin-walled or thick-walled) is shown in the properties of

each cross-section.

In literature, for thin-walled, open sections analytical solutions are widely available. For thin-

walled, closed (hollow) sections with a single opening analytical solutions are also available

Ref.[6] however in case of multiple openings a statically indeterminate problem emerges which

requires a large effort to solve analytically.

Therefore, within Scia Engineer, a numerical 1D Finite Element Method is used to calculate the

torsional properties of any thin-walled section. The main advantages of this method are that it

applies to both open and closed sections and can be used for closed sections with any amount of

openings.

In literature, for thick-walled sections analytical solutions only exist for a few basic shapes such as

rectangles, triangles and ellipses. Within Scia Engineer, for thick-walled sections a numerical 2D

Finite Element Method is used to provide an exact solution for any shape.

In addition, the 2D Finite Element Method can even be applied optionally to thin-walled sections.

Theoretical Background Cross-Section Characteristics

20

The following table summarizes this approach:

Shape Type Method for Torsional Analysis

Thin-walled open section 1D FEM (Optionally 2D FEM)

Thin-walled closed section 1D FEM (Optionally 2D FEM)

Thick-walled section 2D FEM

The following chapters give an overview of both the 1D and 2D Finite Element Methods.

1D FE Method for Thin-Walled Sections

For thin-walled sections (open or closed or a combination of both) a general One-Dimensional Finite

Element approach is applied. For a detailed background regarding this method including calculation

examples reference is made to Ref.[1].

Based on the centerline the cross-section is discretised into nodes and elements as schematised on

the following picture:

Each element is defined with a begin node a, an end node b and a constant thickness t.

Theoretical Background Cross-Section Characteristics

21

The Finite Element analysis is carried out using the following steps:

Step 1: Calculation of the warping ordinate

Equation system (boundary condition:

):

Element matrices:

with:

for D = S

Step 2: Position of the shear centre and standardisation of the warping ordinate:

Step 3: Calculation of the cross-section properties Iw and It

Theoretical Background Cross-Section Characteristics

22

Step 4: Calculation of shear deformations due to shear forces and secondary torsion:

Equation system (boundary condition: u

i

):

Element load vector:

with:

Step 5: Calculation of shear stresses:

Shear stresses due to primary torsion:

linearly via t with:

constantly via t:

Shear stresses due to shear forces and secondary torsion:

The above procedure is given here for informative reasons. For a full description of all abbreviations

used in this procedure as well as background information and worked out examples, reference is made

to Ref.[1].

The main advantage of this method is that it can be used for both open and closed thin-walled sections

or combinations of both (sections with openings and outstands). The method is however only valid for

sections with a continuous centerline i.e. where all parts are connected by one continuous line.

In case of multiple unconnected parts (like a pair section composed out of two thin-walled sections

which do not touch each other) the 1D FE Method cannot be applied since there is no continuous

centerline. In such cases the 2D FE Method should be applied.

Theoretical Background Cross-Section Characteristics

23

2D FE Method for Thick-Walled Sections

For arbitrary thick-walled sections a general Two-Dimensional Finite Element approach is applied.

This is the method used automatically in case of multi-material (composite) sections.

Beside thick-walled sections this method can also be applied to thin-walled sections.

As the name indicates, the 2D FE Method discretises the cross-section using two-dimensional

elements.

The analysis is split into two separate parts: a Torsion Analysis and a Shear Analysis.

The following paragraphs give more information regarding the determination of the default mesh size

and both analysis types.

Default Mesh Size

In case no mesh size is inputted the default mesh size is determined as follows:

1. The cross-section is divided into approximately 250 elements:

With A the area of the cross-section

2. In case the area of the circumscribed rectangle around the cross-section exceeds 10 times the

area A the mesh size of the previous step is halved:

This correction accounts for thin-walled sections.

3. The mesh size of the previous step is then rounded using a .5 accuracy. This is the mesh size

used for the Torsion Analysis.

4. For the Shear Analysis the mesh of the previous step is further refined as follows:

This final step is applied always, also in case a manual input of the mesh size is made.

