Académique Documents

Professionnel Documents

Culture Documents

Corrosion Resistance of Nickel and Nickel Containing Alloys in Caustic Soda and Other Alkalies

Transféré par

rickrobbins0 évaluation0% ont trouvé ce document utile (0 vote)

373 vues42 pagesNIDI - Corrosion resistance of nickel alloy in alkalies

Copyright

© Attribution Non-Commercial (BY-NC)

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentNIDI - Corrosion resistance of nickel alloy in alkalies

Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

373 vues42 pagesCorrosion Resistance of Nickel and Nickel Containing Alloys in Caustic Soda and Other Alkalies

Transféré par

rickrobbinsNIDI - Corrosion resistance of nickel alloy in alkalies

Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 42

CORROSION RESISTANCE OF

NICI<EL AND NICI<EL-CONTAINING ALLOYS

IN CAUSTIC SODA

AND OTHER ALI<ALIES

Publication NQ 281 (CEB-2)

NiDI

Distributed by the

Nickel Development Institute,

courtesy of Inco Limited

Table of Contents

Page

PART I. INTRODUCTION 3

PART II. CORROSION BY CAUSTIC SODA........................... 4

A. Nickel .................................... _ . . . . . . . . . . . . . . . . . 4

1. Effect of Concentration, Temperature and Carbon Content ...... _ . . . . . . 4

2. Effect of Velocity ............... _ ... __ ..................... _ 6

3. Effect of Aeration .......................................... 6

4. Effect of System Thermal Gradients .............................. 7

5. Effect of Impurities .,. _ ................. _ ............ _ . . . . . . . 7

6. Effect of Stress ............................................. 8

7. Effect of Dissimilar Metal Contact .. _ ...... _ ...... _ ............. '. 8

8. Cathodic Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

B. Nickel-Chromium Alloys (Alloy 600) .. _ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

C. NickelCopper Alloys (Alloy 400, Alloy K-500) ....................... _. 10

D. Copper-Nickel Alloys .... _ ...... _ ............. ___ ............ _ ., 11

Copper-Nickel Alloy CA 706 (90-10)

Copper-Nickel Alloy CA 710 (80-20)

Copper-Nickel Alloy CA 715 (70-30)

E. Iron-Nickel-Chromium Alloys (Alloy BOO) ......... _ .............. _ . .. 13

f. Austenitic Chromium-Nickel Stainless Steels (AISI 300 Series) . . . . . . . . . . .. 13

G. Iron-Base NickelChromium...copper-MoJybdenum AHoys and Nickel-Base Chro-

mium...copper-Molybdenum Alloys .......... _ ....... __ ............. , 15

{Alloy 825. CARPENTER 20Cb-3, HASTELlOY alloy G and cast ACt CN-7M alloys}

H. Nickel-Base Molybdenum or MolybdenumChromium-lron Alloys. . . . . . . . . . . 16

(HASTElLOY alloy C-276, Alloy 625. HASTEllOY alloy B)

I. Cast Irons and Ni-Resists .... _ . _ .... __ .. __ . __ . . . . . . . . . . . . . . . . . . . . 17

PART m. CORROSON BY OTHER ALKAliES.. ............... .... .... 19

A. Caustic Potash (KOH) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 19

B. Ammonia and Ammonium Hydroxide ............................... 20

C. Other Alkaline Solutions of Sodium and Potassium Salts ................ 22

PART IV. INDUSTRIAL APPLICATIONS. ... .... . ............... ...... 24

A. Caustic Soda Manufacture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 24

B. Caustic Potash Manufacture ..................................... 28

C. Caustic Soda Storage and Transportation .......................... ". 28

D. Soap Manufacture ....................... _ ......... _ . . . . . . . . . .. 30

E. Pulp and Paper Industry ...... __ ............... _ .. _ . . . . . . . . . . . ... 32

1_ Digesters _............................................ ... 32

2. liquor Heaters ............................................. 33

3. Black liquor Evaporators .................. _ . . . . . . . . . . . . . . . 34

4. Recausticizing ............................................. 34

f. Aluminum Industry. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 35

G. Caustic fusions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 35

H. Petroleum Refining ............ _ .............. _ . _ . . . . . . . . . . . . .. 36

I. Caustic DescaJing . _ . _ .................... _ . . . . . . . . . . . . . . . . 37

J_ Reclaiming Caustic for Economy and Pollution Control. . . . . . . . . . . . . . 37

PART V. WELDING ............. __ ..... _ . . . . . . . . . . . . . . . . . . . . . . 38

A. fabrication of NickelClad Equipment .. _ ..................... " 38.

B. Repair of Equipment in Caustic Service ......... _ ...... _ . . . . . . . . . . .. 39

References .......... _ ......................................... ' 40

Trademarks ..................................... . . ... Inside back cover

Table I

Nominal Compositions of Nickel Alloys in Use or Corrosion Tested in Caustic Solutions

Composition. %

M;aterial Hi Fe Cr Mo Cu C Si Mn

WROUGHT MATERIALS

Nickel

Hickel 200 99.5 0.15

-

-

0.05 0.06 0.05 0.25

Hickel20t 99.5 0.15 - -

0.05 0.01 0.05 0.20

DURAH.CKEL alloy 30t 94.0 0.15 - -

0.15 0.55 0.25 0.25

Nickel-Chromium Alloys

.HCOHEL alloy 600 16.0 7.2 15.8 - 0.10 0.04 0.20 0.20

H.MONtC alloy 75 71.4 0.5 20.5 - - 0.10 - -

Nickel-Copper Alloys

MONU alloy 400 66.0 1.35 - -

ll.5 0.12 0.15 0.90

MON!., al'lI1 K.SO!!:. 65.0 leO

-

- 29.5 0.15 0.15 0.60

Copper-NiCkel Alloys

Copper-Nkke:1 allo, CA 706 10.0 1.25 - - 88.0 - - 0.3

CopperNickel alloy CA 710 20.0 0.75 - -

78.0 - - 0.4

CoppefNlekel alloy cA 715 30.0 0.55

- -

61.0 - - 0.5

IronNickel-Chromium Alloys

'NCOLO"- alloy 800' 32.0 46.0 20.5 -

0.30 O.M 0.35 0.75

Stainless Steels

AISI Type :202 5.0 67.0 18.0

- - 0.15ma. 1.0 max 8.1

AISI Type 31)2 9.0 70.5 18.0

- -

0.15 max 0.5 1.5

AI5ITy, . 304 9.5 70.0 18.0 - -

0J)8 max 0.5 1.5

AISI TYlle 304l 10.0 69.0 18.0

- -

0.03 max 0.5 1.3

AISI tYPe 316 13.0 65.0 17.0 2.0mi ..

-

O.OS max 0.5 1.7

AISI tJllO 316l 13.0 65.0 17.0 2.0 min - 0.03 max 0.5 1.8

AISI Type 309 13.5 60.5 23.0 - - 0.20 malt 1.0 max 2.0m3X

AISI Type 310 20.0 52.0 25.0

-

- 0.25mn 1.0 max 2.0ma.

AISI Type 330 35.0 41.0 1.5.1) - - 0.25 rna. 1.0 rna. 2.0 mal

AISI Type 347 11.0 68.0 18.0 - - 0.08mu 1.0 max 2.0mu

AISI Type. 438

-

Bal 17.0 - - 0.12 max - -

Iron Base NicketChromium-Copper-MoIybxlenum Alloys

Stainless No. 20 <1' 29.0 43.0 20.0 2.0 min 3.0m;n 0.07 max 1.0 0.8

CARPEfC-rR' No. 2OCb-3 34.0 39.0 20.0 2.5 3.3 0.01 max 0.6 08

Nickel Ba';'e l'bn-ChromiumMoIybdenum Anoys

'HCOl.OY- a!Joy 825 41.8 30.0 21.5 3.0 1.8 0.03 0.35 0.65

HASTLLO .. " alloy G 45.0 19.5 22.2 6.5 2.0 0.03 0.35 1.3

:alloy C 5.0 15.5 16.0 - 0.08 max 1.0 rna. 1.0 max

HASTELLO .. - alloy C2l6 54.0 5.0 15.5 16.0 - 0.02 max 0.05max 1.0max

'HC_I:L - alloy 625 60.0 5.0ma. 21.5 9.0 - 0.10 max 0.5 max 0.5 max

Nickel Base Molybdenum Alioy

.. ASULLO'\'- alloy B 61.0 5.0 1.0 max 28.0 - 0.05 max

- -

CAST MATERIALS

Nickel

America .. Casti"e Institute

ACI CZl00 95.0 min 1.5 max

- - - 1.0 max 2 .. 0 1.5 max

NickelCh.romlumfron Alloy

ACI CY40 70.0 9.5 15.5 - - 0.3 3.0 max 1.5 max

Nickel-Copper Alloys

HickelCopper alloy 50S 64.0 2.0 - - 29.0 O.OS 4.0 0.80

ACI "'-35 64.0 3.5 max - -

29.5 (1.35 mall 2:.0 mat 1.5 max

Stainless Steels

ACI Cr-8 19.5 66.0 9.5

- -

0.08mllll: 2.0m,n 1.5 mall

ACI Cf8M 19.5 63.0 10.5 2.5

-

OJl8 max 1.5ma. 1.5 max

ACI CAtS 1.0 max 83.0 12.8 Q.5max

-

0.ISm3l 1.5mu 1.0ma.

