Académique Documents

Professionnel Documents

Culture Documents

Types of PPE

Transféré par

gshdavidCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Types of PPE

Transféré par

gshdavidDroits d'auteur :

Formats disponibles

Learning Challenges

SAFETY

PRESENTATION

The FLATE Center for Manufacturing Education wishes to make available, for educational and non-commercial purposes only, materials of the Safety presentation comprised of images, texts, facilitators notes, and other demonstration materials. This instructional resource forms part of FLATEs outreach efforts to facilitate a connection between students, teachers and manufacturers throughout the State of Florida. We trust that these activities and materials will add value to your teaching and/or presentations. Please visit our website for additional resources, including our Made in Florida Video, a unique behind-the-scenes visit to modern manufacturing plants in the State of Florida. FLATE Center for Manufacturing Education Hillsborough Community College - Brandon 10414 E Columbus Dr., Tampa, FL 33619 (813) 259-6575 www.fl-ate.org and www.madeinflorida.org

See the Notes Page for additional information

This material is based upon work supported by the National Science Foundation under Grant No. 0402215. Any opinions, findings, and conclusions or recommendations expressed in this material are those of the author(s) and do not necessarily reflect the views of the National Science Foundation.

Learning Challenges

TECO and CF Industries

Middle School

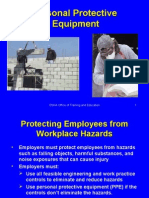

Personal Protective Equipment

Classroom Presentation

Learning Challenges

Different types of Personal Protective Equipment (PPE)

Head Protection Eye and Face Protection Ear Protection Respiratory Protection Hand Protection Body Protection Feet Protection

Learning Challenges

Head Protection

Learning Challenges

Eye and Face Protection

Hazard Assessment

Hazard type Impact Examples of Hazard Common Related Tasks Flying objects such as large Chipping, grinding, machining, chips, fragments, particles, sand, masonry work, wood working, and dirt. sawing, drilling, chiseling, powered fastening, riveting, and sanding. Anything emitting extreme heat. Furnace operations, pouring, casting, hot dipping, and welding. Splash, fumes, vapors, and irritating mists. Harmful Dust. Radiant energy, glare, and intense light Acid and chemical handling, degreasing, plating, and working with blood. Woodworking, buffing, and general dusty conditions. Welding, torch-cutting, brazing, soldering, and laser work.

Heat

Chemicals

Dust Optical Radiation

Learning Challenges

Hazard and Solution

Heat: Spectacles, goggles and face shields

Impact: Spectacles, goggles and face shields

Chemicals: Goggles and face shields

Dust: Spectacles, goggles and face shields

Optical radiation: goggles and face shields

Learning Challenges

Eye and Face Protection

Spectacles Welding

Goggles

Face Shields

Laser

Learning Challenges

Ear Protection

Earmuffs Earplugs Canal Caps

Learning Challenges

Air purifying Respiratory Protection

Have filters, cartridges, or canisters that remove contaminants from the air by passing the ambient air through the airpurifying element before it reaches the user.

Three types:

Particulate Respirators: capture particles in the air, such as dusts, mists, and fumes. Combination Respirators: are normally used in atmospheres that contain hazards of both particulates and gases. Gas & Vapor Respirators: are normally used when there are only hazardous gases and vapors in the air.

Particulate

Combination

Gas & Vapor

Learning Challenges

Atmosphere supplying Respiratory Protection

Supplycleanairdirectlytotheuser fromasourceotherthantheair surroundingtheuser. Threetypes:

AirSuppliedRespirators:makesuse ofahosetodeliverclean,safe air fromastationarysourceof compressedair. CombinationRespirators:havean auxiliaryselfcontainedairsupply thatcanbeusediftheprimary supplyfails. SelfContainedBreathingApparatus: consistsofawearable,cleanair supplypack.

AirSupplied

Combination

SelfContainedBreathingApparatus

Learning Challenges

Hand Protection

NEVER REUSE DISPOSABLE GLOVES

Learning Challenges

Body Protection

Cooling Vest Sleeves and Apron Full Body Suit

Coveralls

Learning Challenges

Feet Protection

Have impact-resistant toes and heat-resistant soles that protect against hot surfaces common in roofing, paving, and hot metal industries. When welding and/or cutting, high top (minimum 6) boot that are covered by the pant leg shall be worn. May be designed to be electrically conductive for use in explosive atmospheres, or nonconductive to protect from workplace electrical hazards.

