Académique Documents

Professionnel Documents

Culture Documents

Acrylic Acid

Transféré par

Elok Faiqotul UmmaDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Acrylic Acid

Transféré par

Elok Faiqotul UmmaDroits d'auteur :

Formats disponibles

PERP/PERP ABSTRACTS 2010

Acrylic Acid

Technology and Cost Estimates for

Production Via Propylene Oxidation,

3HP Fermentation, (Glycerol Derived)

Acrolein, (Ethylene-Oxide Derived) -

Propiolactone, Acetylene Complex.

Regional supply, demand and trade

forecasts.

PERP 08/09

Report Abstract

August 2010

Report Abstract

Acrylic Acid

PERP 08/09

August 2010

www.chemsystems.com

The ChemSystems Process Evaluation/Research Planning (PERP) program is recognized globally as

the industry standard source for information relevant to the chemical process and refining industries.

PERP reports are available as a subscription program or on a report by report basis.

Nexant, Inc. (www.nexant.com) is a leading management consultancy to the global energy, chemical, and related industries. For over 38 years,

ChemSystems has helped clients increase business value through assistance in all aspects of business strategy, including business intelligence, project

feasibility and implementation, operational improvement, portfolio planning, and growth through M&A activities. Nexant has its main offices in

San Francisco (California), White Plains (New York), and London (UK), and satellite offices worldwide.

For further information about these reports, please contact the following:

New York, Dr. Jeffrey S. Plotkin, Vice President and Global Director, PERP Program, phone: + 1-914-609-0315, e-mail: jplotkin@nexant.com;

or Heidi Junker Coleman, Multi-client Programs Administrator, phone: + 1-914-609-0381, e-mail: hcoleman@nexant.com.

London, Dr. Alexander Coker, Manager PERP Program, phone: + 44-(20)-70950-1570, e-mail: acoker@nexant.com.

Bangkok, Maoliosa Denye, Marketing Manager, Energy & Chemicals Consulting: Asia, phone: + 66-2793-4612, e-mail: mdenye@nexant.com.

Website: www.chemsystems.com

Copyright by Nexant Inc. 2010. All Rights Reserved.

www.chemsystems.com

CHEMSYSTEMS PERP PROGRAM

Report Abstract Acrylic Acid 08/09

1

PERP ABSTRACTS 2010 00101.0009.4103

Acrylic Acid

INTRODUCTION

Acrylic acid (also known as propenoic acid) is a colorless transparent liquid with a pungent

smell. This corrosive chemical is miscible in water, alcohol, and esters and polymerizes readily

in the presence of oxygen forming acrylic resins. For this reason, the product is usually

stabilized with polymerization inhibitors such as methyl ethyl hydroquinone (MEHQ).

There are two grades of acrylic acid commercially available:

Technical Grade Acrylic Acid which usually has about 94 percent acrylic acid content (the

remainder being mainly maleic anhydride, propionic acid, acetic acid and furfural). Technical

(also referred to as crude) acrylic acid is suitable for the production of commodity acrylate

esters. Major markets for the commodity esters include surface coating, adhesives and sealants,

textiles, plastic additives, and paper treatment.

Glacial Grade Acrylic Acid is generally used to designate grades of the acid with acrylic acid

content between 98 to 99.7 percent; although in the literature of many companies selling the

product, glacial grade is typically listed as having 99.5 to 99.7 percent acrylic acid content.

Glacial acrylic acid is suitable for the production of super absorbent polymers (for disposable

diapers), detergents, water treatment and dispersants.

The outline of this report is as follows.

Current production technology is discussed including processes for upgrading crude to

glacial product.

Developing technologies are discussed and an overview of key historical processes is

given.

Economics for the established propylene oxidation process, dehydration of (fermentation

derived) 3HP, oxidation of (glycerol derived) acrolein, and catalytic conversion of

(ethylene oxide derived) -propiolactone developing processes, as well as the historical

(gas-derived) acetylene based process are evaluated.

Commercial end-use applications and regional market overview analysis is given.

CURRENT TECHNOLOGY

Today virtually all acrylic acid is manufactured in two stages via propylene-based oxidation

processes, where separate optimization of each step leads to a higher overall yield of acrylic acid.