ACt HA - 87.0 9.0 1.1

-

0,20mu' ).0 rna. O.S

Iron Base Nickel-ChromiUm-CjPper Alloys I

wo ...... tn: Stainless 24.0 48.0 20.0 3.0 1.75 0.1)7 max 3.3 0.6

ACI CN-7M "'0 29.0 44.0 20.0 2.0 mill 3.0 min 0.01 milx 1.0 UiJlnax

Nickel Base 'ron-ChromiumMolybdenum Alloys

CHLORIMT" 3 I 60.0 2.0 18.0 JUt - 0.01ma1l 1.0 1.0

ILLIUM' alloy to 56.0 6.5 22.5 U $.5 0.20 0.65 1.25

Nickel Base Molybdenum Alloy

.'

cHt.o,nMII!T 2 63.0 3.0ma. - 32.0

-

0.15 1.0 1 ..0

Nic,kel Base Sitleon Alloy

alloy D 82.0 2.0lllllx 1.0 rna.

-

3.0 O.l?max 90 0.51.25

Nickel Alloyed Cast Irons

NIRes)st Type 1 15.5 69.0 2.2

-

6.5 2.8 2.0 1.2

HIRu;st Type 2 20.0 70.0 2.2

-

05ma. 3.0 max 1.9 1.2

HI-Resist Type 3 30.0 62.0 3.0

-

O.Sma. 2.6ma. 1.5 0.6

NiResist Type 4 30.5 55.0 5.0

-

0.5 rna. 2.6 mal 5.5 06

NiResist Type D2 20.0 72.0 2.1 - -

3.0 max 2 . .f 0.9

HIResist Type D3 30.0 61.0 3.0

-

-

2.6 max 2.2 O.Sma.

(1) An improved version of this alloy. CARPENTER'" stainless',No. 20Cb3. has replaced CARPENJR'" No. 20

(2) An improved version of this alloy. HASTEllOY alloy C276. has replaced .. ASTUt:OY alloy C.

(3) Cast Alloy 20 alloys such as DUR,MUO alloy 20. ALOYCO" alloy 20. etc

See ins;de back cover for registered trademarks.

2

Otber

-

-

AI 4.5; Ii 0.5

-

Ii 0.l5; AI 0.15

-

AI 2.8: Ti 0.5

Pb 0.05 max; In 1.0 rna.

Pb 0.05 rna.; Zn 1.0 max

Pb 0.05 max; In 1.0 max

-

N 0.25 max

-

-

-

-

-

-

-

-

Cb;- Ta IOxC min

-

-

Cb+Ta 0.6

AI 0.15: Ii 0.9

W 0.5; Cn ,. Ta 2.12

Co 2.5ma<;

W 4.0: V 0.4 max

Co 2.5 rna.;

W 4.0: V OA max

Cb- Ta 3.65

Co 2.5 rna.: V 0.20A;

P 0.025 rna.;

S 0.030 max

-

-

-

-

-

-

-

-

-

-

-

-

-

Co 1.5 max

_.-

-

-

-

--

-

Corrosion Resistance of Nickel and Nickel-Containing

Alloys in Caustic Soda and Other Alkalies

PART I. INTRODUCTION

Caustic soda (sodium hydroxide) is the most

widely used and avaBablealkaline material. In the

United States almost all of the caustic soda is pro-

duced as a co-product in the production of chlorine

by the electrolysis of sodium chloride. The elec-

trolytic cells used can be divided into two general

types: mercury cells and diapllragm cells. With

mercury cells,high purity SOt;(. caustic is pro-

duced directly, whereas with diaphragm cells. the

caustic concentration produced is within the

range of 9 to 15 per cent, and has to be further

purified and concentrated before sale. A small

amount of caustic soda is produced by the lime-

soda proce$S which WaS formerly the prime source

for this chemical.

Caustic soda is generally marketed in concen-

trations of 50 percent, 73 per cent or anhydrous.

The chemical industry is the largest consumer of

caustie soda, followed by the rayon and film in-

dustries. the pulp and paper industry and the

aluminum industry.

A large number of alloys can be used for han-

dling caustic soda, and selection is based upon

such factors as concentration. temperature, im-

3

purities in the caustic, the necessity for product

purity. corrosion rate, susceptibility to stress-

corrosion cracking (caustic embrittlement) and

economics. Caustic soda can be handled in cast

iron or steel equipment at low temperatures. if

iron contamination is not detrimental to end use.

At elevated temperatures, however, iron and steel

are subject to caustic embrittlement and high cor-

rosionrates. Plant and laboratory tests and oper-

ating experience over many years have demon-

strated that nickel and nickel alloys are the

preferred materials for handling caustic solu-

tions in many applications. Nickel can be used for

practically an concentrations and temperatures.

In addition to caustic soda. several other im-

portant alkalies are discussed in this bulletin. but

no attempt has been made to be all-inclusive.

Nominal compositions of alloys referred to in

the text are shown in Table L Materials other

than nickel-eontaining alloys included in a num-

ber of tests are reported for reference purposes.

An corrosion rates are reported as mils pene-

tration per year (mpy). (1 mil = 0.001 inch.)

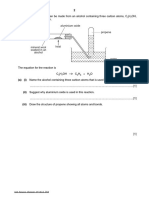

Fig. 1 - These caustic soda evaporator units are a

combination of both solid Nickel 200 and steel clad

with Nickel 200. Diaphragm cell liquor feeds into the

double-effect evaporator: overflow from a settler tank

feeds the single'effect evaporator for conc.entration to

50% caustic soda. The system produces 700 tons of

salt and delivers 434 tons of NaOH (100%1 per day.

Ph%qraDh by courtesy ot

the Swenson Division Of Whiting Corporation.

PART II. CORROSION BY CAUSTIC SODA

A. Nickel

1. Effect of Concentration, Temperature

and Carbon Content

Corrosion test results for nickel in commercial

caustic soda solutions were obtained by a number

of investigators at different times and locations.

Typical test data are shown in Table II and these

have been incorporated in the isocorrosion chart,

Figure 2. Only at high caustic concentration near

the boiling point does the corrosion rate exceed

one mil per year. This isocorrosion chart is in-

tended only as a guide; there are specific condi-

tions under which higher or possibly lower cor-

rosion rates can prevaiL These conditions are

discussed later.

700 r---..,.-----r---r----..,.---"r"> 371

600

500

u... 4oo

..

:;

"0

Q;

Q

100

f-

200

100

316

]60

'13

<OJ mpy

"- 0.1 mpy

38

o '--__ ....l.-_.L---l. __ --''--__ ...L-__ . 17.8

o 20 40 60 80 100

Fig. 2 -Isocorrosion chart for Nickel 200 and Nickel 201

in sodium

Some tests which have been carried out at

elevated temperature and pressure in autoclaves

indicate satisfactory performance for nickel in

caustic soda solutions even above the atmospheric

boiling point, as shown in Table IIU

4

Fig. 3 - View of caustic transfer piping from marine storage

tank area to terminal where rayon grade 50% caustic soeta

is loaded into a barge. Several hundred feet of lightweight.

welded Nickel 200 piping in 8-inch and 12-inch sizes are

used.

In caustic concentrations above 75 per cent and

including molten caustic soda. nickel is second

only to silver in resistance to corrosion. When

nickel is to be used at temperatures above 316 C

(600 F). a low-carbon grade, Nickel 201 (0.02% C

max). should be employed to preclude the possi-

bility of graphite precipitation in the grain boun-

daries and a resultant loss in ductility. Nickel 201

is often used for the construction of tubular evap-

orators for continuous vacuum concentration of

caustic soda from 50 and 73 per cent to anhy-

drous at temperatures up to 404 C (760 F). with

nickel pickup in the finished caustic of only one

to two ppm.

3

Molten caustic soda has been considered as a

heat transfer medium for nuclear energy appli-

cation. In static tests at Harwell in England,

Gregory. et concluded that Nickel 201 was a

satisfactory container material for molten caus-

tic soda at temperatures up to 580 C (l076 F)_

Some of their data are shown in Table IV.

Table II

Typical Corrosion Test Data for Nickel and High Nickel Alloys in Caustic Soda Solutions

HaOH

;oncen-

tration,

%

D-1

4

4

5-10

14

22

34

30"50

49-51

50

50

50

72-73

72

73

73

13

14

15

60 to

nearly

anbydrnus

Temperature

C F

3{l 86

30 86

3{l

86

21-32 70-90

88 190

50-60 12{)-140

65 150

81 178

55-75 131-167

31165 av 149

55-61 131-142

31158 a1l 136

60-70

av65 al/ 149

150 302

116 273

121 282

95-100 203-212

100-120 212-248

avll0 a1l230

104-116 244-251

av 110 av248

130 266

135 271

302-500

Less than 0.005 mils per year.

