Académique Documents

Professionnel Documents

Culture Documents

Acoustic Enclosure

Transféré par

mpwasaCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Acoustic Enclosure

Transféré par

mpwasaDroits d'auteur :

Formats disponibles

ARABIAN THERMAL AIRE INDUSTRIES CO. LTD.

MANUFACTURE OF AIR DISTRIBUTION SYSTEMS

PRODUCT GUIDE Acoustic Enclosure Leveraging Projects

ACOUSTIC ENCLOSURES BY ATAI

ACOUSTIC ENCLOSURES

Arabian Thermal Aire Industries Co. Ltd., is located in the Industrial City of Jubail. Eastern Province of the Kingdom of Saudi Arabia. ATAI, is a leading manufacturer of Air / Management, Distribution & Noise Control System. In Business since 1982, ATAI has come along way in establishing itself as an highly professional company with state of the art manufacturing equipment and communication network throughout its business units.

I A T

Supported by cutting edge technology and a team of professional and experienced engineers, it provides not only quality products but delivers sound engineering solutions to its customers. ATAI prides itself in engineering customized products to suit individual project requirements by working closely with clients. ATAI is an ISO 9000 company, a member of SMACNA and AMCA, the Air Movement and Control Association and the only UL listed damper manufacturer in the Middle East. In its quest for continuous technical advancement and the desire to expand business opportunities, ATAI has technical collaboration for manufacturing and consultancy with industry brand names who are market leaders in their respective business. ATAI manufactures UL classified Fire dampers under license from Ruskin of U.S.A. Vibration Control systems under license from Kinetics, Sound Attenuators, Acoustic doors and Enclosures etc. under license from S.A.L. (Sound Attenuators Ltd., U.K. a member of SALEX group). ATAI also has technical collaboration with Sound Research Laboratories, S.R.L. for Acoustic analysis and study.

PAGE 13.1

ATAI

ACOUSTIC ENCLOSURES BY ATAI

The factory has a licensed capacity of 5500 tons for the manufacturing of Air Distribution and Noise control systems every year. ATAI has proven its expertise in acoustics and manufacturers a range of Sound Attenuators and Acoustic enclosures, Acoustic doors Louvres etc. The selection and design is carried out through a patented computer program which has been validated through actual test carried out at S.R.L (Sound Research Laboratories) in U.K.

A view of Workshop

ACOUSTIC ENCLOSURES

ATAI has carried out acoustical study for projects in Collaboration with Sound Research Laboratories of U.K. who have over 30 years of experience in Noise and Vibration design and control in industry. They are specialists in the field of Acoustic analysis, Surveys and Noise control studies for the Petrochemical, Offshore drilling, Building services and Hospitality industries. In spite of the recession in the construction industry and highly competitive market, ATAI has been successful in posting net profits over the years. This is mainly due to the consistent emphasis on quality of the product and a high customer focus. Customer satisfaction is the primary objective of every employee in the organization. The company exports to most of the GCC countries having a sales office in U.A.E. and representation in Oman, Qatar, Bahrain and Jordan. ATAI manufactures acoustic enclosures for Generator sets and Turbines completely designed and fabricated in house, custom built to satisfy site and specific requirements. These enclosures for turbines have been supplied to Kongsberg Dresser Rand for their Piece Shield Project in the Kingdom. ATAI is currently supplying acoustic enclosures for Generator sets to MEPCO, a G.E. company for SCECO projects.

PAGE 13.2

ATAI

GENERAL MATERIAL SPECIFICATION

The acoustic enclosure system generally comprises of the following items (i) Enclosures casing (ii) Silencers (iii) Louvres Others to suit special requirements

ACOUSTIC ENCLOSURES

(i) ENCLOSURE CASING CONSTRUCTION:

As per the standard construction, the framework will be fabricated using 2mm thick (14gsg) galvanized steel sheet and the acoustic panels are fabricated with 1.6mm (16gsg) galvanized steel sheet. The acoustic infill material is held in place within the panels behind 0.7 mm (24gsg) galvanized perforated sheet steel. The infill material is fiberglass and is inert, rot proof, non hygroscopic and does not support bacteriological growth. This has a class 1 rating for surface spread of flame in accordance with BS 476.

