Académique Documents

Professionnel Documents

Culture Documents

Dextrozyme Application Sheet

Transféré par

I. Murali KrishnaCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Dextrozyme Application Sheet

Transféré par

I. Murali KrishnaDroits d'auteur :

Formats disponibles

Page 1 of 5

Starch - Saccharification

Application Sheet

Content: ! Benefits ! Products

Enhanced dextrose syrup production

Production of dextrose syrups is a well-established process. The enzyme application is rather complex with final syrup requirements determining the optimum saccharification parameters. This also includes the choice of enzyme. Novozymes offers a range of saccharification products designed to cover the entire application spectrum. Benefits

Novozymes saccharification product range provides the following: ! Higher dextrose yield due to lower reversion rate ! Low risk of syrup infections by running at up to 64C ! Stable process allowing for variations in temperature

! Performance ! Usage

Products

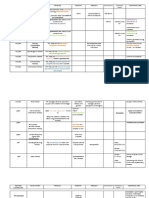

Table 1 provides an overview of process conditions and Novozymes product range characteristics in application. Characteristics Main raw material Dextrose yield target Low reversion rate Smooth wheat syrup filtration High-temperature saccharification Dextrozyme GA and GA 1.5X corn <= 96% +++ ++ Up to 64C Up to 147F Dextrozyme DX and DX 1.5X corn > 96% ++++ + Up to 64C Up to 147F

+++++ = best performance and most recommended. Table 1.Provides an overview of process conditions and characteristics in application

Dextrozyme DX 1.5X gives 1.5 times the performance of Dextrozyme DX. The dose can therefore be reduced. Likewise, Dextrozyme GA 1.5X gives 1.5 times the performance of Dextrozyme GA.

Page 2 of 5

For saccharification of wheat starch, a combination of Finizym W and Dextrozyme DX or Dextrozyme DX 1.5X is recommended. See section on smooth wheat syrup filtration. There is more information about the above-mentioned products available at the Customer Centre.

Performance

Higher dextrose yield and lower reversion rate Figure 1 shows the dextrose development of Dextrozyme DX and Dextrozyme GA under standard saccharification conditions and at different doses.

97

96 Dextrozyme DX 0.84 kg/tDS Dextrozyme GA 0.84 kg/tDS Dextrozyme DX 0.72 kg/tDS Dextrozyme GA 0.72 kg/tDS Dextrozyme DX 0.48 kg/tDS Dextrozyme GA 0.48 kg/tDS

95

Dextrose, %

94

93

92

91 30 50 70 90

Time (h)

Figure 1. Dextrose formation for Dextrozyme GA and Dextrozyme DX. Dry solids: 31% (initial), pH 4.3, 61C (142F), starting DE 10-12 (liquefied with Liquozyme X).

As seen in Figure 1, dextrose maxima are achieved very quickly and are very stable before isomaltose is produced and dextrose levels are reduced. This is due to the high performance of the acid alpha-amylase (for Dextrozyme GA and Dextrozyme GA 1.5X) and pullulanase/acid alpha-amylase (for Dextrozyme DX and Dextrozyme DX 1.5X), which means that lower levels of glucoamylase activities can be used to obtain high saccharification performance. Because of these lower levels of glucoamylase, the reversion of glucose into isomaltose is reduced to the absolute minimum. Peak levels can therefore be maintained for much longer and production variations can be tolerated.

Page 3 of 5

On average, it is possible to achieve dextrose levels that are up to 0.5% higher using Dextrozyme DX or Dextrozyme DX 1.5X rather than Dextrozyme GA or Dextrozyme GA 1.5X. The influence of dry substance on the maximum dextrose peak is given in Figure 2. Here we see that there is a negative effect of high dry substances on the maximum dextrose levels. This effect is the same for Dextrozyme DX products and Dextrozyme GA products. For every 1% increase in dry substance (initial), there is a decrease in final dextrose level of about 0.15%.

97

Dextrose, %

96,8 96,6 96,4 96,2 96 95,8 95,6 95,4 95,2 27 29 31 33 35 37 Dextrozyme DX Dextrozyme GA

Initial dry substance, %

Figure 2. Impact of initial dry substance on dextrose content after 66 hours saccharification. Enzyme dosages: 0.84 kg/t DS, pH 4.3, 61C (142F), starting DE 10-12 (liquefied with Liquozyme X).