Learning Challenges

Your challenge PPE Identification

You are given a series of pictures showing workers wearing various PPE. Study each picture thoroughly. List all the PPE that you can identify. Suggest what hazard each PPE is protecting the worker against. Discuss how each PPE work to protect the worker.

Vous aimerez peut-être aussi

- Questions That Appear On Every NBMEDocument6 pagesQuestions That Appear On Every NBMESanz100% (1)

- Ia - Carpentry - Preparing Stakeout Building LinesDocument18 pagesIa - Carpentry - Preparing Stakeout Building LinesLaRaineBalhon88% (17)

- Refrigeration and Air Conditioning Technology 8th Edition Tomczyk Silberstein Whitman Johnson Solution ManualDocument5 pagesRefrigeration and Air Conditioning Technology 8th Edition Tomczyk Silberstein Whitman Johnson Solution Manualrachel100% (24)

- Early Signs of AutismDocument27 pagesEarly Signs of AutismErica Alejandra Schumacher100% (1)

- BAT Production of Urea and Urea Ammonium NitrateDocument44 pagesBAT Production of Urea and Urea Ammonium NitrateTTaddictPas encore d'évaluation

- What is Intermodulation InterferenceDocument3 pagesWhat is Intermodulation InterferencedekcarcPas encore d'évaluation

- CASE Study PTBDocument53 pagesCASE Study PTBmeleanaquino94% (16)

- Earthquake (Ppe)Document8 pagesEarthquake (Ppe)Mayls Sevilla CalizoPas encore d'évaluation

- Personal Protective Equipment: Khomsatin Nisful Laila, S.STDocument50 pagesPersonal Protective Equipment: Khomsatin Nisful Laila, S.STmaulidatunPas encore d'évaluation

- Personal Protective Equipment: OSHA Office of Training and EducationDocument36 pagesPersonal Protective Equipment: OSHA Office of Training and EducationWaseem YounisPas encore d'évaluation

- 0I. Accident Causes and PreventionDocument52 pages0I. Accident Causes and PreventionGregor CleganePas encore d'évaluation

- Week 4 Engllish For Engineering StudentDocument19 pagesWeek 4 Engllish For Engineering StudentShare linkPas encore d'évaluation

- Personal Protective EquipmentDocument27 pagesPersonal Protective EquipmentDakshinaMoorthyPas encore d'évaluation

- Oshappe TrainingDocument36 pagesOshappe TrainingferozPas encore d'évaluation

- Lecture 2Document23 pagesLecture 2Mahmil ButtPas encore d'évaluation

- Workplace Vocabulary for Esl Students: With Exercises and TestsD'EverandWorkplace Vocabulary for Esl Students: With Exercises and TestsPas encore d'évaluation

- Protecting Workers with PPEDocument48 pagesProtecting Workers with PPEakmeezPas encore d'évaluation

- Safety Info SheetDocument5 pagesSafety Info SheetJohn Edward RaagasPas encore d'évaluation

- UNIT - 5 Personal Protective DevicesDocument50 pagesUNIT - 5 Personal Protective DevicesNithishPas encore d'évaluation

- Personal Protective EquipDocument72 pagesPersonal Protective EquipSasi KumarPas encore d'évaluation

- Ppe 4Document35 pagesPpe 4Amit BhattPas encore d'évaluation

- Personal Protective Clothing and Equipment: Last Updated 6/9/2008Document19 pagesPersonal Protective Clothing and Equipment: Last Updated 6/9/2008emeka2012Pas encore d'évaluation

- Personal Protective Equipment - 4Document18 pagesPersonal Protective Equipment - 4Hamid KhoutnaPas encore d'évaluation

- Engineering Students Learn Health & Safety ProceduresDocument18 pagesEngineering Students Learn Health & Safety ProceduresfalyaPas encore d'évaluation

- Information Sheet 1 SealantDocument7 pagesInformation Sheet 1 SealantCourei-FxAlcazarPas encore d'évaluation

- Risk Control: OSHA Office of Training and EducationDocument60 pagesRisk Control: OSHA Office of Training and EducationAhmed Hassan Sabry100% (1)

- Personal Protective EquipmentDocument10 pagesPersonal Protective EquipmentRai JeanPas encore d'évaluation

- Welding Safety EssentialsDocument8 pagesWelding Safety EssentialsNick PieperPas encore d'évaluation

- PPE EYE PROTECTIONDocument72 pagesPPE EYE PROTECTIONHaseeb AhsanPas encore d'évaluation

