Académique Documents

Professionnel Documents

Culture Documents

Project Feasibility Studies ch8

Transféré par

Pradeep KrishnanTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Project Feasibility Studies ch8

Transféré par

Pradeep KrishnanDroits d'auteur :

Formats disponibles

8

Crockery (Bone China)

PRODUCT CODE QUALITY AND STANDARDS MONTH AND YEAR OF PREPARATION PREPARED BY : 94326 and 94389 : As per Customers Specification : January, 2003 : Small Industries Service Institute, 10 Industrial Estate, Pologround, Indore - 452 015 (M.P.) Phone Nos.: 0731 - 421048/421540/421649 Fax No. : 0731 - 420723 E-mail: sisiind@sancharnet.in Website: www.sisiindore.com

INTRODUCTION

Mankind has a natural liking and inclination towards clay made utensils/crockery. Though a number of substitute items appeared in the market ultimately the clay crockery has sustained. The fancy items of bone china like tableware, crockery, decorative items, lamp shades etc. is finding a good domestic as well as export market.

B ASIS AND PRESUMPTIONS

The unit will run on single shift basis in 300 working days in a year. There will be a 8 hours shift in a day. Furnance will work on three shifts basis. Full production capacity will be achieved in 3 years. Wa g e s a r e t a k e n a s p e r t h e minimum wages of the Government. Rate of interest on borrowings14%. Life of plant and machinery-10 years. Life of furnace-5 years. Cost of plant and machinery as per latest quotations.

MARKET POTENTIAL

The decorative items made of bone china are elegant for while there is a customer preference. The demand of bone china crockery and decorative item in urban areas is gradually increasing. There is a good scope of export to Gulf countries.

50

CROCKERY (BONE CHINA)

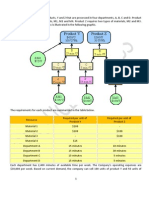

IMPLEMENTATION SCHEDULE

Sl. Activity Period No. (in months) 1. Possession of land 2 2. Construction of building 5 3. Purchase of machinery 8 4. Installation of machinery 12 5. Trial production 14

Motive Power Pollution Control

48 H. P.

Bone China unit has to take no objection certificate from the State Pollution Control Board as per rule.

FINANCIAL ASPECTS

A. Fixed Capital

(i) Land and Building Land 2000 sq. mtr @ Rs. 550 sq. mtr. Building Work shed 500 sq. mtr. @ Rs. 1,550 sq. mtr. Office Store 100 sq. mtr. @ Rs. 1,550 sq. mtr. Total (ii) Machinery and Equipments Particulars Ball mill 5' x 5 1/2' with motor and other accessories Ball mill 3' x 3' with 7 HP motor and other accessories Blunger 10' with 5 HP motor Agitator with 3 HP motor Vibrating screen with magnetic separator Filter press 44' dia, 30 plates De-airing pug mills with 5 HP motor Saggar press hand operated Pot mills 2 HP motor Shuttle kiln 6 Cubic meter Muffle electric furnace Installation, electrification expenditure Plaster of Paris moulds Quantity (Nos.) 3 Value (Rs.) 64,000 7,75,000 1,55,000 20,30,000 (Rs.) 11,00,000

TECHNICAL ASPECTS

Process of Manufacture China clay powder, calcined quartz powder, potash felspar, bone ash and other raw materials are weighed proportionately and fed in to ball mill for fine grinding. This mixture is ground to 300 mesh and sieved after passing through magnetic separator. The slurry is placed in agitator. This slurry is again pumped in to filter press, cake received from filter press is mixed with water and electrolyte to make casting slip. Now desired items are cast in Plaster of Paris moulds. Articles are taken out from moulds and dried. These articles are finished. After finishing and drying articles are biscuit fired. Articles are glazed by dipping or spraying and again after drying these articles are gloss fired. At last ready articles are decorated by transfer papers, ceramic colour or gold. These decorated articles are fired at 650C in electrical furnace. Thus ready articles are sorted and packed for despatch. Quality Control and Standards As per customers specification. Production Capacity (per annum) Bone China Crockery and Art ware Quantity : 130 MT Value : Rs. 94, 50, 000

32,000

1 1 2 1 1 1 1 2 1 L.S. L.S.