Smooth wheat syrup filtration Smooth filtration on a rotary vacuum filter is crucial to wet millers. To obtain this, a combination of Dextrozyme and Finizym W is recommended for wheat starch processing. As Finizym W contains lysophospholipase, it will induce flocculation of the non-starch fat-protein complexes in wheat starch-based syrups. As a result, improved filtration rates are possible with a better clarity of the filtrate. A dramatic reduction in filter aid consumption is also possible. Better filtration improves the performance of the cation resin after filtration. Corn-based dextrose syrups have filtration speeds up to 700-1200 l/m2/h. Without the use of lysophospholipase side activity, the filtration speed on dextrose syrups based on wheat B-starch would be in the range 50-150 l/m2/h, as well as the bad filtrate quality! Using the combination of Dextrozyme and Finizym W, the filtration speed can be increased to corn levels. High-temperature saccharification Another important issue is the stability of the glucoamylases in relation to temperature. Saccharification is normally carried out at about 60-61 (140142F) to ensure microbiological stability. Nevertheless, occasionally infections can occur that decrease the pH of the saccharification and hence the activity of the glucoamylase.

Page 4 of 5

Depending on the saccharification time, saccharifications with Dextrozyme GA or Dextrozyme GA 1.5X can be carried out at higher temperatures. If the saccharification time is < 40 hours, saccharification temperatures of 64C can be used. For longer saccharification times, temperatures of 61C are recommended. The influence of temperature on dextrose development can be seen in Figure 3.

96,5

% Dextrose of total sugars

96,0 95,5 95,0 94,5 94,0 30 40 50 60 70 80 90

Saccharification time [hours]

60C 62C 64C

Figure 3. Influence of saccharification temperature on dextrose development for Dextrozyme GA Dry solids 31% (initial), pH 4.3, 61C (142F), starting DE 10-12 (liquefied with Liquozyme X), Dosage: 0.66 kg Dextrozyme GA/t DS starch.

Dextrozyme DX products have a similar saccharification temperature dependency to Dextrozyme GA products (not shown in Figure 3).

Usage

Saccharification of liquefied starch with Dextrozyme GA and DX products is best carried out at temperatures of 61-62C (142-144F) at pH 4.3. A model for DX and GA prediction for saccharification time above 36 hours is available on the Customer Centre at www.novozymes.com. The primary variables in a saccharification process are initial dry solids (DS), saccharification time, temperature and enzyme dosage. Dextrozyme GA and GA 1.5X Recommended temperature Recommended pH Recommended DS 60-62C 140-144F 4.2-4.5 29-35% Dextrozyme DX and DX 1.5X 60-62C 140-144F 4.2-4.5 29-35%

Table 2. Overview of recommended process conditions and application information.

Dosage Please apply Novozymes on-line saccharification models for dosage recommendations for a given set of saccharification parameters.

Page 5 of 5

Safety, handling and storage Safety, handling and storage guidelines are provided with all products. In addition to the above products, we have a number of other enzyme products available on special request. Please contact us for further details or visit our Customer Centre at www.novozymes.com.

Novozymes A/S Krogshoejvej 36 2880 Bagsvaerd Denmark Tel. +45 8824 9999 Fax +45 8824 9998

For more information and addresses of international offices, please see www.novozymes.com info@novozymes.com

Laws, regulations and third party rights may prevent customers from importing, processing, applying and/or reselling certain products in a given manner. It is the responsibility of the customer that their specific use of products from Novozymes does not infringe relevant laws and regulations and, furthermore, does not infringe patents or other third party rights. The contents of this document are subject to change without further notice. Novozymes A/S No. 2004-05756-03

Vous aimerez peut-être aussi

- Bioprocessing Technology for Production of Biopharmaceuticals and BioproductsD'EverandBioprocessing Technology for Production of Biopharmaceuticals and BioproductsClaire KomivesPas encore d'évaluation

- Sugar Syrups From MaizeDocument8 pagesSugar Syrups From Maizesyenikeyev3220Pas encore d'évaluation