Theoretical Background Cross-Section Characteristics

24

As with any Finite Element approach, to obtain accurate results the mesh needs to be sufficiently

refined.

Torsion Analysis: Prandtl

The Torsion Analysis determines the Torsional constant It, the Warping Constant Iw and the unit

torsion stresses.

The analysis is executed according to the Prandtl theory. Within this paragraph the basic principles of

the theory are explained.

The Prandtl theory (often referred to as the Membrane or Soap-Film Analogy) is based on the similarity

of the torsion stress function equation and the equilibrium equation of a membrane subjected to lateral

pressure.

- Consider an opening in an x-y plane which has the same shape as the cross-section to be

investigated.

- Cover the opening with a homogeneous membrane.

- The pressure against the membrane causes the membrane to bulge out of plane.

- The lateral displacement z(x,y) of the membrane and the Prandtl torsion stress function (x,y)

satisfy the same equation in (x,y)

Prandtl Torsion function:

Elastic Membrane function:

Where z denotes the lateral displacement due to a pressure p and an initial tension S.

Theoretical Background Cross-Section Characteristics

25

The theory concludes with the following:

- Stress components are proportional to the derivatives of the membrane displacement.

- Stresses are proportional to the slope of the membrane.

- The twisting moment is proportional to the volume enclosed by the membrane and x-y plane

Further elaboration and background information regarding the Prandtl theory and 2D FEM analysis

can be found in Ref.[1],[7],[8],[9].

Shear Analysis: Grashof-Jouravski

The Shear Analysis determines the Shear areas Ay & Az and the unit Shear stresses.

The analysis is executed according to the Grashof-Jouravski theory. For background information

reference is made to Ref.[10].

The following paragraphs describe the theory for the shear Area Az. The same logic can be written out

for Ay.

The theory is generally valid in case the following requirements are met:

- The cross-section symmetrical about the z-axis

- The cross-section is massive, without large holes

- Overall the obtained results are better in case the height is bigger than the width

The Shear stresses lead off from the cross-section into one point K.

The area

z

z

A

A

|

= takes on the shear force Q

z

.

yT

zT

T

b

z

y

Qz

K

omax

o

txz

txz t

txy txy

t

Theoretical Background Cross-Section Characteristics

26

The value

z

is calculated from the shear stresses in one of the following ways:

1) Only from the vertical components

(without influence of

)

2

2 2

( )

4 ( )

T

T

y

z

y

A

S z

A

dA

I b z

| =

((

((

]]

2) From both components

and

( )

2

2

2 2

( )

1 tan ( , )

4 ( )

T

T

y

z

y

A

S z

A

z y dA

I b z

| o = +

((

((

]]

In case the cross-section does not meet the requirements of the Grashof-Jouravski theory, the z

values calculated with the influence of

are absolutely incorrect and often unreal. They should

not be used in this case.

Depending on the rate of unrealized conditions, the z values which were calculated only from the

vertical

component (without influence of

) are real and can be used in this case.

The user should in all cases evaluate if the values determined by the theory are acceptable or not.

In case of multi-material (heterogeneous) cross-sections the calculated shear areas Ay and Az can be

used under the following conditions:

- The heterogeneities are symmetrical.

- The heterogeneities do not disturb the Grashof-Jouravski stress theory.

- The heterogeneity is diffused.

- A local heterogeneity consists of less than 10% of the cross-section area.

Openings

As specified, the above theory for shear areas is not valid in case of large openings like for example

openings which divide a cross-section into different unconnected parts. A typical example are web

openings in steel members.

Specifically for such a case a modified procedure is applied:

In case:

- The cross-section consists of multiple unconnected parts i

- The rotation angle of the cross-section is 0

Then the Shear Analysis of the 2D FE Method is used separately for each part i and the shear area

Av,i of each part is stored. The final shear area Av of the cross-section is then calculated as the sum

of the shear areas of the different parts:

Theoretical Background Cross-Section Characteristics

27

Application of Closed-Form Formulae

For many standard cross-section shapes (I-sections, RHS sections, CHS sections ) closed-form

formulae exist for the cross-section properties.