The chemistry of the fundamental oxidation process is summarized by the following chemical

equations:

Acrylic Acid

www.chemsystems.com

CHEMSYSTEMS PERP PROGRAM

Report Abstract Acrylic Acid 08/09

2

PERP ABSTRACTS 2010 00101.0009.4103

A family of catalysts has been developed and modified over the last several years, based on

promoted molybdenum-bismuth systems for the primary oxidation step and promoted

molybdenum-vanadium for the secondary oxidation step.

As with crude acrylic acid synthesis, purification technology varies enormously. Both

crystallization and distillation are used.

EMERGING TECHNOLOGIES

Much work has been carried out on development of a microbe that is capable of a producing 3-

hydroxypropionic acid (3HP) by a fermentation process, with subsequent dehydration to acrylic

acid. According to the companies involved, this process could be commercially available within

the next three years.

Catalysts have been developed to produce acrylic acid from glycerol and according to the

companies involved, pilot/demonstration plants could be in operation anytime between now and

the next four years.

There is developing technology to produce acrylic acid via a -propiolactone intermediate

produced by carbonylation of ethylene oxide using a patented catalyst.

A method of producing acrylic acid involving initial fermentation of a sugar to fumaric acid

followed by cross-metathesis with ethylene is being investigated.

Various companies have independently been working on routes to acrylic acid from propane

feedstock.

ECONOMICS

The following cost estimates have been developed and discussed in the report:

production of crude acrylic acid via propylene oxidation

production of glacial acrylic acid from crude acrylic acid via additive enhanced

distillation

production of glacial acrylic acid from crude acrylic acid via dynamic/static

crystallization

production of 3-hydroxypropionic acid (3HP) via fermentation of dextrose

production of glacial acrylic acid via catalytic dehydration of 3HP

production of crude acrylic acid via dehydration of glycerol to acrolein followed by

oxidation

Acrylic Acid

www.chemsystems.com

CHEMSYSTEMS PERP PROGRAM

Report Abstract Acrylic Acid 08/09

3

PERP ABSTRACTS 2010 00101.0009.4103

production of crude acrylic acid via ethylene oxide carbonylation to -propiolactone

followed by catalytic conversion

production of crude acrylic acid via gas-derived acetylene complex.

A cost comparison discussion of the processes producing crude acrylic acid has been made. The

total cost of production from raw material to crude product and upgrading crude to glacial

product has been made for all the non-fermentation processes (via the crystallization upgrading

process) and compared to the cost of the glacial product produced via fermentation.

COMMERCIAL APPLICATIONS

Acrylic acid and its esters are among the most versatile monomers for providing performance

properties to a wide variety of polymers. The major application for acrylic acid is a feedstock

for commodity acrylate esters, which include methyl, ethyl, n-butyl, and 2-ethylhexyl acrylate.

Acrylate esters impart many desirable qualities to polymeric materials, such as color stability and

clarity when exposed to light, heat and aging resistance, good weatherability, low temperature

flexibility, and acid and base resistance.

In addition to the commodity esters, smaller quantities of other alkyl acrylates are produced for

specialized applications. Functional acrylate oligomers and multifunctional acrylate esters are

consumed as raw materials in radiation curable coatings, inks, electronics manufacturing

processes, and adhesives.

While a relatively large portion of acrylic acid is consumed for production of acrylate esters, a

significant portion is upgraded (purified) into glacial acrylic acid and subsequently utilized for

the production of polyacrylic acid or copolymers which find applications in superabsorbents,

detergent co-builders, dispersants, flocculants, and thickeners. Superabsorbent polymers are

used in a number of applications where rapid absorbance of liquids is needed such as in diapers,

training pants, adult incontinence products, and feminine hygiene products. Polyacrylic acid,

generally as the sodium acrylate homopolymer, is used in replacing phosphates in laundry

detergents. It may be used alone or in conjunction with zeolite builders. Acrylic acid based

dispersants are used with a variety of solid materials, particularly clay, titanium dioxide, and

calcium carbonate. Thickeners are used in cosmetics, personal care products, and textile warp

sizing. Flocculants induce aggregation of suspended colloidal particles.

Commercial applications for commodity acrylates, specialty acrylates, polyacrylic acid, super

absorbent polymers, and detergent are discussed further in this section of the report.