TYPICAL SECTION OF FIXED WALL TYPE

PAGE 13.3

TYPICAL SECTION REMOVABLE TYPE PANELS OR WALL

ATAI

(ii) SILENCERS CONSTRUCTION:

The silencers are the S.A.L. ATAI type RASD for differential pressures up to 1000 N/sq.m. These are constructed with galvanized sheet steel casing with mastic filled Pittsburgh longitudinal joints, and manufactured in the following gages: 0.9 mm for casing with longest side up to 1000 mm 1.2 mm for casings with longest side between 1001/3000 mm. The silencers are the S.A.L. ATAI type RASD for differential pressures up to 1000 N/sq.m. These are constructed with galvanized sheet steel casing with mastic filled Pittsburgh longitudinal joints.

ACOUSTIC ENCLOSURES

The material is galvanized steel to ASTM A 653 LFQ, G90 (Z275) coating. Flanges are ATAI type unless otherwise stated. Arranged within the casing would be attenuating splitter sections of 0.9 mm galvanized steel, fixed to the casing with self tapping screws or rivets 0.7 mm galvanized perforated or expanded metal is used as a protection over the acoustic media.

Attenuators would have aerodynamically shaped bull nose facing the front of the splitters. This type of construction has been tested in accordance with HVAC specification DW142 and at a pressure of 1000N/sq.m with a leakage class C. Acoustic infill fiberglass material bonded with a woven fiber mesh facing of 32 Kg/cu.m density is used. The material is inert, nonhygroscopic, vermin and rot proof and does not support bacteriological growth. This has a class 1 rating for surface spread of flame and has a zero fiber migration property.

Sound Attenuators incorporated in the acoustic enclosure

PAGE 13.4

ATAI

(iii) CONSTRUCTION OF LOUVRE

Steel Louvers:

The outer casing is constructed from 1.6 mm galvanized steel sheet. The blades are fabricated from 1.2mm galvanized steel. Blades are set at 45 degree with 100 mm pitch. The design and size varies depending on site requirements.

Bird screen 12 mm is installed on the rear of the louvre. Mounting is as picture frame which is fitted to the front of the louvre. Finish: As per customer requirement, generally epoxy enamel coated. Powder coating is also possible.

ACOUSTIC ENCLOSURES

Enclosure fitted with acoustic louvers and sound attenuators

(iv) SPECIAL REQUIRMENTS

Enclosures can be fitted out with special requirements. Some of the innovations we have included are an internal overhead crane, inspection windows, internal lighting, motorized air inlet/outlet dampers and fire fighting system. PAGE 13.5

ATAI

ATAI RANGE OF ENCLOSURES

ATAI Manufacturers 3 types of Enclosures: (i) ATAI Drop overy Canopy Type (ii) ATAI Containerised Enclosures (iii) Custom Built Enclosures

ACOUSTIC ENCLOSURES

Isometric view of enclosure

KEY FEATURES

High level acoustic performances Total design flexibility shape, overall dimensions, doors, windows, services access Modular construction, quick easy assembly and demount ability Robustness and enhanced durability Weather-proof option for external applications High quality external finish Interior finish option to architectural standard Total package option with ventilation, lighting, power supply, etc. Rapid GA drawing service Optimum performance: economical cost

PAGE 13.6

ATAI

ATAI CANOPY TYPE ENCLOSURE

The system is framed modular, it can also be preassembled to minimized the number of components parts. A canopy can be built merely with the four walls and the roof that is then simply bolted together on site, thereby saving valuable site occupancy time. The canopy is constructed from a panel system. The basic construction consists of 4 walls and roof, each system will incorporate lifting lugs. The roof will be supplied in two or four sub assemblies depending on the size and requirement for the ease of installation, and also in case of requiring access to the engine. It can be easily removable either individually or collectively. In each long wall, one single leaf access door is supplied. Door furniture consists of 2 point latch with panic override. Hinges will be chrome plated. These can also be supplied based on customers specific requirements. Pipe penetration will be acoustically sealed and will be designed based on actual requirements. The complete canopy will be trial assembled in ATAI works prior to dispatch. This will allow for customer inspection and approval.