After the calculation of properties, depending on the shape specific properties are overruled by fixed

formulae as indicated in the following paragraphs.

Doubly-Symmetric I-section

For Doubly-Symmetric I-sections (Formcode 1) the Torsional constant I

t

is overruled as

follows:

This formula was taken from Ref.[11]

In addition the unit torsion stress per fiber is overruled as follows:

Torsion_stress = Torsion_stress * (I

t,old

/ I

t,new

)

With: I

t,old

The original I

t

value

I

t,new

The new I

t

value calculated by the above formula

These modifications are only done in case the rounding r0 i.e. when it concerns a true rolled section

shape.

Asymmetric I-section

For Asymmetric I-sections (Formcode 101) the Warping constant I

w

is overruled as follows:

This formula was taken from Ref.[12]

Theoretical Background Cross-Section Characteristics

28

Full Circular section

For a Full circular section (Formcode 11 or geometric 'Circle') with diameter D the Area A is

overruled as:

The Second Moments of Area I

y

and I

z

are overruled as:

The Elastic Section moduli W

ely

and W

elz

are overruled as:

The Plastic Section moduli W

ply

and W

plz

are overruled as:

The Torsional constant I

t

is overruled as:

The Shear areas A

y

and A

z

are overruled as:

These formulas were taken from Ref.[4].

Theoretical Background Cross-Section Characteristics

29

Full Rectangular Section

For a Full Rectangular section (Formcode 7 or geometric 'Rectangle' or 'RECT') with width b

and height h the Torsional constant I

t

is overruled as follows:

with

This formula was taken from Ref.[1]

The Shear areas A

y

and A

z

are overruled as:

This formula was taken from Ref.[4].

Polygon with hole

For a polygon with hole (geometric 'Polygon with hole') the Torsional constant I

t

is overruled

using the second formula of Bredt:

With A' the closed in area, taken as:

With S the circumference of the closed in area, taken as:

With r the radius of the polygon, n the number of corners and t the thickness.

The Shear areas A

y

and A

z

are overruled as:

Theoretical Background Cross-Section Characteristics

30

Rectangular Hollow Section

For a symmetrical RHS (Formcode 2) the Torsional constant I

t

is overruled using the second

formula of Bredt:

With A' the closed in area, taken as:

A' = (H - t) * (B - t)

With S the circumference of the closed in area, taken as:

S = 2 * [(H - t) + (B - t)]

Where B is the width of the cross-section, H the height and t the thickness.

The Warping constant I

w

is overruled as follows:

The Shear areas A

y

and A

z

are overruled as:

Ay = A * [ B / (B + H)]

Az = A * [H / (B + H)]

Asymmetric Rectangular Hollow Section

For an asymmetrical RHS (geometric 'O' or geometric 'O asymmetric') the Torsional constant I

t

is overruled using the second formula of Bredt:

With A' the closed in area, taken as:

A' = Hc * Bc

With S the circumference of the closed in area, taken as:

= 2 * (Hc/tha) + (Bc/thb1) + (Bc/thb2)

With Hc and Bc the centerline dimensions:

Hc = H - (thb1 / 2) - (thb2 / 2)

Bc = B - tha

Theoretical Background Cross-Section Characteristics

31

Where B is the width of the cross-section, H the height, tha the web thickness and thb1 & thb2 the

flange thicknesses.

Torsional stresses are calculated using an average thickness.

The Shear areas A

y

and A

z

are overruled as:

Ay = A * [B / (B + H)]

Az = A * [H / (B + H)]

Theoretical Background Cross-Section Characteristics

32

Circular Hollow Section

For a CHS (Formcode 3 or geometric 'Tube') the Area A is overruled as:

The Moments of inertia I

y

and I

z

are overruled as:

The Section moduli W

ely

and W

elz

are overruled as:

The Plastic section moduli W

ply

and W

plz

are overruled as:

The Torsional constant I

t

is overruled using the second formula of Bredt:

With A' the closed in area, taken as:

With S the circumference of the closed in area, taken as:

With Dc the centerline dimension, taken as:

Dc = D - t

With Di the inner diameter taken as:

Di = D - (2 * t)

Where D is the diameter of the cross-section and t the thickness.

