Académique Documents

Professionnel Documents

Culture Documents

Overpressure

Transféré par

ampowersidDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Overpressure

Transféré par

ampowersidDroits d'auteur :

Formats disponibles

Accessories

Overpressure Protector Type 910.13

WIKA Data Sheet 910.13

Applications

Adjustable overpressure protectors are intended to protect pressure gauges against the effect of pressures exceeding their maximum pressure rating Stainless steel version for corrosive pressure media, even in corrosive ambience Process industry: mechanical engineering and plant construction, chemical/petro-chemical, power stations, mining, on- and offshore, environmental technology

Special Features

7 different setting ranges selectable Minimum pressure to 6 psi (0.4 bar) Maximum pressure to 8700 psi (600 bar) Overpressure safe up to 14,500 psi (1000 bar) Vacuum safe

Overpressure protector - male inlet, female outlet

Description

The overpressure protector consists of a spring loaded piston valve. Under normal pressure conditions the spring holds the valve open. When the system pressure exceeds the set pressure, the force exerted by the spring is overcome and the valve closes. The valve will remain closed until the system pressure drops approximately 25% below the closing pressure, where-upon the force of the spring will open the valve. To change pressure setting: Turn adjusting screw clockwise closing pressure higher Turn adjusting screw counter clockwise closing pressure lower. Overpressure protectors must not be used as process control devices.

Standard Features

Pressure Connection 1/2 NPT male inlet, female outlet 1/2 NPT to 1/4 NPT adaptors available Body 316Ti stainless steel Piston Valve 316Ti stainless steel O-Ring FPM (Viton) Operating Temperature (Media) 176 F (80 C maximum)

WIKA Datasheet 910.13 06/2009

Page 1 of 2

R

Optional Extras (by special order)

Other thread connections: 1/4 NPT, G1/4B and G1/2B Other materials: Brass, Monel 400 Material Certificate (3.1 acc. to EN 10 204) Nace Certificate (2.2 acc. to EN 10 204) Oxygen service (oil and grease free) Mounted on pressure gauge with customer specifications, includes SS tag (note 2) Overpressure protector set to customer specifications, includes SS tag (note 2)

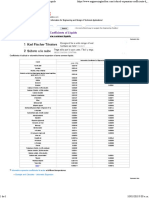

Selectable versions

Range (bar) Range (psi) 0.4 to 2.5 6 to 35 2 to 6 30 to 85 9091971 50681231 5 to 25 85 to 365 9091980 50681249 20 to 60 290 to 870 0690600 50681257 50 to 250 240 to 400 400 to 600 5800 to 8700 50311115 50681281 725 to 3625 3500 to 5800 0690619 50681265 1615130 50681273

Standard 9091963 Part Number 1 Factory Set 50681222 Part Number 2

Note 1: Standard items do not come pre-set from factory. Note 2: Items come pre-set from factory. Customer must specify set or closing pressure. Choose factory set part numbers for pressure gauge mounting and/or factory pre-set.

1. 2. 3. 4. 5. 6. 7. 8. 9. 10.

Body Piston O-ring sealing O-ring sealing Disc Plate Spring Adjusting Screw Sealing Ring Plug Set Screw

Gauge Side

Shut-off Pressure Adjustment

Process Connection Side

Dimensions in mm Ordering Information To order the described products, the 7 or 8 digit product number is sufficient. Optional extras required.

Page 2 of 2

Ordering information Pressure gauge model / Nominal size / Scale range / Size of connection / Optional extras required Specifications and dimensions given in this leaflet represent the state of engineering at the time of printing. Modifications may take place and materials specified may be replaced by others without prior notice.

WIKA Datasheet 910.13 06/2009

R

WIKA Instrument Corporation 1000 Wiegand Boulevard Lawrenceville, GA 30043 Tel (770) 513-8200 Toll-free 1-888-WIKA-USA Fax (770) 338-5118 E-Mail info@wika.com www.wika.com

Vous aimerez peut-être aussi

- Overpressure RegulatorDocument2 pagesOverpressure RegulatorAmine DabbabiPas encore d'évaluation

- Mini Hermet Pressure SwitchesDocument24 pagesMini Hermet Pressure SwitchesMilosglPas encore d'évaluation