A.e1ation Agitation

Nooe Hone

Hone None

Air agitated Air agitated

Extensive due to

filling tank

None None

None due to

filling tank

Extensive Mild

None None

None due to

lining tank

None due to

filling tank

Moderate by lOOgpm

flow from

pump

None None

None due to

filling tank

Moderate due to

filling tank

None by rocking

of tank

None due to

filling tank

None due to

filling tank

Not specified by movement

of tank car

Not specified due 10

filling tank

None None

Test

Period,

days

27

1&2

1&2

124

90

133

37

16

30

135

393

14

183

119

111

52

126

II trips

of 7-9

days

35

2

5

Comments

Test coupons removed,

cleaned and dried each day

fOf lOdays

Average of tests run at

8 separate laboratories

Average of tests run at

8 separate laboratories

Storage lank

First effect of multiple-

effect evaporator

Storage tank coupons

immersed 95% of time

Storage tank in which air was

bubbled through from bottom

Single-effect evaporator_

Rates are average of 3 tests

Storage tank coupons

fully immersed

Storage tank

T ransler piping. at pump

discharge

laboratory test on tubing;

average of 4 coupons

Storage tank

Storage tank

rest tank_ simulating action

of tank car

Storage tank coupons

immersed 95% of time

Storage tank coupons

lully immersed

Coupons in railroad

tank car

Storage tank between

evaporator and finishing pots.

Ammonia Soda Process

Concentration in caustic

evaporator

Corrosion Rate, mils per year

Hicke!

200

0.01

0.05

0.05

0.15

0_02

nil

0.03

0.09

0.02

0.02

0.07

-

0.3

OJ

0.13

0.05

0.02

0.3

1.6

3.9

Nickel-

Copper

Alloy

(MONEL

alloy

40ll)

0.01

0.16

0.21

O.ll

0.05

0_01

-

0.19

0.03

0.02

0.10

-

0.7

0.3

0.16

0.04

0.10

0.4

1.7

13.4

Nickel-

Chromium

Alloy

ltNCONEl

alloy

6nO\

nW

-

-

0.05

0.03

0_01

0.03

-

0.02

0.02

0.03

0.25

0.4

0_1

0.14

0.06

0.0\

-

1.3

-

Table llt

laboratory Corrosion Tests in Caustic Solutions at Elevated Temperatures

NaOH

Concen-

tration,

%

Temperature

C F

Test

Period,

hr

Nickel

206

20

110 262 15 nil

40

110 262 15 nil

60 llO 262 15 nil

80

110 262 15 nil

20 115 272 19 nil

40 115 272 19 nil

60 ll5 272 19 nil

80 US 272 19 nil

20 162 355 19 nil

40 162 355 19 nil

60 162 355 19 nil

80 162 355 19 nil

20 149 332 19

40 149 332 19

60 149 332 19

20

132 270 ]9

40 132 270 19

GO 132 270 19

80 132 270 19

20 111 340 19(2 tests}

40 111 340 19 (2 tests)

60

l7l 340

1912 testsl

80

17l 340 19 (2 tests)

20 156 345 20

40

156 345 20

GO 15G 345 20

86 156 345 20

20 127 293 15

40 127 293 15

GO 127 293 15

80 127 293 IS

20 150 334 18

46 150 334 18

GO 152 336 19

20 183 394 15

GO 183 394 15

80 183 394 15

2. Effect of Velocity

Velocity has little effect on the corrosion rate of

nickel in caustic at temperatures below 500 C

(932 F) but at 540 C (1004 F) and above, increas-

ing velocity may cause a several-fold increase in

the rate of attack. Figure 4 shows the results of

two-week laboratory experiments by Gregory,

et al., in high temperature molten caustic soda

under dynamic conditions.

6

Corrosion Rate, mils per year

MONEL

alloy

400

nil

3

1

WORTHITE sIs

(solution

quenched)

4

9

1

nil

25,69

36.28

2,38

nil. nil

14

17

33

1

3. Effect of Aeration

Hi-

Resist

Type 2

94

6

17

28

Cast ACI

CN7M

10

1

12

nil

151

2

Aeration has not been observed to accelerate

corrosion in lower concentration caustic soda

solutions. However, at high concentrations and

temperatures, such as occur when concentrating

to anhydrous, precautions should be taken to

minimize aeration.

M"lten Coust;c Sodo

720 C (1328 Fl

480

400

>-

680 C (1256 Fl

E

320

0

oc

240

.----------

c

_Q

E

(;

u

600 C {I I 12 Fl

580 C {1076 Fl

540 C (l004 F)

635 C P 175 Fl

400 C ( 752 FI

500 C I 952 F)

100 200 300 400 500 600

Rotot;on $peed_ rpm

Fig. 4 - Corrosion rate of nickel as a function of rotational

speed.'

Table IV

Static Corrosion Rates of Nickel and Nickel Alloys

in Molten Caustic Soda

Corrosion Rate, mils per year

Temperature

460e 500e 58fl e 680e

Alloy (750 f) (932 f) (1076 f) (1256 f)

Hickel20t 0.9 1.3 2.5 37.8

HASTELLOY a!toy e 100.5

HASTELt.OY aUoy D 0.7 2.2 9.9

MONEl. alloy 400 1.8 5.1 17.6

INCONEL aUoy 600 U 2.4 5.1 66.4

OURANICKEI. alloy 30t 1.7 3.2 10.4 40.7

NIMONIC all01 75 1.1 14.3 20.8 47.6

(pitted)

Gained weight. Swollen outside surface largely oxide-heavily cor

roded.

4. Effect of System Thermal Gradients

In molten caustic soda at temperatures above

about 550 C (1022 F), nickel is subject to thermal

gradient mass transfer.:; 4;. 7 In this type of at-

tack, nickel is dissolved in caustic at a high tem-

perature surface and is precipitated at a low

temperature surface in a circulating system.

Gregory, et at, concluded that the corrosion rate

of nickel in molten caustic soda could be ten times

as great under dynamic conditions as it was

under static conditions because of the solubility-

temperature relationship.:;

The mass transfer effect can be inhibited but

not prevented by maintaining a hydrogen-con-

7

taining atmosphere in the vicinity where corro-

sion is occurring. Forestieri and Lad found that,

as a result of the presence of chromite ion

(CrO:I-

1

), mass transfer and cOITosion were

essentially eliminated for 50 hours by one per

cent addition of 325-mesh chromium powder in

a test loop operating at a fluid velocity of 15 fps

and 816 C (i500 F) with a temperature difference

of either 11 C (20 F) or 22 C (40 F) .>1.9 However,

a small mass transfer deposit was obtained after

250 hours, indicating that a single chromium ad-

dition would not protect a nickel system in-

definitely.

5. Effect of Impurities

Chlorates in caustic can increase corrosion rates

as indicated in the later section on caustic soda

manufacture (page 27). Small amounts of so-

dium chlorate are produced in electrolytic dia-

phragm cells. The effect of the chlorate on corro-

sion rate is not critical unless the chlorate is de-

composed. and thermal decomposition does not

occur below a temperature of 260 to 290 C (500 to

554 F). If it is intended to operate nickel equip-

ment at or above this temperature range. four

alternatives are available:

a. Use "rayon grade" caustic which has a speci-

fication of 5 ppm maximum chlorate content.

b. Use caustic produced by electrolytic mercury

cells or by the lime-soda process, or,

c. Use anhydrous caustic; there are no chlorates

in the anhydrous grade .

d. Add reducing agents as discussed in the sec-

tion on caustic soda manufacture (page 27) .

The presence of oxidizable sulfur compounds

in caustic soda tends to increase the corrosion

rate of nickel at elevated temperatures. This is

noted particularly with hydrogen sulfide, mer-

captans, or sodium sulfide, and to a much lesser

extent with partially oxidized compounds such as

thiosulfates and sulfites.

The effect of the addition of oxidizable sulfur

compounds to caustic soda on the corrosion rate

of nickel has been studied in the laboratory with

the results shown in Table V. Test 1 was made

during the evaporation of a commercial caustic

soda solution under 28 inches of vacuum. Sulfur

content of the original caustic. calculated as per

Table V

Effect of Oxidizable Sulfur Compounds on Corrosion

of Nickel 200 in Caustic Soda

Temperature: 130 C c::: 5 C (266 F c::: 9 Fl.

Corrosion

Test Rate,

No. Corrosive mils per year

Commercial Sodium Hydroxide being concentrated

from 50 to 75% NaOH (Sulfur content at start.

calculated as H,S. 0.009%} 1.7

2 75% C.P. Sodium Hydroxide 0.6

3 75% C.P. Sodium Hydroxide plus 0.75% Sodium

Sulfide 22.8

4 75% C.P. Sodium Hydroxide plus 0.75% Sodium

5 75% C.P. Sodium Hydroxide plus 0.75% Sodium

Sulfite 5.2

6 75% C.P. Sodium Hydroxide plus 0.75% Sodium

Su!!ate 0.6

Chemically pure.

cent H;!S in dry caustic, was 0.009 per cent. Test 2

was made in chemically pure caustic soda. Tests 3

through 6 were made in chemically pure caustic

to which the various sulfur compounds had been

added.

It has been found that the detrimental effect

of oxidizable sulfur compounds in caustic can be

counteracted by the addition of sufficient sodium

peroxide to form sulfates. An excess of peroxide

does not seem to be detrimental. as shown in

Table VI which compares the resistance of nickel,

iron, and copper to fused caustic soda with and

without an addition of 5c;. sodium peroxide.

lo

In each test, 5 grams of the substance were fused

for four hours in a laboratory crucible of the

given metal and analyzed for metal pickup.

6. Effect of Stress

Experience has indicated that Nickel 200 is not

subject to stress-corrosion cracking in pure

caustic solutions. However, it is subject to

stress-corrosion cracking by mercury, and there

have been a few cases of cracking of nickel when

"upsets" occur in producing plants that utilize

mercury cells.

In addition, cracking along precipitated grain

boundary jTraphite in Nickel 200 has occurred

after caustic soda exposure above 316 C (600 F).

