Académique Documents

Professionnel Documents

Culture Documents

Ceramic Package - Godparent Review - Apr 2013

Transféré par

Omar Abd Elsalam0 évaluation0% ont trouvé ce document utile (0 vote)

19 vues17 pagesnbkvsx gcsjvxkjba jhvalx bib;n hvilxnn jhvlxj

Copyright

© Attribution Non-Commercial (BY-NC)

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentnbkvsx gcsjvxkjba jhvalx bib;n hvilxnn jhvlxj

Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

19 vues17 pagesCeramic Package - Godparent Review - Apr 2013

Transféré par

Omar Abd Elsalamnbkvsx gcsjvxkjba jhvalx bib;n hvilxnn jhvlxj

Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 17

SSL

LAu Ceramlc ackage

ueslgn, llow, & SLaLus

!ason MchaLe & Cswald Slegmund

LAu Permeuc ackage CodparenL 8evlew

3 Aprll 2013

SSL

Ceramlc ackage ueslgn Cvervlew

use sLandard" sealed Lube

maLerlals and processlng

Ceramlc brazed body wlLh Cu

lndlum well

Slgnals and Pv passed Lhrough

Lhe anode on kovar plns

3mm Lhlck boroslllcaLe (Schou

833) wlndow

na

2

kSb blalkall phoLocaLhode

PoL seal (ln8l alloy)

x" shaped lnLernal supporL

sLrucLure

8.66" square, ~0.68" Lhlck

(lncludlng wlndow)

3 Aprll 2013 LAu Permeuc ackage CodparenL 8evlew 2

Mechanlcal 1esL unlL

SSL

lnLernal SLack-up

Large area requlres lnLernal

supporL sLrucLure Lo prevenL

wlndow/anode cracklng under

aLmospherlc pressure load

ueslre Lo supporL wlLhouL creaung

Lrapped spaces lead Lo x" shaped

supporL sLrucLures

Comblnauon of lnsulaung ceramlc

x-grlds and sLalnless x-shlms

x-grlds lsolaLe Pv poLenuals whlle

x-shlms faclllLaLe Pv dlsLrlbuuon

(and sLack helghL ad[usLmenL)

1op x-grld serves Lo reLaln enure

sLack durlng processlng

1oLal lnLernal sLack helghL ls .003"

Lo .006" !"#$% Lhe Lop of Lhe Cu

well - Lo ensure wlndow seal

3 Aprll 2013 LAu Permeuc ackage CodparenL 8evlew 3

Anode Cap x-grlds lnLer-MC x-grld

CaLhode Cap x-grld Mech. 1esL unlL

Pv lnLernal ulsLrlbuuon Lxample

8ouom Pv ConLacL

SSL

Ceramlc 8razed 8ody Assembly

All maLerlals refracLory or meLal

and proven for vacuum Lube

manufacLurlng

Plgh-Lemp meLalllzed ceramlc

anode wlLh kovar feedLhrough

plns

Ceramlc sldewall frame

lndlum seal well ls sLamped from

ClL copper (used for opumal

lndlum wemng and ducullLy)

Cnly Lwo braze [olnLs (save for Lhe

plns), uslng lnCuSll braze alloy

Large C1L mlsmaLch beLween Cu

and ceramlc, buL Lhe Cu ls very

ducule and does noL over-sLress

Lhe ceramlc

3 Aprll 2013 LAu Permeuc ackage CodparenL 8evlew 4

SSL

Ceramlc Anode

SubsLraLe ls .100" Lhlck 96

alumlna

Plgh-Lemp meLalllzauon

36 slgnal sLrlps lnslde

Solld ground plane ouLslde

Peaded kovar plns for slgnal and

Pv feedLhrough

Pv plns are double-ended Lo

dlsLrlbuLe Pv verucally wlLhln Lhe

Lube - one ln each corner

lns (76 ln LoLal) brazed lnLo

anode one of Lwo ways

CuSll braze prlor Lo body braze

(currenL preferred meLhod)

lnCuSll braze slmulLaneously wlLh

body braze

3 Aprll 2013 LAu Permeuc ackage CodparenL 8evlew 3

SSL

PlsLory of Lhe Ceramlc ackage 8razlng

SLarLed wlLh P

2

brazlng aL unlLed SuperLek (uSl)

lnlually CuSll alloy kovar Lo alumlna brazes, buL close buL noL

perfecL C1L maLch coupled wlLh kovar sLrengLh resulLed ln

cracked ceramlcs - 2 auempLs

1hen lnCuSll alloy brazes wlLh Cu lndlum well (currenL deslgn) -

1 auempL

noL gemng consLrucuve process feedback from uSl

SwlLched Lo vacuum brazlng aL Cmley lndusLrles

lnlually dld lnCuSll alloy brazes wlLh all ln one go (anode plns,

and body [olnLs) - 4 auempLs (all leaky aL plns)