54,000 26,500 54,000 63,000 64,000 17,000 5,500 17,00,000 3,20,000 2,40,000 40,000

C ROCKERY (BONE CHINA)

Particulars Rack, panels etc. Testing equipments Office furniture Total (iii) Pre-operative Expenses Total Fixed Capital Land Building Plant and Machinery Preliminary Expenses Total Quantity (Nos.) L.S. L.S. L.S. Value (Rs.) 16,000 6,000 40,000 27,42,000 Rs. 22,000 (Rs.) 11,00,000 9,30,000 27,42,000 22,000 47,94,000 (iii) Utilities Power 48 HP Diesel L.D.O. 12 KL @ Rs. 16,000 per K.L. Total (iv) Other Contingent Expenses Postage and Stationery Advertisement and publicity Insurance Telephone Bills Consumables Repair and Maintenance Miscellaneous Expenses Total (v) Total Working Capital (per month) Raw Materials Salaries and Wages Utilities Other Contingent Expenses Total Working Capital for 3 months (5,40,000 x 3) Particulars Frit Plaster of Paris Fire clay Sillimanite Decoration paper Packing material Other Contingent expenses Quantity 1 MT 2 MT 3.0 MT 0.18 MT L.S. L.S. L.S. Total or Say Rate (Rs.) 17,000 2,100 1,575 3,700 10,000 10,000 6,500 Cost (Rs.) 17,000 4,200 4,725 666 10,000 10,000 6,500 1,66,351 1,66,400 (Rs.) 15,000 1,92,000 2,07,000 (Rs.) 1,800 1,200 2,800 2,000 1,200 1,200 1,500 11,700 (Rs.)

51

B. Working Capital (per month)

(i) Salary and Wages Particulars Manager Production Manager Supervisors Accountant/Clerk Firemen Moulders Skilled Workers Un-skilled Workers Decorators Peons Electrician Nos. 1 1 3 1 4 2 25 15 2 2 1 Salary (Rs.) 6,500 5,500 3,500 3,000 3,000 2,800 2,200 1,800 2,000 1,800 2,000 Total (Rs.) 6,500 5,500 10,500 3,000 12,000 5,600 55,000 27,000 4,000 3,600 2,000 1,34,700 20,205 Total or Say (ii) Raw Materials Particulars Bone ash China clay Felspar Quantity 9 MT 2.4 MT 6.1 MT Rate (Rs.) 2,650 1,000 Cost (Rs.) 6,360 6,100 1,54,905 1,54,900

Total

1,66,400 1,54,900 2,07,000 11,700 5,40,000 16,20,000

Add Perquisites @ 15%

11,200 1,00,800

C. Total Capital Investment

Fixed Capital Working Capital for 3 months Rs. 47,94,000 Rs. 16,20,000 Total Rs. 64,14,000

52

CROCKERY (BONE CHINA)

FINANCIAL ANALYSIS

(1) Cost of Production (per annum) Total Recurring Cost Depreciation on Building @ 5% Depreciation on furnace @ 20% Depreciation on Plant and Machinery @ 10% Depreciation on Furniture and Fixtures @ 20% Interest on Total Capital Investment @ 14% Total (2) Turnover (per annum) Item Quantity Rate (Tonnes) Value (Rs.) (Rs.) 64,80,000 46,500 4,04,000 38,600 19,200 8,97,960 78,86,260