PAGE 13.7

ACOUSTIC ENCLOSURES

ATAI

Units may be completely pre assembled and ready for installation as a one piece, drop over type of enclosure. This type of unit speeds the packaging time or installation time of a typical generator set. An enclosure ordered pre assembled from ATAI will arrive ready for immediate installation and operation.

ACOUSTIC ENCLOSURES

The above is the exploded view of a kit styles enclosure. This type of unit ships in knockdown form for erection in the facility or in the field. Every knock down type of enclosure is supplied with all the components our factory uses in supplying pre-assembled units. In addition to supplying all the components required to assemble kit style enclosure, complete and detailed erection drawings, assembly instructions and bill of materials are also supplied. A kit style enclosure can be shipped as quickly as two weeks from the date the order is received.

PAGE 13.8

A simple drop over type enclosre

ATAI

ATAI CONTAINERIZED ENCLOSURES

ATAI manufacturers acoustical containers both 20 and 40 to have generating sets in single and dual engine configuration. Containers can be fitted out to have air intake/outlet dampers, fuel tanks, control panels and fire detection and suppression systems. Containers may be designed to suit ambient temp. of 10 to 15 degree centigrade and where metal surface temperature may reach 75 degrees centigrade. Humidity conditions up to 100%. Intakes may be protected with appropriate sand trap louvers. Containers are generally designed to limit noise level outside the containers to a limit of 55 dB(A) measured 3m from the walls.

PAGE 13.9

ACOUSTIC ENCLOSURES

ATAI

CUSTOM BUILT ENCLOSURES

The enclosure system currently being manufactured for Middle East Power Co. (G.E.) comprises an all welded section framework with acoustic panels held permanently in place within the framework. The framework is fabricated using 5mm thick U channel and corners while the base is supported by 8mm thick I beams. The acoustic panels comprise a double skin 1.6 mm (16 gauge) low carbon steel sheet filled with acoustic in fill held in place within the acoustic panel by perforated sheet steel. The acoustic in fill is inert, rot proof, non hygroscopic and has a class 1 rating for surface spread of flame in accordance with BS 476. The roof is supplied in 2 sections for ease of installation, and also in the case of access to the internal components. Individual sections can be easily removed. The roof sections slope to prevent rainwater accumulation. The enclosure has been provided with a movable overhead crane of 1 ton capacity to lift and move internal equipment. The enclosure has stationary acoustic louver designed to prevent noise breakout and an inspection window, for viewing gas module controls. The complete assembly is epoxy finished painted.

ACOUSTIC ENCLOSURES

Gas Module Acoustic Enclosures manufactured for General Electric

ACOUSTIC CONSIDERATIONS:

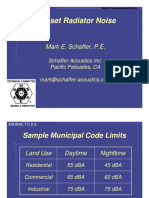

ATAI will guarantee that the acoustic enclosure will ensure that the noise level will not exceed 75 dB(A) at 1.0 m from the wall surfaces and at a height of 1.5 m above ground level. This is based on the engine sound pressure level not exceeding the following.

PAGE 13.10

HZ Lp@1.0m dB

63 125 250 500 1K 99 101 97 95 98

2K 98

4K 94

8K 88

ATAI

Vous aimerez peut-être aussi

- Sound Attenuators LeafletDocument7 pagesSound Attenuators LeafletSundar Ramasamy0% (1)

- Sound Attenuators LeafletDocument7 pagesSound Attenuators LeafletBalanSelvamPas encore d'évaluation

- Silencer PRINTDocument2 pagesSilencer PRINTChandima WijesekeraPas encore d'évaluation

- Sheet Steel Facts 16Document4 pagesSheet Steel Facts 16Giordano VieiraPas encore d'évaluation

- Louvres Bro enDocument84 pagesLouvres Bro entagiriPas encore d'évaluation

- HSE-Acoustic & Fire DoorsDocument6 pagesHSE-Acoustic & Fire DoorsInterior ProjectsPas encore d'évaluation

- C008 - Quiet Revolution Noise Statement 20100803v1Document15 pagesC008 - Quiet Revolution Noise Statement 20100803v1Roland PetersPas encore d'évaluation