- Personal Protective Equipment (Ppe)Document16 pagesPersonal Protective Equipment (Ppe)sritaran100% (1)

- Ppe TrainingDocument38 pagesPpe Trainingrubaganesh maychemicalPas encore d'évaluation

- PPE Guide for Workplace HazardsDocument40 pagesPPE Guide for Workplace HazardstuPas encore d'évaluation

- Training Session On PPE's and Its ImportanceDocument37 pagesTraining Session On PPE's and Its ImportanceparthaPas encore d'évaluation

- PPE .PPT ConstructionDocument39 pagesPPE .PPT Constructiondrnzyme100% (13)

- Common Sulphur ProjectDocument40 pagesCommon Sulphur ProjectAkhilPas encore d'évaluation

- Lo1 Ohs - 2016 2017Document51 pagesLo1 Ohs - 2016 2017pilita_reyes77Pas encore d'évaluation

- Ppe Presentation-1Document17 pagesPpe Presentation-1api-273092669Pas encore d'évaluation

- w2 AdditionDocument39 pagesw2 Additionsyarafi amirPas encore d'évaluation

- Apply Safety PracticesDocument59 pagesApply Safety PracticesEugenio Jr. MatesPas encore d'évaluation

- Safety Requirmrnts Ch-1-1Document34 pagesSafety Requirmrnts Ch-1-1magnifco100% (1)

- Personal Protective Equipment: Helmet MaskDocument52 pagesPersonal Protective Equipment: Helmet MaskANSHUL HIKERPas encore d'évaluation

- PPE Protection for Workplace HazardsDocument40 pagesPPE Protection for Workplace HazardsAamir AliPas encore d'évaluation

- Personal Protective EquipmentDocument12 pagesPersonal Protective EquipmentPAUL BRAMONT ARIAS HILASACAPas encore d'évaluation

- Hazards in WorkplaceDocument25 pagesHazards in WorkplacejordanPas encore d'évaluation

- Lab Report # 01: Submitted To: Engr. Faraz Hussain Submitted By: Usman Liaqat 17MME-S1-313Document9 pagesLab Report # 01: Submitted To: Engr. Faraz Hussain Submitted By: Usman Liaqat 17MME-S1-313Usman GujjarPas encore d'évaluation

- Module7 g7 or 8 Cookery BautistanhsDocument12 pagesModule7 g7 or 8 Cookery BautistanhsSyruseJayLacuataPas encore d'évaluation

- 10-TBT-07 Eye Injury Protection Week-7Document4 pages10-TBT-07 Eye Injury Protection Week-7saad aliPas encore d'évaluation

- Practical Work Book For Health Safety and EnvironmentDocument69 pagesPractical Work Book For Health Safety and EnvironmentAreejPas encore d'évaluation

- Materi Training PPEDocument71 pagesMateri Training PPERifalino Al-habibiePas encore d'évaluation

- Health and SafetyDocument31 pagesHealth and SafetyThebe Tshepiso MaitshokoPas encore d'évaluation

- Ppe American STDSDocument30 pagesPpe American STDSChetana HamsagarPas encore d'évaluation

- Practice Occupational Health And SafetyDocument8 pagesPractice Occupational Health And SafetyCelPas encore d'évaluation

- Q2 MODULE7 G7-OR-8 COOKERY BautistaNHSDocument10 pagesQ2 MODULE7 G7-OR-8 COOKERY BautistaNHSDirty Sam LicudoPas encore d'évaluation

- Sub Module 1. PPEDocument20 pagesSub Module 1. PPEMutabazi Igga powersPas encore d'évaluation

- Ensure legal compliance and safe waste handling for worksite operationsDocument6 pagesEnsure legal compliance and safe waste handling for worksite operationsJim LiebPas encore d'évaluation

- Apply Safety Measures in Farm Operations Animal ProductionDocument18 pagesApply Safety Measures in Farm Operations Animal ProductionCharlote Montefalcon0% (1)

- Induction Training PDFDocument51 pagesInduction Training PDFupender007100% (1)

- Chapter 7. Safety HazardDocument32 pagesChapter 7. Safety HazardKunis AberaPas encore d'évaluation

- Unit 5: Safety PracticesDocument16 pagesUnit 5: Safety PracticesAjith KumarPas encore d'évaluation

- Shielded Metal Arc Welding (SMAW) : Identify Hazards and RisksDocument47 pagesShielded Metal Arc Welding (SMAW) : Identify Hazards and RisksRia TobiasPas encore d'évaluation