Acrylic Acid

www.chemsystems.com

CHEMSYSTEMS PERP PROGRAM

Report Abstract Acrylic Acid 08/09

4

PERP ABSTRACTS 2010 00101.0009.4103

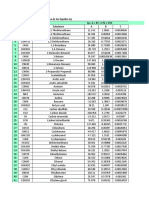

REGIONAL MARKET ANALYSIS

The acrylic acid industry is mature in the United States and Western Europe, but still developing

rapidly in some parts of Asia and the Middle East. End-use demand for acrylic acid in a mature

market is exemplified below.

U.S. Acrylic Acid Consumption by End-Use

Acrylic Acid Production Capacity for the United States, Western Europe and Asia Pacific

is tabulated by company, specific plant location and capacity

Supply, Demand and Trade (including forecast to 2014) for each of these regions is given

and discussed

Detergents,

Flocculants, Others

16%

Acrylate Esters

50%

Superabsorbent

Polymers

34%

Q210_00101.0009. 4103-charts.xls\F9. 1

www.chemsystems.com

Nexant, Inc.

San Francisco

London

Tokyo

Bangkok

Bahrain

New York

Washington

Houston

Phoenix

Madison

Boulder

Dusseldorf

Beijing

Shanghai

Paris

Vous aimerez peut-être aussi

- Child Dental Examination FormDocument1 pageChild Dental Examination FormElok Faiqotul Umma100% (2)

- CaprolactamDocument4 pagesCaprolactamArchie HisolerPas encore d'évaluation

- Fundamentals of MasstransferandkineticshydrogenationDocument14 pagesFundamentals of MasstransferandkineticshydrogenationRamandhaPrasetyaAdibrataPas encore d'évaluation

- Feasibility Study of Dimethyl Carbonate ProductionDocument3 pagesFeasibility Study of Dimethyl Carbonate ProductionIntratec SolutionsPas encore d'évaluation

- AnilineDocument2 pagesAnilineKPAC333100% (2)

- AnilineDocument1 pageAnilineCherry Pearl MiparanumPas encore d'évaluation

- Acrylic Acid Final ReportDocument13 pagesAcrylic Acid Final ReportlynnPas encore d'évaluation

- Synthesis of Ethylbenzene by Alkylation of Benzene With Diethyl Oxalate Over HZSM-5Document6 pagesSynthesis of Ethylbenzene by Alkylation of Benzene With Diethyl Oxalate Over HZSM-5manuel salazarPas encore d'évaluation

- Polyvinylchloride — 2: Main Lectures Presented at the Second International Symposium on Polyvinylchloride, Lyon-Villeurbanne, France, 5 - 9 July 1976D'EverandPolyvinylchloride — 2: Main Lectures Presented at the Second International Symposium on Polyvinylchloride, Lyon-Villeurbanne, France, 5 - 9 July 1976A. GuyotPas encore d'évaluation

- E Book OdontologyDocument347 pagesE Book OdontologyElok Faiqotul UmmaPas encore d'évaluation

- Ethylene Plant Planning StudyDocument8 pagesEthylene Plant Planning StudyAngelica Rosario Flores LecoñaPas encore d'évaluation

- Ethylene Oxide Ethylene Glycol Process Flow DiagramDocument2 pagesEthylene Oxide Ethylene Glycol Process Flow DiagramPrabhdeep Singh Virdi100% (5)

- ISO 14912 CorrectionsDocument3 pagesISO 14912 CorrectionsKazim RazaPas encore d'évaluation

- Acrylic Acid Production - CompressDocument82 pagesAcrylic Acid Production - CompressDavid Berkat H SPas encore d'évaluation

- Ullmann's Enc. of Industrial Chemistry PLANTA.Document12 pagesUllmann's Enc. of Industrial Chemistry PLANTA.yoelarismendi100% (1)

- Market SurveyDocument4 pagesMarket SurveyGenesis LowPas encore d'évaluation

- Acrylic Acid ProductionDocument10 pagesAcrylic Acid ProductionGerrard ArchuletaPas encore d'évaluation

- Kinetics of Propylene Glycol HydrochlorinationDocument4 pagesKinetics of Propylene Glycol HydrochlorinationWidya Isti AriantiPas encore d'évaluation

