Académique Documents

Professionnel Documents

Culture Documents

Simplifying The Complexity of Motion

Transféré par

Steve CarsonDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Simplifying The Complexity of Motion

Transféré par

Steve CarsonDroits d'auteur :

Formats disponibles

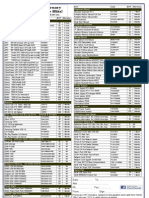

SIMPLIFYING THE COMPLEXITY OF MOTION

State-of-the-Art Controls Give New Life to

this 1950s-era Ingersoll Planer Mill

[photo here]

Paul Schurman Machine (PSM) of Ridgefield, Washington purchased a well worn 1950s-era Ingersoll

planer mill to satisfy a growing demand for large-scale machining. The planer mill required a complete

mechanical rebuild which PSM undertook to restore the machine’s mechanical components. However,

they weren’t sure what could be accomplished when it came to upgrading the machine’s control system.

Can Old and New Work Together?

PSM asked Applied Motion Systems for a cost-effective solution that would allow them to run canned milling, drilling, and tapping

cycles. The planer mill was designed and manufactured before the advent of CNC controls. All axis controls were fully manual and none

were capable of close tolerance positioning, a feature required for a typical CNC controller today.

Solution Development

Applied Motion engineers worked with Greg Somero, PSM’s CNC specialist, to determine the range of intended uses for the machine.

After considering the list of requirements, AMS recommended a flexible CNC controller with custom servo capabilities. The AMS

engineering team then developed software features to address backlash associated with each axis of the machine.

The solution uses both real and virtual axes to provide a stable position loop that automatically compensates for backlash in the

drivetrain. This novel dual-loop approach is implemented in the X, Y, and W axes, resulting in point-to-point positioning accuracy to

within +/- 0.0008” at the spindle throughout the machining envelope (X=432”, Y=88”, W=49”, Z=12”).

Surprising Results

The success of this project is due to the collaboration

between AMS engineers and PSM CNC programmers and

machinists. PSM now has a fully CNC-capable planer mill

that delivers automatic milling, drilling, and rigid tapping

functions using industry standard G-code. Ball bar tests

indicate that circular interpolation features turn in

respectable performance even with significant backlash

issues with both the X and Y axes. Circular interpolated

profiles hold better than +/- 0.005” at 10 ipm using the

original X axis rack drive system.

At AMS we thrive on developing solutions for manufactur-

ing challenges. What can we do for you?

12000 NE 60th Way Vancouver, WA 98682 Phone: 360.253.4810 Fax: 360.253.4818 www.appliedmotionsystems.com

Applied Motion Systems and AMS are trademarks or registered trademarks of Applied Motion Systems, Inc. in the United States and other countries.

Other names and brands may be claimed as the property of others. Copyright © 2009 by Applied Motion Systems, Inc. All rights reserved.

Vous aimerez peut-être aussi

- NIM CommandsDocument4 pagesNIM CommandsSrinivas KumarPas encore d'évaluation

- SSIS Package CreationDocument648 pagesSSIS Package CreationShanmuga VadivelPas encore d'évaluation

- Drawings and Reports Reference Data GuideDocument1 145 pagesDrawings and Reports Reference Data Guidelionstar0007Pas encore d'évaluation

- Camworks 2.5-Axis Milling: For Pocketing, Contouring, and DrillingDocument2 pagesCamworks 2.5-Axis Milling: For Pocketing, Contouring, and DrillingNisarg MehtaPas encore d'évaluation

- HANA Master Guide 2.0Document60 pagesHANA Master Guide 2.0BarasatLocal PassengersPas encore d'évaluation

- Agiecharmilles Cut P Pro Serie - en PDFDocument52 pagesAgiecharmilles Cut P Pro Serie - en PDFdimasPas encore d'évaluation

- Agiecharmilles Cut e 350 600 - enDocument28 pagesAgiecharmilles Cut e 350 600 - enrachid HachhouchePas encore d'évaluation

- CHAPTER 1 - Introduction To Computer BasicDocument9 pagesCHAPTER 1 - Introduction To Computer Basicparishay khan100% (1)

- Brochure Retrofit For Machine Tools 21.09.2017Document12 pagesBrochure Retrofit For Machine Tools 21.09.2017Марко БулатовићPas encore d'évaluation

- STRAUSAK U-Grind 5 Axis CNC Tool GrinderDocument7 pagesSTRAUSAK U-Grind 5 Axis CNC Tool GrinderJayakrishnaPas encore d'évaluation