(6) Break-even Point Fixed Cost 1. Depreciation on Building 2. Depreciation on Plant and Machinery and Furnace 3. Depreciation on Furniture and Fixture 4. Interest on Borrowings @ 14% 5. 40% of Salary and Wages 6. 40% of Other Contingent Expenses 7. Insurance Total B.E.P. = Fixed Cost x 100 Fixed Cost + Profit = 22,26,100 x 100 22,26,100 + 15,63,740 (Rs.) 46,500 4,42,600 19,200 8,97,960 7,43,520 42,720 33,600 22,26,100

Bone China Waxes and Art ware Grade A Grade B 50 M.T. 80 M.T. 85,000 65,000 Total (3) Net Profit (per annum) = Turnover Cost of Production = Rs. 94,50,000 78,86,260 = Rs. 15,63,740 (4) Net Profit Ratio = Net Profit per annum x 100 Turn Over per annum = 15,63,740 94,50,000 x 100 = 16.55% (5) Rate of Return = Net Profit per annum x 100 Total Capital Investment = 15,63,740 x 100 64,14,000 = 24.38% 42,50,000 52,00,000 94,50,000

= 22,26,100 x 100 37,89,840 = 58.74%

Addresses of Plant and Machinery/ Furnace Suppliers 1. M/s. Shiv Industries 206, Veena Dalvi Industrial Estate, Oshiwara, Jogeshwari (W), Mumbai - 400 102 2. M/s. Erich Magnetics 176/6B/10, Old Tijab Mill, Bholanath Nagar, Shahadra, Delhi - 110 032 3. M/s. Amic Industries Private Limited 10, B.T. Road, Kolkata - 700 056 4. M/s. Eleind Engineering Private Limited, D-20/2, Okhla Industrial Area, Phase - II, New Delhi - 110 020

C ROCKERY (BONE CHINA)

53

Raw Material Suppliers 1. M/s. Alam Ji Plaster Udyog Ramji Ki Gol, Tehsil Gurmalani, Barmer (Rajasthan) 2. M/s. Ceekay Plasters and Chemicals, 64, Industrial Area, Bikaner (Rajasthan)

3. M/s. Tower Minerals Post Office- Malpur, Zenipur, (Rajasthan) 4. M/s. Mahavir Minerals Private Limited Jautani Bazar, Ajmer, (Rajasthan)

Vous aimerez peut-être aussi

- 25Document11 pages25Zaheer Ahmed SwatiPas encore d'évaluation

- Case Study MSDocument7 pagesCase Study MSMoaz MunirPas encore d'évaluation

- Exercises Ch05Document3 pagesExercises Ch05Ahmed El KhateebPas encore d'évaluation

- PG 20 024 Miscellaneous AssignmentsDocument21 pagesPG 20 024 Miscellaneous AssignmentsSakshi BakliwalPas encore d'évaluation

- Capacity Planning: Optimize Production Through Demand & Capacity AnalysisDocument11 pagesCapacity Planning: Optimize Production Through Demand & Capacity AnalysisTrisha Sargento EncinaresPas encore d'évaluation

- Location Planning Analysis Solutions Cost Volume ProfitsDocument9 pagesLocation Planning Analysis Solutions Cost Volume ProfitsKenneth KibataPas encore d'évaluation

- CH 09Document3 pagesCH 09ghsoub77750% (2)

- OMDocument1 pageOMLULUPas encore d'évaluation

- Worksheet 17 CBDocument8 pagesWorksheet 17 CBTrianbh SharmaPas encore d'évaluation

- Taller OPT-SoluciónDocument14 pagesTaller OPT-SoluciónMauricio Alejandro Buitrago Soto100% (1)

- Activity No 1Document2 pagesActivity No 1Makeyc Stis100% (1)

- New Microsoft Office Word DocumentDocument5 pagesNew Microsoft Office Word DocumentTariq RahimPas encore d'évaluation

- To Record Raw Materials Purchased On AccountDocument4 pagesTo Record Raw Materials Purchased On AccountKathleen MercadoPas encore d'évaluation

- Q No.1 Use Following Title of Accounts To Complete Journal Entries of Given TransactionsDocument5 pagesQ No.1 Use Following Title of Accounts To Complete Journal Entries of Given TransactionsNoorPas encore d'évaluation