As indicated previously. a low-carbon grade

8

(Nickel 201) will circumvent this problem.

Applied or residual stresses apparently do not

significantly affect the genera! corrosion rate of

nickeL 11

7. Effect of Dissimilar Metal Contact

Galvanic corrosion can occur in caustic soda solu-

tions if different materials of construction are

electrically connected. Whether this effect is aca-

demic or critical depends upon the specific condi-

tions that exist in a partiCUlar installation. For

instance, the data in Table VII illustrate that gray

cast iron corrodes from about one and one-half

Table VI

laboratory Tests in fused Caustic Soda with and

without Addition of 5% Sodium Peroxide

Temperature Metal Pickup. grams

COHosive

Caustic Soda

Caustic Soda

with 5% Sodium

Peroxide

SI rangly attacked

C

350

360

400

450

500

550

600

350

400

450

f Nickel Imn

662 .4

680 .01.02

752 Irace.02 .426

842 .01.02 .2.3

932 .005.015 .2.3

1022 .4.43

1112 .i3.3

662 .0024 .024

752 .0135 .025

842 .OBI .Il

Table VII

Galvanic Corrosion of Gray Cast Iron

Conditions: Corrodent: 5% sodium hydroxide.

Temperature: 43 C (ll 0 F).

Flow: 16 feet per minute.

Aeration: Saturated WIth air.

Cathode to anode area ratio 2: 1.

Copper

trace

.013

.03

Corrosion Rate of Corros ion Rate of

Gray Cast Iron. Cathodic Material,

mils per year mils per year

In In

Cathodic Galvanic Galvanic

Material Insulated Couple Insulated Couple

Nickel 200 l.l 1.5

Nickel 200 0.6 ]6 0 <0.1

MONEL alloy 400 0) 2.1 <01 <0.1

MONEL alloy 400 0.6 17 0 0

0.75 1.72

Average Average

Slight welgh1 gain

to three times its normal rate when connected to

Nickel 200 or MONEL alloy 400, under the given

set of conditions. However, the normal rate for

cast it-on in caustic is so low that these higher

corrosion rates are usually tolerable.

At higher caustic concentrations, tempera-

tures, and with large cathode to anode r;:ttios.

galvanic corrosion becomes more pronounced.

The galvanic current curves shown in Figure 5

are from tests made above and close to the upper

tube sheets of operating caustic evaporators. The

general conclusions to be drawn from these tests

are that in concentrated caustic soda solutions.

significant galvanic corrosion may occur on cast

iron or steel when in contact with nickel or cop-

per. In the construction of caustic evaporators.

it is desirable, if not actuaHy necessary, to use

nickel or nickel-clad steel tube sheets in conjunc-

tion with nickel tubes.

u.

q

b.O

5.0

t

Si 4.0

c

{; 3.0

" o

"

1.0

.(

GoJvonrc Current Flow Between

C05-t 1on end Copper

A"'?oe: !"on . C 3QS -;:: ;:.

Ccpoer 0.*9"4 ;-:: =.

JS

7.0,-----,..-----,----,..-----.--__ -,-____ ,--__ -,-__ --,

0

"

?

U

" "D

"

.(

3.0

2.0

1.0

0

Q

S

Golvonic Cv ... enf flow Between

Cad Iron ond Niclel

Af"-e:2 =-.C J c.

C,+ode: ...:. il.24; 5.;)::.

Fig. 5 -- Current measurements between cast <ron, copper

and nickel specimens set up above and near the upper tube

sheet of an evaporator concentrating caustic soda from 47

to 60 per cent. NaOH under 26 in. vacuum using steam at

a pressure of 75 Ib per sq in.

9

8. Cathodic Protection

In the continuous production of anhydrous caus-

tic, experience has shown that cathodic protection

can be applied successfully to nickel evaporating

equipment. In one such case, a cathode current

density of about 1 ampere per square foot of ex-

posed nickel surface provided satisfactory pro-

tection. In other less corrosive applications, as in

storage of caustic, current densities as low

as 0.01 ampere per square foot have been reported

effective. Nickel 200 anodes are used in these ap-

plications_ Laboratory tests in 75% caustic soda

at 120 C (250 F) and also in fused anhydrous

caustic soda at 480 C (900 F) have shown that

\",ith equal areas of nickel for anode and c.athode,

and with an applied anode current density of

10 amps per square foot, the corrosion rate of

the nickel anode does not exceed that of uncoupled

nickel. A pure technical grade of sodium hydrox-

ide was in these tests, which contained less

than 0.04 per cent of heavy metal impurities. The

result.c; are shown in Table VIn.

Table Viti

laboratory Tests of Nickel 200 Anodes and Cathodes

in 75 Per Cent and Fused Caustic Soda

Temperature: 120C (250F) for 75% caustic.

480 C (900 F) for fused caustic.

Duration of Tests: 1821 hr.

Volume of Solution Used: 1 liter.

Anode Current Density: 10 amp per sq ft.

Area of Specimens: 0.066-0.087 sq ft.

Average Corrosion Rate.

mils lIer year

Nickel 200 Anode

Nickel 200 Cathode

NickeI200-Uncollpletl

75% Caustic

0.8

0.2

1.0

fused Caustic

11.3

0.9

11.2

Note that the cathodic nickel surface benefited

from cathodic protection, while the corrosion rate

of the nickel anode was not increased.

B. Nickel-Chromium Alloys

Nickel-chromium alloys, such as INCONEL alloy

600, are approximately equi\'alent to nickel in

corrosion resistance in caustic soda, as shown in

Tables II, IV and XL.

Alloy 600 is commonly used in equipment for

the production of anhydrous caustic when sulfur-

bearing fuels are used for heating because it is

more resistant to sulfidation than nickel.

There have been a few instances of stress-

corrosion cracking of Alloy 600 in some strongly

alkaline environments. A review of these serviee

failures has indicated that they usually occurred

in concentrated caustic solutions at high tempera-

tures, 190 to 450 C (374 to 842 F). In seven-day

laboratory tests, caustic concentration, tempera-

ture, and the presence of air were shown to be

important variables, as shown in Tables IX and

XIV. No stress-corrosion cracki ng occurred if the

Alloy 600 U-bend specimens were stress-relieved

at 900 C (1650 F) for one hour or 769 C (1400 F)

for four hours after bending.

Table IX

StressCorrosion Cracking of INCONEl Alloy 600

U-Bend Specimens in Caustic Solutions-

Seven-Day Tests

Temperature Over-

pressure.

Caustic CORcentratiolt, weight %

C f 150 psi Caustic 10 50 90

200 390 Air NaOH OK OK

250 480 Air NaOH stress-cracked

300 570 Air NaO" OK stresscracked stresscracked

200 390 Argon NaO" OK OK

250 480 Argon NaOH OK

300 570 Argon NaOH OK OK OK

200 390 Air KOH OK slight inter

granular

penetration

250 480 Air KOH stresscracked

300 570 Air KOH OK OK stress-cracked

Note: Testing performed in autoclaves under static conditions without

replenishment of air or argon.

C. Nickel-Copper Alloys

Nickel-copper anoys, such as MONEL alloy 400,

are practically as resistant to caustic soda as

nickel, as shown in Table II.

The corrosion rate of Alloy 400 is higher than

nickel at caustic soda concentrations above 75 per

cent when concentrating to anhydrous. It is also

10

Fig. 6 - This barge has eight tanks with a capacity of

34,000 barrels .. The are used to carry fuel oil or as

and a specli;ll 54.00barret tank fabricated of INCONEl

alloy 600-clad steel is used to carry 73

0

10 caustic soda, am

moniabasefertilizers, or jet fuels.

higher than nickel at temperatures above the

atmospheric boiling point, as shown in Table III.

However, it should be noted that even in those

cases where AHoy 400 is inferior to nickel, the

corrosion rates are still quite low.

There have been a few reports of stress-corro-

sion cracking of cold-worked and stressed Alloy

400 in caustic soda. However, the eXact conditions

under which most of these failures occurred are

not known. It is known that some of the reported

failures associated with mercury cell caustic were

caused by intergranular attaek by mercury and

subsequent loss of ductility.

Laboratory tests have shown that Alloys 400

and K-500 can be susceptible to stress-corrosion

cracking unde.r extreme exposure conditions. that

is, high stresses in combination with high tem-

peratures and concentrated caustic soda can cause

cracking. Table X shows the results observed

with tensile loaded specimens tested at 300 C

(570 F) in condensing steam after being coated

with either potassium or sodium hydroxide.

Under these exposure conditions, Alloy 400,

which had been cold-worked or cold-worked and

stress-relieved prior to testing, was susceptible

to stress-corrosion cold-worked mate-

rial that had been annealed at 850 C (1560 F) or

950 C (1740 F) prior to testing was resistant. As

with Alloy 400. Alloy K-500 cracked when cold-

Table X

Stress-Corrosion Tests on MONEL Alloy 400 and MONEl Alloy K-500

Alloy Heat Treatment

MONEL alloy 4(1(1 None-as cold-drawn

850 C (1562 fltIti hr/W.O.

MONEL alloy 40(1 Stress relieved

540 C 11004 fl/ z hr

MONEL alloy 40(1 Works anneal

950 C U742 fll Y2 hr

MONEL alloy KS(I(I None-as COld-drawn

870 C U598 f)f5 min/W.O.

580 C (1076 fl/S hf/fC

810 C US98 A/S min/W.O.

+ 580 C {1016 fl/16 hr/FC

MONEL alloy K500 None-as colddrawn

870 C (1598 fl/5 min/W.O.

580 C n076 AIS hrl FC

870 C (1598 fl/5 min/W.Q.

+ saocno76 flfl6 hr/fe

Fumace-coaled at about 10 C (18 Fl/nr to 480 C

(896 Fl then "if.-coa!ed to room lef'lperature.