- Acrylic Acid - MohitDocument42 pagesAcrylic Acid - MohitvickuPas encore d'évaluation

- Phosgene-Free Route To Toluene DiisocyanateDocument399 pagesPhosgene-Free Route To Toluene DiisocyanateAhmed AliPas encore d'évaluation

- PDDocument2 pagesPDnur_ika_1Pas encore d'évaluation

- Hydrogenolysis of Glycerol To Propylene GlycolDocument7 pagesHydrogenolysis of Glycerol To Propylene GlycolLelecosPas encore d'évaluation

- Ethylene GlycolDocument4 pagesEthylene GlycolAli AhsanPas encore d'évaluation

- Vinyl AcetateDocument5 pagesVinyl AcetateroxettePas encore d'évaluation

- Official Acrylic Acid 0712docxDocument42 pagesOfficial Acrylic Acid 0712docxTÚ Cao Ngọc ThiệnPas encore d'évaluation

- Chemical Kinetics On Thermal Decompositions of CumeneDocument8 pagesChemical Kinetics On Thermal Decompositions of CumeneMario Alonso Velasquez FlorezPas encore d'évaluation

- Energy Saving of A Methyl Methacrylate Separation Process PDFDocument11 pagesEnergy Saving of A Methyl Methacrylate Separation Process PDFClaudia CelestinoPas encore d'évaluation

- Dimethyl TerephthalateDocument9 pagesDimethyl Terephthalatehung_metalPas encore d'évaluation

- Manufacturing of Acrylic AcidDocument27 pagesManufacturing of Acrylic Acidnikhil tanwarPas encore d'évaluation

- Acrylic AcidDocument4 pagesAcrylic AcidDita NainggolanPas encore d'évaluation

- Metyl MetacrylatDocument12 pagesMetyl MetacrylatNguyen Duy Vu VuPas encore d'évaluation

- Acrylic Acid ProductionDocument2 pagesAcrylic Acid ProductionZeynep HoşgörPas encore d'évaluation

- N-Butane To Maleic AnhydrideDocument6 pagesN-Butane To Maleic AnhydrideNomeacuerdo Yo MismoPas encore d'évaluation

- Production of Ethylene Glycol PDFDocument89 pagesProduction of Ethylene Glycol PDFwahab aliPas encore d'évaluation

- Report BTPDocument47 pagesReport BTPvpsrpuchPas encore d'évaluation

- AIS-CHEM Polystyrene ProductionDocument58 pagesAIS-CHEM Polystyrene ProductionkaleijaPas encore d'évaluation

- FYP ProposalDocument11 pagesFYP ProposalArslan SamPas encore d'évaluation

- ETHYLBENZENEDocument19 pagesETHYLBENZENEolaPas encore d'évaluation

- Project: Design of A Reactor For The Aniline ProductionDocument19 pagesProject: Design of A Reactor For The Aniline ProductionLUIS ESTEBAN VÁSQUEZ CASTANEDAPas encore d'évaluation

- Progress in Synthesis of Ethylene Glycol Through C1 ChemicalDocument10 pagesProgress in Synthesis of Ethylene Glycol Through C1 ChemicalFelipe A. Peña RincónPas encore d'évaluation

- Reactor Design 7SONDocument53 pagesReactor Design 7SONYasemin KaradağPas encore d'évaluation

- Mtbe 3 - DP 2Document303 pagesMtbe 3 - DP 2Faiz ZainiPas encore d'évaluation

- POLYPROPYLENE I Thesis (Final)Document8 pagesPOLYPROPYLENE I Thesis (Final)falmubaddelPas encore d'évaluation

- Production of IsopropanolDocument9 pagesProduction of IsopropanolJohanPas encore d'évaluation

- The Chemistry of Dimethyl CarbonateDocument11 pagesThe Chemistry of Dimethyl Carbonatenilesh_ghm21Pas encore d'évaluation

- MP DiolDocument6 pagesMP DiolJijo T GeorgePas encore d'évaluation

- Bisphenol A Epoxy ResinDocument1 pageBisphenol A Epoxy ResincnhathoangPas encore d'évaluation

- Vinyl Chloride MonomerDocument10 pagesVinyl Chloride MonomerAndiniPutriPranintyaPas encore d'évaluation