- Tel TruDocument28 pagesTel TruVeronica MendosaPas encore d'évaluation

- Gauge SaverDocument2 pagesGauge SaverabhaychaubePas encore d'évaluation

- WIKA - Data Sheet For SnubberDocument2 pagesWIKA - Data Sheet For Snubberyasser hamzaPas encore d'évaluation

- DS8694 Standard EU EnweeDocument9 pagesDS8694 Standard EU EnweevextersPas encore d'évaluation

- Pressure Control Valves: Backpressure Regulators UV 1.6, 2.6Document2 pagesPressure Control Valves: Backpressure Regulators UV 1.6, 2.6cartarPas encore d'évaluation

- Mallard IOM Series 5600Document13 pagesMallard IOM Series 5600Nacho.pPas encore d'évaluation

- Pressure Reducing Valve YoshitakeDocument82 pagesPressure Reducing Valve Yoshitaketungbk9Pas encore d'évaluation

- Sauter B6R Three-Way Valve With Female Thread, PN 16Document4 pagesSauter B6R Three-Way Valve With Female Thread, PN 16pitanje1991Pas encore d'évaluation

- Barksdale 7000pRESSUREDocument4 pagesBarksdale 7000pRESSUREAdam SamyPas encore d'évaluation

- Ue 24013Document8 pagesUe 24013Johnny CormanPas encore d'évaluation

- Diaphragm Valve, Metal: ConstructionDocument4 pagesDiaphragm Valve, Metal: ConstructionDenial BasanovicPas encore d'évaluation

- DS 117 GBDocument8 pagesDS 117 GBAlexander Ruiz IbaguePas encore d'évaluation

- Diapham Valve PDFDocument8 pagesDiapham Valve PDFthouche007Pas encore d'évaluation

- Prime 4 PD MeterDocument4 pagesPrime 4 PD Metertiualbert8729100% (1)

- Pressure and Vacuum Switches - 216Document32 pagesPressure and Vacuum Switches - 216Nirav GandhiPas encore d'évaluation

- Mechanical Pressure Switches: Version Also AvailableDocument14 pagesMechanical Pressure Switches: Version Also AvailableMohamed Gawad ARayaPas encore d'évaluation

- InlineSamplingValves SIVDocument6 pagesInlineSamplingValves SIVmorizonePas encore d'évaluation

- SBM Technology: Cooling / Air Recovery ValveDocument8 pagesSBM Technology: Cooling / Air Recovery ValveEricsson BotchweyPas encore d'évaluation

- PRH04-300 FLG PDFDocument5 pagesPRH04-300 FLG PDFengp3077Pas encore d'évaluation

- Neojv 0040 enDocument0 pageNeojv 0040 enLuis GuevaraPas encore d'évaluation

- Pfeiffer Br26d EngDocument4 pagesPfeiffer Br26d EngAleksandr KrigerPas encore d'évaluation

- MeasureMaster Dual Chamber Orifice FittingDocument6 pagesMeasureMaster Dual Chamber Orifice FittingirfanPas encore d'évaluation

- 70PCVBA Air BoosterDocument20 pages70PCVBA Air BoosterWirote DewilaiPas encore d'évaluation

- Spirax Sarco BTM-7Document3 pagesSpirax Sarco BTM-7Bambang Agung LaxmonoPas encore d'évaluation

- Crane - Series.rs Center LineDocument23 pagesCrane - Series.rs Center LinenedwestPas encore d'évaluation

- Overpressure Protector Type 910.13: ApplicationsDocument2 pagesOverpressure Protector Type 910.13: ApplicationsSofiani PutriPas encore d'évaluation

- SOR Pressure and Vacuum Detectors CatalogueDocument32 pagesSOR Pressure and Vacuum Detectors CatalogueFerio ArsyadPas encore d'évaluation

- Model 210 Digital Electro-Hydraulic Set Stop - PDF-, AttachmentDocument4 pagesModel 210 Digital Electro-Hydraulic Set Stop - PDF-, AttachmentMohd HassanudinPas encore d'évaluation

- Alco Hi Tek Mono FlangeDocument7 pagesAlco Hi Tek Mono FlangelimresPas encore d'évaluation

- 402 00 GB 0611Document12 pages402 00 GB 0611Branko BabicPas encore d'évaluation