NO = Not Determined

o == Specimen fractured

1 == Coarse 'cracks visible to naked eye

2 == Fine cracks visible to naked eye

3 == Deep cracks visible under microscope

worked and was resistant in the annealed condi-

tion. However. the thermal-hardening treatment

at 580 C (1076 F) rendered the alloy very suscep-

tible to cracking.

The practical interpretation of these data is

difficult because threshold values of stress, caustic

soda concentration, and temperature at which

stress-corrosion cracking will occur have not been

established. With these limitations in mind, it

would appear prudent to stress-relieve AHoy 400

in the range of 538 to 566 C (1000 to 1050 F) or

anneal it ill the range of 760 to 816 C (1400 to

1500 F) for one to three hours when it is to be

used in higher strength caustic at elevated tem-

peratures.

D. Copper-Nickel Alloys

The corrosion resistance of copper-nickel alloys

in can.stic soda solutions is dependent upon the

nickel content of the alloy, as illustrated in Fig-

ure 7. There are a limited amount of additional

data which are shown in Table XI.

11

Yield Applie II

Strength, Stress,

ton/ S1l in. tonI sq in.

43.8 33.1

12.8 16.3

24.0 20.1

11.4 8.3

52.5 33.1

21.2 10.3

65.5 37.2

44.9 37.2

53.2 33.1

NO 10.3

NO 37.2

NO 37.2

Type and Degree of

Cracking

NaO\( KO\(

IIG 41'11

5 5

OIG OIG

5 5

3IG+TG 5

5 5

4TG 5

OrG OIG

4NI

5

OIG

DIG

4 = Shallow cracks visible under microscope

5 = No cracks

TG = Transgranular cracks

IG == Intergranula. cracks

I'll = Type of cracking nQt jdentified-cracks very

short.

>-

0-

E

'" 12

o

a::

5 8

.;;;

l?

4

20 40 60

Per Cent Nidel in Copper.Nickel Alloys

100

Fig. 7 - Results of corrosion tests of copper-nickel alloys

in 50% caustic soda evaporator.

Copper-nickel alloy CA 715 (70% Cu-30% Ni)

possesses excellent resistance to dilute concen-

trations of caustic soda at low temperatures and

appears to have useful resistance to caustic soda

solutions of up to 73 per cent at the boiling point.

However, this resistance does not extend to fused

caustic. Alloy CA 715 has been used successfully

as evaporator tubes for concentrating to 50 per

cent where copper pickup by the caustic could be

tolerated.

Copper-nickel alloys CA 706 Ni)

Table XI

Corrosion of Copper-Nickel Alloys by Caustic Soda Solutions

Nominal

HaOM

Alloy

Composition

Concen- Copper-

Temperature

tration, Hickel Wt% Wt%

% Alloy Cu Hi C F

5 - 60 40 15-20 I 59-68

11 60 40 Hot-Exact temperature

unknown

5 70 30 1520 .1. 59-68

11 70 30 Hot-Exact temperature

unknown

50 70 30 95 203

50 CA 715 70 30 65 149

73 70 30 105 221

60-75 70 30 150-175 302347

60-1Im 70 30 150260 302500

100 70 30 400410 752770

5 80 20 1520 5968

6075 80 20 150-175 302347

CA 710

60100 80 20 150260 302500

100 80 20 400410 752770

50 90 10 95 203

CA 706

73 90 10 105 221

,. Less than 0.1 mit per year.

and CA 710 (80% Cu-20% Ni) have useful resist-

ance to caustic soda solutions but their applica-

tion is limited to lower concentrations and tem-

peratures than AHoy CA 715. Because of the

limited data available it is difficult to define limits

for these two alloys.

While corrosion of the copper-nickel alloys by

caustic solutions may be aggravated by the pres-

ence of sulfur compounds, Alloy CA 715 is able

to resist attack under some conditions, as shown

in Table XII. No data appear to be available on

the susceptibility of these alloys to stress-corro-

sion cracking in caustic soda solutions.

Test Corrosion

Dura- Rate,

tion, mils per

days year Comments

21 Nil laboratory test in glass bottle.

25 0.5 Diaphragm cell liquor

coupons in distributor box to settlers.

21 Nil laboratory test in glass bottle.

25 4.3 Diaphragm cell liquor

coupons in distributor box to settlers.

67 0.8 Velocity 1.8 ftl sec. Salt saturated.

30 Nil In storage tank.

118 1.2

l/Z 4.4 In evaporator concentrating from 60-75%.

2 21 In evaporator concentrating

from 60% to anhydrous.

1 70 In anhydrous melt.

21 Nil laboratory test in glass bottle.

liz 8.1 In evaporator concentrating

from 6075%.

2 28 In evaporator concentrating

from 60% to anhydrous.

1 90 In anhydrous melt.

67 1.8 Velocity 1.8 ft/sec. Salt

saturated.

118 2.0

Table XII

Corrosion Rate of Copper-Nickel Alloy CA 715

in Alkaline Solutions Containing Sulfur Compounds

Corrosion

Duration, Rate,

Conditions of Exposure days mils per year

1. In open tank used to boil 1822 per cent

NaGH to release mercaptans at 80 C (175 fl 30

2. In reboiler of caustic stripper, 12 per cent

NaDH.3 per cent Na,S. 10 per cent sodium

phenolate + 0.7 mg per liter as sodium

25

mercaptides at 124 C (255 Fl 131

3. In 10 per cent sodium sulfide in storage

tank at atmospheric temperature 81

4. In 60 per cent sodium sulfide in flaker

14 feed tank at 171 C (340 f) 28

5. In regenerator reboiler for steam stripping

of mercaptans from solutizer solution

25.2 per cent potassium hydroxide

37.8 per cent potassium isobutyrate

5.5 per cent potassium sulfide

1.9 per cent potassium mercaptides

2.1 per cent potassium carbonate

at 141 C (286 f) 140 15

6. In vapors from solution in item 5 140 12

Pitting up to 3 mils depth.

12

(.

E. IronNickelChromium Alloys

Based upon data obtained in several test expo-

sures and shown in Tables Xln and XL, it appears

that INCOLOY alloy 800 approaches INCONEL alloy

600 in resistance to caustic soda. However, Alloy

800 is more susceptible to stress-corrosion crack-

ing than Alloy 600, as shown in Table XIV.

There has not been sufficient experimental

work on the stre.ss-corrosion cracking of Alloy

800 to determine if stress-relieving in a tempera-

ture range which will cause sensitization (pre-

cipitation of chromium carbides in a continuous

network) renders the alloy more susceptible to

this form of attack. Therefore, it would appear

prudent to anneal the alloy in the range of 1120 to

1150 C (2050 to 2100 F) or stress-relieve and sta-

bilize at 870 C (1600 F) for one to two hours when

it is to be used in higher strength caustic soda

at elevated temperatures.

Table XIV

Laboratory Tests-Results of U-Bend

Specimens in 90% Caustic Soda at 300 C (572 F)

Maximum Depth of Cracks, mils

Argon 15 psig 50 psig 150 psig

atm. air air air

Material 1 week 1 week 8 weeks 1 week

INeOLOY alloy 800 10 7 120lal 1151bl

INCONEL alloy 600 0 0 75 115

Type 304

Stainless Steel 100 110 11 10

(a) Removed at four weeks.

(b) Twoweek test.

Note: Testing performed in autoclaves under static conditions without

replenishment of air or argon.

Table XIII

Plant Tests-Corrosion Rates in Caustic Production Equipment Using Electrolytic Diaphragm Cell Caustic

Exposure times vary from 24 to 29 days

Conditions

NaOH NaGI

Temperature

Concen- Concen

Av Max Min

tration, tration,

% %

G F G F C

10 12 88 190 91 195 82

23 J.8 93 200 104 220 82

35-40 67 116 240 127 102

50 1015 93 200 104 220 71

72 ? 121 250 124 255 119

F. Austenitic Chromium-Nickel

Stainless Steels

F

180

180

215

160

245

Austenitic chromium-nickel stainless steels offer

good corrosion resistance to boiling caustic soda

solutions up to about 10 per cent concentration,

but from 10 to 50 per cent, the temperature for

satisfactory service probably would not exceed

93 to 100 C (200 to 212 F). Generally more severe

but inconsistent corrosion rates occur in more

Corrosion Rate, mils per year

'"

'"

'"

'"

'"

=

=

M

'"

:'a;

:Sa:;

.,.

"

"

.e.e

'"

'"

" '"

<n<n <n<n <n<n

,.

'"

'"

.,. .,. .,.

] c

0

N

W

'" '" '"

1':

0; w

Z M M M

.;;;

t;

0

z

0

'"

"

"

0

"

Z

"'

z

<0.1 <0.1 <0.1 <0.1 0.2 <0.1 0.2 0.2 5 4

0.2 0.1 0.3 0.1 0.4 2 0.4 1 9 2

0.6 0.4 1 0.5 1 2 0.9 3 46 49

<0.1 <0.1 0.2 <0.1 0.2 0.2 0.4 0.4 5 6

13

0.1 <0.1 OJ <0.1 4 3 0.3 5 4 16

concentrated solutions and at higher tempera-

tures. An isocorrosion chart (Figure 8) sum-

marizes the corrosion behavior of austenitic

stainless steels in caustic soda.