SwlLched Lo Lwo sLep process. CuSll anode pln braze, Lhen

lnCuSll body braze - 3 auempLs (wlLh lmprovlng resulLs)

3 Aprll 2013 LAu Permeuc ackage CodparenL 8evlew 6

SSL

1wo-SLep 8razlng rocess

lns brazed lnLo anode rsL

CuSll braze alloy - ~830C process LemperaLure

SLresses are mlnlmal (plns are small) - Muluple re-braze runs posslble

MlugaLes rlsk aL Lhe lncurslon of lncreased expense

1hree consecuuve leak-ughL anode-pln assemblles slnce swlLchlng Lo Lhls

meLhod

8ody brazed uslng pre-plnned anode assembly

lnCuSll braze alloy - ~730C process Lemp, so no re-melL of pln braze CuSll

alloy

lmproved nal assemblles

rlor Lo uslng Lhe Lwo-sLep process, assemblles had gross leaks -

parucularly aL Lhe plns

1he Lwo sLage process lmmedlaLely resulLed ln assemblles LhaL were

much closer Lo leak ughL and lncremenLal progress has been made slnce

3 Aprll 2013 LAu Permeuc ackage CodparenL 8evlew 7

SSL

Ceneral 8raze CommenLs

nelLher braze vendor was pleased wlLh Lhe

meLalllzauon on Lhe anodes

Screenlng performed by CaL-l Class

lnconslsLenL Lhlckness (some qulLe Lhln areas) and poor

reglsLrauon

nelLher vendor parucularly llkes lnCuSll - poor

wemng characLerlsucs compared Lo CuSll (for

example)

Cmley has opLed Lo swlLch anode pln braze Lo alCuSll

uSl has opLed Lo swlLch anode pln braze Lo Cu/Au (braze

washers on order, should arrlve soon)

3 Aprll 2013 LAu Permeuc ackage CodparenL 8evlew 8

SSL

8ecenL 8raze AcuvlLy

Cmley auempLed alCuSll braze on lasL remalnlng anode

from rsL baLch

unsuccessful aer 4 braze runs

know meLalllzauon lssues wlLh Lhls anode, and leaks seem

Lo be where meLalllzauon was scavenged by alloy

llnal 7 sldewalls have been meLalllzed aL uSl and are

ready for braze use. 1hese were done wlLh Lhlcker

meLalllzauon Lhan Lhe rsL baLch.

LasL 6 anode subsLraLes are ln process

Laser machlnlng and nal machlnlng compleLe

MeLalllzauon ln progress aL uSl. Screenlng belng done aL uSl,

and uslng Lhlcker meLalllzauon on Lhese Loo.

LxpecLed dellvery 4-3 weeks

3 Aprll 2013 LAu Permeuc ackage CodparenL 8evlew 9

SSL

8e-8raze of 8razed 8ody Sn07

erformed 2x P

2

re-brazes aL uSl of Cmley 88A Sn07

used a slow Lhermal prole Lo mlnlmlze sLresses ln Lhe body durlng

reheaL

llrsL re-braze was a slmple reheaL wlLh clamplng pressure

Second re-braze added lnCuSll pasLe aL leak slghLs

Can perform muluple processes wlLhouL desLroylng bodles

CreaLly lmproved Lhe leak raLe

lnlual leak raLe was 10

-1

Lorr-l/s (dlsLrlbuLed over several lnches)

osL rsL re-braze now 210

-6

and 410

-8

leaks. Second re-braze

dldn'L change anyLhlng

now our rsL poLenual body for a seal Lube

8elnvlgoraLes Lhe P

2

brazlng program (wlLh caveaL)

8equlres dlrecL personal lnvolvemenL aL Lhe vendor (Lo ensure

approprlaLe auenuon Lo deLall)