- Ethyl Benzene Plant DesignDocument45 pagesEthyl Benzene Plant DesignfaridzawiPas encore d'évaluation

- Azeotropic & Extractive DistillationDocument39 pagesAzeotropic & Extractive DistillationMani EarnPas encore d'évaluation

- 64788Document35 pages64788ghatak2100% (1)

- G 1 PDFDocument199 pagesG 1 PDFKing HenryPas encore d'évaluation

- Ethylbenzene ProductionDocument30 pagesEthylbenzene ProductionUum LukmanPas encore d'évaluation

- Cumene To PhenolDocument73 pagesCumene To Phenolvpsrpuch67% (3)

- Production of Cyclohexanol and Cyclohexanone Through Oxidation of CyclohexaneDocument2 pagesProduction of Cyclohexanol and Cyclohexanone Through Oxidation of CyclohexaneArmin PatelPas encore d'évaluation

- Produxction of Vinyl Acetate From EthyleneDocument9 pagesProduxction of Vinyl Acetate From EthyleneSajid AliPas encore d'évaluation

- Propylene GlycolDocument4 pagesPropylene GlycolApsari Puspita AiniPas encore d'évaluation

- Design Project 2 (Nkb40303) Production of Acrylonitrile From Propylene and AmmoniaDocument75 pagesDesign Project 2 (Nkb40303) Production of Acrylonitrile From Propylene and AmmoniaNUR AKMAL HISHAMPas encore d'évaluation

- QA For Polymer Webinar - FINALDocument7 pagesQA For Polymer Webinar - FINALBamrung SungnoenPas encore d'évaluation

- Vinyl Chloride ProductionDocument11 pagesVinyl Chloride ProductionHabib Maulana YasmintoPas encore d'évaluation

- Ethyl BenzeneDocument11 pagesEthyl BenzeneIan Jasper SabordoPas encore d'évaluation

- Process Evaluation Research Planning Program (Acetic Acid)Document10 pagesProcess Evaluation Research Planning Program (Acetic Acid)Wisnu Rochman Hidayatullah0% (1)

- Mini Project Full PDFDocument37 pagesMini Project Full PDFMohamad El KheirPas encore d'évaluation

- Carboxylic Ortho Acid Derivatives: Preparation and Synthetic Applications: Preparation and Synthetic ApplicationsD'EverandCarboxylic Ortho Acid Derivatives: Preparation and Synthetic Applications: Preparation and Synthetic ApplicationsPas encore d'évaluation

- How to Name an Inorganic Substance: A Guide to the Use of Nomenclature of Inorganic Chemistry: Definitive Rules 1970D'EverandHow to Name an Inorganic Substance: A Guide to the Use of Nomenclature of Inorganic Chemistry: Definitive Rules 1970Évaluation : 5 sur 5 étoiles5/5 (1)

- Icd 10 Diagnosa GigiDocument2 pagesIcd 10 Diagnosa GigiElok Faiqotul UmmaPas encore d'évaluation

- Curaprox BrochureDocument68 pagesCuraprox BrochureElok Faiqotul UmmaPas encore d'évaluation

- Contoh Rundown Basic Life SupportDocument2 pagesContoh Rundown Basic Life SupportElok Faiqotul Umma100% (1)

- Jadwal AcaraDocument2 pagesJadwal AcaraElok Faiqotul UmmaPas encore d'évaluation

- Gambaran Tumpatan Amalgam Dan Semen Ionomer Kaca Pada Masyarakat Kelurahan Kalumpang Kecamatan Ternate TengahDocument2 pagesGambaran Tumpatan Amalgam Dan Semen Ionomer Kaca Pada Masyarakat Kelurahan Kalumpang Kecamatan Ternate TengahElok Faiqotul UmmaPas encore d'évaluation

- Tongue DisordersDocument68 pagesTongue DisordersSiskaJanerPas encore d'évaluation

- Medicallycompromised 1233751509281867 3Document31 pagesMedicallycompromised 1233751509281867 3Wafa AL-sooryPas encore d'évaluation

- SPSS Step-by-Step Tutorial: Part 2Document48 pagesSPSS Step-by-Step Tutorial: Part 2Elok Faiqotul UmmaPas encore d'évaluation