Typical corrosion rates for several stainless

steels are shown in Tables XV and XL. Type 316

stainless steel does not appear to offer any ap-

preciable improvement in corrosion resistance

over Type 304 stainless steel in caustic soda solu-

tions.

700 .-----r-------,-----r----r------.-. 3 It

600

500

'-'-. 400

"

Q.

E

200

100

.

\ .1\ I

C'OC';"1 Bou"cio,y

\ Bo;';n9 P;i",

\ 0' 30moy

\.

,

f to ' .......

50 mpy

.-: 1 ::npv

AU Grades

lib

2&0

Q)

19

17 S

OL-____

o 20 &0 ,,-' 100

fig. 8 - Isocorrosion chart for austenitic chromium nickel

'stainless steels in sodium hydroxide,

J. M. Stone observed that Type 304 stainless

steel sensitized for one hour at 677 C (1250 F)

was not susceptible to intergranular corrosion

during 40-week exposures in: 1:!0

1. 10% NaOH at room temperature

2. 10% NaOH boiling at about 102 C (216 F)

3. 50% NaOH at room temperature. and

4. 50% NaOH at 60 C (140 F).

Therefore. post-weld heat treatment of regular

(0.08 max) carbon grades or the selection of a

low-carbon or stabilized grade of stainless steel

does not appeal' to be required for these exposure

conditions. However, intergranular corrosion of

sensitized Type 304 stainless steel was observed

by Agrawal and Staehle in boiling solutions of

20 to 80('; NaOH.I:t

Chromium-nickel stainless steels are subject

to stress-corrosion cracking in caustic soda solu-

tions at elevated temperatures. Nathorst

H

re-

ported several cases of stress-corrosion cracking

of austenitic stainless i3teels caused by alkalies.

A comparison of the cracking behavior of Type

304 and Alloys 600 and 800 is given in Table XIV.

A stress-corrosion cracking zone based upon these

and other known failures reported in the litera-

ture is shown in Figure 8. A dashed line was used

to indicate the temperature-concentration bound-

ary because this zone is probably not completely

defined. Agrawal and Staehle have shown that

sensitized Type 304 stainless steel is more prone

than annealed material to stress-corrosion crack-

ing in boiling caustic sodaP A portion of their

data is shown in Figure 9. The cracking obtained

was predominantly intergranular in the sensi-

tized material and predominantly transgranular

in the annealed material.

Commercial standard grade 50r;. caustic soda

from diaphragm cells can have up to 11.000 ppm

chlorides. and commercial 50

c

; caustic soda from

mercury cells and reagent grade anhydrous caus-

tic can have up to 50 ppm chlorides. It has been

Table XV

Corrosion of Stainless Steels by Caustic Soda Solutions

HaOH

Concel!-

Temperature

Test Corrosion

AISI tration. Duration. Rate.

Type % C F days mils per year Comments

302 20 5060 122140 134 <0.1 storage tank

309 20 50-60 122140 134 <0.1 storage tank

310 20 50-60 122140 134 <0.1 storage tank

304 22 50..60 122140 133 <0.1 storage tank

309 34 65 149 37 <0.1 storage tank

310 34 65 149 37 <0.1 ;Iorage tank

309 50 21 70 134 <001 storage tank

3to 50 21 70 134 <0.1 storage tank

202 50 5065 122149 167 0.5 storage tank

304 50 50..65 122149 167 <01 storage tank

14

10'

L

'"

.}

j

10

So;\;"9

lcood JOO

e

"_ Y e':i >'tres,"

,O','="O----::l:?O=----=li:-O--.. -'=0---SOL----/,L.O---L70---180

Fig. 9 - Stresscorrosion cracking of annealed and sensi

tized Type 304 stainless steel in caustic soda solutions.

l3

suggested that unreported chloride impurities

are responsible for some of the stress-corrosion

cracking. I;; Whether the reported cracking was

caused by caustic solutions or the chlorides these

solutions contain is an academic point. In any

case. consideration should be given to the tem-

perature and stress limitations of austenitic

stainless steel in caustic soda solutions.

Autoclave tests have been run on some of the

cast stainless steels at temperatures both above

and below the boiling point. II; Data for ACI alloy

CF-8 from these tests are shown in Table XVI.

Table XVI

Corrosion of Cast ACI AUoy CF8

in Caustic Soda at High Temperature

HaOH

Concentration,

%

20

40

60

80

Temperature

C f

119 245

138 280

185 365

119 245

138 280

185 365

219 425

119 245

138 280

185 365

219 425

119 245

138 280

185 365

Corrosion Rate Range,

mils per year

05

2050

20-50

05

20-50

50-200

>200

5-20

50-200

50-200

>200

0-5

5-20

2050

15

Fig. 10 - Piping and certain internal parts of these two

KAMYR digesters used in the pulp and paper industry are

Type 316L stainless steel to resist caustic soda and sodium

sulfide. Insulation sheathing is Type 304 stainless steel to

resist alkaline spills.

See inside back cove<for registered trademarks_

The authors reported that the results for ACI

CF -8M were similar. Alloys CF -8 (cast equivalent

of wrought Type 304) and CF-8M (cast equiva-

lent of wrought Type 316) both exhibited increas-

ing corrosion rates with increasing temperature.

G. Iron-Base Nickel-Chromium-

Copper-Molybdenum Alloys

and

Nickel-Base Chromium-Copper-

Molybdenum Alloys

The limited corrosion test data for wrought alloys

such as CARPENTER 20Cb-3. INCOLOY alloy 825.

HASTELLOY alloy G, and cast ACI CN-7M composi-

tions in caustic soda solutions. shown in Tables

III, XVII and XL, indicate appreciable corrosion

resistance. These alloys fall between the austenitic

chromium-nickel stainless steels su!:h as Type 304

or cast ACI CF-8 and the nickel-chromium alloys

such as Alloy 600 in resistance to caustic soda

solutions. They are markedly superior to Type

304 stainless steel and ACf CF-8 in concentrated

solutions above 95 C (205 F)_

At least one plant has used WORTHITE stainless

steel pumps for handling 73('; caustic soda at

140 C (284 F).I' However, the same reference

also cites high corrosion rates for alloys of less

than 70'; nickel, which would include WORTHITE

stainless steel, in a storage tank handling 73'";

caustic soda at temperatures ranging from 120 to

171 C (248 to 340 F). Thus, the 140 C (284 F) ap-

plication may be at the upper limit of usefulness

for this aHoy.

if these alloys are to be used in conjunction

with nickel and high nickel alloy equipment in

strong caustic soda solutions at elevated tempera-

tures, consideration should be given to electrical

insulation between the dissimilar alloys so as to

prevent harmful galvanic effects.

H. Nickel-Base Molybdenum or

Molybdenum-Chromium-Iron Alloys

Materials such as HASTELLOY alloys Band C-276.

INCONEL alloy 625 and cast CHLORIMET alloys 2

and 3 have not been used to any great extent in

caustic soda solutions. Ag a result. corrosion data

for them are rather Tables IV and XVIII

show the results of some iabonltory corrOfiion

tests. From these data. it is evident that HASTEL-

LOY alloy B can be in concentrations up to 50

per cent at the boiling point and that the tempera-

ture limit for HASTELLOY alloy C-276 would be

somewhat less than with Alloy B. Temperature

limitations in caustic soda concentrations

Table XVIII

Corrosion of HASTEllOY Alloys Band C

in Caustic Soda Solutions 18

NaOH

Temperature Corrosion Rate. mils per year

Concen-

tration. HASTEllOY HASTELlOY

% C F alloy B aUoyC

5 Room Room Nil Nil

5 66 150 Nil Nil

5 102 215 Nil Nil

to Room Room Nil Nil

10 103 217 <2 220

10 121 250 220

20 107 225 <2 220

25 Room Room Nil Nil

25 66 150 Nil Nil

30 166 240 <2 220

40 Room Room Nil Nil

40 128 261 <2 2-20

50 Room Room Nil Nil

50 66 150 Nil Nil

50 144 291 <2 220

50 400 750 152

60 165 328 220 220

70 191 375 220 2-20

Note: I) N.t means no measurable corrosion was observed in five

24hour test periods.

2) 2-20 means corrosion (ate was within this range.

than 50 per cent C.lllnot be determined with the

exi::;ting data. HASTELLOY alloy C and INCONEL

alloy 625 were both found to be subject to stre::;s-

corrosion cracking in seven-day tests in aerated

90'; NaOH at 300 C (572 F). but did not crack if

was Sub5tituted for the air in tests at the

Paul D. Merica Laboratory of The Inter-

national Xickel Company. Inc.

Table XVII

HaOH

toncel}-

tration.

%

10

10

13

74

Iron Base Nickel-Chromium-Copper-Molybdenum Alloys

and

Nickel Base ChromiumCopper-Molybdenum Alloys

in Caustic Soda Solutions

Temperature

C F

24 75

66 150

95100 203212

130 265

Test

Period.

days

111

II trips

of 79 days

16

Comments

laboratory test.

INCOLOY alloy 825

laboratory test.