- Handbook of Food Isotherms: Water Sorption Parameters For Food And Food ComponentsD'EverandHandbook of Food Isotherms: Water Sorption Parameters For Food And Food ComponentsÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Novozymes LiquefactionApplicationSheetDocument5 pagesNovozymes LiquefactionApplicationSheetI. Murali KrishnaPas encore d'évaluation

- Wed09 NovozymesDocument29 pagesWed09 NovozymesPulbere NeagraPas encore d'évaluation

- Hypobaric Storage in Food Industry: Advances in Application and TheoryD'EverandHypobaric Storage in Food Industry: Advances in Application and TheoryPas encore d'évaluation

- TG Cheese and Yogurt 012710Document37 pagesTG Cheese and Yogurt 012710Rafael de la Huerta0% (1)

- Chitosan in the Preservation of Agricultural CommoditiesD'EverandChitosan in the Preservation of Agricultural CommoditiesSilvia Bautista-BañosPas encore d'évaluation

- Defining High Fiber Ingredient Terminology Chapter 1Document27 pagesDefining High Fiber Ingredient Terminology Chapter 1Horacio Cuevas100% (1)

- Production of Economically Important Products by The Use of Pullulanase EnzymeDocument8 pagesProduction of Economically Important Products by The Use of Pullulanase EnzymeijsidonlineinfoPas encore d'évaluation

- Transglutaminase and Alginates Products by BDF Natural IngredientsDocument5 pagesTransglutaminase and Alginates Products by BDF Natural IngredientsBDF Transglutaminase AlginatesPas encore d'évaluation

- Efficient LiquifactionDocument10 pagesEfficient LiquifactionMuhammadTalalNooriPas encore d'évaluation

- 1,3 Propaneidol PDFDocument12 pages1,3 Propaneidol PDFJesus MendezPas encore d'évaluation

- Measurement of The Starch Content of Commercial Starches PDFDocument3 pagesMeasurement of The Starch Content of Commercial Starches PDFwahyuthp43Pas encore d'évaluation

- Cross-Linking Starch at Various Moisture Contents by PhosphateDocument4 pagesCross-Linking Starch at Various Moisture Contents by PhosphateMateo Torres TorresPas encore d'évaluation

- Enzymes in OilDocument49 pagesEnzymes in OilsudhirkromPas encore d'évaluation

- Presentation Products Transglutaminase AlginatesDocument25 pagesPresentation Products Transglutaminase AlginatesBDF Transglutaminase AlginatesPas encore d'évaluation

- Proteases For Biocatalysis: For Smarter Chemical SynthesisDocument6 pagesProteases For Biocatalysis: For Smarter Chemical Synthesisyamid pismagPas encore d'évaluation

- Cold Active Enzymes in Food Processing - UpdatedDocument34 pagesCold Active Enzymes in Food Processing - UpdatedAn Ngoc Hoai100% (1)

- 14 075 Propanediol ProductionDocument12 pages14 075 Propanediol ProductionAly FirdausPas encore d'évaluation

- Amylase Development For Starch Liquefaction: Carsten Andersen Novozymes R&DDocument26 pagesAmylase Development For Starch Liquefaction: Carsten Andersen Novozymes R&DGXGGXGPas encore d'évaluation

- Functional FibreDocument10 pagesFunctional Fibresofia NunesPas encore d'évaluation

- Corn Steep Liquor in Microbiology PDFDocument15 pagesCorn Steep Liquor in Microbiology PDFNasser KemmouPas encore d'évaluation

- Aacc 10-13aDocument18 pagesAacc 10-13aЕлена СтариноваPas encore d'évaluation

- Viscosity XylitolDocument31 pagesViscosity XylitolleoPas encore d'évaluation

- Fatty Esters: Che 321 Oleochemical TechnologyDocument26 pagesFatty Esters: Che 321 Oleochemical TechnologyMohd RafiqPas encore d'évaluation

- Carbohydrate Based Fat - ReplacersDocument66 pagesCarbohydrate Based Fat - ReplacersSadasis SinghPas encore d'évaluation

- DSM Enzymes For Biscuits Crackers WafersDocument19 pagesDSM Enzymes For Biscuits Crackers WafersRoxana Larisa Olteanu100% (1)

