Académique Documents

Professionnel Documents

Culture Documents

Delivering London 2012: Geotechnical Enabling Works: Proceedings of Ice

Transféré par

presario60Description originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Delivering London 2012: Geotechnical Enabling Works: Proceedings of Ice

Transféré par

presario60Droits d'auteur :

Formats disponibles

Proceedings of ICE

Civil Engineering 164 November 2011 Pages 510 Paper 11-00030 http://dx.doi.org/10.1680/cien.2011.164.6.5 environment; geotechnical engineering; olympics

Keywords

Delivering London 2012: geotechnical enabling works

MBA, PhD, DIC, MSc, CEng, FICE

Jan Hellings

is project sponsor at the Olympic Delivery Authority

MSc, CEng, MIStructE, MICE

Martyn Lass

is enabling works project manager at Atkins

Selecting the Stratford site for the London 2012 Olympic and Paralympic Games provided an opportunity to regenerate a rundown area of historical industrial development and dereliction, as well as remediate the significant levels of contamination that had accumulated over a century and a half. The Olympic Delivery Authority established the enabling works project to clear the site and create the development platform on which the Olympic Park would be founded and to remediate the effects of contamination. This paper covers the geotechnical and geo-environmental aspects of the work, including site investigation, demolition and site clearance, bulk earthworks, soil remediation and groundwater treatment.

James Apted

PhD, CEng, MICE

is enabling works, earthworks and remediation design lead at Atkins

The responsibilities of the Olympic Delivery Authority (ODA) included provision of the Olympic Park development platform of approximately 200ha for the London 2012 Olympic and Paralympic Games in Stratford, east London. The works were carried out under two enabling works contracts, for the north and south parts of the site respectively. This paper covers the geotechnical and geoenvironmental aspects of the platform and, in particular, deals with n site investigation, demolition and site clearance n bulk earthworks n soil remediation n groundwater treatment. The paper also provides information about the site prior to the commencement of the works, the fundamental strategy upon which the redevelopment of the Olympic Park was based, the planning regime that operated and a summary of key quantities. It concludes with lessons

learnt, which highlight some of the main points that have contributed to a successful and timely delivery of the platform.

Site history

Historical maps confirmed over a century and a half of mixed industrial land use on the Olympic Park site with a potential for generating contamination. Additionally, significant importation of fill material had been carried out in several phases to reclaim the original marsh land. The initial filling was during the mid to late period of the Industrial Revolution; this was supplemented by demolition material from the clearance of damaged buildings in the London area from World War II and then material from nineteenth and twentieth century rubbish tips. At the time the site was handed over to ODA, following completion of land assembly by the London Development Agency (LDA), land use included offices and warehouses, car breakers, servicing units and parts storage, chemical works,

MSc, CGeol, CSci, FGS

Ian Mead

is enabling works deputy project manager (remediation) at Atkins

C I V I L

ENG I NEER I NG

HELLINGS, LASS, APTED AND MEAD

food processing facilities, concrete plants, bus garages, railway sidings, residential and travellers sites, hardstanding concrete, access roads and derelict areas (Figure 1).

Geology

The typical geological profile under the site is as follows. n Made ground this covers the whole site and thickness varies from a few metres to 15m. n Alluvium, 13m thick, consisting of soft silty clay. n River terrace deposits, around 35m thick deposits of sands and gravels. n Lambeth Group deposits, generally around 2030m thick, made up of interbedded clays, silts and sands. n Thanet Sand, 1020m thickness of very dense, very silty fine sand. n Chalk.

0 250 m 500 m

There are two groundwater regimes across the site: an upper groundwater table within the river terrace deposits separated from a lower groundwater table in the chalk and Thanet Sand by the Lambeth Group.

Planning requirements

The local planning authority was ODAs planning decisions team, which was established through the London Olympic Games and Paralympic Games Act 2006 (2006). ODA took responsibility for remediation of the Olympic Park site in February 2007 under an agreement with landowner LDA, although early access enabled the works to start earlier, in December 2006. The agreement obligated ODA to meet the requirements for both games and post-games legacy, as set out in the master plans approved in the site preparation planning applications in February 2007. ODA was also required to minimise residual maintenance and future environmental monitoring requirements on the site, while reducing potential below-ground constraints on future development. To allow the enabling works to begin prior to the approval of the full planning application, a number of early planning permissions were granted for zones around the Olympic Park. These permissions were later superseded by the main site preparation application. As a major consultee, the Environmental Agency (EA) was involved from the outset in the planning process. In view of the scale of the works and the need for timely responses in the planning process, EA provided a dedicated site-based co-located team to work closely with not only the planning decisions team but also with the designers and contractors involved in the development platform. To assist all project participants, EA produced a guide to contractors on the Olympic Park which provided guidance on the main licences and consents required and detailed the processes to be followed. Monthly coordination meetings were undertaken with all regulators, consultants, contractors and ODA, so that attendees were kept informed of progress and any issues that required early resolution.