INCOlOY alloy 825

Test tank simulating

action of lank car.

WORTHITE stainless steet

rest iOl tank car.

CARP[NHR alloy 20

Corrosion

Rate.

mils per year

<0.1

<0.1

0.2

0.30.9

I. Cast Irons and Ni-Resists

The beneficial etred of nickel additions 011 the

corro:,ioll t'esistance of cast irons in moderately

concentrated caustic alkali is shown by data in

Tables XIX, XX Hnd XX I. It is evident that nickel

contents of 20 to 30 per cent pro\'ide vet'y marked

improvement in resistance to corrosion as com-

pared 'with unalloyed cast iron. It is also apparent

that as lo'w as 3 to 5

c

; nickel may improve the

corrosion resistance of cast iron in some con-

centration ranges,

Table XIX

Effect of Nickel Additions on Corrosion Rates

of Cast Irons in 50 to 65% Caustic Soda

Temperature: Boiling under 26 in. (mercury) vacuum.

Duration: 81 days.

Nickel, %

o

o

o

3.5

5

15

20

20 (plus 2% Chromiuml

30

Corrosion Rate,

mils per year

73

91

86

47

49

30

3.3

S.O

0.4

In practice. the nickel cast irons most widely

used with caustic solutions, where minimum con-

tamination of the caustic is desired. are the Ni-

Resist alloys and their spheroidHl graphite coun-

terparts. the ductile Ni-Resist alloys, The corro-

sion rates of these alloys fora number of different

exposures are shown in Table XXII.

Table XX

Corrosion of Nickel Cast Irons in the

Evaporation of Caustic Soda from 37 to 50 Per Cent

Average Temperature: 120 C (248 F).

Duration: 51 days.

Corrosion

Nickel, Chromium, Copper, Silicon. Carbon. Rate.

% % % % % mils per year

28.60 1.71 1.30 2.87 17

28.37 1.50 2.72 18

14.26 2.39 6.08 1.62 3.15 22

19.40 1.42 3.15 24

19.02 2.90 1.22 3.18 28

20.53 1.25 2.91 31

17

Fig. 11 - Moiten sodium hydroxide at an initial tempera

ture of 370 C (700 F) is converted to flake caustic by this

flaker and breaker. All surfaces exposed to caustic are nickel

except for l'li'Resist Type 3 cooling drum.

Table XXI

Plant Corrosion Test in 74%

Caustic Soda in Storage Tank

Specimens exposed for total of 32 days (20 days in liquid

and 12 days in vapor).

Corrosion rates based on 20 days exposure to liquid.

Temperature:. 125 C (260 n.

Material

MONEl. alloy 400

H.i-Resist Type 3

HiResist Ductile rron Type 02

Hi-Resist TYlIe 2

Type 304 Stainless Steel

Mild Steel

Cast Iron

Corrosion Rate,

mils per year

0.9

2.5

5

6

15

75

76

Copper-free Ni-Resist Type 2 may be used in

preference to Xi-Resist Type 1 (6.50:-; copper)

where it is desired to keep copper content of the

solution at a minimum, The 30

r

;. nickel cast iron

(Ni-Resist Type 3), in addition to having some-

what g-rcater resistance to corrosion by hot caus-

tic solutions than Ni-Resist TypeS 1 and 2, has a

low coefticient of expansion, an advantage for

expOSUI"C conditions invo!\'ing sudden changes in

temperature.

Of the fi\'e basic types of Type 3 ap-

pear:' to be the best suited to meet the require-

ments for caustic sen"ice. !'\i-l1e::;ist Type 3 or

Type D3 can be con::;idered as alternate materials

to nickel and the high nickel alloys for caustic

soda concentrations up to 73 per cent, but nickel

is preferred for higher concentrations.

There have been occasional stress-corrosion

cracking failures with the Ni-Resists in high-

chloride aqueous environments. Although these

environments did not include caustic soda, it

\\"ollld appear a reasonable precaution to stress-

reliew these alloys at 677 C (1250 F) for one

hour before use in hot caustic soda solutions.

Table XXII

Corrosion Rates of the Ni-Resists in Caustic Soda

Corrosion Rate. mils per year

NaOH

'" '" '" '"

c

C>

Concen-

Temperature

Test

";:;fN "Vi v

tration, Period,

"'", "'", "'", "'", .- '"

'70.. '70.. '70.. '70..

'" % C F Aeration Agitation days - >-

.- >. .- >. .- >. =:Ii ..!. >..

'"

x>- X..- 201- XI- c2O>- c..>

8.5-9 82 180 None due to 32 plus 1515.5% 2.5 0.8 1.5 15

filling tank NaCI in storage

tank

10 88 190 Moderate due to 279 plus 12');' NaCl

0.2 4

filling tank in storage tank

I

!

14 88 190 None due loevap. 90 lirst eHect of

i

8

multiple effect !

evaporator

I

23 93 200 Moderate Medium 48 plus 7-8% NaCI 1.2 21

in salt settler

30 85 185 Moderate Moderate 82 plus heavy con- 0.8 0.4 0.1 0.5 6

centratlOn of

suspended NaG!

in sail settler

35-45 116 240 Moderate Small 24 plus 6-7% NaGI 3.3 49

in salt settler.

Intermittent ex-

I

posure to vapor

49-51 55 149 None due to 30 storage tank

I

II

filling tank

50 55 131 Moderate 1.8 Ips 173 plus heavy con- 0.5 0.2 I <0.1 0.2 1.2

cen,ration of

,

I

I

suspended NaC!

I

in transfer line

I I

50 71-104 160-220 Moderate 1 Ips llS plus 1015% NaG! OA 6

in cooling tank

50 95 203 Moderate 1.8 Ips 67 plus heavy con- 1.0 0.6 0.4 11

cent ration of

suspended NaGl

in transfer line

50 21-127 70-260 None None 10 days

@250F

laboratory test 4.7 5.0

& 4 days

@70r

50-65 Boiling None due to evap. 81 30 3.3 OA 86

50-70 121 250 None due to evap. 10 in evaporator

90 290

72 121 250 Moderate very small 1]9 star age lank 4.7 15

74 127 260 Above & Slight 20 specImens

6 2.5 5.5

Below

exposed in storage

liquid

lank for 32 days

level

(20 days in liquid

and 12 days in vaporl.

Corrosion

rales based on 20 days

I None

exposure in liquid

!60

100 510 950

Moderate 14 concentratIOn in 70 87 534 60 141

open pot

18

PART III. CORROSION BY OTHER ALKALIES

A. Caustic Potash (KOH)

Caustic potash is produced by the electrolysis

of muriate (potassium chloride) brine. Several

types and concentrations of KOH are available,

but 45 and 50 per cent liquid and 85 and 90 per

cent solid are most commonly marketed. Above

about 50 per cent concentration, caustic potash

has a higher boiling point than caustic soda of

the same concentration. This differential is espe-

cially pronounced at high concentrations. For

this reason. the commercial product is usually not

concentrated above 90 per cent because of the

high temperatures involved.

In general. those materials which are useful in

caustic soda are also suitable for caustic potash.

Nickel 200 and INCONEL aHoy 600 are both suit-

able for service in hot caustic potash. as indicated

by the data presented in Table XXIII. Negligible

data exist for other nickel alloys in caustic potash.

Gegner has suggested that because caustic potash

is so similar to caustic soda. the corrosion data in

caustic soda of similar concentration and tem-

perature can be used to approximate corrosion

resistance in caustic potash. Iff

Under extreme conditions, some nickel alloys

are subject to stress-corrosion cracking in caustic

potash solutions. However, the information pre-

sented in Tables IX and X suggests that stress

corrosion cracking of Alloy 600, Alloy 400 and

Alloy K-500 is not quite as severe with caustic

potash as with caustic soda.

The beneficial effect of nickel in cast iron ex-

posed to caustic potash is shown in Table XXIV.

The reductions in corrosion rates are similar to

those obtained in caustic soda solutions.

Table XXV shows the results of laboratory cor-

rosion tests of several Ni-Resist alloys in hot. con-

centrated caustic potash. Lower corrosion rates

would be expected with a decrease in either tem-

perature or caustic potash concentration. Ni-

Resist Type 3 appears to have equivalent, and

sometimes superior. corrosion resistance in com-

parigon to Types 1 and 2.

Table XXIII

KO"

COllcen-

tration.

%

13

30

47

50

50

50

10

10

Temperature

C F

30 85

113 236

139 281

28 82

150 300

.

150 300

150 300

150 300

Aeration

None

None

None

None

None

None

None

None

Corrosion Tests in Caustic Potash Solutions

Agitation

due to

filling tank

Boiling

Boiling

due to

lilting lank

2\.61pm

3481pm'

21.6fpm

3481pm"

Test

Period.

days

207

26

26

207

7

35

7

35

Comments

storage tank impurities-

K Jeo J 3 gpl. KCf 170 gpl.

KClO .. 0.1%

laboratory test-saturated

with KCf. 0.05% KClO,

laboratory test-saturated

with KG\. 0.18% KClO,

storage tank impurilies-

K,CO. 0.3%. KGI 0.75%.

KGto, 0.10%

laboratory test-UBend

specimen showed

no cracking

laboratory test

laboratory test

laboratory test

nil-less than 0.05 mils pel'" year. l-liQuid V-Vapor

." Specimens m ~ v e at th!s veloc11y fof'" 8 hr each working day and at zero ft per mtn overn1ght and duong

weekends. Th,s was equlvatent to ten 24 hour days at the high velocity rate.