- 299HDocument20 pages299HJulian Esteban Arnaiz VargasPas encore d'évaluation

- Norgren N - UK - 1 - 5 - 135 - PRA - 182000 PDFDocument12 pagesNorgren N - UK - 1 - 5 - 135 - PRA - 182000 PDFpichooooPas encore d'évaluation

- Application Example: Pneumatic 2-Finger Parallel GripperDocument35 pagesApplication Example: Pneumatic 2-Finger Parallel GripperBaltazar EspinosaPas encore d'évaluation

- Automatic Valve Gemue DB - 512 - GBDocument6 pagesAutomatic Valve Gemue DB - 512 - GBTaher Yusuf100% (1)

- R07-200 RNKG PDFDocument4 pagesR07-200 RNKG PDFAlexandre EmmerickPas encore d'évaluation

- Guth VSR Modulating ValvesDocument8 pagesGuth VSR Modulating ValvesRaul Guevara TorresPas encore d'évaluation

- Regulador de Modulo Dival 600Document8 pagesRegulador de Modulo Dival 600Cory HansonPas encore d'évaluation

- Differential Pressure Gauge Model 732.51, Stainless Steel Version, With Diaphragm Element All Welded ConstructionDocument4 pagesDifferential Pressure Gauge Model 732.51, Stainless Steel Version, With Diaphragm Element All Welded ConstructionClarence AG YuePas encore d'évaluation

- DS ACC Cooling Element en Us 17070Document4 pagesDS ACC Cooling Element en Us 17070behnamatgPas encore d'évaluation

- Amco CR4000Document4 pagesAmco CR4000Arwin TroconisPas encore d'évaluation

- PRH09 PDFDocument4 pagesPRH09 PDFengp3077Pas encore d'évaluation

- Reg RedQ Specialy Regulators PDFDocument20 pagesReg RedQ Specialy Regulators PDFDavid SaldarriagaPas encore d'évaluation

- Regulador American Meter PDFDocument6 pagesRegulador American Meter PDFjmcg1974Pas encore d'évaluation

- Api Plan 11Document6 pagesApi Plan 11johnsaballaPas encore d'évaluation

- Sor Adjustable Dead Band Pressure SwitchDocument16 pagesSor Adjustable Dead Band Pressure SwitchAdam SamyPas encore d'évaluation

- T101 Drilling MachineDocument4 pagesT101 Drilling MachineFranklin Avendaño ArapaPas encore d'évaluation

- T101 Drilling Machine BrochureDocument4 pagesT101 Drilling Machine BrochureRicardo OrtegaPas encore d'évaluation

- HYD. PumpDocument40 pagesHYD. Pumprohitbhat2345Pas encore d'évaluation

- Condensadora TTB TraneDocument24 pagesCondensadora TTB TraneRoberto Reyes Lara100% (1)

- Wellmark Section-5.1-W7702 (1) BPRDocument2 pagesWellmark Section-5.1-W7702 (1) BPRJoeset Wu100% (1)

- Dies Se ProductsDocument10 pagesDies Se ProductscastrojpPas encore d'évaluation

- Cameron Temperature Switches Technical Data SheetDocument28 pagesCameron Temperature Switches Technical Data Sheetvlcmstne04Pas encore d'évaluation

- How to prepare Welding Procedures for Oil & Gas PipelinesD'EverandHow to prepare Welding Procedures for Oil & Gas PipelinesÉvaluation : 5 sur 5 étoiles5/5 (1)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitD'EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitPas encore d'évaluation

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsD'EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsPas encore d'évaluation

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationD'EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationPas encore d'évaluation

- MCGB - Data Sheet For Suppliers Old MAT Nos.: 211, - , - : Heat-Treatable Steel, Low Alloy Steel, Cr-MoDocument3 pagesMCGB - Data Sheet For Suppliers Old MAT Nos.: 211, - , - : Heat-Treatable Steel, Low Alloy Steel, Cr-Mobaskaran ayyapparajPas encore d'évaluation

- IncinerationDocument50 pagesIncinerationinder4180100% (1)

- Gulf Fasteners & Metal Industries ProfileDocument4 pagesGulf Fasteners & Metal Industries ProfiledprosenjitPas encore d'évaluation