3 Aprll 2013 LAu Permeuc ackage CodparenL 8evlew 10

SSL

8razlng luLure lans

P

2

braze one anode wlLh Cu/Au alloy aL uSl

lf lL's leak ughL, Lhen use lL ln a CuSll body braze

lf noL successful, conslder reLurnlng Lo Cmley

We plan Lo be conservauve wlLh our lasL 6 blLes aL

Lhls apple

Should geL more plece parLs ln Lhe plpellne once Lhe

fundlng slLuauon has seuled ouL?

n8: P

2

brazlng aL uSl ls abouL 40 Lhe cosL of

vacuum brazlng aL Cmley

3 Aprll 2013 LAu Permeuc ackage CodparenL 8evlew 11

SSL

8razed 8ody labrlcauon llow

Metallization

(4-5 weeks)

Laser cutting

(1-2 weeks)

Finish machining

(2-3 weeks)

Anode substrates

(4-5 weeks)

Kovar pins

(4-8 weeks)

Copper wells

(large stock)

Ceramic sidewalls

(6-7 weeks)

Metallization

(2-3 weeks)

InCuSil BODY

BRAZE

(<1 week)

CuSil ANODE

BRAZE

(<1 week)

Leak test

(1 day)

Leak test

(1 day)

VIABLE

BRAZE BODY

18 uecember 2012 LAu uCL ro[ecL 8evlew 12

SSL

88A 8ased uemounLable

Allows Lube-llke Lesung of MC and

oLher lnLernal componenLs ln

brazed body wlLh uP readouL

elecLronlcs prlor Lo Lube fabrlcauon

A good use for one of Lhe leaky all-

lnCuSll brazed bodles - Celvaseal

Lhe leaks

Cu lndlum well o-rlng seals Lo

mounung backplaLe

8ackplaLe mounLs Lo exlsung 8" xuL

demounLable deLecLor Lank

laLe epoxled Lo anode Lo mlnlmlze

vacuum bowlng and provlde a

mounung locauon for elecLronlcs

ueslgn near compleuon, golng Lo

fabrlcauon soon

3 Aprll 2013 LAu Permeuc ackage CodparenL 8evlew 13

SSL

near-1erm lans

labrlcaLe brazed bodles from plece parLs currenLly ln

process (slx assemblles maxlmum)

llnallze deslgn & fabrlcaLe Lhe 88A demounLable

ush 88A Sn07 Lhrough Lube processlng

8e-braze 88A Sn06 as backup Lo Sn07

3 Aprll 2013 LAu Permeuc ackage CodparenL 8evlew 14

SSL

8ACku SLluLS

3 Aprll 2013 LAu Permeuc ackage CodparenL 8evlew 13

SSL

8" 1ube rocess llow

Mount Sb and alkali

sources on FW ange

Functional test

MCP

scrubbing

Photocathode

shoot

QE check

(Hot)

Receive and

inspect 8.66" B33

window

Inspect, clean,

test body sub-

assy, Indium ll,

vacuum bakeout,

leak test

Wet clean and

plasma clean

Prepare tank

tooling for detector

body assy

Load getters,

X-Grids, MCPs,

and make HV

contacts

Check, test and

clean MCPs

Inspect & clean

internal parts

Vacuum

bakeout

Functional test

Functional test

Window seal

(Hot)

Functional test

(Cold)

TANK LOAD

Prepare electronic/

optical test station

Prepare QE test optics,

lters and std diodes

Up to Air

Scrub source, &

recording setup

RGA setup

Blue Processes

at Vacuum

Black Processes

at Air

Evaporate NiCr &

Cu border

Plasma clean

Prepare & clean

tank tooling for

8.66" windows

Prepare & clean

forming well ange

Detailed assembly ow in backup matl.

