Académique Documents

Professionnel Documents

Culture Documents

Stellite 6 Data Sheet

Transféré par

Arlen NurlanDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Stellite 6 Data Sheet

Transféré par

Arlen NurlanDroits d'auteur :

Formats disponibles

H A R D FA C I N G A L L O Y D I V I S I O N

S T E L L I T E 6 ALLOY

TIG & OXY-ACETYLENE WELDING

T E C H N I C A L D ATA

MIG WELD DEPOSITION PTA & LASER WELD DEPOSITION Thermal Spray Deposition

MMA WELD DEPOSITION

Nominal Composition (mass %) and Physical Properties Co

Base

Cr

27 - 32

W

4-6

C

0.9-1.4

Others

Ni, Fe, Si, Mn, Mo

Hardness

36-45 HRC 380-490 HV

Density

8.44 g/cm-3 0.305 lb/in3

Melting Range

2340-2570 F 1285-1410 C

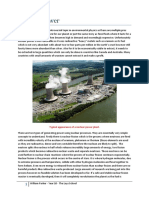

Stellite cobalt base alloys consist of complex carbides in an alloy matrix. They are resistant to wear, galling and corrosion and retain these properties at high temperatures. Their exceptional wear resistance is due mainly to the unique inherent characteristics of the hard carbide phase dispersed in a CoCr alloy matrix. Stellite 6 is the most widely used of the wear resistant cobalt based alloys and exhibits good all-round performance. It is regarded as the industry standard for general-purpose wear resistance applications, has excellent resistance to many forms of mechanical and chemical degradation over a wide Scanning Electron Micrograph of Cast Stellite 6 at 1000x magnification. temperature range, and retains a reasonable level of hardness up to 500C (930F). It also has good resistance to impact and cavitation erosion. Stellite 6 is ideally suited to a variety of hardfacing processes and can be turned with carbide tooling. Examples include pump shafts, bearings and valve contact surfaces in the Oil & Gas and Power Generation industries; combustion engine valves; erosion shields; thermowells; hot forging clipping tools and bearing bushes. It is often used self-mated. Corrosion Resistance The typical electrode potential in sea water at room temperature is -0.25V (SCE). Like stainless steels, Stellite 6 corrodes primarily by a pitting mechanism and not by general mass loss in seawater and chloride solutions. Its mass loss in sea water is below 0.05mm per year at 22C. More information regarding corrosion resistance can be provided on request. Teknokraft Asia Jakarta 021-7805402 teknokraft@teknokraft.com

Nominal Thermal Expansion Coefcient (from 20C/68F to stated temperature) 100C (212F) m/m.K -inch/inch.F 11.35 6.31 200C (392F) 12.95 7.20 300C (572F) 13.6 7.56 400C (752F) 13.9 7.72 500C (932F) 14.2 7.89 600C 700C 800C 900C 1000C (1112F) (1292F) (1472F) (1652F) (1832F) 14.5 8.06 14.7 8.17 15.05 8.36 15.5 8.61 17.5 9.72

Nominal Tensile Properties at Room Temperature Ultimate Tensile Strength Rm ksi Castings Stellite HS-6 (*)

Yield Stress Rp(0.2%) ksi 101.5 109 MPa 700 750

Elongation A(%) <1 3-5

Elastic Modulus psi 30.3x10 34x10

6 6

MPa 850 1265

GPa 209 237

123 183.5

(*) HS = HIP-consolidated. Ref: Ashworth et al. Powder Metal. 1999 42[3] p.243-249 and internal tests.

Nominal Hot Hardness (DPH) as-cast 20C (68F) 410 100C (212F) 390 200C (392F) 356 300C (572F) 345 400C (752F) 334 500C (932F) 301 600C (1112F) 235 700C (1292F) 155 800C (1472F) 138 900C (1652F) 95

Thermal and Electrical Properties Approximate value at Room Temperature Thermal conductivity Electrical resistivity 14.82 W/m.K 106 -ohm.cm 102.7 Btu-in/hr/ft2/F 41.7 -ohm.inch

Product Forms and Cross Reference Specications

Stellite 6 is available as welding wire, rod, powder, and electrodes; nished castings and P/M parts. Deloro Stellite also oers hardfacing services. A separate brochure is available for the wrought forms of this alloy, namely Stellite 6B and Stellite 6K. Stellite 6 can be supplied to the following specications: SPECIFICATION PRODUCT FORM SPECIFICATION PRODUCT FORM

UNS R30006 UNS R30106 UNS W73006 UNS W73036 UNS 5387 AMS 5788

Rod, Castings P/M Parts Electrode Wire Castings Rod, Wire

AWS A5.21 / ASME BPVC IIC SFA 5.21 ERCoCr-A AWS A5.21 / ASME BPVC IIC SFA 5.21 ERCCoCr-A AWS A5.13 / ASME BPVC IIC SFA 5.13 ECoCr-A

Rod Wire Electrode

Stellite is a registered Trade Name of Deloro Stellite.