- Request 15 NoiseDocument28 pagesRequest 15 NoiseHannibal1969Pas encore d'évaluation

- Updated Silencers Bro PDFDocument20 pagesUpdated Silencers Bro PDFdimchienPas encore d'évaluation

- 1 ISTIQ Acoustic DoorDocument6 pages1 ISTIQ Acoustic DoorjaladimudaPas encore d'évaluation

- Tetra Tech Sound Vibration Analysis 201704Document86 pagesTetra Tech Sound Vibration Analysis 201704OpgcPas encore d'évaluation

- Acoustic EnclosuresDocument4 pagesAcoustic EnclosuresushakunaPas encore d'évaluation

- Genset Noise Outdoor Environment Sound SilencerDocument18 pagesGenset Noise Outdoor Environment Sound SilencerTrần Quang ToánPas encore d'évaluation

- Soundproofing Solutions-En 2019 02 PDFDocument182 pagesSoundproofing Solutions-En 2019 02 PDFTanase MariusPas encore d'évaluation

- Insulation Material Sound PDFDocument15 pagesInsulation Material Sound PDFKirti gargPas encore d'évaluation

- Acoustic GuideDocument17 pagesAcoustic GuideMohamad ShabeerPas encore d'évaluation

- Kenneth Kaliski Slides 6.7.11Document21 pagesKenneth Kaliski Slides 6.7.11Northeast Wind Resource Center (NWRC)Pas encore d'évaluation

- White Book C04 Partitions Section 3Document180 pagesWhite Book C04 Partitions Section 3Chris FindlayPas encore d'évaluation

- Acoustic CatalogDocument12 pagesAcoustic CatalogrohizatPas encore d'évaluation

- Acoustical Considerations For Hotels and Hostels As Per NBCDocument10 pagesAcoustical Considerations For Hotels and Hostels As Per NBCashPas encore d'évaluation

- HVAC Noise and Vibration Control SummaryDocument37 pagesHVAC Noise and Vibration Control SummaryYel DG100% (1)

- Noise and Vibration Control For Hvac Piping and EquipmentDocument15 pagesNoise and Vibration Control For Hvac Piping and EquipmentarjantinPas encore d'évaluation

- BD Systems Brochure 2016 05Document164 pagesBD Systems Brochure 2016 05Rajat KatyalPas encore d'évaluation

- Entran: Noise AssessmentDocument28 pagesEntran: Noise AssessmentNaken FittaPas encore d'évaluation

- Acoustics GuidelinesDocument20 pagesAcoustics Guidelinesrommel duran100% (1)

- Transformers Are Never SilentDocument4 pagesTransformers Are Never SilentEngr. AbdullahPas encore d'évaluation

- Crosstalk Attenuators Reduce Duct Noise TransmissionDocument2 pagesCrosstalk Attenuators Reduce Duct Noise TransmissionabdulzameerPas encore d'évaluation

- Aqua Silencer Report 2Document25 pagesAqua Silencer Report 2avikashPas encore d'évaluation

- Top 10 Noise Control Solutions 2015 EmailDocument12 pagesTop 10 Noise Control Solutions 2015 EmailRodrigo MottaPas encore d'évaluation

- Acoustic Performance Goals for Doha Oasis Theme ParkDocument43 pagesAcoustic Performance Goals for Doha Oasis Theme Parkabdullah amanullahPas encore d'évaluation

- MEC 115 Noise Vibration&ControlDocument150 pagesMEC 115 Noise Vibration&ControlMauricePas encore d'évaluation

- AcousticInsulation enDocument97 pagesAcousticInsulation enBernardo ArevalilloPas encore d'évaluation

- HVAC SYSTEM DESIGNDocument19 pagesHVAC SYSTEM DESIGNmostafa HusseinPas encore d'évaluation

- Performance of sealed curtain wall spandrel panels that direct sunlight deep into buildingsDocument21 pagesPerformance of sealed curtain wall spandrel panels that direct sunlight deep into buildingstroyel99Pas encore d'évaluation

- ATSL Brochure (201310)Document30 pagesATSL Brochure (201310)dgtdejanPas encore d'évaluation