Figure 1. Historical aerial photo of the southern section of the Olympic Park site, now the site of the Aquatics Centre

Not in Olympic Park

Planning delivery zone Construction zone

Figure 2. Construction zones for the control and implementation of remediation works

PrOCEEdings Of thE InstitutiOn Of Civil EnginEErs CIVIL ENGINEERING, 2011, 164, No. CE6 issn 0965 089 X

DElivEring LOndOn 2012: gEOtEchnical Enabling wOrks

Strategy

The two key elements of the remediation strategy were to protect against the risk to human health once construction was complete and to protect against the risk of contamination to environmental receptors such as watercourses and aquifers. The fundamental approach to human health protection was to establish a separation layer of material at the ground surface, of suitable quality for the proposed use of the site, to isolate occupants from any residual below-ground contamination. ODA used an approach based on quantitative assessment of the risks posed by contaminants to the receptors, these being the human occupiers of the site and controlled waters in this case, the surface water features and the chalk aquifer. This approach targeted and removed contaminated material from below the earthworks formation level in identified hotspot areas of contamination.

Following handover of the land to ODA, site clearance and investigation works ran in parallel wherever space allowed. The principles of the investigation were established early on with the planning decisions team to ensure that the information provided would be appropriate and sufficient to support the design and implementation works. Around 3500 investigation points, consisting of cable-tool boreholes, window-sampled boreholes and trial pits, were evaluated at approximately 25m centres across the site. For demolition and site clearance works, ODAs sustainable development strategy set a target of 90% for the reuse or recycling of arising materials. A figure of 98% reuse or recycling of arising materials was actually achieved, including n maximising the reuse of materials from the approximately 200 buildings demolished n eight steel-framed buildings reclaimed for reuse elsewhere, including three by their original owners n 12 roof trusses reclaimed for use as constructed n 150000 yellow stock bricks reclaimed n 13millionm2 site clearance undertaken, including reclamation of items such as granite sets, cobbles and railway track for reuse on the Olympic Park or offsite. Bulk earthworks Responding to the needs for a sustainable development, the bulk earthworks design was focused on maximising materials reuse on site. As such, only material that was geotechnically and/or chemically unsuitable, and which could not be ren-

dered or treated suitable for reuse, was disposed offsite to landfill. Around 2millionm3 of cut and 2millionm3 of fill were undertaken in the bulk earthworks operations; some 80% of the arisings were reused in the works (Figure3). Separation layer A separation layer of clean surface material was required to provide protection to human health from any contamination that remained in the ground. In the case of the Greenwich peninsula remediated in 1998, this layer is typically 1m thick but reaches a maximum thickness of 145m. In March 2004, the Building Research Establishment published Cover Systems for Land Remediation (BRE, 2004). This report identified that separation layers typically ranged from 03m to 3m and concluded that 06m represented the appropriate thickness required in a cover layer to provide suitable protection for future users. Based on guidance, it was decided that the separation layer in the Olympic Park should be no less than 06m thick and more typically 08m to allow a 02m construction tolerance. The separation layer is generally identified by an underlying marker layer consisting of a brightly coloured geotextile fabric. The planning decisions team and the environmental health officers from the four host boroughs subsequently approved the concept of a minimum 06m separation layer on the Olympic Park. The design profile is illustrated in Figure 4. The separation layer was constructed in two stages. The first stage was by the enabling works contract and the

Original ground level (level varies) Final finished level minimum 600 mm above marker layer Enabling works formation level Enabling works sub-formation level Sub-grade Undisturbed made ground Controlled water/ human health hotspot

Implementation

The site was divided into a number of construction zones for the control and implementation of the remediation works (Figure 2). The remediation works included n site investigation, demolition and site clearance n bulk earthworks and separation layer n soil treatment n groundwater treatment. Site investigation and clearance Site investigation works, where access allowed, commenced in advance of site clearance and demolition works in 2006.

Separation layer > 600 mm

300 mm (typically) 300 mm (typically)

Final construction finishes Lower section by enabling works General fill

Marker layer

Base of unsaturated zone/top of alluvium

Figure 3. Bulk earthworks included creating a bowl for the Olympic Stadium

Figure 4. Design profile of the ground, showing the 06m separation layer constructed in two stages

issn 0965 089 X

PrOCEEdings Of thE InstitutiOn Of Civil EnginEErs CIVIL ENGINEERING, 2011, 164, No. CE6

