Académique Documents

Professionnel Documents

Culture Documents

CT 211may2010

Transféré par

Bisma MasoodTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

CT 211may2010

Transféré par

Bisma MasoodDroits d'auteur :

Formats disponibles

STATE OF CALIFORNIABUSINESS, TRANSPORTATION AND HOUSING AGENCY

California Test 211 May 2010

DEPARTMENT OF TRANSPORTATION

DIVISION OF ENGINEERING SERVICES Transportation Laboratory 5900 Folsom Blvd. Sacramento, California 95819-4612

METHOD OF TEST FOR ABRASION OF COARSE AGGREGATE BY USE OF THE LOS ANGELES ABRASION TESTING MACHINE

A. SCOPE

This test method describes the procedure used to determine the resistance of coarse aggregate to impact in a rotating cylinder containing metallic spheres. This test is also known as the Los Angeles Rattler Test. B. REFERENCES

California Test 201 Soil and Aggregate Sample Preparation California Test 202 Sieve Analysis of Fine and Coarse Aggregates AASHTO M 92 Wire-Cloth Sieves for Testing Purposes AASHTO T 96 Resistance to Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in the Los Angeles Machine ASTM C 131 Standard Test Method for Resistance to Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in the Los Angeles Machine C. APPARATUS 1. Los Angeles Abrasion Testing Machine: the Los Angeles Abrasion Testing Machine must conform to the essential design characteristics in Figure 1 and the narrative below. The testing machine must consist of a hollow steel cylinder, closed at both ends, with an inside diameter of 28 in. 0.2 in. and an inside length of 20 in. 0.2 in. The steel cylinder must be mounted on stub shafts attached to the ends of the cylinder but not entering it, and must be mounted in such a manner that it may be rotated about its axis in a horizontal position. An opening in the cylinder must be provided for the introduction of the test sample. The opening must be closed with a dust-tight cover that is easily removed. The cover must be so designed as to maintain the cylindrical contour of the interior surface unless the shelf is so located that the charge will not fall on the cover or come in contact with it during the test. A removable steel shelf projecting radically 3.5 in. 0.1 in. into the cylinder and extending its full length must be mounted along one element of the interior surface of the cylinder. The shelf must be of such thickness and be mounted, by bolts or other approved means, so as to be firm and rigid. The position of the shelf must be such that the distance from the shelf to the opening, measured along the circumference of the cylinder in the direction of rotation, is not less than 50 in. The shelf may also be mounted on the inside of the cover plate (Figure 1). The shelf must be made of wear-resistant steel and must be rectangular in crosssection. The Los Angeles Abrasion Testing Machine must be driven and counter balanced so as to maintain 100 revolutions in 190 s 10 s. The machine must be equipped with an adjustable counter, which can be set to stop the machine at the required number of revolutions.

-1-

California Test 211 May 2010

2. 3. 4.

Balance: a balance having a capacity of at least 5500 g sensitive to 0.1 g or less. Sieves: No. 4 and No. 12 woven wire sieves conforming to AASHTO M 92. These sieves should be at least 12 in. in diameter. Abrasive Charge: a. Each abrasive charge must consist of a solid, steel sphere having a weight between 390 g and 445 g. A solid, steel sphere with a diameter of 1 in. 116 in. typically meets this requirement. The abrasive charge, depending upon the grading of the test specimen as described under Section D, must be as follows:

Grading A B C D Number Of Spheres 12 11 8 6 Weight of Charge, grams 5000 25 4584 25 3330 20 2500 15

b.

D.

PREPARATION OF TEST SPECIMEN 1. Prepare the sample in accordance with California Test 201. When necessary, blend the natural material and the material obtained from crushing the oversized particles in accordance with California Test 201, Section H. Wash dirty or coated aggregate and dry to constant weight in accordance with California Test 226 at 230F 9F. Cool the aggregate to room temperature before preparing the test specimen. Select the grading from Table 1 most nearly representative of the aggregate furnished for the work. Separate the aggregate on the required sieve sizes. Prepare the test specimen using the weight of each sieve size fraction specified for the grading selected. Determine and record the weight of the prepared test specimen to the nearest 1 g. If the coarse aggregate has been separated into 2 or more sieve sizes, select the grading from Table 1 most nearly representative of the combined aggregate mix to be furnished. TABLE 1. Gradings for Test Specimens

Sieve Size Passing Retained on 1 in. 1 in. 1 in. in. in. in. in. in. in. in. in. No. 4 No. 4 No. 8 Total Weight Weight in Grams for Each Grading B C D 25 25 10 2500 10 10 2500 10 2500 10 2500 10 5000 10 5000 10 5000 10 5000 10 5000 10 A 1250 1250 1250 1250

2.

3.

-2-

California Test 211 May 2010

E.