- Interview Questions Big Data AnalyticsDocument27 pagesInterview Questions Big Data AnalyticsSenthil KumarPas encore d'évaluation

- Power-Bend Pro: 3 Axes (R Manual) CNC Press BrakeDocument15 pagesPower-Bend Pro: 3 Axes (R Manual) CNC Press Brakecisar0007Pas encore d'évaluation

- Promaster 7225Document12 pagesPromaster 7225AdragPas encore d'évaluation

- MT SS First Choice For SpecialistsDocument3 pagesMT SS First Choice For Specialistsstanalina00Pas encore d'évaluation

- Ansys Turbo Machinery FlyerDocument2 pagesAnsys Turbo Machinery FlyermilanstrPas encore d'évaluation

- MDLL2015Q00 Power Suplly Num ManualDocument5 pagesMDLL2015Q00 Power Suplly Num ManualVOLTA PROPas encore d'évaluation

- Universal Machining CentersDocument4 pagesUniversal Machining CentersAdhiraj SinghPas encore d'évaluation

- MH Hexagon NCGage Product Brochure enDocument8 pagesMH Hexagon NCGage Product Brochure enphungPas encore d'évaluation

- SolidCAM - Mill Turn BrochureDocument12 pagesSolidCAM - Mill Turn BrochureBosko BijelacPas encore d'évaluation

- Aberlink Zenith TooDocument8 pagesAberlink Zenith Toodanielbo2220Pas encore d'évaluation

- Brosur - Autodesk Solutions (New) - CompressedDocument4 pagesBrosur - Autodesk Solutions (New) - CompresseddelcamdmiPas encore d'évaluation

- CNC Machine SheetDocument2 pagesCNC Machine SheetChris BalanPas encore d'évaluation

- Mastercam Mill Is Rich in Features Yet Still Simple and Intuitive To UseDocument4 pagesMastercam Mill Is Rich in Features Yet Still Simple and Intuitive To UseODEH ABU YAHIAPas encore d'évaluation

- VX 135 - CNC Machines, CNC Turning Centre, CNC Vertical Machining Centre, CNC Machinery India - MacPowerDocument2 pagesVX 135 - CNC Machines, CNC Turning Centre, CNC Vertical Machining Centre, CNC Machinery India - MacPowercm_chemical81Pas encore d'évaluation

- Powermill 1Document2 pagesPowermill 1workman1Pas encore d'évaluation

- NX CAM Robot ProgrammingDocument2 pagesNX CAM Robot ProgrammingCabinet OrthopédiquePas encore d'évaluation

- Trust The Leader For Speed and ConfidenceDocument4 pagesTrust The Leader For Speed and Confidenceraf szPas encore d'évaluation

- H-E Parts Flyer Liner DevelopmentDocument2 pagesH-E Parts Flyer Liner DevelopmentJorge VillalobosPas encore d'évaluation

- STC Vacuum Series Semi Conductor enDocument12 pagesSTC Vacuum Series Semi Conductor enShady MohamedPas encore d'évaluation

- Experience Perfect Interaction With Vista.: SimplymeasureDocument6 pagesExperience Perfect Interaction With Vista.: SimplymeasureCDELVO1382Pas encore d'évaluation

- Agiecharmilles Cut E350 600 enDocument28 pagesAgiecharmilles Cut E350 600 enKADİRPas encore d'évaluation

- Ram Concept DatasheetDocument2 pagesRam Concept DatasheetKilaru HareeshPas encore d'évaluation

- Ceco Brochure PDFDocument8 pagesCeco Brochure PDFHerdi PriyoPas encore d'évaluation

- Elektor CNC U0701014 PDFDocument5 pagesElektor CNC U0701014 PDFNick LastPas encore d'évaluation

- Berchtesgaden 2001 16 Eur Use Conf Paper - 61aDocument14 pagesBerchtesgaden 2001 16 Eur Use Conf Paper - 61aengineeringmtePas encore d'évaluation

- Edm Die Sinker Form 20 30Document16 pagesEdm Die Sinker Form 20 30HaruDoT TVPas encore d'évaluation

- BOMAG - Brochure - BF600-700-800-3 - PRE107416 - 2103Document32 pagesBOMAG - Brochure - BF600-700-800-3 - PRE107416 - 2103Jason TanPas encore d'évaluation

- Vertical Milling Center MAXXMILL 400 630 750Document13 pagesVertical Milling Center MAXXMILL 400 630 750danielPas encore d'évaluation