- Passive Noise Control in BuildingsDocument12 pagesPassive Noise Control in BuildingsANJUSREE B.S. MBT18CE025Pas encore d'évaluation

- Effect of Altitude On Audible Noise Generated by AC Conductor CoronaDocument68 pagesEffect of Altitude On Audible Noise Generated by AC Conductor CoronaAhsan MahmoodPas encore d'évaluation

- As 1277-1983 Acoustics - Measurement Procedures For Ducted SilencersDocument8 pagesAs 1277-1983 Acoustics - Measurement Procedures For Ducted SilencersSAI Global - APACPas encore d'évaluation

- Architectural Acoustics SolutionsDocument56 pagesArchitectural Acoustics Solutionsshyma_97Pas encore d'évaluation

- Product Specification: Leminar Air-Conditioning Industries LLCDocument8 pagesProduct Specification: Leminar Air-Conditioning Industries LLCMaher Al LobnanyPas encore d'évaluation

- Cooling Tower Noise Control Silencers Reduce SoundDocument37 pagesCooling Tower Noise Control Silencers Reduce SoundUllas EK100% (1)

- Rectangular Duct AtteDocument4 pagesRectangular Duct AtteShahrukh AnsariPas encore d'évaluation

- Smoke Fans CatalogueDocument54 pagesSmoke Fans CataloguejayanthahhyPas encore d'évaluation

- Classroom Acoustics Report Printed VersionDocument44 pagesClassroom Acoustics Report Printed Versionnr2006Pas encore d'évaluation

- Price Noise Control OverviewDocument62 pagesPrice Noise Control OverviewJulián PassardiPas encore d'évaluation

- Noise Reduction in Centrifugal Fans: A Literature SurveyDocument29 pagesNoise Reduction in Centrifugal Fans: A Literature SurveyPooria1989Pas encore d'évaluation

- Muffler Design For Automotive Exhaust Noise Attenuation - A ReviewDocument4 pagesMuffler Design For Automotive Exhaust Noise Attenuation - A ReviewStylishrockerPradeepPas encore d'évaluation

- Building Acoustics TerminologyDocument10 pagesBuilding Acoustics TerminologyanhnguyenhaiPas encore d'évaluation

- Effectiveness of en 12354-6Document6 pagesEffectiveness of en 12354-6Neeskens D'melloPas encore d'évaluation

- Sound Absorbing Materials: Types, Mechanisms and ApplicationsDocument26 pagesSound Absorbing Materials: Types, Mechanisms and Applicationsfranobeljo27Pas encore d'évaluation

- Noise Control GuidelinesDocument11 pagesNoise Control GuidelinesRique BenitesPas encore d'évaluation

- Transmission Losses in Reactive MufflerDocument6 pagesTransmission Losses in Reactive MufflerVignesh PadmanabhanPas encore d'évaluation

- Interior Architecture Building Science 142 ASCIE 1202: Room AcousticsDocument18 pagesInterior Architecture Building Science 142 ASCIE 1202: Room AcousticsMuhamad Helmi Hairi ZulkifliPas encore d'évaluation

- Stretch Ceiling SystemsDocument16 pagesStretch Ceiling SystemsDan CristeaPas encore d'évaluation

- Engineering Acoustics Lecture 11Document27 pagesEngineering Acoustics Lecture 11Isuru Kasthurirathne100% (1)

- Control of Reverberation Times in Dome1Document4 pagesControl of Reverberation Times in Dome1haiobPas encore d'évaluation

- Air Master SilencersDocument17 pagesAir Master SilencersZainul Abedin SayedPas encore d'évaluation

- 08 11 16cliDocument7 pages08 11 16clibrian walter abarintosPas encore d'évaluation

- Company ProfileDocument28 pagesCompany ProfileAnil Kumar SinghPas encore d'évaluation

- 1400/1400W/1455 Wall GuardsDocument2 pages1400/1400W/1455 Wall GuardsGerman Ramirez TovarPas encore d'évaluation

- ANSI - AHRI Standard 1061 (SI) - 2011Document12 pagesANSI - AHRI Standard 1061 (SI) - 2011mpwasaPas encore d'évaluation