- Review For Quiz 3 Part 2Document18 pagesReview For Quiz 3 Part 2Mariah ValizadoPas encore d'évaluation

- Estimating service costs in a consulting firmDocument11 pagesEstimating service costs in a consulting firmPat0% (1)

- Gutierrez Construction Company journal entriesDocument3 pagesGutierrez Construction Company journal entriesAj GuanzonPas encore d'évaluation

- Activity No. 5 Comprehensive ProblemsDocument1 pageActivity No. 5 Comprehensive ProblemsZenCamandang100% (1)

- Projected Financials for Water Refilling StationDocument9 pagesProjected Financials for Water Refilling StationjanePas encore d'évaluation

- Group 4 Optimal Combination of InputsDocument7 pagesGroup 4 Optimal Combination of InputsJessaPas encore d'évaluation

- Planning, Control and Performance Management: Time Allowed 3 Hours ALL FOUR Questions Are Compulsory and MUST Be AnsweredDocument5 pagesPlanning, Control and Performance Management: Time Allowed 3 Hours ALL FOUR Questions Are Compulsory and MUST Be Answeredapi-19836745Pas encore d'évaluation

- Chapter8 Activity Based CostingEuroDocument3 pagesChapter8 Activity Based CostingEuroShaheera SuhaimiPas encore d'évaluation

- Capital Budgeting AnalysisDocument6 pagesCapital Budgeting AnalysisSufyan Ashraf100% (1)

- Accounting 11 Activity 1Document1 pageAccounting 11 Activity 1Ma Trixia Alexandra CuevasPas encore d'évaluation

- Dissolution of Partnership Firm Accounting ProblemsDocument5 pagesDissolution of Partnership Firm Accounting ProblemsPrageeth Roshan WeerathungaPas encore d'évaluation

- AIS Activity No. 2 Journalizing Using Peachtree and Generation FSDocument2 pagesAIS Activity No. 2 Journalizing Using Peachtree and Generation FSShaira UntalanPas encore d'évaluation

- Financial AssumptionsDocument4 pagesFinancial AssumptionsMary Ann AntenorPas encore d'évaluation

- Accounting 11 Activity 2Document1 pageAccounting 11 Activity 2Ma Trixia Alexandra CuevasPas encore d'évaluation

- Final Exam Joint Arrangements - ACTG341 Advanced Financial Accounting and Reporting 1Document7 pagesFinal Exam Joint Arrangements - ACTG341 Advanced Financial Accounting and Reporting 1Marilou Arcillas PanisalesPas encore d'évaluation

- Mini Case Capital Budgeting ProcessDocument6 pagesMini Case Capital Budgeting Process032179253460% (1)

- OPERATIONS RESEARCH Assignment - 1 Formulation of LPPDocument5 pagesOPERATIONS RESEARCH Assignment - 1 Formulation of LPPVatsal Singh100% (2)

- CostDocument2 pagesCostjeams vidalPas encore d'évaluation

- Pacific Pool CompanyDocument10 pagesPacific Pool CompanyAnayeli SanchezPas encore d'évaluation

- Hart Nike Case ADocument19 pagesHart Nike Case Atanmay786Pas encore d'évaluation

- Coffee Bean IncDocument5 pagesCoffee Bean Inctiff556Pas encore d'évaluation

- Module 9 AssignmentDocument4 pagesModule 9 AssignmentJessica TurnerPas encore d'évaluation

- Selected Account Balances and Transactions of Titan Foundry Inc Follow MayDocument2 pagesSelected Account Balances and Transactions of Titan Foundry Inc Follow MayAmit PandeyPas encore d'évaluation

- Logitech Case SampleDocument3 pagesLogitech Case SampleRi VaPas encore d'évaluation