HELLINGS, LASS, APTED AND MEAD

second stage by the follow-on works. This was considered to be an effective use of the final finishes. The separation layer was designed to consist of general earthworks materials. Both granular and cohesive fill were permitted. Given the wide range of surface finishes and the fact that their locations had yet to be fixed at the time of the earthworks design, it was considered impractical to be any more prescriptive or to set special performance requirements for the separation layer, other than a California bearing ratio value of 5%. However, as the works progressed, and where the nature of the surface finish was defined, the selection of separation layer materials was modified to suit the final surface use. For example, where permanent ground slabs or highway pavements were to be placed, it was agreed that these could be used to form the separation layer and thus reduce the need for fill of separation layer quality. Generally, the made ground from the on-site earthworks was not of sufficient chemical quality, even after treatment, to be used in the separation layer. The materials that were used included n Thanet Sand derived from the tunnelling works undertaken to take the power lines that formally crossed the site underground (Twine et al., 2011) n crushed bricks and concrete derived from the demolition works n imported clean fill. The works following on from the enabling works and the creation of the separation layer included laying of services

and construction of foundations, much of them piled. These works inevitability led to breaches of the separation layer. These were controlled, including the reinstatement works, by a licensing procedure applied by the ODA team. Soil treatment The traditional approach, used previously to remediate contaminated land on sites such as Greenwich peninsula, is to excavate all contaminated material, export it from site and replace it with an imported layer of clean fill to provide a separation layer. However, the transport of large quantities of bulk materials to and from the site had considerable sustainability implications. In addition to the sizeable carbon dioxide footprint, the large number of lorry movements would have had direct consequences on local traffic conditions and landfill sites would have had to be found for the exported contaminated material. ODA adopted an on-site treatment approach to maximise the quantity of excavated material that was rendered suitable for use as fill. This approach minimised the quantity of contaminated material for removal from the site for disposal and provided better value for money. All excavated materials from the bulk earthworks operations were in the first instance sampled and tested by an on-site testing laboratory to classify them for reuse, disposal to landfill or treatment as appropriate. Sub-grade level sampling and testing confirmed the suitability of soils to remain in situ and, if required, further excavation was carried out. Approximately 80% of the material to be remediated onsite was made ground, which varied considerably in soil and contaminant types and required a wide range of treatments technologies. The treatment technologies employed included n n n n n n n simple/primary screening crushing soil washing bioremediation chemical stabilisation geotechnical stabilisation complex sorting.

Figure 5. The north soil hospital was one of two treatment centres on the site and used physicochemical technology to remove a wide range of contaminants

Prior to reuse or treatment, the majority of arisings were screened using a vibrating screen or screens to separate soils

from oversized and biodegradable materials so as to comply with specification requirements. The treatment of contaminated soil was carried out in the two main on-site treatment centres, north and south, known as soil hospitals (Figure 5). Treatment commenced initially with a single soil-washing plant in July 2007 and this was followed by the main soil hospital centres in January 2008. Within the treatment centres, soil washing and soil stabilisation were common to both centres. A complex sorting operation was set up on the north site. For soil washing, five plants were procured to treat around 700000m3 of soil out of the total earthworks of just over 2millionm3 (i.e. 32%). They used physicochemical technology to remove a wide range of contaminants including organics such as total petroleum and polyaromatic hydrocarbons and inorganics such as heavy metals, arsenic and cyanides. Four output materials were produced from the soil-washing plants, of which two were capable of being reused in the form of sands (>2mm diameter, generally around 40%) and gravels (<50mm diameter, generally 4050%). The fine silts and clays present as filter cake (generally 1518%), the fine and coarse organic matter and ash and coke materials (generally 25%) were all disposed of offsite. For finer grained soils that did not lend themselves to soil washing, one of two options was utilised depending on their contaminant profiles. For soft alluvium or cohesive materials with principally hydrocarbon (organic) contaminants, bioremediation using a bioremediation bed (biopile) system was utilised. However, this technique was only used on a small quantity of material: around 30000m3 of soil, just 15% of the total earthworks volume, was bioremediated over a period of 19months and then successfully reused as general fill. An idealised section through the bioremediation bed is shown in Figure 6. The white circles indicate the pipes from which air was introduced into the system through the sand layer. Heating and cooling was controlled by hot and cold water pipes (red and blue circles respectively), with heat movements indicated by the respective arrows. Alternatively, for soils with leachable

PrOCEEdings Of thE InstitutiOn Of Civil EnginEErs CIVIL ENGINEERING, 2011, 164, No. CE6 issn 0965 089 X

DElivEring LOndOn 2012: gEOtEchnical Enabling wOrks

contaminants, chemical stabilisation was carried out ex situ in a pugmill using proprietary and specialised reagents. Some 50000m3 of soil was processed by this technique. River silts and soft alluvium had their material strength properties enhanced by way of geotechnical stabilisation with lime using specialist machines. Some 210000m3 of soils from the made ground have been stabilised, together with a further 157000m3 of silty sand from the Thanet Sand arising from the power line undergrounding project; these were predominantly used in the initial part of the separation layer as noted earlier. The materials excavated from the nineteenth and twentieth century landfill sites required sorting prior to any other treatment to render them suitable for reuse. The sorting machinery used a number of vibrating screens to separate soil from general landfill materials. The soil was then treated using electromagnets to remove metal fragments and then processed through a manual picking zone for final removal of deleterious items. Approximately 82000m3 of material was treated by this process. Around 600000m3 of the excavated made ground was reused without treatment, with the surplus, including the filter cake from the soil-washing plant, taken off site. Groundwater treatment Three main techniques were utilised on the Olympic Park to treat and remediate groundwater. To protect the watercourses surrounding the Olympic Stadium site, a hydraulic capture system was constructed around the stadium to prevent the lateral migration of contaminated groundwater within the river terrace deposit aquifer. The groundwater pumping rate was such that a local reversal of groundwater flow direction occurred, thereby preventing migration of contaminants. In the northern portion of the system, pumped water was treated at a purposebuilt treatment plant, with the majority of the effluent being discharged to sewer. A portion of the pumped water was dosed with Archaea to reduce ammonia concentrations before being re-injected back into the aquifer. A similar system was operissn 0965 089 X