TEST PROCEDURE 1. 2. 3. Place the test specimen and abrasive charge in the Los Angeles Abrasive Testing Machine and close the opening with the dust-tight cover. Start the testing machine and run it for the required number of revolutions. When the testing machine has completed the required number of revolutions, remove the cover and carefully empty the entire contents into a pan. Remove the abrasive charge from the pan. Separate the test specimen on the No. 4 sieve and sieve the passing No. 4 material on the No. 12 sieve. Combine the material retained on the No. 4 and No. 12 sieves in accordance with California Test 202. Weigh and record these values to the nearest 1 g. If the weight of material retained on the No. 12 sieve was determined after 100 revolutions, return the entire test specimen, including the material passing the No. 12 sieve, to the testing machine. Close the opening in the testing machine and operate for the required number of additional revolutions, then repeat Steps 3 and 4.

4.

5.

F.

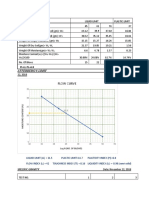

CALCULATION

Calculate the "Percent Wear" to the nearest percent using the following equation:

Percent Wear

A B 100

A

Where: A= B= Weight of original test specimen to the nearest 1 g Weight retained on the No. 12 sieve after the specified number of revolutions to the nearest 1 g

G.

REPORTING RESULTS

Report the grading of the test specimen and the percent wear at the number of revolutions tested. H. PRECAUTIONS 1. It is essential that the entire test specimen, including the passing No. 12 sieve portion, be returned to the testing machine after determining the loss at 100 revolutions. Loss of fines during this phase of the operation will generally cause a higher than normal percent wear at 500 revolutions. Backlash or slip in the driving mechanism is very likely to result in erroneous test results. Occasionally, check machine for worn gears, improperly tensioned belts, worn bearings, etc., to reduce possibility of improper operations. The shelf of the Los Angeles Abrasion Testing Machine should be inspected periodically for wear and distortion.

2.

3.

-3-

California Test 211 May 2010

If the shelf is bent, either lengthwise or from its normal radial position with respect to the cylinder, it should be repaired or replaced before further abrasion tests are made. If a ridge develops on the working surface of the shelf, it should be ground off if its height exceeds 0.1 in. I. HEALTH AND SAFETY

It is the responsibility of the user of this test method to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Prior to handling, testing or disposing of any materials, testers must be knowledgeable about safe laboratory practices, hazards and exposure, chemical procurement and storage, and personal protective apparel and equipment. Caltrans Laboratory Safety Manual is available at: http://www.dot.ca.gov/hq/esc/ctms/pdf/lab_safety_manual.pdf

End of Text (California Test 211 contains 5 Pages)

-4-

California Test 211 May 2010

FIGURE 1. Los Angeles Abrasion Testing Machine

-5-

Vous aimerez peut-être aussi

- Fundamental AnalysisDocument48 pagesFundamental AnalysisBisma MasoodPas encore d'évaluation

- Blastec, Inc // North, Alpharetta, GA: ITE NO. Description NODocument1 pageBlastec, Inc // North, Alpharetta, GA: ITE NO. Description NOBisma MasoodPas encore d'évaluation

- ACS Rebar Plant PDFDocument2 pagesACS Rebar Plant PDFBisma MasoodPas encore d'évaluation

- Certification Plants States 072717Document1 pageCertification Plants States 072717Bisma MasoodPas encore d'évaluation

- A N E SIO R NAP 100: H I T N NE IdleDocument8 pagesA N E SIO R NAP 100: H I T N NE IdleBisma MasoodPas encore d'évaluation

- Root Cause & Corrective Action Corrective Action (RCCA) (RCCA)Document37 pagesRoot Cause & Corrective Action Corrective Action (RCCA) (RCCA)Bisma Masood100% (1)

- Basic TPS Handbook v1Document9 pagesBasic TPS Handbook v1Bisma MasoodPas encore d'évaluation

- Section 8 Illustrations and Parts List: Sullair CorporationDocument1 pageSection 8 Illustrations and Parts List: Sullair CorporationBisma MasoodPas encore d'évaluation

- Section 8 Illustrations and Parts ListDocument1 pageSection 8 Illustrations and Parts ListBisma MasoodPas encore d'évaluation

- Camfil Farr Gold Series Dust Collector Instruction ManualDocument44 pagesCamfil Farr Gold Series Dust Collector Instruction ManualBisma MasoodPas encore d'évaluation

- Iball Service CentresDocument12 pagesIball Service CentresMasood AlamPas encore d'évaluation

- Method For Evaluating Bend Test Results ofDocument10 pagesMethod For Evaluating Bend Test Results ofBisma MasoodPas encore d'évaluation

- Elcometer 214Document15 pagesElcometer 214Bisma MasoodPas encore d'évaluation

- Test Sieving Manual - New Doc - 2Document26 pagesTest Sieving Manual - New Doc - 2Bisma MasoodPas encore d'évaluation