- Managerial Acctg Problems & Exercises in CVP AnalysisDocument4 pagesManagerial Acctg Problems & Exercises in CVP AnalysisJanellePas encore d'évaluation

- 2 Abm Fabm2 12 W2 3 Melc 4 1Document9 pages2 Abm Fabm2 12 W2 3 Melc 4 1Rializa Caro BlanzaPas encore d'évaluation

- Accounting 1 FinalDocument2 pagesAccounting 1 FinalchiknaaaPas encore d'évaluation

- Accounting Cycle Journal Entries Without Chart of Accounts Case IIIDocument3 pagesAccounting Cycle Journal Entries Without Chart of Accounts Case IIIGoogle UserPas encore d'évaluation

- Date Accounts Debit CreditDocument3 pagesDate Accounts Debit Creditjordan_09Pas encore d'évaluation

- Wheatco-Chemco partnership tensionsDocument3 pagesWheatco-Chemco partnership tensionsBelly Satrio Wiwoho0% (3)

- Cost Volume Profit AnalysisDocument4 pagesCost Volume Profit AnalysisBeatriz Basa DimainPas encore d'évaluation

- Easy Company Financial PositionDocument2 pagesEasy Company Financial PositionSheila May SantosPas encore d'évaluation

- Economics PrelimsDocument2 pagesEconomics PrelimsYannie Costibolo IsananPas encore d'évaluation

- 3, Fa1 Question Book 2021 (Gen 5) - G I Cho Sinh ViênDocument76 pages3, Fa1 Question Book 2021 (Gen 5) - G I Cho Sinh ViênHoàng Vũ HuyPas encore d'évaluation

- Business Improvement Plan Presentation Dti Region 11 - Province - Negosyo CenterDocument12 pagesBusiness Improvement Plan Presentation Dti Region 11 - Province - Negosyo CenterNhizza Dawn Aleria-Daligdig Tuburan100% (1)

- Eoq PDFDocument23 pagesEoq PDFMica Ella Gutierrez0% (1)

- Lettuce ProductionDocument14 pagesLettuce ProductionJay ArPas encore d'évaluation

- Sales Budget, Production Budget, Materials Purchases Budget (James IncDocument6 pagesSales Budget, Production Budget, Materials Purchases Budget (James IncGiselle MartinezPas encore d'évaluation

- Practice Set - A3Document6 pagesPractice Set - A3Dayanara VillanuevaPas encore d'évaluation

- Straight ProblemsDocument1 pageStraight ProblemsMaybelle100% (1)

- MFI Staff Guide Break-Even AnalysisDocument7 pagesMFI Staff Guide Break-Even AnalysismhussainPas encore d'évaluation

- Shuttle Cock Manufacturing Project ProfileDocument5 pagesShuttle Cock Manufacturing Project Profilepradip_kumarPas encore d'évaluation

- Bleaching and Dyeing of Cotton Knitted Fabric: NtroductionDocument5 pagesBleaching and Dyeing of Cotton Knitted Fabric: NtroductionPRATEEKMAHAJAN02Pas encore d'évaluation

- Ice Cream Churner Manufacturing Project ProfileDocument9 pagesIce Cream Churner Manufacturing Project ProfileBunty RathorePas encore d'évaluation

- CH 21Document5 pagesCH 21Kader Kunju RizwanPas encore d'évaluation

- Uniform Dietary Requirements+measurementsdraftDocument2 pagesUniform Dietary Requirements+measurementsdraftPradeep KrishnanPas encore d'évaluation

- BMP51 Brochure Europe EnglishDocument8 pagesBMP51 Brochure Europe EnglishPradeep KrishnanPas encore d'évaluation

- Asus G703vm-E13530 - GL503VD - VM - GL703VD - VM - V2 - ADocument108 pagesAsus G703vm-E13530 - GL503VD - VM - GL703VD - VM - V2 - APradeep KrishnanPas encore d'évaluation

- Money MavericksDocument205 pagesMoney MavericksPradeep KrishnanPas encore d'évaluation