ated to the south of the Olympic Stadium although, due to the organic nature of the contaminants, the treatment was through stripping towers, skimming tanks and activated carbon filters (Figure 7). In three areas, the injection of reagents into river terrace deposit groundwater was undertaken. The reagents included oxygen-release compounds, base-activated sodium persulphate, Fentons reagent, potassium permanganate, emulsified vegetable oil and a combination of zero-valent iron with a carbon source (vegetable oil). These reagent injections enabled the insitu treatment of both organic and inorganic contaminants through both single and multiple rounds of injection. In each case, the injection was specifically tailored to the concentration and type of contaminant present. In addition, where free products in the form of nonaqueous phase-separated liquids were present, their removal by skimming of lighter and heavier products from the surface of the aquifer and the top of the underlying strata respectively was undertaken. The third technique utilised a sheet-pile wall as an in-ground barrier to cut off the flow of contaminated perched water within the made ground to the adjacent river. Any rise in the level of the perched water behind the barrier was controlled and collected using a French drain, pumped to a treatment plant and, once treated, the contaminated water was discharged to sewer. Potential radioactive contamination was also considered by the remediation strategy. Site areas that posed a potential risk, such as former landfills or previous industrial factories, were identified and both the workforce and excavation arisings from these areas were screened for radioactivity. A small number of discrete low-level radioactive items (e.g. luminescent dials from old vehicles or aircraft) were recovered and stored in sealed barrels that were subsequently transported to the low-level radioactive depository at Drigg, Cumbria. In addition, 7600t of exempt very low-level radioactive waste containing naturally occurring isotopes were encountered during excavation in the areas of the West Ham tip and Lloyds Shoot landfill. This material was of sufficiently low level that it was not subject to controls under the Radioactive Substances Act 1993

(1993). It was however agreed with the EA that this material would be placed in the southern L03 bridge abutment and covered with a minimum of 25m of earth to provide suitable protection. With completion of the L03 abutment, any additional exempt material encountered was to be transported to an appropriately licensed landfill facility.

Validation

The final part of the remediation process was the production of validation reports. These provided the formal basis for the planning authority to satisfy itself that remediation had been completed and that all the requirements set out in

Soil

250 mm sand layer

Hot water

Air

Cold Air water

Figure 6. Typical section through bioremediation beds showing movements of air and heat

Figure 7. Groundwater treatment plant some of the effluent was re-injected into the aquifer

PrOCEEdings Of thE InstitutiOn Of Civil EnginEErs CIVIL ENGINEERING, 2011, 164, No. CE6

HELLINGS, LASS, APTED AND MEAD

the site-specific remediation strategy had been achieved. This allowed the planning authority to confirm that planning conditions related to ground contamination and its subsequent remediation had been discharged. ODA regularly consulted with a number of expert regulators and stakeholders. These included EA, British Waterways, environmental health officers from the London boroughs of Newham, Waltham Forest, Hackney and Tower Hamlets, and ERM and Hyder independent and specialist technical consultants acting for the planning authority.

n around 600000m3 reused without treatment, with the surplus taken off site n over 200000m3 of groundwater treatment together with approximately 150 injection wells.

exceedences that require immediate intervention works.

Acknowledgements

ODA (client); CLM (programme and project manager); Atkins (NEC3 project manager/design team); Gardiner & Theobald (cost consultant); BAM Nuttall (contractor); Galliford Try Infrastructure T/A Morrison Construction Ltd (contractor); Arup (CDM coordinator); Land Use Consultants (ecology consultant); Capita Symonds (archaeology, remediation strategy and environmental impact assessment support); Masons Land Survey (topographical survey); Birse, DEC, HBR (remediation and water treatment); Brown & Mason, Clifford Devlin, McGee, Scudder, Windmill (demolition); Erith (demolition and asbestos removal); Museum of London Archaeology, RPS Group, Wessex Archaeology (archaeology).