- Safety Officer Interview Questions and Answers: What Is The Safety?Document11 pagesSafety Officer Interview Questions and Answers: What Is The Safety?adeelkhanafePas encore d'évaluation

- Concrete Technology 1Document77 pagesConcrete Technology 1Sempiira StevenPas encore d'évaluation

- NOISE & HEARING Conservation ProgramDocument80 pagesNOISE & HEARING Conservation ProgramChristinePas encore d'évaluation

- Lecture-2.1 - GikDocument24 pagesLecture-2.1 - GikAffan KhanPas encore d'évaluation

- Dust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesD'EverandDust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesPas encore d'évaluation

- Technology Entrepreneurship: Taking Innovation to the MarketplaceD'EverandTechnology Entrepreneurship: Taking Innovation to the MarketplaceÉvaluation : 4 sur 5 étoiles4/5 (1)

- Consentry Into Sanitary PitsDocument30 pagesConsentry Into Sanitary PitsgshdavidPas encore d'évaluation

- P&ID DiagramDocument6 pagesP&ID DiagramMejdi Sylas ToudjiPas encore d'évaluation

- Crude Oil Properties (Laboratory)Document15 pagesCrude Oil Properties (Laboratory)gshdavidPas encore d'évaluation

- WWC Technical Data BookDocument73 pagesWWC Technical Data BookMario BertoneriPas encore d'évaluation

- Gap Analysis FinalDocument2 pagesGap Analysis FinalZetty BlackPas encore d'évaluation

- Inspection and Testing of Piping Systems ES-14-602-02Document44 pagesInspection and Testing of Piping Systems ES-14-602-02Edmund MoraldePas encore d'évaluation

- Dew Point Basics-Compressed Air PDFDocument4 pagesDew Point Basics-Compressed Air PDFgshdavidPas encore d'évaluation

- PLEATED SS Steam DDPP PDFDocument2 pagesPLEATED SS Steam DDPP PDFgshdavidPas encore d'évaluation

- Basket Strainer Intro PDFDocument4 pagesBasket Strainer Intro PDFgshdavidPas encore d'évaluation

- Worksafe Bulletin: Safe Procedures For Vacuum Truck OperationsDocument2 pagesWorksafe Bulletin: Safe Procedures For Vacuum Truck OperationsgshdavidPas encore d'évaluation

- Why Dry Compressed Air PDFDocument9 pagesWhy Dry Compressed Air PDFgshdavidPas encore d'évaluation

- GAP AnalysisDocument4 pagesGAP AnalysisTushar PareekPas encore d'évaluation

- M146content PDFDocument90 pagesM146content PDFgshdavidPas encore d'évaluation

- Drying PDFDocument11 pagesDrying PDFgshdavidPas encore d'évaluation

- Mesh Size EquivalentsDocument2 pagesMesh Size EquivalentsFrancisco Chavez ContrerasPas encore d'évaluation

- 007 UTube CleaningDocument2 pages007 UTube CleaninggshdavidPas encore d'évaluation

- Hot Tapping GuideDocument3 pagesHot Tapping GuidegshdavidPas encore d'évaluation

- P&ID SymbolDocument18 pagesP&ID SymbolBagus Okti100% (1)

- MSC Prac 30500Document8 pagesMSC Prac 30500gshdavidPas encore d'évaluation

- Hot Tapping: Typical Hot Tap ApplicationDocument1 pageHot Tapping: Typical Hot Tap ApplicationgshdavidPas encore d'évaluation

- Benzene Methods 2520of 2520productionDocument4 pagesBenzene Methods 2520of 2520productionHưng LucaPas encore d'évaluation

- Distillation - How It WorksDocument8 pagesDistillation - How It WorksOmar KallufPas encore d'évaluation

- Hot Tap ToolsDocument17 pagesHot Tap ToolsgshdavidPas encore d'évaluation

- Hot Tap ProcedureDocument21 pagesHot Tap ProcedureImanuel Sitepu100% (1)

- Avoid Syn Gas Catalyst Mal-Operation WSVDocument48 pagesAvoid Syn Gas Catalyst Mal-Operation WSVgshdavidPas encore d'évaluation

- Hot Tapping GuideDocument3 pagesHot Tapping GuidegshdavidPas encore d'évaluation

- 2008 Midwest Regional Heard Catalyst PassivationDocument23 pages2008 Midwest Regional Heard Catalyst PassivationgshdavidPas encore d'évaluation