- BMP 71 Nimh Batteries SdsDocument11 pagesBMP 71 Nimh Batteries SdsPradeep KrishnanPas encore d'évaluation

- BMP41 Printer BrochureDocument12 pagesBMP41 Printer BrochurePradeep KrishnanPas encore d'évaluation

- BMP51 BMP53 BrochureDocument20 pagesBMP51 BMP53 BrochurePradeep KrishnanPas encore d'évaluation

- Natural Gas in EuropeDocument48 pagesNatural Gas in EuropePradeep KrishnanPas encore d'évaluation

- Bretton Woods Agreements Act: IMF and World BankDocument41 pagesBretton Woods Agreements Act: IMF and World BankPradeep KrishnanPas encore d'évaluation

- BSP41 Sellsheet Europe EnglishDocument2 pagesBSP41 Sellsheet Europe EnglishPradeep KrishnanPas encore d'évaluation

- Brady Workstation BrochureDocument6 pagesBrady Workstation BrochurePradeep KrishnanPas encore d'évaluation

- Asbestos Pressure Pipes and FittingsDocument6 pagesAsbestos Pressure Pipes and FittingsPradeep KrishnanPas encore d'évaluation

- BradyPrinter I7100 Brochure Europe EnglishDocument16 pagesBradyPrinter I7100 Brochure Europe EnglishPradeep KrishnanPas encore d'évaluation

- BMP71 Brochure Europe EnglishDocument32 pagesBMP71 Brochure Europe EnglishPradeep KrishnanPas encore d'évaluation

- Brady360-5year Warranty Informational SheetDocument2 pagesBrady360-5year Warranty Informational SheetPradeep KrishnanPas encore d'évaluation

- Project Feasibility Studies ch2Document7 pagesProject Feasibility Studies ch2Pradeep KrishnanPas encore d'évaluation

- Project Feasibility Studies ch6Document5 pagesProject Feasibility Studies ch6Pradeep KrishnanPas encore d'évaluation

- Project Feasibility Studies ch10Document6 pagesProject Feasibility Studies ch10Pradeep KrishnanPas encore d'évaluation

- Flooring Tiles (Granite) Production ReportDocument6 pagesFlooring Tiles (Granite) Production ReportRajneesh RawatPas encore d'évaluation

- Project Feasibility Studies ch3Document7 pagesProject Feasibility Studies ch3Pradeep KrishnanPas encore d'évaluation

- Project Feasibility Studies ch7Document5 pagesProject Feasibility Studies ch7Pradeep KrishnanPas encore d'évaluation

- Project Feasibility Studies ch9Document7 pagesProject Feasibility Studies ch9Pradeep KrishnanPas encore d'évaluation

- Cement Mosaic Flooring Tiles Production GuideDocument6 pagesCement Mosaic Flooring Tiles Production GuidePradeep KrishnanPas encore d'évaluation

- Project Feasibility Studies ch2Document7 pagesProject Feasibility Studies ch2Pradeep KrishnanPas encore d'évaluation

- Asbestos Pressure Pipes and FittingsDocument6 pagesAsbestos Pressure Pipes and FittingsPradeep KrishnanPas encore d'évaluation

- AtropineDocument1 pageAtropinePradeep KrishnanPas encore d'évaluation

- Shiva Home - DCFDocument2 pagesShiva Home - DCFshyamsundar_cePas encore d'évaluation

- Kinematics Problem SetDocument1 pageKinematics Problem SetMohammad JubranPas encore d'évaluation

- Equations 2Document8 pagesEquations 2Patrick ValdezPas encore d'évaluation

- The Focus Shooting Method CourseDocument48 pagesThe Focus Shooting Method CourseKobiXDPas encore d'évaluation

- Vedic Astrology OverviewDocument1 pageVedic Astrology Overviewhuman999100% (8)