- Maturex LDocument5 pagesMaturex LHụê ChanPas encore d'évaluation

- Utlisation of Roasted Guar Korma As Alternative For Fishmeal and Soybean Meal in Shrimp DietsDocument6 pagesUtlisation of Roasted Guar Korma As Alternative For Fishmeal and Soybean Meal in Shrimp DietsInternational Aquafeed magazinePas encore d'évaluation

- Effects of Different Emulsifiers On Rheological and Physical Properties of ChocolateDocument6 pagesEffects of Different Emulsifiers On Rheological and Physical Properties of ChocolateAnisah CuzPas encore d'évaluation

- FoodPro Protease Enzymes GuideDocument2 pagesFoodPro Protease Enzymes GuideChar YosPas encore d'évaluation

- HUMECTANTDocument12 pagesHUMECTANTSakhtar_ft100% (2)

- Micro Filtration of ButtermilkDocument9 pagesMicro Filtration of ButtermilkbastassynelcoPas encore d'évaluation

- Quantiplate Protocol Quantum Blue BWDocument10 pagesQuantiplate Protocol Quantum Blue BWIrene Sinung HaripratiwiPas encore d'évaluation

- High-Fructose Corn Syrups (HFCS) : Table 4.3Document40 pagesHigh-Fructose Corn Syrups (HFCS) : Table 4.3Gabriel HerreraPas encore d'évaluation

- Aerowhip WhipcreamDocument32 pagesAerowhip Whipcreampedrazas0% (1)

- Industrial Uses of Enzymes: Dr. Reda Mahgoub MohamedDocument23 pagesIndustrial Uses of Enzymes: Dr. Reda Mahgoub MohamedIslam ImadPas encore d'évaluation

- Production of Instant Soymilk Powders by Ultra Ltration, SprayDocument12 pagesProduction of Instant Soymilk Powders by Ultra Ltration, SprayNguyễn Quang100% (2)

- Product Data Sheet: Novamyl® 1500 MGDocument2 pagesProduct Data Sheet: Novamyl® 1500 MGمحمد صبحيPas encore d'évaluation

- Determination of Phytase Activity in Feed by A Colorimetric Enzymatic Method: Collaborative Interlaboratory StudyDocument5 pagesDetermination of Phytase Activity in Feed by A Colorimetric Enzymatic Method: Collaborative Interlaboratory StudyTalhaPas encore d'évaluation

- Cap - Novos Métodos ReológicosDocument14 pagesCap - Novos Métodos ReológicosAlexandra SoaresPas encore d'évaluation

- Glycerol Production by Microbial Fermentation A ReviewDocument23 pagesGlycerol Production by Microbial Fermentation A ReviewMiki LevyPas encore d'évaluation

- Guar Galactomannans Depolymerization Assesment in Yogurt Prepared From Cow MilkDocument87 pagesGuar Galactomannans Depolymerization Assesment in Yogurt Prepared From Cow MilkMuhammad Umair100% (1)

- Thermal Hydrolysis of Sucrose KineticsDocument6 pagesThermal Hydrolysis of Sucrose KineticsWida AdeliaPas encore d'évaluation

- New Technologies in Paneer MakingDocument6 pagesNew Technologies in Paneer MakingAnur SinglaPas encore d'évaluation

- Determination of Total Fat and Free Fat ContentDocument13 pagesDetermination of Total Fat and Free Fat ContentCesar Augusto Torres LinaresPas encore d'évaluation

- Emulsifier in BreadDocument8 pagesEmulsifier in BreadNajeeb ShamaaPas encore d'évaluation

- (Chemistry Research and Applications) Fitzgerald, Adrienne - Emulsifiers - Properties, Functions, and Applications-Nova Science Publishers (2015) PDFDocument116 pages(Chemistry Research and Applications) Fitzgerald, Adrienne - Emulsifiers - Properties, Functions, and Applications-Nova Science Publishers (2015) PDFStefania DavidPas encore d'évaluation

- Gravimetric Determination of Acid Detergent Fiber and Lignin in Feed: Interlaboratory StudyDocument17 pagesGravimetric Determination of Acid Detergent Fiber and Lignin in Feed: Interlaboratory StudySV_TokanPas encore d'évaluation

- Enzymatic Starch HydrolysisDocument107 pagesEnzymatic Starch HydrolysisManuel Rojas100% (1)

- Bio-Butanediol Production From GlucoseDocument1 pageBio-Butanediol Production From GlucoseBramJanssen76Pas encore d'évaluation