- Catalyst in Refining PetrochemicalsDocument5 pagesCatalyst in Refining PetrochemicalsgshdavidPas encore d'évaluation

- Mesh Size EquivalentsDocument2 pagesMesh Size EquivalentsFrancisco Chavez ContrerasPas encore d'évaluation

- Certificate of Employment Document TitleDocument1 pageCertificate of Employment Document TitleAyni ReyesPas encore d'évaluation

- Rorschach y SuicidioDocument17 pagesRorschach y SuicidioLaura SierraPas encore d'évaluation

- UK & India Health Insurance Actuarial ExamDocument4 pagesUK & India Health Insurance Actuarial ExamVignesh SrinivasanPas encore d'évaluation

- Annotated Bibliography Graphic OrganizerDocument4 pagesAnnotated Bibliography Graphic Organizerapi-348035481Pas encore d'évaluation

- Galapagos Penguins: Shelter, Niche and NeedsDocument8 pagesGalapagos Penguins: Shelter, Niche and Needsjim munkPas encore d'évaluation

- LLL'DSWD: Administrative Order No. Series 2017Document18 pagesLLL'DSWD: Administrative Order No. Series 2017SGTPas encore d'évaluation

- Osteo Book Final 2014Document51 pagesOsteo Book Final 2014hyanandPas encore d'évaluation

- Un Primer Acercamiento A La Escritura Científica: OPI LabDocument66 pagesUn Primer Acercamiento A La Escritura Científica: OPI LabLolaPas encore d'évaluation

- WASA Wastewater and Potable Water Design Requirements PDFDocument233 pagesWASA Wastewater and Potable Water Design Requirements PDFYassin AlkadyPas encore d'évaluation

- Registration Hike2help 15Document2 pagesRegistration Hike2help 15api-275580337Pas encore d'évaluation

- Q A With Jaquelyn BurrerDocument3 pagesQ A With Jaquelyn Burrerapi-480718823Pas encore d'évaluation

- Review of Literature Review of LiteratureDocument31 pagesReview of Literature Review of LiteratureeswariPas encore d'évaluation

- CN LSHC The Future of Pharmacy en 031120Document8 pagesCN LSHC The Future of Pharmacy en 031120marina_netPas encore d'évaluation

- Asian Organized CrimeDocument17 pagesAsian Organized CrimeMagr EscaPas encore d'évaluation

- Caregiving Learning Activity SheetDocument7 pagesCaregiving Learning Activity SheetJuvy Lyn Conda100% (5)

- Physical Therpay Protocols For Conditions of Neck RegionDocument74 pagesPhysical Therpay Protocols For Conditions of Neck Regionjrpsaavedra4599Pas encore d'évaluation

- Lesson 1:: Introduction To Science, Technology and SocietyDocument17 pagesLesson 1:: Introduction To Science, Technology and SocietyAlexis A. AguilarPas encore d'évaluation

- Materi Bahasa Inggris Kelas 9 - LabelsDocument12 pagesMateri Bahasa Inggris Kelas 9 - LabelsEnglish Is fun67% (3)

- 'S Outfits and Emergency Escape Breathing Devices (Eebd)Document11 pages'S Outfits and Emergency Escape Breathing Devices (Eebd)Thurdsuk NoinijPas encore d'évaluation

- Binac Ao STR EET: Vicinity Map & Street View, Source Google MapsDocument17 pagesBinac Ao STR EET: Vicinity Map & Street View, Source Google MapsBee AnquilianoPas encore d'évaluation

- Cabuyao Integrated National High School: The Problem and Its BackgroundDocument4 pagesCabuyao Integrated National High School: The Problem and Its BackgroundJohn Carlo MolinaPas encore d'évaluation

- Chemistry Tshirt ProjectDocument7 pagesChemistry Tshirt Projectapi-524483093Pas encore d'évaluation

- (Distracted Subjects) CHAPTER 2. Reading The Language of Distraction - Hamlet, Macbeth, King LearDocument23 pages(Distracted Subjects) CHAPTER 2. Reading The Language of Distraction - Hamlet, Macbeth, King LearLCAP ConsultingPas encore d'évaluation

- Drug Study Pre OpDocument6 pagesDrug Study Pre OpgiaPas encore d'évaluation

- Narrative Poetry 6305Document14 pagesNarrative Poetry 6305Siti AisyahPas encore d'évaluation