Lessons learned

The lessons learned on the enabling project can be summarised as follows. n Pragmatic use of risk assessment. Central to the design of the remediation was the use of detailed quantitative risk assessment. As further earthworks information became available, the risk assessments were reviewed and refined by the team. Throughout this process, discussions were held with the regulator on treatability requirements, contamination impacts and validation, which led to the generation of pragmatic and effective treatment solutions. n Soil hospitals. In addition to the development platform earthworks, earthworks activities were undertaken by many contracts across the Olympic Park. To maximise the reuse of materials, soil hospitals were set up to receive all soil arisings from across the park for testing, processing, treating and blending to render soils suitable for reuse. Engineering classes of material were produced from the excavated materials, thereby saving on quarry imports. n Appropriate long-term land use. The remediation design allowed for games and subsequent legacy use, thereby minimising future development remediation requirements. n Follow-on projects interface. Followon projects need to understand fully the ongoing requirements of maintaining a remediated site both in terms of physical works and ongoing relationships with the regulator and stakeholders. ODA set up processes and protocols to ensure a smooth transition from the enabling works to the venue, infrastructure and landscaping contractors. n Site handovers and exceedences. Validation data must be reviewed immediately on receipt to identify any

Conclusions

The enabling works project started in October 2006 and was substantially completed on programme in September 2009. The anticipated final cost is 393million. The project demonstrates the benefits of developing remediation technology to maximise on-site soil treatment, thereby minimising the requirement to transport contaminated material to landfill and reduce the subsequent volume of imported clean fill material. It has enabled the delivery of an Olympic Park that is safe for human use, meets the prevailing planning conditions and satisfies the requirements set by both the Olympic and legacy use master plans. The minimum 06m separation layer is in line with BRE best practice and is consistent with expected site uses. As a result, the project has set a benchmark for future large-scale land development works. This has been recognised in a number of audits and industry best practice awards. The key quantities involved in the project were n around 3500 intrusive site investigations n 140 archaeology pits n 200 buildings demolished, including eight dismantled for reuse n approximately 98%, or 445000t, of demolition arisings recycled or reused on site n some 2millionm3 of bulk earthworks cut and 2millionm3 of bulk earthworks fill, with 80% reuse of arisings n over 900000m3 of soils treated for reuse, including washing of some 700000m3 of soil

References

BRE (Building Research Establishment) (2004) Cover Systems for Land Regeneration: Thickness of Cover Systems for Contaminated Land. BRE, Watford. London Olympic Games and Paralympic Games Act 2006 (2006) Elizabeth II. Chapter 12. Her Majestys Stationary Office, London. Radioactive Substances Act 1993 (1993) Elizabeth II. Chapter 12. Her Majestys Stationary Office, London. Twine D, Shiplee H and Thurston M (2011) Delivering London 2012: power lines undergrounding. Proceedings of the Institution of Civil Engineers Civil Engineering 164(6): 1116, http://dx.doi.org/10.1680/ cien.2011.164.6.11

What do you think?

If you would like to comment on this paper, please email up to 200 words to the editor at journals@ice.org.uk. If you would like to write a paper of 2000 to 3500 words about your own experience in this or any related area of civil engineering, the editor will be happy to provide any help or advice you need.

10

PrOCEEdings Of thE InstitutiOn Of Civil EnginEErs CIVIL ENGINEERING, 2011, 164, No. CE6 issn 0965 089 X

Vous aimerez peut-être aussi

- Cien 165 4 179 PDFDocument6 pagesCien 165 4 179 PDFMarshall BravestarPas encore d'évaluation

- MackiesSite PDFDocument8 pagesMackiesSite PDFMarshall BravestarPas encore d'évaluation

- Guide To Trench ExcavationsDocument43 pagesGuide To Trench ExcavationsmlakkissPas encore d'évaluation

- Geoen Module1 6 HcetDocument158 pagesGeoen Module1 6 HcetJayakrishnanPas encore d'évaluation

- The Importance of Site Investigation in The Construction Industry: A Lesson To Be Taught To Every Graduate Civil and Structural EngineerDocument6 pagesThe Importance of Site Investigation in The Construction Industry: A Lesson To Be Taught To Every Graduate Civil and Structural EngineerSherly MPas encore d'évaluation

- 12dpr005q Feis 08 HazmatDocument5 pages12dpr005q Feis 08 HazmatKim HiềnPas encore d'évaluation

- Challenges in Slope Engineering in Hong KongDocument15 pagesChallenges in Slope Engineering in Hong KongFatin AmilinPas encore d'évaluation

- 1609-B08-Cheng Chin Keong-Multi Curvatire Sewer - Bahrain - AllDocument37 pages1609-B08-Cheng Chin Keong-Multi Curvatire Sewer - Bahrain - AllCHENG Kim HuaPas encore d'évaluation

- Preliminary Impact Assessment ReportDocument22 pagesPreliminary Impact Assessment ReportyoussefPas encore d'évaluation

- Highway, Mining, SWM, Hydro ProjectsDocument32 pagesHighway, Mining, SWM, Hydro ProjectsAbinand PNPas encore d'évaluation