The Shear areas A

y

and A

z

are overruled as:

Theoretical Background Cross-Section Characteristics

33

Corrugated Web SIN1

For a corrugated web section SIN1 the Area A is overruled as:

A = 2 * B * t

The inertia I

y

is overruled as:

In which the distance z

1

is determined as follows:

z1 = ( H - t ) / 2

The section modulus W

ely

is overruled as:

The plastic modulus W

ply

is calculated by multiplying this W

ely

value with the ratio of the original W

ely

and W

ply

of the (full) section

The shear area A

z

is calculated as:

In these formulas B indicates the width of the cross-section, H the height, Hw the height of the web, t

the flange thickness and s the web thickness. The parameters w and sw describe the geometry of the

corrugation.

These formulas were provided by the company Zeman, Austria.

Theoretical Background Cross-Section Characteristics

34

Corrugated Web SIN2

For a corrugated web section SIN2 the Area A is overruled as:

A = Bt * tt + Bb * tb

The inertia I

y

is overruled as:

In which the distances z

1

and z

2

are determined as follows:

z1= h - (tb / 2)

z2 = H - h - (tt / 2)

The distance h is determined as:

h = Sy / A

With the modulus S

y

calculated as:

The section modulus W

ely

is overruled as:

The plastic modulus W

ply

is calculated by multiplying this W

ely

value with the ratio of the original W

ely

and W

ply

of the (full) section

The shear area A

z

is calculated as:

In these formulas Bt and Bb indicate the width of the top and bottom flange, tt and tb the thicknesses

of the flanges, H the height of the cross-section, Hw the height of the web and s the web thickness.

The parameters w and sw describe the geometry of the corrugation.

These formulas were provided by the company Zeman, Austria.

Theoretical Background Cross-Section Characteristics

35

Profile Library Properties

For those cross-section defined in the Profile Library the properties defined in the Library are used to

overrule the calculated properties.

As can be seen on the Overall procedure diagram, the properties from the Profile Library are applied

after all properties have been calculated. The logic behind this is that the Profile Library might not

define all properties but only a few or even none at all.

In addition the overruling is done only in case the difference between the calculated property and the

property inputted in the Profile Library differs less than 10%.

This "10% rule" serves as a safety margin to avoid the application of incorrectly inputted properties in

the Profile Library.

Theoretical Background Cross-Section Characteristics

36

References

[1] Steel Structures: Design using FEM

Kindmann R., Kraus M.

Ernst & Sohn, 2011

[2] The Behaviour and Design of Steel Structures to EC3

Fourth edition

Trahair N.S., Bradford M.A., Nethercot D.A., Gardner L.

Taylor & Francis, 2008

[3] Moments of Area: Introductory Engineering Mechanics

Alexander N.A.

University of Bristol, 2004

[4] Formulas in Solid Mechanics

Dahlberg T.

Linkping University Sweden, 2003

[5] eCourse mechanics

Ch 6. Advanced Beams, Composite Beams

Gramoll K.

http://www.ecourses.ou.edu/

[6] Torsion and Shear Stresses in Ships

Shama M.

Springer-Verlag, 2010

[7] Handbook of engineering mechanics

First edition

W.Flgge

McGraw-Hill, 1962

[8] Berekening van constructies: bouwkunde en civiele techniek

Vandepitte D.

Story-Scientia, 1979

www.berekeningvanconstructies.be

[9] Membrane Analogy for Torsion

Lagace P.A.