Deloro Stellite manufactures sophisticated alloys in the form of castings, powders, coatings, consumables, and machined parts that resist wear, corrosion, and abrasion. Information provided in this document is intended only for general guidance about Deloro Stellite products and is the best information in our possession at the time. Product users may request information about their individual use of our products, but Deloro Stellite does not warrant or guarantee this information in any way. Selection and purchase of Deloro Stellite products is the sole responsibility of the product user based on the suitability of each use. Individual applications must be fully evaluated by the user, including compliance with applicable laws, regulations, and non-infringement. Deloro Stellite cannot know or anticipate the many variables that aect individual product use and individual performance results may vary. For these reasons, Deloro Stellite does not warrant or guarantee advice or information in this document, assumes no liability regarding the same, and expressly disclaims any warranty of any kind, including any warranty of tness for a particular purpose, regarding the same.

UK SALES OFFICE

US SALES OFFICE

CHINA SALES OFFICE

Deloro Stellite Cheney Manor Industrial Estate Swindon SN2 2PW UK Tel: (+44) 1793-498500 Fax: (+44) 1793-498501 E-Mail: saleshad@stellite.com DSHFAD/ST6/R1.0 / SC-1938 Copyright 2007 Deloro Stellite Printed in USA www.stellite.com

Stellite Coatings 1201 Eisenhower Drive North Goshen, Indiana 46526 USA Tel: (+1) 574-534-2585 Fax: (+1) 574-534-3417 E-Mail: saleshad@stellite.com

Shanghai Stellite Co. Ltd. 1799 Bao Jia Road Jia-Ding District , 201800 Shanghai, Peoples Republic of China

Teknokraft Asia Jakarta

021-7805402

teknokraft@teknokraft.com

Vous aimerez peut-être aussi

- CTS S Solarflex FolderDocument6 pagesCTS S Solarflex FolderArlen NurlanPas encore d'évaluation

- Gauge - Pole - Cover - For - Floating - Roof - Tanks LR PDFDocument2 pagesGauge - Pole - Cover - For - Floating - Roof - Tanks LR PDFArlen NurlanPas encore d'évaluation

- EN10060 HotRolledParts DimensionaandTolerancesDocument12 pagesEN10060 HotRolledParts DimensionaandTolerancesEidrish ShaikhPas encore d'évaluation

- Lean Manufacturing-SMART-R1 PDFDocument29 pagesLean Manufacturing-SMART-R1 PDFArlen NurlanPas encore d'évaluation

- MaterialsDocument2 pagesMaterialsAkshay PoddarPas encore d'évaluation

- Applicable Codes and StandardsDocument48 pagesApplicable Codes and Standardskiki270977Pas encore d'évaluation

- EN10060 HotRolledParts DimensionaandTolerancesDocument12 pagesEN10060 HotRolledParts DimensionaandTolerancesEidrish ShaikhPas encore d'évaluation

- Lean Manufacturing-SMART-R1 PDFDocument29 pagesLean Manufacturing-SMART-R1 PDFArlen NurlanPas encore d'évaluation

- Aws b5.9 Specification For The Qualification of Welding SupervisorsDocument15 pagesAws b5.9 Specification For The Qualification of Welding SupervisorsJose EstibenPas encore d'évaluation

- Torit Cyclone CollectorsDocument4 pagesTorit Cyclone CollectorsArlen NurlanPas encore d'évaluation

- Kepmen No 275 1989Document3 pagesKepmen No 275 1989Arlen Nurlan100% (1)

- ITSC Bid For 2016 in MelbourneDocument1 pageITSC Bid For 2016 in MelbourneArlen NurlanPas encore d'évaluation

- Thermal Metal SprayingDocument4 pagesThermal Metal SprayingArlen NurlanPas encore d'évaluation

- AcceptedPractices1 - Modified Layer Removal Method For Evaluating Residual Stresses in Thermal Spray CoatingsDocument25 pagesAcceptedPractices1 - Modified Layer Removal Method For Evaluating Residual Stresses in Thermal Spray CoatingsArlen NurlanPas encore d'évaluation

- Safety1 - Guidelines For The Use of Personal Protective Equipment in Thermal SprayingDocument33 pagesSafety1 - Guidelines For The Use of Personal Protective Equipment in Thermal SprayingArlen NurlanPas encore d'évaluation