- Aerated Food GelsDocument12 pagesAerated Food GelsOana SilviaPas encore d'évaluation

- Sorbitol Industry PDFDocument7 pagesSorbitol Industry PDFLucas Ferreira LozPas encore d'évaluation

- VB Citricacid Technology enDocument6 pagesVB Citricacid Technology enGospodin RajkovićPas encore d'évaluation

- Anaysis of MilkDocument14 pagesAnaysis of MilkSaman AkramPas encore d'évaluation

- Enzyme in Bread Making: Course: Enzyme and Food Fermentation Instructor: Dr. Le Hong Phu Group 3Document51 pagesEnzyme in Bread Making: Course: Enzyme and Food Fermentation Instructor: Dr. Le Hong Phu Group 3Quoc KhanhPas encore d'évaluation

- CEREALS PPT 72Document72 pagesCEREALS PPT 72Raifa FathimaPas encore d'évaluation

- The Unfinished Memoirs (1952du1971@ Gmail - Com)Document376 pagesThe Unfinished Memoirs (1952du1971@ Gmail - Com)Ataur RahmanPas encore d'évaluation

- A History of Lactic Acid MakingDocument1 pageA History of Lactic Acid MakingI. Murali KrishnaPas encore d'évaluation

- Reineveld CentrifugeDocument12 pagesReineveld CentrifugeI. Murali KrishnaPas encore d'évaluation

- Raiders in Kashmir by Maj Gen Akbar KhanDocument161 pagesRaiders in Kashmir by Maj Gen Akbar KhanI. Murali Krishna60% (5)

- Telangana Sayudha PoratamDocument37 pagesTelangana Sayudha PoratamI. Murali KrishnaPas encore d'évaluation

- Biranpally 1948Document32 pagesBiranpally 1948Surender WarangalPas encore d'évaluation

- Andhra Pradesh Abhivriddhilo AntaraluDocument87 pagesAndhra Pradesh Abhivriddhilo AntaraluI. Murali KrishnaPas encore d'évaluation

- Encyclopedia of Industrial ChemistryDocument55 pagesEncyclopedia of Industrial ChemistryStephanie Maley100% (1)

- UnitOperationsInFoodProcessing R.L.earleDocument6 pagesUnitOperationsInFoodProcessing R.L.earleI. Murali KrishnaPas encore d'évaluation

- Fermentation and Distillation of Corn StarchDocument9 pagesFermentation and Distillation of Corn StarchI. Murali Krishna100% (1)

- Biotechnological Production of Gluconic Acid Future ImplecationsDocument10 pagesBiotechnological Production of Gluconic Acid Future ImplecationsI. Murali KrishnaPas encore d'évaluation

- Ferrous Gluconate (Processed With Citric Acid)Document40 pagesFerrous Gluconate (Processed With Citric Acid)I. Murali KrishnaPas encore d'évaluation

- Factors Regulating Production of Glucose Oxidase by Aspergillus NigerDocument5 pagesFactors Regulating Production of Glucose Oxidase by Aspergillus NigerI. Murali KrishnaPas encore d'évaluation

- D Gluconic Acid D Glucano Delta LactoneDocument3 pagesD Gluconic Acid D Glucano Delta LactoneI. Murali KrishnaPas encore d'évaluation

- TheoryDocument2 pagesTheoryDenicia KnuttPas encore d'évaluation

- Microbial TransformationDocument30 pagesMicrobial TransformationBijayaKumarUpretyPas encore d'évaluation

- Heterogeneous Catalysis For Today's Challenges: Synthesis, Characterization and ApplicationsDocument152 pagesHeterogeneous Catalysis For Today's Challenges: Synthesis, Characterization and ApplicationsAbdulhamid AliPas encore d'évaluation

- 1 Chem113 LecDocument10 pages1 Chem113 LecJamaica M DanguecanPas encore d'évaluation

- Bioethanol Paper UAS S2 ChemDocument11 pagesBioethanol Paper UAS S2 Chemrichiealdo7Pas encore d'évaluation

- Salt HydrolysisDocument7 pagesSalt HydrolysisKamlesh YadavPas encore d'évaluation