19

Corrosion Rate. mils per year

Nickel

200

nil'

l. 0.2

V.0.3

l. 0.1

V.O.3

nil

nil

nil

0.4

1.6

INCONEl.

alloy

600

nil

l. 0.1

V.O.1

l. 0.4

V.O.1

nil

0.5

0.5

0.7

5.7

MONEl.

aUoy

400

nil

nil

Table XX'V

Effect of Nickel in Cast Iron

on Corrosion by Caustic Potash

Concentration: 950 g KOH per liter.

Temperature: 400 C (750 F).

Nickel Content of Alloy Iron,

%

o

3

6.5

12.4

Table XXV

Corrosion Rate,

mils per year

21-30

3.0

2.0

0.4

Corrosion of Ni-Resists in Caustic Potash

Hi-Resist ClIrrosjon Rate,

Type Exposure mils per year

1 68-hour test in 81 % KOlt at 225 C (437 f) 30

2 68-hour test in 81% KOH at 225 C (437 f) 20

3 68-hour test in 81 % KOH at 225 C (437 f) 10

2 36-hour test in 92% KOlt at 268 C 1516 f) 10

3 3S-hour test in 92% KOlt at 268 C (516 f) 10

B. Ammonia and

Ammonium Hydroxide

Most of the nickel-base alloys, with the exception

of the nickel-copper alloys and nickel itself, resist

all concentrations of ammonium hydroxide up to

the boiling point.

Among the nickel-containing alloys, the aus-

tenitic stainless steels are most frequently em-

ployed in ammonia and ammonium hydroxide

solutions. Austenitic stainless steels exhibit good

resistance to all concentrations of ammonia and

ammonium hydroxide up to the boiling point.

Tables XXVI through XXIX show the results of

plant corrosion tests in ammonia- and ammonium

hydroxide-containing process streams.

Stone .determined that Type 304 stainless steel,

which had been sensitized at 677 C (1250 F) for

one hour, was not subject to intergranular corro-

sion during a 40-week exposure in 28% NH4 0H

at room temperature.

12

However, this resistance

does not extend to elevated temperatures in com-

mercial solutions, as shown in Table XXVI.

20

Considerable amounts of Types 316 and 316L

stainless steels are used in the ammonia-soda

process for the production of soda ash (Na2C03 ).

The main reaction involves the carbonation of an

ammoniated brine to form sodium bicarbonate

and ammonium chloride. The ammonia is recov-

Table XXVI

Plant Corrosion Test in Ammonia

Surge Vessel of Urea Manufacturing Plant

Solution: 22% NH, 71 % H,O, 7% CO, and trace of

NH.NO, .

Temperature: 66C (150 F).

Test Period: 300 days.

Aeration: None.

Agitation: Moderate.

Location: Uquid phase at bottom of aqua ammonia surge

vessel.

Material

INCOlOY alloy 825

Type 347 Stainless Steel

Type 316 Stainless Steel

Type 304 Stainless Steet

Type 316 Stainless Steel <Sensitized)

CARPENTER alloy 20

INCONEL alloy 600

Type 304 Stainless SteellSensitized)

Type 410 Stainless Steel

Mild Steel

Table XXVII

Corrosion Rate,

mUs per year

<0.1

<0.1

<0.1

0.3

0.3

0.4

3.4

7.6

Missing-presumed

corroded away

Missing-presumed

corroded away

Plant Corrosion Test in Mixed Ammonia-Carbon

Dioxide Gas Stream in a Chemical Plant

Gas: Mixture of NHJ and CO2 with probably some moisture

present.

Temperature: 20 to SOC (68 to 176 F).

Test Period: 68 days.

Aeration: None.

Agitation: Gas flow.

Location: Suspended in gas stream.

Material

Type 304 Stainless Steet

Type 316 Stainless Steel

MONEL alloy 400

tNCONEL alloy 600

Mild Steel

Nickel 200

Silicon Bronze

Nil == Less than 0.01 mill><" year.

Corrosion Rate,

mils per year

Nil

Nil

2.2

3.0

5.1

5.3

72

Table XXVIII

Plant Corrosion Test in Ammonia-Carbon

Dioxide Gas Stream in a Metal Refining Plant

Gas: 26% NHJ 14% CO,. balance water vapor.

Temperatur-e: 66 ro 93 C (150 to 200 F); Average 82 C

(l80 F).

Test Period: 65 days.

Aeration: Moderate.

Agitation; 25 to 40 fps gas flow.

Location: H C O ~ stripping still overhead line.

Material

Type 202 Stainless Steel

Type 304 Stainless Steel

Type 316 Stainless Steel

INCOlOY alloy 825

INCOLOY alloy 800

INCONEl alloy 600

Type 410 Stainless Steel

Type 502 Stainless Steel

Mild Steet

Table XXIX

Corrosion Rate.

mils per year

<0.1

<0.1

<0.1

<0.1

1.5

4.1

0.1

20

22

Plant Corrosion Test in Contaminated

Ammonia Vapors in a Coke By-Products Plant

Gas: Ammonia vapors plus H,S. CO,. HCN. phenols and

steam.

Temperature: 100 to 110 C (212 to 230 F); Average 105 C

(221 F).

Test Period: 144 days.

Aeration: None.

Agitation: High velocity gas flow.

location: Ammonia liquor still vapor outlet.

Material

Type 304 Stainless Steel

Type 316 Stainless Steel

I NCONEl alloy 600

Mild Steel

MONEL alloy 400

Nickel 200

Nil "" 1.ess tban 0.04 mils per year.

Corrosion Rate,

mils per year

KiI-

Nil'

0.1

S.O

>40

(corroded away)

>40

(corroded away)

ered in this process for reuse. Table XXX shows

corrosion rates for metals and alloys in an am-

monia recovery still in a soda ash plant. The pos-

sibility of pitting must be taken into account in

the design of equipment where there are such

high chloride levels, so as to avoid crevices where

chlorides can concentrate to even higher levels

and promote crevice corrosion.

21

Table XXX

Plant Corrosion Test in Ammonia Recovery Still,

Ammonia-Soda Process for Production

of Sodium Carbonate

Middle Section

Temperature: 60 to 71 C (140 to 160 F).

Liquor Composition: 2% NHl , 9% NH.CI,

14% NaCl, 2% CO2

Test Period: 220 days.

Top Section

Temperature: 60 to 71 C (140 to 160 F).

Liquor Composition: 5% NHl 9% NH.CI,

14% NaCl, 3.4% CO2

Test Period: 220 days.

Corrosion Rate, mils per year

Middle lop

Material Section Section

Type 316 Stainless Steel OJ 0.1

Zirconium 0.1 0.1

Titanium 0.1 0.2

HASTEllOY alloy C 0.1 14'

Nickel 200 >33" >32"

Mild Steet >73" >71"

Specimen pitted in crevice beneath insulating wasber.

Specimens cQrroded away ..

Nickel is not attacked by anhydrous ammonia,

but is resistant to ammonium hydroxide solutions

in concentrations only up to about one per cent.

Aeration may induce passivity in concentrations

under 10 per cent, but even in the presence of air,

more concentrated solutions are highly corrosive

to nickel. The corrosion data shown in Table XXXI

were obtained in room-temperature laboratory

tests ()f 48-hour duration in one normal ammo-

nium hydroxide, following a previous 48-hour ex-

Table XXXI

Corrosionof Nickel 200 in One Normal

Ammonium Hydroxide (1.7% NHa)

Test Condition

Total Immersion

Quiet

Air"'Agitated

Alternate Immersion

Conti!luous

lntermittent

Spray {4 to 30 Daysl

Corrosion Rate,

milspllryear

0.8

<0.1

2.7

0.4

<0.1

Specimens exposed at room temperature tor 2 days after a previous

2-day exposure except for spray expo'Sure.

posure. The of 20-hour tests in highly

agitated ammonium hydroxide solutions at room

tempelature are shown in Table XXXII. Typical

corrosion rates for Nickel 200 in several indus-

trial exposures are also given in Table3 XXVII,

XXIX and XXX.

Table XXXU

Corrosion of Nickel 200 in

Ammonium Hydroxide Solutions

NH.OH Cancentration,

%

1.1

12.9

20.2

27.1

CCIfI"lISion Rate,

mils per year

o

560

370

180

Tests run to agitated solution at room temperature for 20 hours.

Nickel-copper alloys. such as Alloy 400, are re-

sistant to anhydrous ammonia and are slightly

more resistant than commercially pure nickel in

ammonium hydroxide solutions. as shown in Table

XXXIII. However, their usefulness is restricted

to dilute solutions up to about 3<1 ammonium

hydroxide. In solutions of higher concentration.

corrosion rates are increased considerably by

aeration and agitation.

TableXXXm

laboratory Corrosion Tests of

MONEL alloy 400 in Ammonium Hydroxide

Temperature: Room. Test Period: 20 hours.

Agitation: 371 feet per minute.

HH3 Cancentration,

%

2.7

3.6

5.5

8.2

11.1

18.3

25.8

Carrosian Rate,

mils per year

o

70

298

317

327

231

36

C. Other Alkaline Solutions of

Sodium and Potassium Salts

Salts as sodium sulfide. sodium carbonate,

sodium silicates, trisodium phosphate and others

form alkaline water solutions. These alkaline