- Burning Mouth SyndromeDocument4 pagesBurning Mouth SyndromeElok Faiqotul UmmaPas encore d'évaluation

- 04 1 Pengaturan Proses PemasakanDocument79 pages04 1 Pengaturan Proses PemasakanSasqia Annissa P0% (1)

- Plant Hormones #7Document120 pagesPlant Hormones #7vineethPas encore d'évaluation

- United States Patent (19) : 11 Patent Number: 45 Date of PatentDocument7 pagesUnited States Patent (19) : 11 Patent Number: 45 Date of PatentRizky AnandaPas encore d'évaluation

- Repsol Polyether Polyols CASE Eng tcm14-31249Document11 pagesRepsol Polyether Polyols CASE Eng tcm14-31249Santos GarciaPas encore d'évaluation

- HYDROCAL 1009-3 English - R03 (01.2019)Document2 pagesHYDROCAL 1009-3 English - R03 (01.2019)Tuan NguyenPas encore d'évaluation

- Ethylene Oxide Product TreeDocument1 pageEthylene Oxide Product TreeManojPas encore d'évaluation

- Plant Growth Regulators - PGR - MarketDocument15 pagesPlant Growth Regulators - PGR - MarketAgriculturePas encore d'évaluation

- Petrochemicals GeneralDocument6 pagesPetrochemicals GeneralPiyush AmbulgekarPas encore d'évaluation

- Production of 70000 Mta Ethylene From MethaneDocument42 pagesProduction of 70000 Mta Ethylene From MethaneSyarif Wira'i100% (2)

- Process TechnologyDocument22 pagesProcess TechnologyJose Paolo MamuyacPas encore d'évaluation

- Compressor DocsDocument28 pagesCompressor DocsMohd Yameen100% (1)

- KALREZ DupontDocument20 pagesKALREZ DupontNet WalkerPas encore d'évaluation

- Chandra AsriDocument49 pagesChandra AsriIrvan VerdianPas encore d'évaluation

- TablasDocument4 pagesTablasMigueAngelPF100% (1)

- Acetylene Reactor PerformanceDocument19 pagesAcetylene Reactor Performancevenkateshs_g5420Pas encore d'évaluation

- Knowledge Valley Classes: Class 11 Exercise Solution (Hydrocarbon)Document24 pagesKnowledge Valley Classes: Class 11 Exercise Solution (Hydrocarbon)Sagar AgarwalPas encore d'évaluation

- Ethylene Plant ReportDocument76 pagesEthylene Plant Reportfarwa rizviPas encore d'évaluation

- Executive Summary: Ethylene OxideDocument7 pagesExecutive Summary: Ethylene OxideBlueblurrr100% (1)

- Manufacturing of Acrylic AcidDocument27 pagesManufacturing of Acrylic Acidnikhil tanwarPas encore d'évaluation

- Process For Purification of HCL From Edc PyrolysisDocument6 pagesProcess For Purification of HCL From Edc Pyrolysisu2051721Pas encore d'évaluation

- Zhang 2018 Recent Developments in The Enhancement of Some Postharvest Biocontrol Agents With Unconventional Chemicals CompoundsDocument37 pagesZhang 2018 Recent Developments in The Enhancement of Some Postharvest Biocontrol Agents With Unconventional Chemicals CompoundsInfinita SouvenirsPas encore d'évaluation

- 2018 04 HPDocument149 pages2018 04 HPVS2712Pas encore d'évaluation

- Alkenes 1Document33 pagesAlkenes 1Abdullah AmjadPas encore d'évaluation

- CLS Aipmt-15-16 XIII Bot Study-Package-3 Set-1 Chapter-12 PDFDocument24 pagesCLS Aipmt-15-16 XIII Bot Study-Package-3 Set-1 Chapter-12 PDFSudhir Kumar DasPas encore d'évaluation

- Las Shs Gen - Chem Melc 13 q2 Week-7Document11 pagesLas Shs Gen - Chem Melc 13 q2 Week-7Kim Francis Beluso Dollete IIPas encore d'évaluation

- ZFaisalCV Experienced Facilities EngineerDocument7 pagesZFaisalCV Experienced Facilities EngineerlukmpiPas encore d'évaluation

- Polymers - Library ContentDocument141 pagesPolymers - Library ContentCH M RehanPas encore d'évaluation