- Colorimetric Test That Utilizes: Lactate+ NADDocument4 pagesColorimetric Test That Utilizes: Lactate+ NADPurple basketPas encore d'évaluation

- Ethyl Lauroyl ArginateDocument5 pagesEthyl Lauroyl ArginatettnduyPas encore d'évaluation

- CH 08 - BioDocument44 pagesCH 08 - Bioklopos1234Pas encore d'évaluation

- Optimisation of Enzymatic Hydrolysis of Apple PomaceDocument13 pagesOptimisation of Enzymatic Hydrolysis of Apple PomaceDea Inthay WulanPas encore d'évaluation

- Exhanger Leakages in VDU - ModifiedDocument14 pagesExhanger Leakages in VDU - ModifiedJay LawsonPas encore d'évaluation

- Michael J. Waites, Neil L. Morgan, John S. Rockey, Gary Higton-Industrial Microbiology - An Introduction-Wiley-Blackwell (2001) - DikonversiDocument29 pagesMichael J. Waites, Neil L. Morgan, John S. Rockey, Gary Higton-Industrial Microbiology - An Introduction-Wiley-Blackwell (2001) - Dikonversiegi maulanaPas encore d'évaluation

- 3 Principles of Cell MetabolismDocument53 pages3 Principles of Cell MetabolismKristine Claire TarucPas encore d'évaluation

- Food and Humans: Multiple-Choice QuestionsDocument55 pagesFood and Humans: Multiple-Choice QuestionsRyanPas encore d'évaluation

- Oct. 28, 1958 R. M. Thomas Etal 2,858,345: Filed March 30, 1956Document3 pagesOct. 28, 1958 R. M. Thomas Etal 2,858,345: Filed March 30, 1956Poetri RagafadmiPas encore d'évaluation

- Biomolecules and Polymers - DTS 1 Adv (Archive) SolDocument2 pagesBiomolecules and Polymers - DTS 1 Adv (Archive) SolShreyas MuthaPas encore d'évaluation

- Ii Puc Chemistry: Passing Capsule 2021Document24 pagesIi Puc Chemistry: Passing Capsule 2021Thiruvengadam BalajeePas encore d'évaluation

- 1 s2.0 S2452223620301115 MainDocument10 pages1 s2.0 S2452223620301115 MainDrawing and Artistic DecorationsPas encore d'évaluation

- UNITI Biomolecules PDFDocument18 pagesUNITI Biomolecules PDFdrugdrug100% (1)

- EN Production of Fish Hydrolysates ProteinDocument8 pagesEN Production of Fish Hydrolysates ProteinKhaerul FadlyPas encore d'évaluation

- A Review On The Degradability of Polymeric Composites Based On Natural Fibres PDFDocument19 pagesA Review On The Degradability of Polymeric Composites Based On Natural Fibres PDFThiago SantosPas encore d'évaluation

- Fermenation MediaDocument13 pagesFermenation MediaChandiniPas encore d'évaluation

- Amino Acid AnalysisDocument37 pagesAmino Acid AnalysisIslah MuttaqinPas encore d'évaluation

- Unit 4Document34 pagesUnit 4adarshclash18Pas encore d'évaluation

- Amylase Activity TestDocument14 pagesAmylase Activity TestSanya chauhanPas encore d'évaluation

- Disaccharide QuestionsDocument2 pagesDisaccharide QuestionsMichael WrightPas encore d'évaluation

- BBL Crystal Identification Systems Enteric-Nonfermenter ID KitDocument16 pagesBBL Crystal Identification Systems Enteric-Nonfermenter ID KitWinona ShenaniPas encore d'évaluation

- Structure of Disaccharides & PolysaccharidesDocument12 pagesStructure of Disaccharides & PolysaccharidesD K SRIVASTAVA100% (1)

- SCES3329 2 Induced Approximation-StudentDocument21 pagesSCES3329 2 Induced Approximation-Studenthairul_tajuddinPas encore d'évaluation

- Branchzyme Alpha Glucotransferase - Encapsultation PDFDocument7 pagesBranchzyme Alpha Glucotransferase - Encapsultation PDFMatichon ChamchooklinPas encore d'évaluation

- Sodium Bicarbonate: Nature's Unique First Aid RemedyD'EverandSodium Bicarbonate: Nature's Unique First Aid RemedyÉvaluation : 5 sur 5 étoiles5/5 (21)