- AcceptedPractices1 - Modified Layer Removal Method For Evaluating Residual Stresses in Thermal Spray CoatingsDocument25 pagesAcceptedPractices1 - Modified Layer Removal Method For Evaluating Residual Stresses in Thermal Spray CoatingsArlen NurlanPas encore d'évaluation

- Thermal SprayingDocument91 pagesThermal Spraying12345marian100% (1)

- Safety1 - Guidelines For The Use of Personal Protective Equipment in Thermal SprayingDocument33 pagesSafety1 - Guidelines For The Use of Personal Protective Equipment in Thermal SprayingArlen NurlanPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Dental Materials: Metals (Alloys) Non-MetalsDocument32 pagesDental Materials: Metals (Alloys) Non-MetalsShahriar honarmandPas encore d'évaluation

- Nuclear Power: Pros, Cons and FutureDocument4 pagesNuclear Power: Pros, Cons and FutureSamarthPas encore d'évaluation

- Astm B479 19Document3 pagesAstm B479 19mohamedsamireldeep70Pas encore d'évaluation

- Ammonia Synthesis Process OverviewDocument31 pagesAmmonia Synthesis Process OverviewKhalid AkPas encore d'évaluation

- Equivalent Valve Forged Cast PDFDocument2 pagesEquivalent Valve Forged Cast PDFAlessandro Marcio LiraPas encore d'évaluation

- Lab 2 - StoichiometryDocument4 pagesLab 2 - Stoichiometryapi-272470922100% (3)

- Coconut Shell Based Activated Carbon W No Greeen House Gas EmissionDocument4 pagesCoconut Shell Based Activated Carbon W No Greeen House Gas Emissionmragul22Pas encore d'évaluation

- SodaPDF-converted-Exercise No. 7 - Soil Sample Collection and PreparationDocument30 pagesSodaPDF-converted-Exercise No. 7 - Soil Sample Collection and PreparationJacky Lou GermanoPas encore d'évaluation

- Biochem Proteins ReviewerDocument4 pagesBiochem Proteins ReviewerStefany JoyPas encore d'évaluation

- Colorimeter Principle PDFDocument2 pagesColorimeter Principle PDFNicholasPas encore d'évaluation

- HPLC ExperimentDocument4 pagesHPLC ExperimentFrances PaulinePas encore d'évaluation

- Fermi DistrbutionDocument17 pagesFermi DistrbutionnazarPas encore d'évaluation

- BCH 2202 Chemical Thermodynamics ModuleDocument84 pagesBCH 2202 Chemical Thermodynamics Modulefrancis100% (5)

- CarbonicAnhydrases Manuscript withDOIDocument11 pagesCarbonicAnhydrases Manuscript withDOIFadhil MiftahulPas encore d'évaluation

- Vortex Quantum SeriesDocument34 pagesVortex Quantum SeriesmiguelcPas encore d'évaluation

- Polysiloxane CoatingsDocument8 pagesPolysiloxane CoatingsminhnnPas encore d'évaluation

- VAPOR AND COMBINED POWER CYCLESDocument9 pagesVAPOR AND COMBINED POWER CYCLESzabidullahPas encore d'évaluation

- XY-6S-10 English ManualDocument28 pagesXY-6S-10 English ManualShishir Kumar100% (1)

- Hazop StudyDocument7 pagesHazop StudyAnderson JoePas encore d'évaluation

- Rongalit ST LiqDocument11 pagesRongalit ST LiqMayank DhawanPas encore d'évaluation

- 1229.1 Steam Sterilization by Direct ContactDocument3 pages1229.1 Steam Sterilization by Direct ContactWasimPas encore d'évaluation

- Exp 2 Protein DeterminationDocument5 pagesExp 2 Protein DeterminationNur Fadhilah100% (1)

- SEPCO 12 Productos de Fibra de VidrioDocument3 pagesSEPCO 12 Productos de Fibra de VidrioVictor Flores ResendizPas encore d'évaluation

- Tea Processing: How Leaves Become Black Tea in 4 StepsDocument27 pagesTea Processing: How Leaves Become Black Tea in 4 StepsSaidur Rahman KhanPas encore d'évaluation

- Erba URIC ACID DESDocument2 pagesErba URIC ACID DEShexamed bme100% (1)

- Ganoderma laccase optimizationDocument9 pagesGanoderma laccase optimizationRajeshKumarPas encore d'évaluation

- PH Scale BrochureDocument1 pagePH Scale BrochureMherwin RetanalPas encore d'évaluation

- Corrosion of Iron: An Electrochemical ProcessDocument5 pagesCorrosion of Iron: An Electrochemical ProcessVickyPas encore d'évaluation

- Chemical Injection SkidDocument6 pagesChemical Injection SkidRaheel SultanPas encore d'évaluation