- Fracture Mechanics Analysis of CoatingDocument12 pagesFracture Mechanics Analysis of CoatingBisma MasoodPas encore d'évaluation

- Sample Letter of Intent: M. Burns, 2004Document1 pageSample Letter of Intent: M. Burns, 2004Bisma MasoodPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Policy Schedule Personal Accident Insurance Policy: (Plan 5)Document2 pagesPolicy Schedule Personal Accident Insurance Policy: (Plan 5)Rana BiswasPas encore d'évaluation

- Solar Powered Water Pumping System PDFDocument46 pagesSolar Powered Water Pumping System PDFVijay Nishad100% (1)

- Pieces 1 Cod Amount Product Detail 36 Cotton Pant RemarksDocument4 pagesPieces 1 Cod Amount Product Detail 36 Cotton Pant RemarksFaizan AhmadPas encore d'évaluation

- English BeginnersDocument34 pagesEnglish BeginnersCristina ZamfirPas encore d'évaluation

- FiltrationDocument22 pagesFiltrationYeabsira WorkagegnehuPas encore d'évaluation

- Ergo 1 - Workshop 3Document3 pagesErgo 1 - Workshop 3Mugar GeillaPas encore d'évaluation

- Clinical Features, Evaluation, and Diagnosis of Sepsis in Term and Late Preterm Infants - UpToDateDocument42 pagesClinical Features, Evaluation, and Diagnosis of Sepsis in Term and Late Preterm Infants - UpToDatedocjime9004Pas encore d'évaluation

- Ce Mark - Application FormDocument3 pagesCe Mark - Application Formrajivsinghal90Pas encore d'évaluation

- Medical Nutrition Therapy For DiabetesDocument27 pagesMedical Nutrition Therapy For Diabetesdr.Uci BaharPas encore d'évaluation

- The Aging Brain: Course GuidebookDocument126 pagesThe Aging Brain: Course GuidebookIsabel Cristina Jaramillo100% (2)

- Women and International Human Rights Law PDFDocument67 pagesWomen and International Human Rights Law PDFakilasriPas encore d'évaluation

- 00516-CLIA-Newsletter Jan 06Document4 pages00516-CLIA-Newsletter Jan 06losangelesPas encore d'évaluation

- Unmasking Pleural Mesothelioma: A Silent ThreatDocument11 pagesUnmasking Pleural Mesothelioma: A Silent ThreatCathenna DesuzaPas encore d'évaluation

- Plastic As Soil StabilizerDocument28 pagesPlastic As Soil StabilizerKhald Adel KhaldPas encore d'évaluation

- Osh e MeerDocument3 pagesOsh e MeerfatduckPas encore d'évaluation

- Data Obat VMedisDocument53 pagesData Obat VMedismica faradillaPas encore d'évaluation

- WEEK 7-8: Health 9 Module 4Document8 pagesWEEK 7-8: Health 9 Module 4Heidee BasasPas encore d'évaluation

- Electronic Over Current Relay (EOCR)Document2 pagesElectronic Over Current Relay (EOCR)BambangsPas encore d'évaluation

- Epoxy Data - AF35LVE TDS - ED4 - 11.17Document8 pagesEpoxy Data - AF35LVE TDS - ED4 - 11.17HARESH REDDYPas encore d'évaluation

- Risk Appetite PresentationDocument10 pagesRisk Appetite PresentationAntonyPas encore d'évaluation

- Self Reflection 1Document5 pagesSelf Reflection 1api-270873994Pas encore d'évaluation

- CatalogDocument12 pagesCatalogjonz afashPas encore d'évaluation

- What Does She/He Look Like?: Height Build AGEDocument18 pagesWhat Does She/He Look Like?: Height Build AGEHenrich Garcia LimaPas encore d'évaluation

- A656 GR 80 Brochure 06-26-08Document2 pagesA656 GR 80 Brochure 06-26-08OsmanPas encore d'évaluation

- Bee Keeping-KVK MorenaDocument6 pagesBee Keeping-KVK MorenaAsh1Scribd100% (1)

- Installation Manual: 1.2 External Dimensions and Part NamesDocument2 pagesInstallation Manual: 1.2 External Dimensions and Part NamesSameh MohamedPas encore d'évaluation

- Case Study LenovoDocument10 pagesCase Study LenovoGOHAR GHAFFARPas encore d'évaluation

- Lab CompilationDocument11 pagesLab CompilationJanita SiddiquiPas encore d'évaluation

- BRS PDFDocument14 pagesBRS PDFGautam KhanwaniPas encore d'évaluation

- Guimbungan, Core Competency Module 1 - Part 3 PDFDocument11 pagesGuimbungan, Core Competency Module 1 - Part 3 PDFSharlyne K. GuimbunganPas encore d'évaluation