3 Aprll 2013 LAu Permeuc ackage CodparenL 8evlew 16

SSL

Ceramlc ackage LlecLronlcs

3 Aprll 2013 LAu Permeuc ackage CodparenL 8evlew 17

8eadouL elecLronlcs for Lhe ceramlc package provlded by u of

Pawall (varner Lalk on LlecLronlcs)

8ased on 8elle-ll l1C readouL elecLronlcs

18x 4-channel pre-ampller boards

9x 8-channel analog Lo dlglLal daughLer cards

1x lnLerface board and 1x power board

8eady for Lesung

need ceramlc package based demounLable deLecLor or Lube Lo LesL

Vous aimerez peut-être aussi

- Hamada 5 NDocument8 pagesHamada 5 NOmar Abd ElsalamPas encore d'évaluation

- Fiber 0Document8 pagesFiber 0Omar Abd ElsalamPas encore d'évaluation

- Valuation TechDocument4 pagesValuation TechOmar Abd ElsalamPas encore d'évaluation

- Chemicals ListDocument2 pagesChemicals ListOmar Abd ElsalamPas encore d'évaluation

- 978 3 659 36178 4 - Coverpreview 2Document1 page978 3 659 36178 4 - Coverpreview 2Omar Abd ElsalamPas encore d'évaluation

- Synthetic Fibres & PlasticsDocument17 pagesSynthetic Fibres & PlasticsOmar Abd ElsalamPas encore d'évaluation

- NBSS Final PresentationDocument15 pagesNBSS Final PresentationOmar Abd ElsalamPas encore d'évaluation

- LCA Mari NissinenDocument25 pagesLCA Mari NissinenOmar Abd ElsalamPas encore d'évaluation

- Particle Processing Research: Terry A. Ring Chemical Engineering University of UtahDocument58 pagesParticle Processing Research: Terry A. Ring Chemical Engineering University of UtahOmar Abd ElsalamPas encore d'évaluation

- Fibers 2Document25 pagesFibers 2ineboluuPas encore d'évaluation

- Ceramics 130430211844 Phpapp02Document62 pagesCeramics 130430211844 Phpapp02Omar Abd ElsalamPas encore d'évaluation

- Fortna SyllabusDocument10 pagesFortna SyllabusOmar Abd ElsalamPas encore d'évaluation

- Esi JCR BrochureDocument4 pagesEsi JCR BrochureOmar Abd ElsalamPas encore d'évaluation

- Ceramicsmaterialspropthermalandmechanical 121004140222 Phpapp01Document43 pagesCeramicsmaterialspropthermalandmechanical 121004140222 Phpapp01Omar Abd ElsalamPas encore d'évaluation

- Graphene Materials 2Document2 pagesGraphene Materials 2Omar Abd ElsalamPas encore d'évaluation

- CeramicsDocument39 pagesCeramicsAlok MahadikPas encore d'évaluation

- Ceramic Technology SyllabusDocument41 pagesCeramic Technology SyllabusOmar Abd ElsalamPas encore d'évaluation

- Art 4915Document5 pagesArt 4915Omar Abd ElsalamPas encore d'évaluation

- Ceramics 120325085721 Phpapp02Document13 pagesCeramics 120325085721 Phpapp02Omar Abd ElsalamPas encore d'évaluation

- Electron Withdrawing and Electron Donating GroupsDocument2 pagesElectron Withdrawing and Electron Donating GroupsOmar Abd ElsalamPas encore d'évaluation

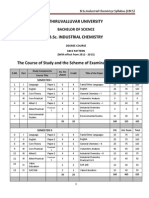

- B.sc. Industrial ChemistryDocument79 pagesB.sc. Industrial ChemistryOmar Abd Elsalam0% (1)

- Syllabus For Ceramics and Ceramics and Ceramic Sculpture: Hans CoperDocument9 pagesSyllabus For Ceramics and Ceramics and Ceramic Sculpture: Hans CoperOmar Abd ElsalamPas encore d'évaluation

- The Structure of A Microemulsion DropletDocument4 pagesThe Structure of A Microemulsion DropletOmar Abd ElsalamPas encore d'évaluation

- SPSSDocument29 pagesSPSSOmar Abd Elsalam100% (1)

- Physico-Chemical Properties of Metal Nanopowders Prepared For Advanced Technological ApplicationsDocument77 pagesPhysico-Chemical Properties of Metal Nanopowders Prepared For Advanced Technological ApplicationsOmar Abd ElsalamPas encore d'évaluation

- AnticorrosionDocument128 pagesAnticorrosionOmar Abd ElsalamPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- City Limits Magazine, December 1981 IssueDocument28 pagesCity Limits Magazine, December 1981 IssueCity Limits (New York)Pas encore d'évaluation

- Thermal Physics Lecture 1Document53 pagesThermal Physics Lecture 1Swee Boon OngPas encore d'évaluation