- Ansi - Ahri 850 2004Document12 pagesAnsi - Ahri 850 2004mpwasaPas encore d'évaluation

- Smoking System DesignDocument1 pageSmoking System DesignmpwasaPas encore d'évaluation

- Smoking RoomsDocument4 pagesSmoking RoomsmpwasaPas encore d'évaluation

- Section 1:: DampersDocument8 pagesSection 1:: DampersmpwasaPas encore d'évaluation

- Pipes-Technical Data CatalougsDocument16 pagesPipes-Technical Data CatalougsmpwasaPas encore d'évaluation

- Reference Calculation Output: Flow L/s GPM L/s GPM FlowDocument8 pagesReference Calculation Output: Flow L/s GPM L/s GPM Flowmpwasa100% (1)

- VAV TypesDocument39 pagesVAV TypesmpwasaPas encore d'évaluation

- ASHRAE Journal - VAV Box Duct Design - TaylorDocument8 pagesASHRAE Journal - VAV Box Duct Design - TaylorsajuherePas encore d'évaluation

- Smoking System DesignDocument1 pageSmoking System DesignmpwasaPas encore d'évaluation

- Smoking Room Design 3Document1 pageSmoking Room Design 3mpwasaPas encore d'évaluation

- SAAF Technote Tobacco Smoke GPF 8 103B NewDocument2 pagesSAAF Technote Tobacco Smoke GPF 8 103B NewmpwasaPas encore d'évaluation

- Pressure Tank Sizing WasaDocument5 pagesPressure Tank Sizing WasampwasaPas encore d'évaluation

- Tech Notes 1Document3 pagesTech Notes 1mpwasaPas encore d'évaluation

- Air Balancing Method StatementDocument1 pageAir Balancing Method StatementmpwasaPas encore d'évaluation

- Air Balancing Method StatementDocument1 pageAir Balancing Method StatementmpwasaPas encore d'évaluation

- Linear Bar GrillesDocument7 pagesLinear Bar GrillesmpwasaPas encore d'évaluation

- Valves & FittingsDocument56 pagesValves & FittingsmpwasaPas encore d'évaluation

- Egg Crate Grills SampleDocument3 pagesEgg Crate Grills SamplempwasaPas encore d'évaluation

- Central Medical Gas Systems 24506901708Document9 pagesCentral Medical Gas Systems 24506901708PrestoneKPas encore d'évaluation

- Kitchen Extractors: CK Series Metallic RangeDocument3 pagesKitchen Extractors: CK Series Metallic RangempwasaPas encore d'évaluation

- BUILDING SCHEDULE RATESDocument7 pagesBUILDING SCHEDULE RATESisharaPas encore d'évaluation

- Basic Principles For Sizing Grease InterceptorsDocument5 pagesBasic Principles For Sizing Grease InterceptorsAwais JalaliPas encore d'évaluation

- Diffuser Cd300 & 200Document5 pagesDiffuser Cd300 & 200mpwasaPas encore d'évaluation

- VFDDocument260 pagesVFDluqmanblue100% (1)

- Kitchen Exhaust Air Cleaning SystemDocument20 pagesKitchen Exhaust Air Cleaning SystemmpwasaPas encore d'évaluation

- MEP Planning ManualDocument196 pagesMEP Planning Manualantonyscorpio95% (21)

- VFDs Can Control Multiple MotorsDocument8 pagesVFDs Can Control Multiple MotorsmpwasaPas encore d'évaluation

- DuctHeaters Catalog PDFDocument8 pagesDuctHeaters Catalog PDFmpwasaPas encore d'évaluation

- Duct Heaters PDFDocument32 pagesDuct Heaters PDFmpwasaPas encore d'évaluation

- Euskron Profile ENGDocument14 pagesEuskron Profile ENGEuskron Cutting ToolsPas encore d'évaluation

- Equipment Initial Production Control SystemDocument1 pageEquipment Initial Production Control Systemsrmohapatra5086Pas encore d'évaluation

- The Envelopes of The Arts Centre in SingaporeDocument12 pagesThe Envelopes of The Arts Centre in SingaporeAndriPas encore d'évaluation