MIT, 2001

[10] Grasshof-uravskho teorie

FEM Consulting

Brno

Theoretical Background Cross-Section Characteristics

37

[11] Sections and Merchant Bars

Sales Programme

Arcelor Mittal, Edition 2011-1

[12] Torsional Section Properties of Steel Shapes

Canadian Institute of Steel Construction, 2002

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Advaita Vedanta and Modern ScienceDocument63 pagesAdvaita Vedanta and Modern ScienceKaushik Saha100% (1)

- Pimsleur Chinese I - A Pronunciation and Character GuideDocument234 pagesPimsleur Chinese I - A Pronunciation and Character GuideDavid Kim100% (12)

- XML Format Description EnuDocument31 pagesXML Format Description Enupopaciprian27Pas encore d'évaluation

- Optimizare SciaDocument2 pagesOptimizare Sciapopaciprian27Pas encore d'évaluation

- Concrete Slenderness LimtiationDocument1 pageConcrete Slenderness Limtiationpopaciprian27Pas encore d'évaluation

- Andreatta Precast ItalyDocument5 pagesAndreatta Precast Italypopaciprian27Pas encore d'évaluation

- Dezactivarea Optiunii de Limitare A ZveltetiiDocument1 pageDezactivarea Optiunii de Limitare A Zveltetiipopaciprian27Pas encore d'évaluation

- Steel Cold Formed SectionsDocument18 pagesSteel Cold Formed SectionsVlad Mos50% (2)

- Theory NA en 1993 EnuDocument45 pagesTheory NA en 1993 EnuDaerdorPas encore d'évaluation

- U 3 DDocument1 pageU 3 Dpopaciprian27Pas encore d'évaluation

- Theory NA en 1990 EnuDocument25 pagesTheory NA en 1990 Enupopaciprian27Pas encore d'évaluation

- Theory NA en 1991 EnuDocument29 pagesTheory NA en 1991 EnutzzutzuPas encore d'évaluation

- Pad Foundation Theory EnuDocument23 pagesPad Foundation Theory Enupopaciprian27Pas encore d'évaluation

- Theory NA en 1995 EnuDocument16 pagesTheory NA en 1995 Enupopaciprian27Pas encore d'évaluation

- Steel Connections Theory EnuDocument143 pagesSteel Connections Theory Enupopaciprian27100% (1)

- Post Tension Ed Concrete SlabsDocument92 pagesPost Tension Ed Concrete Slabspopaciprian27100% (3)

- Soilin PDFDocument54 pagesSoilin PDFstonerrrockPas encore d'évaluation

- Steel Code Check Theory EnuDocument341 pagesSteel Code Check Theory Enupopaciprian27Pas encore d'évaluation

- Protection 2012Document28 pagesProtection 2012popaciprian27Pas encore d'évaluation

- Redistribution of Bending MomentsDocument46 pagesRedistribution of Bending Momentspopaciprian27Pas encore d'évaluation

- SCIA Engineer CADS RC Designers Link EnuDocument16 pagesSCIA Engineer CADS RC Designers Link Enupopaciprian27100% (1)

- Pile FoundationDocument26 pagesPile Foundationpopaciprian27100% (1)

- PGNL Theory EnuDocument19 pagesPGNL Theory Enupopaciprian27100% (1)

- ProtectionDocument25 pagesProtectionpopaciprian27Pas encore d'évaluation

- SDNF InterfaceDocument11 pagesSDNF Interfacepopaciprian27Pas encore d'évaluation

- Orthotropy Theory EnuDocument39 pagesOrthotropy Theory Enupopaciprian27Pas encore d'évaluation

- Mapping Database EditorDocument12 pagesMapping Database Editorpopaciprian27Pas encore d'évaluation

- Manual Profile Library Editor EnuDocument68 pagesManual Profile Library Editor Enupopaciprian27Pas encore d'évaluation

- LTA Manual EnuDocument73 pagesLTA Manual Enupopaciprian27Pas encore d'évaluation

- Manual Hollow Core SlabDocument88 pagesManual Hollow Core Slabpopaciprian27100% (3)

- Cold Formed Steel DesignDocument2 pagesCold Formed Steel DesignkiplingkipPas encore d'évaluation

- Transpo, Min, Rail, Traffic, PortsDocument57 pagesTranspo, Min, Rail, Traffic, PortsGraciella Angela NebresPas encore d'évaluation

- Conversion Factors For Oilfield UnitsDocument12 pagesConversion Factors For Oilfield Unitsmd_mohshinPas encore d'évaluation