- An Applied Guide to Water and Effluent Treatment Plant DesignD'EverandAn Applied Guide to Water and Effluent Treatment Plant DesignÉvaluation : 5 sur 5 étoiles5/5 (4)

- Process Plant Equipment: Operation, Control, and ReliabilityD'EverandProcess Plant Equipment: Operation, Control, and ReliabilityÉvaluation : 5 sur 5 étoiles5/5 (1)

- Well Control for Completions and InterventionsD'EverandWell Control for Completions and InterventionsÉvaluation : 4 sur 5 étoiles4/5 (10)

- Guidelines for Chemical Process Quantitative Risk AnalysisD'EverandGuidelines for Chemical Process Quantitative Risk AnalysisÉvaluation : 5 sur 5 étoiles5/5 (1)

- The Perfumed Pages of History: A Textbook on Fragrance CreationD'EverandThe Perfumed Pages of History: A Textbook on Fragrance CreationÉvaluation : 4 sur 5 étoiles4/5 (1)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsD'EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsPas encore d'évaluation

- Mastering Biochemistry: A Comprehensive Guide to ExcellenceD'EverandMastering Biochemistry: A Comprehensive Guide to ExcellencePas encore d'évaluation

- Piping Engineering Leadership for Process Plant ProjectsD'EverandPiping Engineering Leadership for Process Plant ProjectsÉvaluation : 5 sur 5 étoiles5/5 (1)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersD'EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersPas encore d'évaluation

- Lees' Process Safety Essentials: Hazard Identification, Assessment and ControlD'EverandLees' Process Safety Essentials: Hazard Identification, Assessment and ControlÉvaluation : 4 sur 5 étoiles4/5 (4)

- Handbook of Cosmetic Science: An Introduction to Principles and ApplicationsD'EverandHandbook of Cosmetic Science: An Introduction to Principles and ApplicationsH. W. HibbottÉvaluation : 4 sur 5 étoiles4/5 (6)

- Fun Facts about Carbon : Chemistry for Kids The Element Series | Children's Chemistry BooksD'EverandFun Facts about Carbon : Chemistry for Kids The Element Series | Children's Chemistry BooksPas encore d'évaluation

- Troubleshooting Vacuum Systems: Steam Turbine Surface Condensers and Refinery Vacuum TowersD'EverandTroubleshooting Vacuum Systems: Steam Turbine Surface Condensers and Refinery Vacuum TowersÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- A New Approach to HAZOP of Complex Chemical ProcessesD'EverandA New Approach to HAZOP of Complex Chemical ProcessesPas encore d'évaluation

- Pulp and Paper Industry: Emerging Waste Water Treatment TechnologiesD'EverandPulp and Paper Industry: Emerging Waste Water Treatment TechnologiesÉvaluation : 5 sur 5 étoiles5/5 (1)

- Distillation Design and Control Using Aspen SimulationD'EverandDistillation Design and Control Using Aspen SimulationÉvaluation : 5 sur 5 étoiles5/5 (2)

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsD'EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsPas encore d'évaluation

- Fun Facts about Hydrogen : Chemistry for Kids The Element Series | Children's Chemistry BooksD'EverandFun Facts about Hydrogen : Chemistry for Kids The Element Series | Children's Chemistry BooksPas encore d'évaluation

- Biochemical and Photosynthetic Aspects of Energy ProductionD'EverandBiochemical and Photosynthetic Aspects of Energy ProductionAnthony San PietroPas encore d'évaluation

- Cathodic Protection: Industrial Solutions for Protecting Against CorrosionD'EverandCathodic Protection: Industrial Solutions for Protecting Against CorrosionPas encore d'évaluation

- Bioinspired Materials Science and EngineeringD'EverandBioinspired Materials Science and EngineeringGuang YangPas encore d'évaluation

- Fundamentals of Risk Management for Process Industry EngineersD'EverandFundamentals of Risk Management for Process Industry EngineersPas encore d'évaluation

- Sustainable Plastics: Environmental Assessments of Biobased, Biodegradable, and Recycled PlasticsD'EverandSustainable Plastics: Environmental Assessments of Biobased, Biodegradable, and Recycled PlasticsPas encore d'évaluation