Académique Documents

Professionnel Documents

Culture Documents

Spring Support Erection

Transféré par

Sachin SuvarnaDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Spring Support Erection

Transféré par

Sachin SuvarnaDroits d'auteur :

Formats disponibles

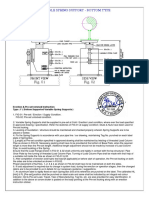

VARIABLE SPRING SUPPORT - BOTTOM TYPE

Fig. 01

Nut No. 4

Nut No. 3

Nut No. 1

Nut No. 2

Nut No. 1

Fig. 02

Nut No. 4

Nut No. 3

Nut No. 2

SIDE VIEW FRONT VIEW

STRUCTURE /

FOUNDATION

Erection & Pre-set removal Instruction

Type : F ( Bottom Supported Variable Spring Supports )

1. FIG-01: Pre-set / Erection / Supply Condition.

FIG-02: Pre-set unlocked condition.

2. Variable Spring Supports shall be supplied in pre-set at Cold / Erection Load condition, where ever the load specified

in approved drawing / specification. Refer the sketches of FIG-01 at supply condition; Studs & Nuts have been used for

Pre-set locking.

3. Leveling of foundation / structure should be maintained and checked properly wherein Spring Supports are to be

placed or bolted.

4. Fix the Spring Supports is accordance with your pipe line / our drawing, maintaining Tag No. punched on each label

plate of Spring Box.

L [Length] at Pre-set condition specified in approved drawing shall be maintained by twisting of threaded Load Column

Pipe as shown in FIG-02. Necessary packing shall have to be provided at the bottom of Base Plate, when the required

length is more than the Pre-set length. Additional length adjustment should not be made by increase of Load Column

Pipe, to avoid buckling of the Spring.

Ensure that the Load Flange shown in FIG-01 & 02 shall uniformly and rigidly in contact with the top structural / Pipe

Shoe Plate by fine turning of threaded Load Column Pipe. Turning of Load Column Pipe shall be made with that help of

a suitable rod inside the hole as shown in FIG-01 & 02.

5. After completion of erection and hydro test load [if applicable] or before start of operation, the Pre-set locking on both

the sides are to be unlocked as shown in FIG:02.

Proper placement of Nut Nos. 1, 2, 3 & 4 as shown in FIG-02 shall have to be maintained on both the sides.

6. If load adjustment is required due to change in system load, during the erection or operation stages, then the changed

data's are to be provided to us in details for our necessary guidance / suggestions.

7. An aluminum label is rigidly fixed on each Spring Box and all its reference are punched on the label. The calibrated HL

[Hot] & PL [Pre-set] position shall be punched on label scale and same shall be indicated by an integral red colour

indicator. Hot & Pre-set Load, Travel, Year of Manufacturing, Tag No. etc. are also provided for easy identification. In

addition to the above an arrow sticker is pasted on the body pointing at the Pre-set locking along with an erection

instruction sticker.

Vous aimerez peut-être aussi

- 454 GD & HS Fuel Pump Timing & CalibrationsDocument15 pages454 GD & HS Fuel Pump Timing & Calibrationsslipsittin75% (4)

- Alignment and Installation Procedure For UW EqptsDocument79 pagesAlignment and Installation Procedure For UW EqptsSanthosh Kumar100% (1)

- Mechanical Completion Check ListDocument6 pagesMechanical Completion Check Listmanish2089Pas encore d'évaluation

- NBT47065.1 5 2018容器支座Document245 pagesNBT47065.1 5 2018容器支座Kimi ShenPas encore d'évaluation

- Nozzle Orientation DrawingDocument40 pagesNozzle Orientation DrawingKavin Kumar100% (3)

- Erection & Pre-Set Removal InstructionDocument4 pagesErection & Pre-Set Removal InstructionUJJAL KUMAR BHATTACHARYAYPas encore d'évaluation

- Installation, Operation, & Maintenance Manual: Wall Mounted Articulating Jib CraneDocument12 pagesInstallation, Operation, & Maintenance Manual: Wall Mounted Articulating Jib CraneFernando Gonzales HPas encore d'évaluation