- Nozzle PRODocument3 pagesNozzle PROhgagPas encore d'évaluation

- Cadwind 2007 BrochureDocument6 pagesCadwind 2007 BrochureHelber Guzmán JiménezPas encore d'évaluation

- STAR-CCM v7 BrochureDocument6 pagesSTAR-CCM v7 BrochureAntonio MartinsPas encore d'évaluation

- Agiecharmilles Specificati MasinaDocument20 pagesAgiecharmilles Specificati MasinaBarbulescu Andreea0% (1)

- Awr Axiem: SheetDocument4 pagesAwr Axiem: SheetArtur Gomes TuyamaPas encore d'évaluation

- Solutions: With Weighing Technology and Control Systems For Concrete Plant DesignDocument2 pagesSolutions: With Weighing Technology and Control Systems For Concrete Plant Designشادي العزبيPas encore d'évaluation

- Feature-Based CAM Software For Mills, Multi-Tasking Lathes and Wire EDMDocument11 pagesFeature-Based CAM Software For Mills, Multi-Tasking Lathes and Wire EDMpatgigPas encore d'évaluation

- Agiecharmilles Cut e 350 600 - enDocument28 pagesAgiecharmilles Cut e 350 600 - enPedro Anastasio SimeonPas encore d'évaluation

- Brochure Product Overview IGDocument16 pagesBrochure Product Overview IGmaicol21nPas encore d'évaluation

- CatRoverA Mag17 ENG LRDocument36 pagesCatRoverA Mag17 ENG LRcsontosbaluPas encore d'évaluation

- MITSUBISHI CNC M800-M80 Series PDFDocument17 pagesMITSUBISHI CNC M800-M80 Series PDFEgroj Luis100% (1)

- Siemens Oil and Gas Duty Motors-The Ultimate For Assured Performance and Long Life enDocument2 pagesSiemens Oil and Gas Duty Motors-The Ultimate For Assured Performance and Long Life enssPas encore d'évaluation

- Kohler Coil-Handling-Lines Small enDocument11 pagesKohler Coil-Handling-Lines Small enAli BÜLBÜLPas encore d'évaluation

- Design of High-Speed Cam Profiles For Vibration Reduction Using Command Smoothing TechniqueDocument7 pagesDesign of High-Speed Cam Profiles For Vibration Reduction Using Command Smoothing TechniqueArcenio GutierrezPas encore d'évaluation

- Cnc-Machining An: Engine BlockDocument4 pagesCnc-Machining An: Engine BlockКуэнка МануэлPas encore d'évaluation

- Bro Tire 5 Axis Cam Software Hypermill enDocument8 pagesBro Tire 5 Axis Cam Software Hypermill enVinicius Sabrina PedroPas encore d'évaluation

- MAE Automatic Straightening Machines - M-AHDocument24 pagesMAE Automatic Straightening Machines - M-AHsemarasik_651536604Pas encore d'évaluation

- Bro Blow Mold 5 Axis Cam Software Hypermill enDocument6 pagesBro Blow Mold 5 Axis Cam Software Hypermill enVinicius Sabrina PedroPas encore d'évaluation

- Technological and Simulative Analysis of Power SkivingDocument6 pagesTechnological and Simulative Analysis of Power SkivingFernando OteroPas encore d'évaluation

- World-Leading CAM Software For Production MachiningDocument11 pagesWorld-Leading CAM Software For Production MachiningpatgigPas encore d'évaluation

- CNC M800 M80 Series - Bnpa1231engdDocument17 pagesCNC M800 M80 Series - Bnpa1231engdRogério PereiraPas encore d'évaluation

- Eagle CSDocument2 pagesEagle CSAzerPas encore d'évaluation

- Servo MotorsDocument32 pagesServo MotorsThamizhselvan KPas encore d'évaluation

- 5 - PowerMill 2019 BrochureDocument4 pages5 - PowerMill 2019 BrochureAhmedBrahamPas encore d'évaluation

- Máquina Tridimensional Horizon CMM DatasheetDocument2 pagesMáquina Tridimensional Horizon CMM Datasheetdanielbo2220Pas encore d'évaluation

- CNC m800 - m80 SeriesDocument17 pagesCNC m800 - m80 Series罗佳佳Pas encore d'évaluation

- Technology Modul Cam Profile: Drive Center International ContDocument8 pagesTechnology Modul Cam Profile: Drive Center International ContRich_78Pas encore d'évaluation