- Review of Some Drained Reclamation Works - Hongkong PDFDocument54 pagesReview of Some Drained Reclamation Works - Hongkong PDFJamie MoorePas encore d'évaluation

- Landfill After UseDocument10 pagesLandfill After UseLeung LiangPas encore d'évaluation

- 2 - Yee, Ding, Lim, Wang - Geotextile Containment and Dewatering of Contaminated Sediments in ChinaDocument0 page2 - Yee, Ding, Lim, Wang - Geotextile Containment and Dewatering of Contaminated Sediments in ChinaEmilia MAndradePas encore d'évaluation

- Report PDFDocument11 pagesReport PDFRecordTrac - City of OaklandPas encore d'évaluation

- Summary Tailings DesignDocument1 pageSummary Tailings DesignChamel “cham” RuperezPas encore d'évaluation

- Tentang Ruang Dalam Bumi Sebagai BahanDocument28 pagesTentang Ruang Dalam Bumi Sebagai BahanTyas LegawaPas encore d'évaluation

- Earthworks in Landfill EngineeringDocument66 pagesEarthworks in Landfill EngineeringMelissa GrahamPas encore d'évaluation

- Lalgarh Coal Block (North) ECDocument3 pagesLalgarh Coal Block (North) ECuttamksrPas encore d'évaluation

- Standard TOR - Isolated StorageDocument8 pagesStandard TOR - Isolated Storageaftab_jamalPas encore d'évaluation

- Management of Ash Disposal: Naresh, D.NDocument8 pagesManagement of Ash Disposal: Naresh, D.NUjjaval MistryPas encore d'évaluation

- Geo SyntheticsDocument20 pagesGeo SyntheticsPradeepBansalPas encore d'évaluation

- Kolkata International Logistic City by Havelock Properties LTDDocument9 pagesKolkata International Logistic City by Havelock Properties LTDPratik ChawlaPas encore d'évaluation

- In Situ Chemical Oxidation for Groundwater RemediationD'EverandIn Situ Chemical Oxidation for Groundwater RemediationPas encore d'évaluation

- Landfill Planning and Design Considerations: January 2012Document12 pagesLandfill Planning and Design Considerations: January 2012Prosper BabrusPas encore d'évaluation

- Dr. Rakesh KumarDocument34 pagesDr. Rakesh KumarEjo ShetPas encore d'évaluation

- Bohloli Et Al - GHGT-15-full-paperDocument10 pagesBohloli Et Al - GHGT-15-full-paperbahmanbohloliPas encore d'évaluation

- EIA-1054MAKINDU-FILLING-STATION-pdf - Environmental Impact Assessment Study Report, 2013Document63 pagesEIA-1054MAKINDU-FILLING-STATION-pdf - Environmental Impact Assessment Study Report, 2013handsam84Pas encore d'évaluation

- MPES100-Revised+article DentoniDocument13 pagesMPES100-Revised+article DentoniDavid Esteban Meneses RendicPas encore d'évaluation

- Update: Environmental Assessment of Mining ProjectsDocument12 pagesUpdate: Environmental Assessment of Mining ProjectsVara Prasad Raju P100% (1)

- F2004-06 09d Risk Management For Microtunneled SewersDocument15 pagesF2004-06 09d Risk Management For Microtunneled SewersswhuntPas encore d'évaluation

- Oryx GTL PDFDocument6 pagesOryx GTL PDFRaka Fajar NugrohoPas encore d'évaluation

- The in Salah CO Storage Project: Lessons Learned and Knowledge TransferDocument11 pagesThe in Salah CO Storage Project: Lessons Learned and Knowledge TransfergregPas encore d'évaluation

- Eg4 326Document99 pagesEg4 326niharika meena100% (1)

- Sustainability 13 06083Document15 pagesSustainability 13 06083RUCELO BUSCAGANPas encore d'évaluation

- Chapter8 MineClosureandRehabDocument16 pagesChapter8 MineClosureandRehabJonPas encore d'évaluation

- Group 5 Civil Engineering Management AssignmentDocument10 pagesGroup 5 Civil Engineering Management Assignmentomonaedwin2Pas encore d'évaluation

- HarbourDocument48 pagesHarboursimonelytang30Pas encore d'évaluation

- Using GIS Tools To Build New Main Mine AccessDocument0 pageUsing GIS Tools To Build New Main Mine AccessFrancisca DiazPas encore d'évaluation

- DEFRA CoP Soil Use On Construction SitesDocument64 pagesDEFRA CoP Soil Use On Construction SitespiugabiPas encore d'évaluation

- Project Summary Mount Morgan MineDocument4 pagesProject Summary Mount Morgan Minecharles3488Pas encore d'évaluation

- Environmental Impact Assessment of Mining Projects: Dr. Gurdeep Singh 1.0 ScreeningDocument10 pagesEnvironmental Impact Assessment of Mining Projects: Dr. Gurdeep Singh 1.0 ScreeningSureshRichards100% (1)