- SNAME T and R Bulletin 2 29A Vibration Measurement and Eval Jan 2004 T RDocument68 pagesSNAME T and R Bulletin 2 29A Vibration Measurement and Eval Jan 2004 T RAnthonyPas encore d'évaluation

- CP 1 Experiment 2Document3 pagesCP 1 Experiment 2Mavy KylinePas encore d'évaluation

- P13ME51 BN AjanaDocument3 pagesP13ME51 BN AjanaRocky FxPas encore d'évaluation

- CO-PO MappingDocument6 pagesCO-PO MappingArun Kumar100% (1)

- Loaded Flat Plates PDFDocument6 pagesLoaded Flat Plates PDFantoninoPas encore d'évaluation

- Physics Notes PDF For Class 9Document3 pagesPhysics Notes PDF For Class 9Mithilesh Kr Prem100% (1)

- Modul Fizik F5 2023 (Answers)Document25 pagesModul Fizik F5 2023 (Answers)nyshahidaPas encore d'évaluation

- Non Newtonian FluidsDocument17 pagesNon Newtonian FluidsSalman Haroon100% (1)

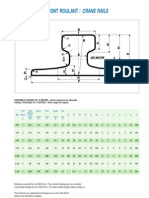

- Crane RailsDocument2 pagesCrane Rails_at_to_100% (1)

- Chapter 37【Wave Optics (I) 】Document22 pagesChapter 37【Wave Optics (I) 】陳慶銘Pas encore d'évaluation

- Introduction To Mechanical VibrationDocument1 pageIntroduction To Mechanical VibrationDomingo Joshua Eduard C.Pas encore d'évaluation

- Physics Honors Chapter 2 Practice TestDocument3 pagesPhysics Honors Chapter 2 Practice TestAref DahabrahPas encore d'évaluation

- Lab 5Document10 pagesLab 5Tayyab ZafarPas encore d'évaluation

- Stress Analysis of Pressure Vessels Based On ANSYSDocument4 pagesStress Analysis of Pressure Vessels Based On ANSYSsandeeppandey0789Pas encore d'évaluation

- Dynamic Characteristics of VehicleDocument26 pagesDynamic Characteristics of VehiclesurabhiPas encore d'évaluation

- Tutorial 1 SolutionDocument10 pagesTutorial 1 SolutionSu YiPas encore d'évaluation

- Applied Thermal Engineering: Han-Taw Chen, Shih-Ting Lai, Li-Ying HaungDocument9 pagesApplied Thermal Engineering: Han-Taw Chen, Shih-Ting Lai, Li-Ying HaungSaiful AzriePas encore d'évaluation

- Kinematics of Particles Plane Curvilinear MotionDocument16 pagesKinematics of Particles Plane Curvilinear Motionson gokuPas encore d'évaluation

- ME 408 Lecture2Document47 pagesME 408 Lecture2reader1900Pas encore d'évaluation

- Chapter 3. Failure of MaterialsDocument20 pagesChapter 3. Failure of MaterialsVishal ShuklaPas encore d'évaluation

- 2foundation Moments Hydraulics and CM Self Study QuestionsDocument40 pages2foundation Moments Hydraulics and CM Self Study QuestionsAngel TeyPas encore d'évaluation

- 0.25 Marks X 40 MCQ 10 MarksDocument5 pages0.25 Marks X 40 MCQ 10 MarksNilPas encore d'évaluation

- .In-Deduction of Gas Laws From Kinetic TheoryDocument2 pages.In-Deduction of Gas Laws From Kinetic TheoryMridul BhaskarPas encore d'évaluation

- ANSYS Mechanical APDL Theory Reference PDFDocument908 pagesANSYS Mechanical APDL Theory Reference PDFNam Vo100% (1)

- ch4 Mechanical Properties of Wood PDFDocument46 pagesch4 Mechanical Properties of Wood PDFdan-gabiPas encore d'évaluation

- Unit I: Basics of MechanismsDocument118 pagesUnit I: Basics of MechanismsajitsssPas encore d'évaluation