- Lesson 10 Developing A National Geospatial Strategy and Action Plan GKI by DR - Zaffar - Sadiq - Mohamed GhouseDocument42 pagesLesson 10 Developing A National Geospatial Strategy and Action Plan GKI by DR - Zaffar - Sadiq - Mohamed GhouseBala RaoPas encore d'évaluation

- Resonant Interface: Steven HeimDocument11 pagesResonant Interface: Steven HeimDeepak DahiyaPas encore d'évaluation

- Deploying Avaya Call Management System in An Avaya Customer Experience Virtualized EnvironmentDocument44 pagesDeploying Avaya Call Management System in An Avaya Customer Experience Virtualized EnvironmentJuan Carlos FernandezPas encore d'évaluation

- Credit Assessment and Robotics Transformation (C.A.R.T) : Ai Driven Solutions For Smoother Banking ExperienceDocument11 pagesCredit Assessment and Robotics Transformation (C.A.R.T) : Ai Driven Solutions For Smoother Banking ExperiencevijayambaPas encore d'évaluation

- An Introduction To The BIOS: in This GuideDocument3 pagesAn Introduction To The BIOS: in This GuideAnilPas encore d'évaluation

- Lesson5 Hyperlink and Embedding ObjectDocument16 pagesLesson5 Hyperlink and Embedding ObjectHanz DeañoPas encore d'évaluation

- RPAS Configuration GuideDocument272 pagesRPAS Configuration Guidevarachartered283Pas encore d'évaluation

- DSA Short NotesDocument4 pagesDSA Short NotesJitendra ChoudharyPas encore d'évaluation

- How To Disable Visual Studio Debugger - Stack OverflowDocument4 pagesHow To Disable Visual Studio Debugger - Stack Overflowguruh anindraPas encore d'évaluation

- MN 123b 6100 099 VPad 623 Operators ManualDocument118 pagesMN 123b 6100 099 VPad 623 Operators ManualAbdalazeez AlsayedPas encore d'évaluation

- 3rd G7 Lesson 4 Weekly Home Learning Plan in COMPUTERDocument5 pages3rd G7 Lesson 4 Weekly Home Learning Plan in COMPUTERHans Jhayson CuadraPas encore d'évaluation

- Core AppDocument680 pagesCore Appvijay AkkaladeviPas encore d'évaluation

- Install Mediatek Mt65xx Usb Vcom Drivers For Windows AllDocument79 pagesInstall Mediatek Mt65xx Usb Vcom Drivers For Windows Alladriano castroPas encore d'évaluation

- XVR4B04/08: 4/8 Channel Penta-Brid 1080N/720P Cooper 1U Digital Video RecorderDocument3 pagesXVR4B04/08: 4/8 Channel Penta-Brid 1080N/720P Cooper 1U Digital Video RecorderKoushik KarmakarPas encore d'évaluation

- Summative TestDocument3 pagesSummative TestSalveBLaurillaPas encore d'évaluation

- The Dream Mill (Companies House) DirectorsDocument2 pagesThe Dream Mill (Companies House) DirectorsCazzac111Pas encore d'évaluation

- 2018R - B Tech ESE Timetable - Nov 2021Document13 pages2018R - B Tech ESE Timetable - Nov 2021AkashArunPas encore d'évaluation

- Manual Sizer ComponentoneDocument191 pagesManual Sizer ComponentoneGilbertoJulioMuñozPas encore d'évaluation

- Opencv2refman PDFDocument899 pagesOpencv2refman PDFrosasilbusPas encore d'évaluation

- VNX SPS Reemplazo de Unidad-Cambio Alimentación ElectricaDocument15 pagesVNX SPS Reemplazo de Unidad-Cambio Alimentación Electricadvecchio2014Pas encore d'évaluation

- Karl Dvorak, Geschichte Des K.K. Infanterie-Regiments Nr. 41, Vol. IIIDocument322 pagesKarl Dvorak, Geschichte Des K.K. Infanterie-Regiments Nr. 41, Vol. IIIGiovanni Cerino-BadonePas encore d'évaluation

- Autosar Srs GptdriverDocument18 pagesAutosar Srs GptdriverjaanduPas encore d'évaluation

- CS White Paper - CloudsigmaDocument5 pagesCS White Paper - CloudsigmadannymnPas encore d'évaluation

- Bondwell Specials Combo SpecDocument1 pageBondwell Specials Combo SpecMaxFijiPas encore d'évaluation