- Divide and Conquer (Closest Pair, Convex Hull, Strassen Matrix Multiply) DemoDocument27 pagesDivide and Conquer (Closest Pair, Convex Hull, Strassen Matrix Multiply) DemoAnand KumarPas encore d'évaluation

- Psychopathology: Dr. Shafqat Huma MBBS, FCPS (Psychiatry) Fellowship in Addiction Psychiatry (USA)Document48 pagesPsychopathology: Dr. Shafqat Huma MBBS, FCPS (Psychiatry) Fellowship in Addiction Psychiatry (USA)sfrtr100% (1)

- Blower Selection For Wastewater Aeration PDFDocument10 pagesBlower Selection For Wastewater Aeration PDFRobert MontoyaPas encore d'évaluation

- Multi Purpose StadiumDocument130 pagesMulti Purpose StadiumEmmanuel SolomonPas encore d'évaluation

- LearnEnglish Video Zone How These Women Changed Science ForeverDocument3 pagesLearnEnglish Video Zone How These Women Changed Science ForeverDaniella MensatoPas encore d'évaluation

- Module 1 Introduction To Ecology and The BiosphereDocument38 pagesModule 1 Introduction To Ecology and The BiosphereFrancis Rey Bactol PilapilPas encore d'évaluation

- Bentone LTDocument2 pagesBentone LTdamiendamPas encore d'évaluation

- CSO Skull SeriesDocument2 pagesCSO Skull SeriesWilchanPas encore d'évaluation

- Pharmaceutics | Water Solubility and Dissolution RateDocument11 pagesPharmaceutics | Water Solubility and Dissolution RateAnnisa AgustinaPas encore d'évaluation

- Research PaperDocument13 pagesResearch PaperHamid ElmyPas encore d'évaluation

- Avh p6050dvd EngDocument119 pagesAvh p6050dvd EngcaimanaterPas encore d'évaluation

- MSDS Corn CobDocument2 pagesMSDS Corn CobMUHAMMAD YOGA BRILLIANTOPas encore d'évaluation

- Organization Structure Training KAJARIADocument30 pagesOrganization Structure Training KAJARIAViswanth GanaparthiPas encore d'évaluation

- CodigosDocument73 pagesCodigosEnzo Miguel Sarabia MontesPas encore d'évaluation

- Design and Development of Manually Operated ReaperDocument8 pagesDesign and Development of Manually Operated ReaperIOSRjournalPas encore d'évaluation

- AUS Triboard ManuaDocument112 pagesAUS Triboard ManuaWan RidsPas encore d'évaluation

- Lea 2 PDFDocument21 pagesLea 2 PDFKY Renz100% (1)

- 5-in-1 Document Provides Lessons on Trees and Environmental ConservationDocument45 pages5-in-1 Document Provides Lessons on Trees and Environmental ConservationPriya DharshiniPas encore d'évaluation

- ASSIGNMENTDocument10 pagesASSIGNMENTKoleen Lopez ÜPas encore d'évaluation

- ParikalpDocument43 pagesParikalpManish JaiswalPas encore d'évaluation

- Dr. Ghusoon Mohsin Ali: Al-Mustansiriya University College of Engineering Electrical Engineering DepartmentDocument89 pagesDr. Ghusoon Mohsin Ali: Al-Mustansiriya University College of Engineering Electrical Engineering Departmentهمام الركابي100% (1)

- RLCraft v2.9 ChangelogDocument28 pagesRLCraft v2.9 ChangelogSơn TrươngPas encore d'évaluation

- What Is RTN/Microwave TechnologyDocument27 pagesWhat Is RTN/Microwave TechnologyRavan AllahverdiyevPas encore d'évaluation

- Contemporary Philippine Arts From The Regions: Quarter 3Document15 pagesContemporary Philippine Arts From The Regions: Quarter 3Ackie Inacay RosarioPas encore d'évaluation

- Motherboards Tuf z270 Mark 2Document70 pagesMotherboards Tuf z270 Mark 2Jonah HexPas encore d'évaluation