- Controlled Vadose Zone Saturation and Remediation (CVSR)Document35 pagesControlled Vadose Zone Saturation and Remediation (CVSR)FranciscoGarciaPas encore d'évaluation

- Designing Banihal To Srinagar Tunnel On NHDocument11 pagesDesigning Banihal To Srinagar Tunnel On NHAMIT KACHROO100% (1)

- Road Work SpecificationsDocument71 pagesRoad Work SpecificationsAbdulla NaushadPas encore d'évaluation

- Seismic SurveyDocument19 pagesSeismic SurveyAdebisi AdenugaPas encore d'évaluation

- Acidic Drainage ReportDocument72 pagesAcidic Drainage ReportSnycnelPas encore d'évaluation

- Ce 4240 Design Project 1Document18 pagesCe 4240 Design Project 1api-297914209Pas encore d'évaluation

- Final ReportDocument42 pagesFinal Reportsidikmar1425Pas encore d'évaluation

- Application of Risk Management Techniques For The Remediation of An Old Mining Site in Greece - Waste ManagementDocument8 pagesApplication of Risk Management Techniques For The Remediation of An Old Mining Site in Greece - Waste ManagementChachi CPas encore d'évaluation

- Use of Aggregates From Recycled Construction and Demolition Waste in ConcreteDocument11 pagesUse of Aggregates From Recycled Construction and Demolition Waste in ConcreteJulian PerezPas encore d'évaluation

- 2 - Mastin, Lebster - Use of Geotube Dewatering Containers in Environmental DredgingDocument20 pages2 - Mastin, Lebster - Use of Geotube Dewatering Containers in Environmental DredgingJavier DiazPas encore d'évaluation

- Waste Materials in Construction: Science and Engineering of Recycling for Environmental ProtectionD'EverandWaste Materials in Construction: Science and Engineering of Recycling for Environmental ProtectionPas encore d'évaluation

- Negative Emissions Technologies for Climate Change MitigationD'EverandNegative Emissions Technologies for Climate Change MitigationPas encore d'évaluation

- Integrated Sand Management For Effective Hydrocarbon Flow AssuranceD'EverandIntegrated Sand Management For Effective Hydrocarbon Flow AssurancePas encore d'évaluation

- Landscape dimensions: Reflections and proposals for the implementation of the European Landscape ConventionD'EverandLandscape dimensions: Reflections and proposals for the implementation of the European Landscape ConventionPas encore d'évaluation

- Soils for Landscape Development: Selection, Specification and ValidationD'EverandSoils for Landscape Development: Selection, Specification and ValidationÉvaluation : 5 sur 5 étoiles5/5 (1)

- Geohazards and Pipelines: State-of-the-Art Design Using Experimental, Numerical and Analytical MethodologiesD'EverandGeohazards and Pipelines: State-of-the-Art Design Using Experimental, Numerical and Analytical MethodologiesPas encore d'évaluation

- Design—Operation Interactions at Large Treatment Plants: Proceedings of a Workshop Held in ViennaD'EverandDesign—Operation Interactions at Large Treatment Plants: Proceedings of a Workshop Held in ViennaS. H. JenkinsPas encore d'évaluation

- Minimizing Construction Disputes: The Relationship Between Risk Allocation and Behavioural AttitudesDocument13 pagesMinimizing Construction Disputes: The Relationship Between Risk Allocation and Behavioural Attitudespresario60Pas encore d'évaluation

- Role Profile: Job Title: Region & Location Middle East - Dubai Sector: P S&I Reporting Line: TBC Role DescriptionDocument1 pageRole Profile: Job Title: Region & Location Middle East - Dubai Sector: P S&I Reporting Line: TBC Role Descriptionpresario60Pas encore d'évaluation

- Result TemplateDocument1 pageResult Templatepresario60Pas encore d'évaluation

- Bim Journal Vol.3 Final Low Res 2Document43 pagesBim Journal Vol.3 Final Low Res 2presario60Pas encore d'évaluation

- Specifications: Sunny From Aed 43,500Document2 pagesSpecifications: Sunny From Aed 43,500presario60Pas encore d'évaluation

- Cost Value Reconciliation and Earned ValueDocument8 pagesCost Value Reconciliation and Earned ValueAdoi Valentine Elaigwu100% (1)

- VRM WorkshopDocument13 pagesVRM Workshoppresario60Pas encore d'évaluation

- Rics 2011 BIM Survey ReportDocument31 pagesRics 2011 BIM Survey Reportpresario600% (1)

- Reuse and Recycling On London 2012 Olympic Park Oct 2011Document44 pagesReuse and Recycling On London 2012 Olympic Park Oct 2011presario60Pas encore d'évaluation

- Construction Variations A Scourge or A NecessityDocument9 pagesConstruction Variations A Scourge or A Necessitypresario60100% (2)

- Nervous SystemDocument40 pagesNervous SystemJanePas encore d'évaluation

- 447.010 Screen Operating Manual v001Document67 pages447.010 Screen Operating Manual v001José CarlosPas encore d'évaluation