- Instructions For Installation Operation Maintenance of Helical Sootblower PS-SB-BDocument57 pagesInstructions For Installation Operation Maintenance of Helical Sootblower PS-SB-BEyuPas encore d'évaluation

- Catalogue Spring HangersDocument57 pagesCatalogue Spring HangersVeman ReddyPas encore d'évaluation

- Op 54Document5 pagesOp 54Rezicky ImamPas encore d'évaluation

- Erection Procedure Rev 0Document5 pagesErection Procedure Rev 0Arturo Suarez VillaoPas encore d'évaluation

- HCB DS-72KV TO 245KV (Manual)Document10 pagesHCB DS-72KV TO 245KV (Manual)Nixon Quispe SanchezPas encore d'évaluation

- Mody Leo Toro en r4Document28 pagesMody Leo Toro en r4SinaPas encore d'évaluation

- Standard Erection Manual (Pressure Parts)Document138 pagesStandard Erection Manual (Pressure Parts)rarundivya100% (1)

- KochDocument181 pagesKochRichard FelipPas encore d'évaluation

- Comments On Valve DrawingsDocument3 pagesComments On Valve DrawingsNaveen NagisettiPas encore d'évaluation

- Heater Erection Procedure PDFDocument7 pagesHeater Erection Procedure PDFhasan_676489616Pas encore d'évaluation

- Installation Manual - Constant Spring Supports - Rev 2Document17 pagesInstallation Manual - Constant Spring Supports - Rev 2Tonthat QuangPas encore d'évaluation

- Figure 1: Adding Fittings To The Inboard Main Gear Attach BracketsDocument1 pageFigure 1: Adding Fittings To The Inboard Main Gear Attach BracketsMark Evan SalutinPas encore d'évaluation

- 600 MOM ASME Discussion - Reply by DerekDocument3 pages600 MOM ASME Discussion - Reply by DerekarissaPas encore d'évaluation

- Channel Master 2-4m ManualDocument9 pagesChannel Master 2-4m ManualWilfredo AriasPas encore d'évaluation

- Inlet Line Replacement ProcedureDocument6 pagesInlet Line Replacement ProcedureM HamzaPas encore d'évaluation

- Mechanical CompletionDocument6 pagesMechanical CompletionYosses Sang NahkodaPas encore d'évaluation

- ESP Erection ManualDocument35 pagesESP Erection Manualneeraja100% (1)

- The U.S. M1911 M1911A1 Pistols and Commercial M1911 Type Pistols - A Shop Manual (PDFDrive) - Unlocked-6Document15 pagesThe U.S. M1911 M1911A1 Pistols and Commercial M1911 Type Pistols - A Shop Manual (PDFDrive) - Unlocked-6Violeta Sosa rosarioPas encore d'évaluation

- Specified Anchor Bolt Category Bolt Standards Nut StandardsDocument3 pagesSpecified Anchor Bolt Category Bolt Standards Nut StandardsrefaePas encore d'évaluation

- Technical Bulletin: CopierDocument22 pagesTechnical Bulletin: CopiernickypanzePas encore d'évaluation

- G MECHA (Panasonic)Document14 pagesG MECHA (Panasonic)phil_meePas encore d'évaluation

- BD0425A-57A1 - Bolt Up Procedure For Critical FlangesDocument22 pagesBD0425A-57A1 - Bolt Up Procedure For Critical Flangesvpkaranam1100% (1)

- Procedure QualificationDocument68 pagesProcedure QualificationParvee K Nakwal100% (1)

- PUSNES Deck Machinery Installation ProcedureDocument18 pagesPUSNES Deck Machinery Installation ProcedurexatzaraPas encore d'évaluation

- Method Statement For Anchor Bolt FiixingDocument5 pagesMethod Statement For Anchor Bolt Fiixingsunparamar50% (2)

- Collar Bolts in Shell and Tube Heat ExchangersDocument3 pagesCollar Bolts in Shell and Tube Heat ExchangersBaher ElsheikhPas encore d'évaluation

- QC Installation GuideDocument25 pagesQC Installation GuideSinan AslanPas encore d'évaluation