- 07P Operating Manual Vc999Document74 pages07P Operating Manual Vc999yeraslash100% (4)

- Siebel Field ServiceDocument4 pagesSiebel Field ServicesubbaraocrmPas encore d'évaluation

- Tugas Enterprise Resource Planning: Kelas ADocument4 pagesTugas Enterprise Resource Planning: Kelas ARizka HadiwiyantiPas encore d'évaluation

- Multi-Entity Work Process Dor: Attachment B (Sample)Document2 pagesMulti-Entity Work Process Dor: Attachment B (Sample)Gordon LongforganPas encore d'évaluation

- Abhishek Kumar SinghDocument3 pagesAbhishek Kumar SinghAshutosh UpadhyayPas encore d'évaluation

- Configure MSS (WDA) Settings in SAP NetWeaver BCDocument6 pagesConfigure MSS (WDA) Settings in SAP NetWeaver BCThandile FikeniPas encore d'évaluation

- Wilson Sporting Goods V Rawlings Sporting GoodsDocument38 pagesWilson Sporting Goods V Rawlings Sporting GoodsDarren Adam HeitnerPas encore d'évaluation

- Inventor ReportDocument7 pagesInventor Report2cekal50% (2)

- Sanitary Napkin Vending MachineDocument11 pagesSanitary Napkin Vending Machineshobanraj1995Pas encore d'évaluation

- Configuration of FSCM Dispute ManagementDocument36 pagesConfiguration of FSCM Dispute Managementsapfico2k875% (4)

- Unit 8. English Daily Test For Grade 5Document3 pagesUnit 8. English Daily Test For Grade 5NINGSIHPas encore d'évaluation

- CAT992Document24 pagesCAT992Miriam Ruiz Cabellos100% (1)

- CH 02Document39 pagesCH 02enamislamPas encore d'évaluation

- A Burners PDFDocument37 pagesA Burners PDFaldoking202028Pas encore d'évaluation

- Problem Set Ee8205 PDFDocument4 pagesProblem Set Ee8205 PDFksajjPas encore d'évaluation

- My Updated CVDocument5 pagesMy Updated CVSaleem UddinPas encore d'évaluation

- bb9df927-5af1-44e0-ae49-d3fd10a5eb4b (1)Document6 pagesbb9df927-5af1-44e0-ae49-d3fd10a5eb4b (1)anonymphantomPas encore d'évaluation

- Fidic Quality Based Consultant Selection GuideDocument20 pagesFidic Quality Based Consultant Selection GuideJuan McdanielPas encore d'évaluation

- AD 302: Tightening of Ordinary Bolts: Sci Advisory DeskDocument2 pagesAD 302: Tightening of Ordinary Bolts: Sci Advisory DeskLightninWolf32Pas encore d'évaluation

- Cat35xt002 - Xtro Primitives IIDocument34 pagesCat35xt002 - Xtro Primitives IIKari Wilfong100% (4)

- Family Entertainment CentersDocument4 pagesFamily Entertainment CentersAnusha PalakurthyPas encore d'évaluation

- Forged Gate, Globe and Check Valves CatalogDocument80 pagesForged Gate, Globe and Check Valves CatalogSulist N WahyudiePas encore d'évaluation

- Turbomachinery For Ammonia Plants: Man TurboDocument20 pagesTurbomachinery For Ammonia Plants: Man TurboavwnashPas encore d'évaluation

- Cylinders FullDocument110 pagesCylinders FulltnvishPas encore d'évaluation

- Actual4Test: Actual4test - Actual Test Exam Dumps-Pass For IT ExamsDocument4 pagesActual4Test: Actual4test - Actual Test Exam Dumps-Pass For IT ExamsLovis NKPas encore d'évaluation

- Design and Analysis of Filament Wound Composite Pressure Vessel With Integrated-End DomesDocument9 pagesDesign and Analysis of Filament Wound Composite Pressure Vessel With Integrated-End DomesmrezaianPas encore d'évaluation

- Bajaj Electricals Limited Vs Metals & Allied Products and Anr. On 4 August, 1987Document8 pagesBajaj Electricals Limited Vs Metals & Allied Products and Anr. On 4 August, 1987RajesureshPas encore d'évaluation