- Alginate Impression MaterialDocument92 pagesAlginate Impression MaterialrusschallengerPas encore d'évaluation

- PRICELIST E Katalogs IVD 06042023 INDOPUTRA - PDF TerbaruDocument6 pagesPRICELIST E Katalogs IVD 06042023 INDOPUTRA - PDF Terbaruseksi sspk sarprasPas encore d'évaluation

- Morning in Nagrebcan - Manuel E. ArguillaDocument8 pagesMorning in Nagrebcan - Manuel E. ArguillaClara Buenconsejo75% (16)

- Application of Land Suitability AnalysisDocument16 pagesApplication of Land Suitability AnalysisHải Anh Nguyễn100% (1)

- Cleavage in MammalsDocument51 pagesCleavage in MammalsIrfan Azram100% (4)

- E2788-11 Standard Specification For Use of Expanded Shale, Clay and Slate (ESCS) As A Mineral Component in The Growing Media and The Drainage Layer For Vegetative (Green) Roof SystemsDocument3 pagesE2788-11 Standard Specification For Use of Expanded Shale, Clay and Slate (ESCS) As A Mineral Component in The Growing Media and The Drainage Layer For Vegetative (Green) Roof SystemsSatya kaliprasad vangaraPas encore d'évaluation

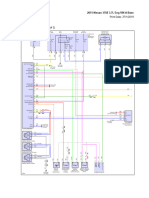

- 2015 Nissan 370Z 3.7L Eng VIN A BaseDocument69 pages2015 Nissan 370Z 3.7L Eng VIN A BaseData TécnicaPas encore d'évaluation

- The CyclotronDocument10 pagesThe CyclotronSupriya DuttaPas encore d'évaluation

- Version 2 Dog Legged Stair ES EN 1992-1-1 2015Document29 pagesVersion 2 Dog Legged Stair ES EN 1992-1-1 2015Khaja100% (2)

- Manual Placa Mae Ga 945gcmx-s2 6.6Document72 pagesManual Placa Mae Ga 945gcmx-s2 6.6luisb3toPas encore d'évaluation

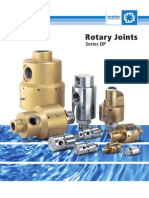

- Catálogo DP InglêsDocument20 pagesCatálogo DP Inglêsjf2003Pas encore d'évaluation

- Proyector SNF 111Document3 pagesProyector SNF 111Liliana Patricia PederneraPas encore d'évaluation

- The Girl Who CanDocument4 pagesThe Girl Who CanMadhu50% (2)

- 12V-100Ah FTA DatasheetDocument1 page12V-100Ah FTA Datasheetchandrashekar_ganesanPas encore d'évaluation

- Experiment - 5Document26 pagesExperiment - 5Dilip GangopadhyayPas encore d'évaluation

- Mikrotik Kung Fu Kitab 2Document68 pagesMikrotik Kung Fu Kitab 2aditya ferdiansyahPas encore d'évaluation

- Portland PortDocument18 pagesPortland PortAnonymous Lx3jPjHAVLPas encore d'évaluation

- r315 Quick Start PDFDocument80 pagesr315 Quick Start PDFfdsfasdsfadsPas encore d'évaluation

- CR300 Wireless Communication ProtocolDocument130 pagesCR300 Wireless Communication ProtocolHenry Martinez BedoyaPas encore d'évaluation

- Prepared by (Hospital Pharmacist) Primary & Secondary Healthcare DepartmentDocument11 pagesPrepared by (Hospital Pharmacist) Primary & Secondary Healthcare DepartmentwaqasPas encore d'évaluation

- Jurnal Semi FowlerDocument6 pagesJurnal Semi FowlerHartina RolobessyPas encore d'évaluation

- CF1900SS-DF Example Spec - Rev1Document1 pageCF1900SS-DF Example Spec - Rev1parsiti unnesPas encore d'évaluation

- NEET MADE EJEE Complete Handwritten Formulae Chemistry NEET andDocument90 pagesNEET MADE EJEE Complete Handwritten Formulae Chemistry NEET andliyanderPas encore d'évaluation

- Animal Whisperer PDFDocument4 pagesAnimal Whisperer PDFKevinPriestmanPas encore d'évaluation

- Effect of Calorie Restriction and Exercise On Type 2 DiabetesDocument18 pagesEffect of Calorie Restriction and Exercise On Type 2 DiabetesDitya Monica 065Pas encore d'évaluation

- What Is Geyi - V MairDocument31 pagesWhat Is Geyi - V MairbodhitanPas encore d'évaluation

- Ford6000cd Rear ConnectorDocument2 pagesFord6000cd Rear ConnectorAnonymous WcYW9AePas encore d'évaluation

- Roadmap: B1+ Students' Book Audio ScriptsDocument44 pagesRoadmap: B1+ Students' Book Audio ScriptsThanh Dat Phan100% (4)