- INS-P-034, Surface AlignmentDocument10 pagesINS-P-034, Surface AlignmentDeepakPas encore d'évaluation

- Technical Bulletin: Tion 129.00, and Aft and Down To The Fuel Vent Line Hole at Station 131.00Document17 pagesTechnical Bulletin: Tion 129.00, and Aft and Down To The Fuel Vent Line Hole at Station 131.00sebastian cruzPas encore d'évaluation

- Constant Spring Units: Carpenter & Paterson LTDDocument9 pagesConstant Spring Units: Carpenter & Paterson LTDhcsharma1967Pas encore d'évaluation

- Modern Blanking and Piercing DiesDocument58 pagesModern Blanking and Piercing DiesMustafa Sert100% (4)

- Alert Service Bulletin 429-13-08 PSL 7000000041: BHT-429-MM Chapters 5 53Document12 pagesAlert Service Bulletin 429-13-08 PSL 7000000041: BHT-429-MM Chapters 5 53Samir PeraltaPas encore d'évaluation

- Clarification For Auto Coal Sampling System) Dated 11.02.19Document1 pageClarification For Auto Coal Sampling System) Dated 11.02.19SHIBSANKAR MAHAPATRAPas encore d'évaluation

- MS of Segment Casting - 12345Document7 pagesMS of Segment Casting - 12345Anup SrivastavaPas encore d'évaluation

- Crankshaft AlignmentDocument4 pagesCrankshaft AlignmentPPG Construction CorporationPas encore d'évaluation

- WK Operating InstructionsDocument39 pagesWK Operating InstructionsR PrasadPas encore d'évaluation

- Connecting SphereDocument2 pagesConnecting SphereRamalingam PrabhakaranPas encore d'évaluation

- Comments On Fabrication DetailsDocument1 pageComments On Fabrication DetailskaarthikeyanPas encore d'évaluation

- Fouress Valve DrawingsDocument3 pagesFouress Valve DrawingsNaveen NagisettiPas encore d'évaluation

- MEGA Operating InstructionsDocument14 pagesMEGA Operating InstructionsSumit SinghaPas encore d'évaluation

- Example Method Statement Jack in-PPCDocument4 pagesExample Method Statement Jack in-PPCLatifi AmirPas encore d'évaluation

- ABB Texlim Edition 1Document30 pagesABB Texlim Edition 1Pardeep SindhuPas encore d'évaluation

- Breaker Piping InstallationDocument11 pagesBreaker Piping InstallationZawminhtunPas encore d'évaluation

- Spare Parts, Instruction and Maintenance Manual For Spanco Model 301 Jib CranesDocument20 pagesSpare Parts, Instruction and Maintenance Manual For Spanco Model 301 Jib Cranesabhi arotePas encore d'évaluation

- Tank Erection ProcedureDocument13 pagesTank Erection ProcedureAshokkumar ThangarajPas encore d'évaluation

- Documents - MX Pragati BTP Turret Manual - PDFDocument31 pagesDocuments - MX Pragati BTP Turret Manual - PDFPetar Petrovic100% (3)

- Alignment For A Reciprocating CompressorDocument2 pagesAlignment For A Reciprocating CompressorMVSEETARAMANPas encore d'évaluation

- C-2152 Modification Procedure: 1. Removing Transfer Belt UnitDocument4 pagesC-2152 Modification Procedure: 1. Removing Transfer Belt UnitbripservPas encore d'évaluation

- Wing Valve Orientation VariationDocument61 pagesWing Valve Orientation VariationMurugan VellaichamyPas encore d'évaluation

- Wing Valve Orientation VariationDocument61 pagesWing Valve Orientation VariationMurugan VellaichamyPas encore d'évaluation

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceD'EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenancePas encore d'évaluation

- Acetone ProductionDocument8 pagesAcetone ProductionZahraa GhanemPas encore d'évaluation

- ) 1D Consolidation Analysis and Design - SoilWorksDocument59 pages) 1D Consolidation Analysis and Design - SoilWorksDeepthiPas encore d'évaluation

- AC Servo Spindle System (V2.5) - UDocument79 pagesAC Servo Spindle System (V2.5) - UDmytroKrPas encore d'évaluation