- Dist - Propor.danfoss PVG32Document136 pagesDist - Propor.danfoss PVG32Michal BujaraPas encore d'évaluation

- PathologyDocument31 pagesPathologyStudy Usmle100% (1)

- Investment Analysis and Portfolio Management: Frank K. Reilly & Keith C. BrownDocument113 pagesInvestment Analysis and Portfolio Management: Frank K. Reilly & Keith C. BrownWhy you want to knowPas encore d'évaluation

- 5 Ways To Foster A Global Mindset in Your CompanyDocument5 pages5 Ways To Foster A Global Mindset in Your CompanyGurmeet Singh KapoorPas encore d'évaluation

- Vest3000mkii TurntableDocument16 pagesVest3000mkii TurntableElkin BabiloniaPas encore d'évaluation

- Air Blower ManualDocument16 pagesAir Blower ManualshaiknayeemabbasPas encore d'évaluation

- DL Manual - Com Vs Controller Gs Driver p100 Operating ManualDocument124 pagesDL Manual - Com Vs Controller Gs Driver p100 Operating ManualThiago Teixeira PiresPas encore d'évaluation

- What Is The PCB Shelf Life Extending The Life of PCBsDocument9 pagesWhat Is The PCB Shelf Life Extending The Life of PCBsjackPas encore d'évaluation

- Optical Transport Network SwitchingDocument16 pagesOptical Transport Network SwitchingNdambuki DicksonPas encore d'évaluation

- Introduction Spreadable Media TtsDocument22 pagesIntroduction Spreadable Media TtsYanro FerrerPas encore d'évaluation

- Study Notes - Google Project Management Professional CertificateDocument4 pagesStudy Notes - Google Project Management Professional CertificateSWAPNIL100% (1)

- E Voting PPT - 1Document11 pagesE Voting PPT - 1madhu100% (2)

- Porter's 5-Force Analysis of ToyotaDocument9 pagesPorter's 5-Force Analysis of ToyotaBiju MathewsPas encore d'évaluation

- Kiraan Supply Mesin AutomotifDocument6 pagesKiraan Supply Mesin Automotifjamali sadatPas encore d'évaluation

- Employee of The Month.Document2 pagesEmployee of The Month.munyekiPas encore d'évaluation

- Initial Police Report: Calamba City Police Station Brgy Real, Calamba City, Laguna E-Mail: 545-1694/545-6789 Loc 8071Document1 pageInitial Police Report: Calamba City Police Station Brgy Real, Calamba City, Laguna E-Mail: 545-1694/545-6789 Loc 8071Jurish BunggoPas encore d'évaluation

- Written Report SampleDocument16 pagesWritten Report Sampleallanposo3Pas encore d'évaluation

- Level of Organisation of Protein StructureDocument18 pagesLevel of Organisation of Protein Structureyinghui94Pas encore d'évaluation

- The Original Lists of Persons of Quality Emigrants Religious Exiles Political Rebels Serving Men Sold For A Term of Years Apprentices Children Stolen Maidens Pressed and OthersDocument609 pagesThe Original Lists of Persons of Quality Emigrants Religious Exiles Political Rebels Serving Men Sold For A Term of Years Apprentices Children Stolen Maidens Pressed and OthersShakir Daddy-Phatstacks Cannon100% (1)

- Role of Communication at Mahabharatha WarDocument19 pagesRole of Communication at Mahabharatha WarAmit Kalita50% (2)

- Population Second TermDocument2 pagesPopulation Second Termlubna imranPas encore d'évaluation

- CV Ashish PDFDocument3 pagesCV Ashish PDFRoshan KejariwalPas encore d'évaluation

- DP-1520 PMDocument152 pagesDP-1520 PMIon JardelPas encore d'évaluation

- Standard BMW PDFDocument19 pagesStandard BMW PDFIna IoanaPas encore d'évaluation

- 02 CT311 Site WorksDocument26 pages02 CT311 Site Worksshaweeeng 101Pas encore d'évaluation

- 9701 Nos Ps 23Document5 pages9701 Nos Ps 23Hubbak KhanPas encore d'évaluation

- Chronic Renal FailureDocument54 pagesChronic Renal FailureAkia Cayasan BayaPas encore d'évaluation

- Sheetal PatilDocument4 pagesSheetal PatilsheetalPas encore d'évaluation