- GB 17107 Part4Document4 pagesGB 17107 Part4Imran IshakPas encore d'évaluation

- Fire and Gas Detection SpecificationDocument4 pagesFire and Gas Detection SpecificationAris KancilPas encore d'évaluation

- TSI Runflat Systems: Fitting Instructions and User GuideDocument6 pagesTSI Runflat Systems: Fitting Instructions and User Guideabdelrhmangbr86Pas encore d'évaluation

- 02 Generic - Types - Grade1Document34 pages02 Generic - Types - Grade1Aravind BabuPas encore d'évaluation

- 1998 Chevrolet Camaro & Pontiac Firebird Service Manual Volume 2Document545 pages1998 Chevrolet Camaro & Pontiac Firebird Service Manual Volume 2SeanPas encore d'évaluation

- Mohican Manual No.12Document273 pagesMohican Manual No.12carabeiropuebla67% (3)

- Paint Master Bonding Liquid - TDSDocument2 pagesPaint Master Bonding Liquid - TDSMichael JoudalPas encore d'évaluation

- BQ With PriceDocument26 pagesBQ With PriceLee Yuxuan100% (1)

- Ignition System VijayDocument19 pagesIgnition System VijayIshita SharmaPas encore d'évaluation

- Volumetric or Cubical Expansion Coefficients of LiquidsDocument1 pageVolumetric or Cubical Expansion Coefficients of LiquidsImmerPas encore d'évaluation

- ME 375 - Refrigeration & Building Mechanical Systems - BME0319 Manchar - Lecture 01Document12 pagesME 375 - Refrigeration & Building Mechanical Systems - BME0319 Manchar - Lecture 01Ahmed Zawad ShovonPas encore d'évaluation

- Addressing Some Issues in Drop Weight Testing - A Material Science ApproachDocument16 pagesAddressing Some Issues in Drop Weight Testing - A Material Science ApproachManish BhadauriaPas encore d'évaluation

- Sb70491atosh9 PDFDocument1 pageSb70491atosh9 PDFCarlosPas encore d'évaluation

- Chapter 1 Two-Phase Flow and Boiling Heat TransferDocument44 pagesChapter 1 Two-Phase Flow and Boiling Heat TransferjackleesjPas encore d'évaluation

- Measuring Thermal Mass of Sustainable Concrete Mixes: K0838912@kingston - Ac.ukDocument8 pagesMeasuring Thermal Mass of Sustainable Concrete Mixes: K0838912@kingston - Ac.ukMickey DalbeheraPas encore d'évaluation

- Anchor - Bolt 12 MKD' NO. 1642001ABD-0002: Grid LocationDocument1 pageAnchor - Bolt 12 MKD' NO. 1642001ABD-0002: Grid LocationGHULAM NABIPas encore d'évaluation

- HYROTEST Procedure Tank NSIDocument4 pagesHYROTEST Procedure Tank NSIluhur prandika100% (1)

- Fibre Reinforced Concrete PDFDocument6 pagesFibre Reinforced Concrete PDFAref AbadelPas encore d'évaluation

- Azkoyen Palma M Tech ManualDocument42 pagesAzkoyen Palma M Tech ManualrxPas encore d'évaluation

- Prashant Mishra ReportDocument27 pagesPrashant Mishra ReportPrashant MishraPas encore d'évaluation

- Metal DetectorDocument8 pagesMetal DetectorsamodraPas encore d'évaluation

- FMDS 03 10 - Installation & Maintenance of Fire Service MainsDocument59 pagesFMDS 03 10 - Installation & Maintenance of Fire Service MainsNazri Nawi100% (1)

- DIY Hot Air Soldering Iron 1 PDFDocument11 pagesDIY Hot Air Soldering Iron 1 PDFztmp1Pas encore d'évaluation

- Grouting Work and Jet-Grouting - ENDocument92 pagesGrouting Work and Jet-Grouting - ENLucki Yohan GunawanPas encore d'évaluation

- Air CompressorDocument48 pagesAir CompressorMarius Condurache0% (1)

- Hindalco Rolled - Products - Cold - Rolleds PDFDocument4 pagesHindalco Rolled - Products - Cold - Rolleds PDFamitkdewPas encore d'évaluation

- Chemical Spill Response GuideDocument7 pagesChemical Spill Response GuideDaniel BobbittPas encore d'évaluation