- Astm D2573 D2573M 18Document4 pagesAstm D2573 D2573M 18deptrailaikieuPas encore d'évaluation

- Anti Graffiti BrochureDocument2 pagesAnti Graffiti BrochurecaronieblesPas encore d'évaluation

- Chapter 17 Electromagnetic Induction Notes Answers PDFDocument2 pagesChapter 17 Electromagnetic Induction Notes Answers PDFabdul halimPas encore d'évaluation

- ME 388 Assignment - NTMDocument3 pagesME 388 Assignment - NTMGanesh ChelluboyinaPas encore d'évaluation

- Experimental Investigations of Buckling Behaviour of Steel ScaffoldsDocument30 pagesExperimental Investigations of Buckling Behaviour of Steel ScaffoldsMarah Husin Fadli LubisPas encore d'évaluation

- LsppscriptingDocument30 pagesLsppscriptingimechanicaPas encore d'évaluation

- 40C Lab 3 Capacitors8Document8 pages40C Lab 3 Capacitors8Desiree Mae IbonPas encore d'évaluation

- Cired 2019 - 1606Document5 pagesCired 2019 - 1606romany allamPas encore d'évaluation

- An Elementary Proof For Fermat's Last Theorem Using An Euler's EquationDocument9 pagesAn Elementary Proof For Fermat's Last Theorem Using An Euler's EquationGagan DeepPas encore d'évaluation

- Underground Wiring InstallationDocument6 pagesUnderground Wiring InstallationCarbelyn BartePas encore d'évaluation

- 049-Itp For Lighting and Small Power (Building) PDFDocument15 pages049-Itp For Lighting and Small Power (Building) PDFKöksal Patan100% (1)

- 4c Lab3 Heat EnginesDocument4 pages4c Lab3 Heat EnginesAiza AliPas encore d'évaluation

- Yeast 4Document2 pagesYeast 4tanzeemPas encore d'évaluation

- Calculation Method of Permanent-Magnet Pickups For Electric GuitarsDocument6 pagesCalculation Method of Permanent-Magnet Pickups For Electric GuitarsangelaPas encore d'évaluation

- 2006 01 0884Document38 pages2006 01 0884Yosra RamadhanPas encore d'évaluation

- Micropreparation of RuH2 (P (C6H5) 3) 4: A Transition Metal Hydride CompoundDocument17 pagesMicropreparation of RuH2 (P (C6H5) 3) 4: A Transition Metal Hydride CompoundramlihitamPas encore d'évaluation

- RRB Junior Engineer Civil Solved Model Question Paper 5 PDFDocument18 pagesRRB Junior Engineer Civil Solved Model Question Paper 5 PDFankit0076Pas encore d'évaluation

- MIT6 003F11 hw04 PDFDocument14 pagesMIT6 003F11 hw04 PDFSudheer KumarPas encore d'évaluation

- Steel Beam DesignDocument4 pagesSteel Beam DesignasiawiPas encore d'évaluation

- AUC SheetDocument26 pagesAUC SheetTanmay SagarPas encore d'évaluation

- Adaptive Control PDFDocument2 pagesAdaptive Control PDFArjun PrasadPas encore d'évaluation

- Solar System JeopardyDocument52 pagesSolar System JeopardyKayla RhodesPas encore d'évaluation

- ME 534 - 02 Modeling I (Rev. 1.5)Document13 pagesME 534 - 02 Modeling I (Rev. 1.5)Michael PalmerPas encore d'évaluation

- Maths MethodsDocument6 pagesMaths MethodsTarek FoudaPas encore d'évaluation

- Chapter 10 - Cooling TowerDocument24 pagesChapter 10 - Cooling TowerAsyraf Sabri100% (1)

- Design Guideline For Hydraulic Fluid CleanlinessDocument24 pagesDesign Guideline For Hydraulic Fluid CleanlinessCarlosPas encore d'évaluation

- JEST-Volume 16-Issue 4 - Page 36-44Document9 pagesJEST-Volume 16-Issue 4 - Page 36-44Abi NikilPas encore d'évaluation